Kerosene is a flammable fraction of oil, a transparent liquid with an oily structure and a light yellow color. The liquid flammable carbons from which it consists are distinguished by a very high boiling point, from +150°C to +250°C. The characteristics and flammable properties of this petroleum product allow it to be used for refueling aircraft and automobile equipment, devices used for lighting, and stoves.

The ancient Greek word "Kηρóς", meaning wax, gave its name to kerosene.

Kerosene, types, chemical composition, properties and applications.

Kerosene is a flammable liquid, a flammable fuel. It is a flammable mixture of liquid hydrocarbons (from C8 to C15) with a boiling point in the range of 150-250 °C, obtained by direct distillation or rectification of oil.

Kerosene as fuel

Physical properties of kerosene

Types, types and brands of kerosene

Chemical (component, hydrocarbon and elemental) composition of kerosene

Obtaining kerosene

Application of kerosene

Other fuels: biodiesel, biofuel, gas oil, oil shale, kerosene, naphtha, fuel oil, petroleum, associated petroleum gas, natural gas, landfill gas, shale oil, shale gas, synthesis gas

Lamp "Bat"

To protect the flame from the wind, special models were produced - “Bat” lanterns.

This popular name comes from the German company FlederMaus, which in the 19th century launched the production of wind-resistant lanterns.

This name has firmly taken root in everyday life. It’s like with a Primus (Primus is primarily a company, not a product) or a Xerox.

Although at first there was an alternative name for such products - a storm lamp.

Among the branded manufacturers of kerosene lamps, the most popular now are Petromax and Feuerhand Baby Special.

The protective kerosene stove is capable of trouble-free operation in wind conditions of up to 15 m/s!

It should be noted that this is a very strong gusty wind. If you have a poorly secured electric light on your porch, then such gusts can easily shake off and damage even a modern incandescent light bulb.

Meanwhile the kerosene stove will burn!

Kerosene lamps occupied a special page in history during the Great Patriotic War. At the front, of course, there was no electricity.

Meanwhile, dugouts, headquarters, and medical battalions needed to be illuminated with something. In this connection, a number of factories were quickly converted to mass production of such products.

Even today, military warehouses maintain a supply of kerosene lamps.

Kerosene as fuel:

Kerosene (English kerosene from ancient Greek κηρός - “wax”) is a flammable mixture of liquid hydrocarbons (from C8 to C15) with a boiling point in the range of 150-250 °C, obtained by direct distillation or rectification of oil.

Externally, kerosene is a transparent, colorless (or slightly yellowish, or light brown), slightly oily liquid to the touch. Has a characteristic smell of petroleum products.

Kerosene is a flammable, flammable liquid. Refers to low-hazard substances and, in terms of the degree of impact on the human body, in accordance with GOST 12.1.007, belongs to the 4th hazard class. Combustible fuel.

Kerosene is lighter than water. Does not dissolve in water.

Kerosene forms explosive mixtures with air

Petrol

The fuel is most popular, especially among car owners. It consists of a mixture of hydrocarbons, nitrogen, sulfur, and oxygen. There are different brands of gasoline. Each of them contains more or less of the listed components. Because of this, performance characteristics differ.

Evaporation temperature

The term refers to the thermal threshold, after passing which gasoline spontaneously mixes with air. It cannot be determined using one number.

This value depends on the following factors:

- saturated vapor pressure;

- fractional composition;

- tension surface viscosity;

- density;

- heat capacity.

The evaporation temperature of gasoline of different compositions does not differ too much from each other. This occurs at 30°C, and if the fractions are heavy – 205°C. When it's cold outside, gasoline needs to expend more energy to get into the combustion chamber and start the engine.

Boiling temperature

Young car enthusiasts do not know that in the heat, when the fuel boils in the carburetor, the car could become immobilized. There were plugs in the fuel system due to overheating of the light fractions. They separated from the heavy ones, becoming gas bubbles. The vehicle needed to cool down and then continue traveling.

