The profession of a welder is not as simple as it may seem to the average person at first glance. Otherwise, special certification would not have been carried out, there would have been no qualification tests of specialists’ knowledge to extend their rank or increase it. So we can say that the work of a welder is responsible and complex, because it is he who performs labor-intensive and important welded joints and seams. A mandatory element required by highly qualified specialists is the welder’s mark. We'll talk about it today.

Type and code

In some cases, the first letters of the welder's last name or a series of numbers are used as identification. But most often the welder’s mark code is generated automatically. The basis is the specialist’s date of birth, his last name, first name and patronymic. Usually the mark does not change either during renewal, or when passing certification, or when changing the welding method.

There are several versions of the instrument. For example, numbers in two lines - without a frame or with a frame, numbers in a triangle, rhombus or square. The height of the symbols is usually 6 millimeters, however, in cases where the welder performs special work, a larger or smaller mark may be used. It is worth noting that this circumstance must first be discussed with management!

Impact stamps

| +7 Andrey Manager of the metalworking shop. |

It is made in the form of a metal rod (bar) made of steel U8A GOST 1435-99 with a hardness for the working part of 55...60 HRC and 33...38 HRC for the impact part (the one that is hit with a hammer).

Brands can be made by several methods such as laser engraving, electroerosion and industrial (mechanical) engraving. The main and optimal method for producing impact stamps is mechanical engraving.

Application of impact stamps

- for marking gas cylinders

- for individualization of metal parts of machines and mechanisms

- during welding work as a personal welder’s mark

- branding of jewelry with name marks and hallmarks

- calibration and verification marks are used by metrologists when certifying measuring instruments

Product examples:

Information for ordering impact stamps

When ordering, it is necessary to take into account that in order to obtain a good impression, the ridge of the stamp must be “sharp”, so the sketch of the stamp is drawn with thin lines without shading. Also, it is advisable to make the size of the design as small as possible, since the smaller the area of the stamp, the weaker the blow required.

Complex small designs are made by laser engraving, the height of the relief is usually 0.2...0.5 mm. When branding, the part must be securely fastened or be quite massive. The place where the brand breaks through must be level.

Otherwise, you will not be able to get a high-quality print.

Cost of making impact stamps

| Diameter up to 10 mm | Industrial engraving | 0,9-1,3 | 2550rub | 2200rub | 2000rub | Call |

| Diameter 11 - 15 mm | Industrial engraving | 0,9-1,3 | 2750rub | 2450rub | 2250rub | Call |

| Diameter 16 mm | Industrial engraving | 0,9-1,3 | 2950rub | 2500rub | 2400rub | Call |

| Diameter 17 mm | Industrial engraving | 0,9-1,3 | 3250rub | 2850rub | 2690rub | Call |

| Diameter 18 mm | Industrial engraving | 0,9-1,3 | 3350rub | 2900rub | 2790rub | Call |

| Diameter 19 mm | Industrial engraving | 0,9-1,3 | 3515r | 3040r | 2945rub | Call |

| Diameter 20 mm | Industrial engraving | 0,9-1,3 | 3700rub | 3200rub | 3150rub | Call |

| Diameter from 21 to 30 mm | Industrial engraving | 0,9-1,3 | Call | Call | Call | Call |

- We deliver throughout Russia “to the door” or to the terminal of the transport company

- We will pay for delivery in St. Petersburg to the terminal of the TC “Business Lines” or AutoTrading

- Delivery from the terminal in St. Petersburg to your city is paid upon receipt according to TK tariffs.

Methods for making impact stamps

| Industrial (Mechanical) engraving. This method is the main one for making impact stamps for metal. Allows you to make stamps quite quickly, from 3 working days. After engraving, the stamp is subjected to hardening and tempering, as a result of which the hardness of the working part is 56-58 units. according to Rockwell. This method allows you to make the relief of the design as sharp as a knife blade. Thanks to this, it is necessary to use less effort to mark parts, and also allows you to increase the life of the impact stamp | Production of impact stamps using laser engraving. Calibration and verification stamps for metrology, name tags for jewelers, stamps with complex small patterns are usually made using laser engraving. In this case, it is possible to obtain a letter size of about 1 mm, so the area of the print can be only a few square millimeters. You can see such a print using a 4-8X magnifying glass in good lighting. |