Flash point

The oil product does not have its own formula. It includes many components. Gasoline can ignite at -40 °C if an open fire occurs.

Combustion temperature

The octane number does not affect it. Only resistance to detonation depends on it. Popular brands of gasoline have almost the same characteristics. The temperature in the engine is 900-1100 °C, maybe lower. This is affected by cylinder pressure. As for open fire, for gasoline it is 800-900 °C.

Physical properties of kerosene:

| Parameter name: | Meaning: |

| Density of kerosene at 20 °C, g/cm3 (depends on the hydrocarbon composition, type and grade of kerosene)* | from 0.78 to 0.85 |

| Density of kerosene at 20 °C, kg/m3 (depending on the hydrocarbon composition, type and grade of kerosene)* | from 780 to 850 |

| Melting/freezing point (depending on the hydrocarbon composition and type of kerosene), °C | from -60 °C to -40 °C |

| Boiling point (depending on the hydrocarbon composition and type of kerosene), °C | from +150°C to +250°C |

| Kinematic viscosity at 20 °C (depending on the hydrocarbon composition, type and grade of kerosene), mm²/s | from 1.2 to 4.5% |

| Flash point** (depending on the hydrocarbon composition, type and grade of kerosene), °C | from +28 °С to +72 °С |

| Ignition temperature** (depends on the hydrocarbon composition, type and grade of kerosene), °C | from -10 °С to +105 °С |

| Self-ignition temperature (depending on the hydrocarbon composition, type and grade of kerosene), °C | 220 °C |

| Explosive concentrations of a mixture of kerosene with air (depending on the hydrocarbon composition, type and grade of kerosene), % by volume | from 0.6 to 8.0 |

| Specific heat of combustion of kerosene (depending on the hydrocarbon composition, type and grade of kerosene), mJ/kg | from 42.9 to 46.2 |

| Sulfur content (depending on the hydrocarbon composition, type and grade of kerosene), %% | no more than 1.0 |

Note:

* with increasing temperature, the density of kerosene decreases.

** ignition temperature is the temperature of a flammable substance at which it emits flammable vapors and gases at such a speed that, after ignition from the ignition source, stable combustion occurs;

** flash point - the temperature at which petroleum product vapors form a mixture with the surrounding air that flares up when a fire is brought to it.

Open fire temperature: temperature of the fire in the lighter, influencing factors and classification

A flame is a phenomenon that is caused by the glow of a gaseous hot medium. In some cases, it contains dispersed solids and (or) plasma, in which transformations of reagents of a physical and chemical nature occur. It is they that lead to self-heating, heat release and glow.

The gaseous environment of the flame contains charged particles - radicals and ions . This explains the existence of electrical conductivity of the flame and its interaction with electromagnetic fields.

Devices that can suppress a fire, change its shape, or tear it away from flammable materials using electromagnetic radiation are built on this principle.

The glow of fire is divided into two types:

- non-luminous;

- glowing.

Almost every glow is visible to the human eye, but not every one is capable of emitting the required amount of luminous flux.

The glow of the flame is determined by the following factors.

- Temperature.

- The density and pressure of the gases that participate in the reaction.

- Presence of solid matter.

The most common cause of glowing is the presence of a solid substance in the flame .

Many gases burn with a faintly luminous or non-luminous flame.

Of these, the most common are hydrogen sulfide (blue flame, like combustion), ammonia (pale yellow), methane, carbon monoxide (pale blue flame), and hydrogen.

The vapors of some volatile liquids burn with a barely luminous flame (alcohol and carbon disulfide), and the flame of acetone and ether becomes slightly smoky due to the slight release of carbon.

Flame temperature

For different flammable vapors and gases, the flame temperature is not the same. Also, the temperature of different parts of the flame is not the same, and the area of complete combustion has higher temperatures.

When burned, a certain amount of combustible substance releases a certain amount of heat. If the structure of the substance is known, then the volume and composition of the resulting combustion products can be calculated. And if you know the specific heat of these substances, then you can calculate the maximum temperature that the flame will reach.

It is worth remembering that if a substance burns in air, then for every volume of oxygen that reacts there are four volumes of inert nitrogen. And since nitrogen is present in the flame, it is heated by the heat that is released during the reaction. Based on this, we can conclude that the flame temperature will consist of the temperature of combustion products and nitrogen.

It is impossible to determine the temperature precisely, but it can be approximated since the specific heat changes with temperature.

Here are some indicators for the temperature of an open fire in different materials.

- Magnesium combustion is 2200 degrees.

- The combustion of alcohol does not exceed a temperature of 900 degrees.

- Gasoline combustion is 1300-1400 degrees.

- Kerosene - 800, and in an environment of pure oxygen - 2000 degrees.

- Propane-butane combustion can reach temperatures from 800 to 1970 degrees.

- When wood burns, the temperature ranges from 800 to 1000 degrees, and it ignites at 300 degrees.

- The burning temperature of a match is 750−850 degrees.

- In a burning cigarette - from 700 to 800 degrees.

- Most solid materials ignite at a temperature of 300 degrees.

The flame, which every person can observe when a candle, match or lighter burns, is a stream of hot gases that are pulled vertically upward, thanks to the force of Archimedes.

The candle wick first heats up and the paraffin begins to evaporate. The lowest part is characterized by a slight blue glow - there is little oxygen and a lot of fuel.

It is because of this that the fuel does not burn completely and carbon monoxide is formed, which, when oxidized at the very edge of the flame cone, gives it a blue color.

Due to diffusion, a little more oxygen enters the center. Subsequent oxidation of the fuel occurs there and the temperature increases. But this is not enough for complete combustion of fuel. At the bottom and in the center there are coal particles and unburned droplets. They glow due to intense heat.

But evaporated fuel, as well as combustion products, water and carbon dioxide, practically do not glow. At the very top there is the highest concentration of oxygen. There, the unburnt particles that glowed in the center are burning out.

It is for this reason that this zone practically does not glow, although the temperature there is the highest.

Flame classification

The glow of fire is classified as follows.

- According to visual perception: colored, transparent, smoky.

- Height: short and long.

- By speed of spread: fast and slow.

- By temperature indicator: high temperature, low temperature, cold.

- According to the nature of movement of the reaction medium: pulsating, turbulent, laminar.

- According to the state of the flammable medium: pre-mixed and diffusion.

- By radiation: colorless, colored, luminous.

- According to the state of aggregation of flammable substances: flame of aerodispersed and solid reagents, liquid and gaseous.

In a diffuse laminar flame, three shells (zones) are distinguished. Inside the cone of flame there is:

- dark zone, where there is no combustion due to the small amount of oxidizer - 300-350 degrees;

- luminous zone, where thermal decomposition of fuel occurs and it partially burns - 500-800 degrees;

- the zone is slightly luminous, where the products of fuel decomposition finally burn and a maximum temperature of 900-1500 degrees is reached.

The temperature parameter of the flame depends on the intensity of the oxidizer supply and the nature of the combustible substance. The flame spreads through the pre-mixed medium. Propagation occurs along the normal from each point of the front to the flame surface.

In real-life gas-air mixtures, propagation is always complicated by disturbing external influences, which are caused by friction, convective flows, gravity and other factors.

It is because of this that the real speed of propagation always differs from the normal one. Depending on the nature of the propagation speed, the following ranges are distinguished:

- During detonation combustion - more than 1000 meters per second.

- With explosive - 300−1000.

- With deflagration - up to 100.

It is located in the very top part of the fire, which has the highest temperature. In this zone, flammable substances are almost completely converted into combustion products. There is a lack of fuel and an excess of oxygen . It is for this reason that substances that are placed in this zone are intensively oxidized.