| Making impact stamps using the electroerosion method This method is used in cases where a sharp ridge on the stamp is not necessary. These can be marks for working with non-ferrous or hot metal, as well as in the case when products are marked using a press. Electroerosion is advantageous for large-sized stamps. | Stamping using “Low Stress” technology The image consists of individual dots, which reduces surface damage during the marking process |

| Grounding and CE logo marks The stamps are made from high-quality tool steel. Hand stamps with special symbols in accordance with technical and international standards:

| Ready-made sets of impact stamps. The typeface on the stamps corresponds to DIN 1451 (GOST 26.020-80) Each stamp is marked: 1. Brand symbol2. Brand symbol size3. "MADE IN GERMANY"4. International symbol “eye protection”Hardness of the stamp material: 58-60 HRC Sets of stamps of all sizes, including 15 mm. supplied in unbreakable blue plastic boxes |

Why do you need a stamp?

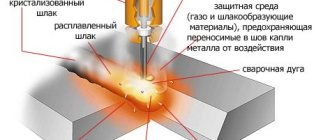

When welding particularly critical metal structures, certified welders make an impression with their mark next to the welded seam. This procedure is a sign of confirmation that a certain connection has been completed by the welder whose stamp numbers are applied to this product. That is, the assignment of a welder’s mark can be called the assignment of a kind of signature that confirms the high-quality performance of welding work.

It is impossible to confuse welders - each mark is called personal because it bears an individual number. If some kind of defect or defect was suddenly discovered, the mark could be used to identify the performer who performed poor-quality work. By the way, on October 8, 2014, federal norms and rules regulating certain requirements for work at hazardous facilities came into force. Thanks to this innovation, a single database has appeared that contains information about all certified welders. The database contains information about the position, date of certification and its field, code of the welder's mark, category, type of activity.

What does it represent

The shape and geometric dimensions of the welder's mark in accordance with GOST

The mark is made in accordance with GOST 25726-83 and is a hand tool in the form of a metal rod made of tool steel with a strength of 50-60 HRC. On one side there is a mirrored alphabetic and numerical designation, the other is intended for striking. As a result of the impact, a direct relief image remains on the product.

Where and when are they stamped?

According to paragraph 21 of the FNP “Welding at HPFs,” welded joints whose walls are thicker than 6 millimeters must be marked with the number of the welder who performed the work. And according to GOST 25225-82, the welder must mark his place of work with his mark.

Where exactly is it customary to place the mark? Primarily on the following structures:

- metal channels and beams;

- ceiling bases;

- It is possible (but not necessary) to use a stamp in fastening reinforcement or welding elements less than 6 millimeters.

After completing welding work at hazardous production facilities, the welder is required to affix a mark next to the completed seam. After this, it is necessary to fill out a work log and connection test reports.

NEW REQUIREMENTS FOR WELDERS' STAMPS

News Published by: Kirill B.

# rostekhnadzor nax stamp ntd

In connection with the entry into force of the Federal norms and rules in the field of industrial safety “Requirements for welding work at hazardous production facilities” (hereinafter referred to as FNP “Welding at HPFs”), new requirements for welders’ marks are being introduced.

FNP “Welding at hazardous production facilities” was approved by order of the Federal Service for Environmental, Technological and Nuclear Supervision dated March 14, 2014 No. 102 and registered by the Ministry of Justice of Russia on May 16, 2014 (registration No. 32308). Came into force on October 8, 2014.

Read the document

FNP “Welding at HPF” establishes requirements for the organization and performance of welding work at facilities, technical devices and structures of hazardous production facilities (hereinafter referred to as HPF) supervised by the Federal Service for Environmental, Technological and Nuclear Supervision or other authorized bodies for control and supervision of hazardous production facilities (hereinafter referred to as HPF). activities in the field of industrial safety. The standards are intended for legal entities and individual entrepreneurs who carry out welding, soldering, surfacing and tack welding of elements of technical devices and structures used and/or operated at hazardous production facilities, including their structures, assembly units, parts, semi-finished products and blanks.

Clause 8 of the FNP “Welding at hazardous production facilities” reads:

The qualifications of welders must meet the requirements established by the Russian Ministry of Labor. Welders must have a valid certification certificate for the appropriate welding method and have no medical contraindications to the work performed. Information about certificate numbers, their validity periods and welder mark codes must be posted in the public register of certified personnel on the Internet, and certificates must have a corresponding QR code to verify their authenticity. The brand codes assigned during certification must be assigned to welders by order of the organization performing welding work.

Welders are allowed to perform welding work specified in their certificates.

The requirements of this paragraph for stamps are unambiguous, and provide for the mandatory assignment of stamp codes to welders who perform work at facilities controlled by Rostechnadzor.

The brand code is generated automatically by the EDI system based on your full name and date of birth. This code is assigned to the welder and does not change during renewal, periodic certification, certification for other welding methods, etc.

Regarding the specialists who were certified before the FNP “Welding at hazardous production facilities” came into effect, Rostechnadzor sent to the President of the SRO NP “NAKS” N.P. Official letter to Aleshin. The letter states that welders who passed certification before the entry into force of the FNP can use previously assigned marks, fixed by order of the organization.

The letter was posted on the website naks.ru

In addition, the FNP “Welding at HPF” establishes requirements for the procedure for branding and identification of the welder who performed the welded joint.

Clause 21 of the FNP “Welding at hazardous production facilities”

Welded joints of elements with a wall thickness of more than 6 mm are subject to marking indicating the codes of the welders' marks, which allow identifying the welders who performed the welding. The need and method for marking welded joints with a wall thickness of less than 6 mm are established by the requirements of the PDD. The marking method must exclude hardening, hardening, or unacceptable reduction in the thickness of the metal and ensure the safety of the marking throughout the entire period of operation of the technical device.

When a welded joint is made by several welders, it must be marked with the marks of all welders involved in the welding.

When all welded joints are performed by one welder, it is allowed to indicate the code of the welder’s mark in a place accessible for inspection, enclosed in a frame applied with indelible paint. In this case, the marking location must be indicated in the technical device passport.

Clause 23 of the FNP “Welding at hazardous production facilities”

When carrying out welding work, as-built documentation is drawn up, including welding work logs, inspection reports, test reports of welded joints, which make it possible to identify records with completed welded joints using welder mark codes and welded joint diagrams.

Take these requirements into account when organizing welding work at hazardous production facilities.

Review prepared by Kirill B.

When using this material, a link to the YASVARSHCHIK resource is required.

How to put a stamp

Every certified welder should know how to apply a mark correctly. It is customary to place it at a distance of 20-50 millimeters from the edge of the weld. It is necessary to put a stamp on the outside. If the seams on the outer and inner sides are welded by different specialists, the marks are placed on the outer side - through the shot. The numerator is the mark of the specialist who welded the parts from the outside, the denominator, in turn, is the welder on the inside.

For longitudinal seams, the welder's mark must be placed at the beginning of the seam and at its end. It is important to maintain a distance of 100 millimeters from the circumferential seam. If the welder performed a circumferential seam, he knocks out a mark at the intersection of the circumferential seam with the longitudinal ones. The mark is repeated every two meters. It is worth noting that each such seam must have at least two marks. The place where each seam is branded must be enclosed in a clearly visible frame of indelible paint.

Another point of the Federal norms and rules states: if all welding work at a site is carried out by one welder, there is no need to indicate an identification code on each connection. One stamp, located in a place accessible for inspection, is enough. At the same time, if several specialists were working on one complex connection, everyone should leave their own cipher.

How and where to get a stamp

Assigning a mark to a welder, a sample order for which you can see below, is a rather complicated process. To do this, it is necessary to undergo certification by NAKS - the National Welding Control Agency. This agency is a structural division of SASv - the so-called Welding Certification System.

In order to pass certification, you must successfully pass various tests. Only after this, along with the certification certificate, the welder is given a mark code.

Please note: a mark that was issued before the Federal Tax Code came into force is valid only until the next certification. If it is successfully completed, the specialist receives a new one that meets the new standards.

Basic orders for welding work

We are a specialized enterprise, quite well known in certain circles both in Russia and abroad. The number of employees is about 3000 people. The geography of construction is all of Russia.