Restorative flame

This part is closest to the center or located just below it. There is little oxygen for combustion and a lot of fuel. If a substance containing oxygen is introduced into this area, it will be taken away from the substance.

Fire temperature in a lighter

A lighter is a portable device that is designed to produce fire. It can be gasoline or gas, depending on the fuel used. There are also lighters that do not contain their own fuel. They are designed to ignite a gas stove. A high-quality turbo lighter is a relatively complex device. The fire temperature in it can reach 1300 degrees.

Chemical composition and color of flame

Pocket lighters are small in size, which allows them to be carried without any problems. It is quite rare to find a table lighter. After all, due to their large size, they are not intended to be carried. Their designs are varied . There are fireplace lighters. They have a small thickness and width, but are quite long.

Today, promotional lighters are becoming popular. If there is no electricity in the house, then it is impossible for it to light a gas stove. The gas is ignited by the resulting electric arc. The advantages of these lighters are the following qualities.

- Durability and simplicity of design.

- Fast and reliable gas ignition.

The first lighter with modern flint was created in Austria in 1903 after the invention of ferrocerium alloy by Baron Karl Auer von Welsbach.

The development of lighters accelerated during the First World War. The soldiers began to use matches in order to see the road in the dark, but their location was revealed by the intense flash when ignited. The need for fire without significant flash fueled the development of lighters.

At that time, the leaders in the production of flint lighters were Germany and Austria. Such a portable device, which is designed to produce fire, found in the pocket of many smokers, can be fraught with many dangers if handled incorrectly.

The lighter should not spray sparks around itself during operation. The fire should be stable and even. The fire temperature in pocket lighters reaches approximately 800-1000 degrees. The red or orange glow is caused by carbon particles that have become hot.

For household burners and turbo lighters, butane gas is mainly used, which burns easily and is odorless and colorless. Butane is obtained by processing oil and its fractions at high temperatures.

Butane is a flammable hydrocarbon, but it is absolutely safe in modern lighter designs.

Such lighters are very useful in everyday life. They can set fire to any flammable material. The set of turbo lighters includes a table stand.

The color of the flame depends on the combustible material and combustion temperature. The flame of a fire or fireplace generally has a motley appearance . The burning temperature of wood is lower than the burning temperature of a candle wick.

It is because of this that the color of the fire is not yellow, but orange.

Copper, sodium and calcium glow in different colors at high temperatures.

The electric lighter was invented in 1770. In it, a hydrogen jet was ignited by a spark from an electrophore machine. Over time, gasoline lighters gave way to gas lighters, which are more convenient. They must contain a battery - a source of energy.

Not very long ago, touch lighters appeared, in which, without mechanical action, gas is ignited by acting on a touch sensor. Pocket-type touch lighters. Basically, they contain advertising-type information, which is printed using pad or silk-screen printing.

Types, types and brands of kerosene:

The following types of kerosene are distinguished: aviation kerosene (jet fuel), rocket kerosene, technical kerosene and lighting kerosene.

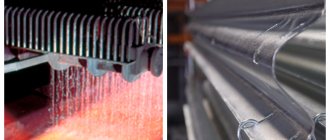

Aviation kerosene is a motor fuel for turboprop and turbojet engines of various aircraft, and is also used as a coolant in various heat exchangers (fuel-air radiators), as a lubricant for moving parts of fuel and engine systems, and as a solvent.

In Russia, five grades of aviation kerosene are produced for subsonic aviation (TS-1, T-1, T-1S, T-2 and RT), and two for supersonic aviation (T-6 and T-8B). RT brand aviation kerosene is a standardized fuel and is intended for use on aircraft with both subsonic and supersonic flight speeds.

Rocket kerosene is a jet fuel used in air-breathing rocket engines. It is also the working fluid of the engine mechanism.

Technical kerosene is used as a raw material for the pyrolytic production of ethylene, propylene and aromatic hydrocarbons, as a fuel mainly for firing glass and porcelain products, and as a solvent for washing mechanisms and parts.

Two grades of technical kerosene are produced: KT-1 and KT-2.

Lighting kerosene is a special type of kerosene intended for refilling lamps and heating devices. It is also used for degreasing rolled metal and spare parts, washing mechanisms and parts.

Four grades of lighting kerosene are produced in Russia: KO-20, KO-22, KO-25, KO-30.

Additives

Antistatic Many years of experience in operating domestic and foreign air transport have proven that when pumping fuel or when refueling aircraft, static electricity can accumulate. Due to the unpredictability of the process, there is a danger of explosion at any time. To combat this dangerous phenomenon, antistatic additives are added to fuels. They increase the electrical conductivity of the fuel to 50 pS/m, which ensures the safety of aircraft refueling and fuel transfer. The additives used abroad are ASA-3 (Shell) and Stadis-450 (Dupount). In Russia, the additive Sigbol (TU 38.101741-78) has become widespread, approved for addition to TS-1, T-2, RT and T-6 fuels in amounts up to 0.0005%. Added during production. Anti-water crystallization When refueling with fuel at a temperature of -5...+17 °C, within 5 hours of flight the temperature in the tank drops to -35 °C. The record temperature drop is -42 °C (TU-154) and -45 °C (tanks feeding the outer IL-62M engines). At these temperatures, ice crystals form in the fuel and clog fuel filters, which can cause fuel to be cut off and the engine to stall. Already at a water content of 0.002% (wt.), aircraft filters with a pore diameter of 12-16 microns begin to clog. To prevent ice crystals from falling out of the fuel at low temperatures, anti-water crystallization additives are introduced into the fuel directly at the aircraft refueling site. Ethyl cellosolve (liquid I) according to GOST 8313-88, tetrahydrofuran (THF) according to GOST 17477-86 and their 50% mixtures with methanol (additives I-M, THF-M) are widely used as such additives. Additives can be added to almost any fuel. They are added on site. Antioxidant Introduced into hydrotreated fuels (RT, T-6, T-8V) to compensate for the chemical stability reduced as a result of hydrotreating. In Russia, the additive Agidol-1 (2,6-di-tert-butyl-4-methylphenol) is used according to TU 38.5901237-90 in a concentration of 0.003-0.004%. In such concentrations, it almost completely prevents fuel oxidation, including at elevated temperatures (up to 150 °C). It is added during production. Anti-wear Designed to restore the anti-wear properties of fuels lost as a result of hydrotreating. It is introduced into the same fuels as the antioxidant additive. In Russia, the Sigbol additive and the composition of the Sigbol and PMAM-2 additives (polymethacrylate type - TU 601407-69) are used. For RT fuels, the “K” additive is often used (GOST 13302-77), which in terms of efficiency corresponds to the Sigbol additive, and also, due to the shortage of the “K” additive, the Hitek-580 additive. Added during production.

Chemical (component, hydrocarbon and elemental) composition of kerosene:

Kerosene in its chemical composition is a mixture of various hydrocarbon and non-hydrocarbon components:

– saturated, saturated hydrocarbons (alkanes) – 20-60%,

– cyclic saturated hydrocarbons (naphthenes) – 20-50%,

– aromatic hydrocarbons (arenes) – 5-25%,

– unsaturated hydrocarbons – up to 2%,

– impurities of sulfur, nitrogen or oxygen compounds.

Alkanes (saturated hydrocarbons, paraffins) are acyclic hydrocarbons of linear or branched structure, containing only simple chemical bonds and forming a homologous series with the general formula CnH2n+2. Alkanes are saturated hydrocarbons, meaning they contain the maximum possible number of hydrogen atoms for a given number of carbon atoms.

Naphthenes , also cycloalkanes, polymethylene hydrocarbons, cyclanes or cycloparaffins are cyclic saturated hydrocarbons with chemical properties close to saturated hydrocarbons. They have the chemical formula CnH2n and a cyclic structure (i.e. closed rings of carbon atoms).