In addition to government orders, we work with large mining corporations and mining construction sites. All facilities are classified as hazardous production facilities (HPO), controlled by Rostechnadzor.

This is for understanding: compliance with labor protection and all building codes and regulations is literal! TB specialists, customers and all kinds of inspectors are pressing from all sides...

Therefore, the documents produced are truly relevant and labor-stained.

Decide for yourself whether you need them and in what form, but I strongly advise you to get acquainted with them, even if you don’t have a public education program.

Regarding the “not applicable” status of some of the regulatory documents mentioned here: as a rule, even canceled regulatory legal acts are still considered legitimate to the extent that they do not contradict the current ND. So it’s better to be on the safe side...

Order “On the appointment of persons responsible for welding production”

This order is the result of many years of efforts to introduce by order a detailed functional delineation of duties and responsibilities between management specialists and line engineering and technical personnel, as well as within the engineering and technical personnel structure itself (for example, between eternally squabbling foremen and mechanics).

The order on those responsible for welding work was born in accordance with the requirements of paragraphs of various regulatory documents (ND), here are some of them:

- clause 10.1.1. SP 7013330.2012 “Load-bearing and enclosing structures”; clause 31 of the FNP according to Order of Rostechnadzor N 519 dated December 11, 2020; clause 1.2.5 RD 34 15.132-96 regarding the appointment of the Person in charge of welding work and maintaining the “Welding Work Log”;

- clause 18 of the FNP according to Order of Rostechnadzor N 519 on a welding production specialist developing PDD;

- Clause 56 of Order of the Ministry of Labor No. 884n dated December 11, 2020 regarding the appointment of workers responsible for maintaining welding equipment in good condition.

“On the appointment of persons responsible for welding production”

The Order appoints:

- responsible for the development of welding technologies, for organizing the certification of welders and welding production specialists, for organizing the certification and operation of welding equipment (chief welder in one person);

- managers of welding work (heads of sections, workshops and their deputies);

- those responsible for the execution of work, compliance with welding technologies and the quality of work performed (foremen);

- Responsible for the proper maintenance and safe operation of welding and gas-cutting equipment (mechanics, electromechanics).

In addition, the document delegates the powers of the Person in charge of welding work

(level III specialist) line engineering and technical personnel in terms of operational control, compliance with welding technologies, and maintaining equipment in good condition.

A list of persons who are level II welding specialists (foremen, foremen) has been determined by name, whose written or oral instructions are mandatory for welders to carry out when carrying out welding work.

Link to download the Order on those responsible for welding work (sample) in pdf format.

Order “On assigning marks to welders”

Why does a welder need a stamp? To determine the name of the welder who performed the weld, this is the first and main reason.

Brands also appear in welding logs and various quality control inspection reports for welds during production control.

All welders of the enterprise must have stamps, regardless of the category and complexity of the work performed. Since, according to ETKS, even a 2nd category welder is required to weld seams in the lower position with 100 percent quality.

If you think that this is someone's whim, then you are mistaken! Welding is too important and responsible type of production. The integrity of a critical structure and someone’s life may depend on one weld...

It was precisely because of the analysis of the causes of the increasing frequency of major accidents in the country, which revealed low quality control and responsibility when performing welds, that SASv was conceived (and implemented) on a national scale (under the leadership of Rostekhnadzor) - the Certification System for Welding Production, the center of which is NAKS. We'll talk about this in another post!

Welders certified by NAKS have a mark that is listed as international, with Latin numerals. If the welded product does not have the NAKS mark, then it is assigned the mark of the enterprise (you come up with the marking yourself). We do not use NAKS stamps in production (although they appear in the order) due to their length and the presence of Latin letters.

The need for this order is due, in particular:

- clause 10.1.15. SP 7013330.2012 “Load-bearing and enclosing structures”;

- clause 11 of the FNP according to Order of Rostechnadzor N 519;

- clause 1.3.21 RD 34 15.132—96 “Welding and quality control...”;

- clause 4.10.5 GOST 23118-2019 “Steel structures...”.

“On assigning marks to welders”

The columns of this order must include the full names of the welders and their marks: NAKS and production marks.