Aromatic compounds (arenes) are cyclic organic compounds that contain an aromatic system.

Unsaturated hydrocarbons are open-chain hydrocarbons in whose molecules there are double or triple bonds between carbon atoms.

Sulfur compounds : hydrogen sulfide H2S, mercaptans, mono- and disulfides, thiophenes and thiophanes, as well as polycyclic (heterocyclic) sulfur compounds, etc.

Nitrogen compounds : mainly homologues of pyridine, quinoline, indole, carbazole, pyrrole, as well as porphyrins.

Oxygen compounds : naphthenic acids, phenols, resinous asphaltene and other substances.

The component composition of kerosene depends on the chemical composition and method of processing the feedstock - oil, as well as the type of kerosene.

To conclude what has been said

All jet and turbojet fuels can be roughly divided into three main types: • Kerosene: consists primarily of hydrocarbons with carbon atoms ranging from C9 to C16. Jet A, Jet A1, JP 8, Jet A50. • “Blended”: Kerosenes are mixed with low-flash point naphthas to produce a low-boiling fuel containing hydrocarbons with carbon atoms ranging from C4 to C16. Jet B, JP 4. • High temperature kerosene: a mixture of kerosene having a minimum flash point of 60°C. Kerosene aviation fuel is mainly used. Civil aircraft are fueled with TS-1 - Russia, Jet A1 (Jet A in the USA/Canada) and Jet A50 brands, and military aircraft are fueled with JP8. Military aircraft also use “mixed” fuel (JP4), but its use accounts for less than 1% of total kerosene consumption. JP 5 is used for naval aircraft. The difference between TS-1 jet fuel, which is widely used in Russia, and its European analogue, Jet A-1, lies mainly in the production technology. Jet A-1 undergoes hydrotreating, it contains antistatic and stabilizing additives, it is less environmentally harmful, and the flash point is 10 degrees higher. It is considered safer in Europe for transporting and refueling aircraft. But here it should be noted that in world flight practice not a single accident related to the technical characteristics of TS-1 kerosene has been recorded. Moreover, the advantage of Russian jet fuel is that it can be used at much lower temperatures.

| Comparative characteristics of jet fuels TS-1 and Jet A-1 | ||

| Options | TS-1 | Jet A-1 |

| Acidity, KOH mg/100 cm3 | 0,7 | 0,1 |

| Mass fraction RSH*, % | 0,003 | 0,003 |

| Mass fraction of total sulfur, % | 0,2 | 0,3 |

| Kinematic viscosity, mm2/sec. | 8.0 (-40°С) | 8.0 (-20°С) |

| Density, kg/m3 | 780 (20°C) | 775 (15°C) |

| Flash point, °C | 28 | 38 |

| Height of non-smoking flame, mm | 25 | 25 |

| * RSH—content of mercaptan sulfur compounds | ||

Certification In the USA Jet., Europe Jet A1. In Canada Jet A (analogue of Jet A-1, Jet), Jet B (analogue of TS-1, lighter than Jet A) In Russia TS-1 (GOST 10227-86)

Application of kerosene:

Kerosene is used as fuel for various engines, as a lubricant for moving parts, as a solvent for washing mechanisms and parts, as a means for degreasing surfaces, as a valuable raw material for the chemical industry, and in folk medicine.

History of the kerosene lamp

Until the second half of the 19th century, animal or vegetable fats were used as fuel in household lamps. They were set on fire in oil lamps and received a dim, smoky, but still reliable source of light.

Kerosene did not exist then. His invention immediately reduced the formation of soot, but most importantly increased light output and brightness.

Thanks to the evaporation of kerosene, the device has become much simpler. There is also no need to pump fuel into the lamp under pressure.

Historically, it is believed that the kerosene lamp appeared in 1853. Austrian pharmacists in Lviv were the first to use kerosene as fuel.

There is quite an interesting story connected with this. At that time, Pyotr Mikolyash lived in Lviv, who owned one of the city pharmacies. Two businessmen from another city offered him a lucrative deal - the pharmacist buys distillate from them at a cheap price, and he distills it into alcohol.

The profit was promised to be astronomical. The distillation process was carried out by a pharmacy laboratory technician named Jan Zech. It was he, together with his colleague Ignatius Lukasiewicz, who, in pursuit of profit, began to spend all their days and nights in the pharmacy.

At the same time, in the process of their work, they actively experimented with petroleum products. Having obtained some semblance of kerosene, they tried to use it in a modernized oil burner. The result exceeded all expectations.

The owner of the pharmacy first put a copy of such a lamp on display, and after a while they began to actively illuminate the streets of Lviv. Rumors of the use of revolutionary lighting reached Austria.

It was there that Rudolf Ditmar's company, having filed a patent, began mass production of a similar product for home use. Kerosene became cheaper and more accessible every year. It was then also called coal oil.

Gradually, the invention reached our open spaces. Initially, all sizes of glass and wicks for kerosene lamps were indicated in “lines”. This tradition has been preserved to this day.

What it is? One line is 1/10 inch (10 dots), which equals 2.54mm. For example, the diameter of the lamp glass at the bottom is 20 lines (50mm).

The wick was also measured in the lines. A lamp with a wick width of 7 lines is about 18mm. Based on this size, it got its name - a seven-line kerosene lamp or seven-line.

The wider the wick, the brighter the lamp shines. One seven-line at maximum brightness is equivalent to a 35W incandescent light bulb.

Flash point

The next characteristic after the boiling point of kerosene is the flash point. This is a parameter that determines the degree of fire hazard of a given liquid. Here the flash point of kerosene will vary from 28 to 60 °C.

It must be said that this characteristic is strictly controlled by standards to prevent gasoline from entering the fuel, which can dramatically increase its flammability. The practical determination of the temperature of reactive flashes of kerosene liquid is prescribed by the standards of all countries of the world.

Electricity from a kerosene lamp

With the advent of electricity, kerosene lamps arose a serious competitor, whose triumphant march completely ousted all such lamps from the lighting market in one fell swoop. It was impossible to stop the technological revolution.

However, inventors have already come up with the reverse process in our time. The point is that, under certain conditions, electricity can easily be generated from a kerosene lamp.

Such a thermogenerator was produced in the USSR after the war in the 50s. It was called TGK-3.

It was designed to power household tube receivers. Most often used in remote settlements in the taiga and at weather stations.

You can learn more about the operating principle of the TGK-3 thermoelectric generator from here. And here is a clear example of how such a device works live.

https://youtube.com/watch?v=qeUERF_P5vs

GNP

This abbreviation refers to the height of the non-smoking flame of the petroleum product. In particular, this is an important characteristic for KO-25 kerosene. Determines its ability to burn in a standard wick lamp (with a wick diameter of 6 mm) with a white, uniform flame without the formation of soot or soot.

This is a numerical indicator measured in millimeters. It must be indicated on the labels of the corresponding lighting brands of the product. GNP is directly influenced by the chemical and fractional compositions of kerosene.

Spread speed

Flame propagation through a pre-mixed (undisturbed) medium occurs from each point of the flame front normal to the flame surface. The magnitude of this normal flame propagation speed (hereinafter referred to as NFSP) is the main characteristic of a flammable environment. It represents the minimum possible flame speed. NSRP values differ for different combustible mixtures - from 0.03 to 15 m/s.

The spread of flame through real-life gas-air mixtures is always complicated by external disturbances caused by gravity, convective flows, friction, etc. Therefore, the actual flame propagation speeds always differ from normal ones. Depending on the nature of combustion, flame propagation speeds have the following ranges of values:

- deflagration combustion – up to 100 m/s;

- explosive combustion – from 300 to 1000 m/s;

- detonation combustion – over 1000 m/s.

The color of the flame is determined by the radiation of electronic transitions (for example, thermal radiation) of various excited (both charged and uncharged) particles formed as a result of a chemical reaction between fuel molecules and oxygen in the air, as well as as a result of thermal dissociation. In particular, when carbon fuel burns in air, the blue part of the flame color is due to the radiation of CN ±n particles, the red-orange part is due to the radiation of C2 ±n particles and soot microparticles. The radiation of other particles formed during the combustion process (CHx ±n, H2O ±n, HO ±n, CO2 ±n, CO ±n) and main gases (N2, O2, Ar) lies in the UV and IR part of the spectrum, invisible to the human eye. In addition, the color of the flame is greatly influenced by the presence of compounds of various metals, primarily sodium, in the fuel itself, the design details of burners, nozzles, and so on. In the visible part of the spectrum, the radiation of sodium is extremely intense and is responsible for the orange-yellow color of the flame, while the radiation of the slightly less abundant potassium turns out to be practically indistinguishable against its background (since most organisms have K+/Na+ channels in their cells, then in the carbon fuel of plant or animal origin for every 3 sodium atoms there are on average 2 potassium atoms).

Source: Tideman B.E., Sciborsky D.B. Chemistry of combustion. –L., 1935.

Kinematic viscosity

When characterizing kerosene according to GOST, this position will also be relevant. It must be said that the viscosity of the hydrocarbons included in this product changes significantly with a decrease/increase in its temperature. The higher the latter is, the lower the viscosity becomes.

This is a very important characteristic. The viscosity of kerosene has a great influence on a number of operational features of aircraft fuel systems, as well as combustion and mixture formation processes in the engine.

Thus, the viscosity of kerosene at 20 °C is 1.2 - 4.5 mm2/s.

Sequence for determining the specific heat of combustion

The indicator of the specific heat of combustion of kerosene establishes the conditions for its ignition in various devices - from engines to kerosene cutting devices. In the first case, the optimal combination of thermophysical parameters should be determined more carefully. There are usually several schedules for each fuel combination. These graphs can be used to evaluate:

- Optimal ratio of mixture of combustion products.

- Adiabatic flame temperature of combustion reaction.

- Average molecular weight of combustion products.

- Specific heat ratio of combustion products.

This data is necessary to determine the speed of the exhaust gases emitted from the engine, which in turn determines the engine's thrust.

The optimal fuel mixture ratio gives the highest specific impulse of energy and is a function of the pressure at which the engine will operate. An engine with high combustion chamber pressure and low exhaust pressure will have the highest optimum mixture ratio. In turn, the pressure in the combustion chamber and the energy intensity of kerosene fuel depend on the optimal mixture ratio.

In most engine designs using kerosene as fuel, much attention is paid to the conditions of adiabatic compression, when the pressure and volume occupied by the combustible mixture are in constant relationship - this affects the durability of engine elements. In this case, as is known, there is no external heat transfer, which determines the maximum efficiency.

Classification

Flames are classified according to:

- state of aggregation of flammable substances: flame of gaseous, liquid, solid and aerodispersed reagents;

- radiation: luminous, colored, colorless;

- state of the fuel-oxidizer environment: diffusion, pre-mixed media;

- the nature of the movement of the reaction medium: laminar, turbulent, pulsating;

- temperature: cold, low temperature, high temperature;

- propagation speeds: slow, fast;

- height: short, long;

- visual perception: smoky, transparent, colored.

In a laminar diffusion flame, 3 zones (shells) can be distinguished.

Inside the flame cone there are:

- dark zone (300-350 °C), where combustion does not occur due to a lack of oxidizing agent;

- luminous zone where thermal decomposition of fuel and its partial combustion occurs (500-800 ° C);

- a barely luminous zone, which is characterized by the final combustion of fuel decomposition products and a maximum temperature (900-1500 ° C).