You can include a lot more information, although it is better not to overdo it, otherwise one day you may be asked to re-sign the entire order due to a change in the rank of one single welder.

I will make a separate note and attach an editable file (which I myself have developed for many years and successfully use) on the effective accounting of welding production specialists and welding equipment at the enterprise.

It is not necessary to reissue this order every time you hire a new welder. Add-ons can be released throughout the year. They are also issued, but in the header it is written “issued in addition to Order No. XX dated 00.00.00.” and only new welded ones are listed in the table.

In general (see clause 10.1.15 SP 7013330.2012), the welder must place a personal mark at a distance of 40-60 mm from the border of the weld seam he has made: by one welder - in one place, when performed by several welders - at the beginning and end of the seam . In some cases, marking can be replaced by drawing up diagrams attached to the Welding Record Book.

The method of marking (impact, application of indelible paint or electrode surfacing) must be defined in the design or working documentation.

The RD for specific technical devices may contain specific requirements for branding methods.

Thus, for some critical structures it is specifically stipulated that the method should not lead to thinning of the metal. For example, high-pressure pipelines for aggressive liquids with a pipe wall thickness of up to 4 mm or the stretched zone of the lower belt of a welded crane beam truss.

And for especially critical technical devices, the impact method and the surfacing method are expressly prohibited.

However, the surfacing method is already officially prohibited. We use it only when it is specified in specific technical conditions issued a very, very long time ago (USSR), but the customer is not going to revise them.

Link to download the Order on assigning marks to welders (sample) in pdf format.

Order “On securing equipment for gas welding work”

The reason for the appearance of this order is a single paragraph of a document that is not currently in force.

We are talking about clause 60 of Order of the Ministry of Labor of Russia N 1101n dated December 23, 2014 “On approval of the Rules for labor protection when performing electric welding and gas welding work”:

However, the replacement Order of the Ministry of Labor of Russia N 884n dated December 11, 2020 “On approval of the Rules...” no longer contains this paragraph.

It seems that now there is no reason to issue such an order at the enterprise “On securing...”, but...

Have you ever seen a gas cylinder explode or gas hoses begin to shoot off? I was “lucky”.

When I was still working as a 2nd grade welder, in the workshop next to me a friend was cutting a fairly thick sheet of steel (about 80 mm). I didn’t even hear the claps themselves, but someone’s screams and, throwing back my mask, I saw, as in a snapshot of a camera: faces frozen in tense fear, puffs of smoke mixed with workshop dust, the foreman rushing towards the oxygen cylinder...

I didn’t immediately understand what was happening; awareness and fear came later, when we stood near the sleeves and listened to the stories of the old welders. They didn’t bother much with fire-preventing and check valves back then...

Much later, I saw the consequences of a cylinder explosion on an open construction site. Oh, how many trials and punishments follow! Fines and deductions from wages for material damage. And it’s good if no one gets hurt!

“On securing gas welding equipment”

We are talking not only about gas-flame equipment, which no experienced production worker would treat negligently! Because sad precedents will teach caution, and “orphan” equipment will not remain operational and safe for long.

We are also talking about expensive gas welding installations! If desired, this also indirectly includes equipment for gas-shielded welding and plasma cutting.

Of course, if you don’t have complex, expensive equipment, and if at the same time you don’t bother with the fact that cutters and burners are lying around anywhere under your feet, then your choice...

We are issuing such an order. And we include everything there except manual electric welding:

- plasma cutting installations;

- sets of gas welding and gas cutting equipment;

- semi-automatic machines for welding in inert and shielding gases;

- orbital welding installations.

This is duplicated in the journals of orders for the sections under the signature of the workers and recorded in the personal Cards for recording the issued equipment, tools and inventory. So that not only engineers, but also workers, take this issue seriously.

Link to download the Order on securing welding equipment (sample) in pdf format.

Order “On approval of permanent places for welding and other hot work”

This order not only officially defines the places where welding and gas-flame work is to be carried out, but also appoints those responsible for their proper registration, provision of serviceable welding equipment, fire extinguishing equipment, organization of ventilation, and safe performance of work.

For our organization, the basis for issuing the order is clause 1.7 “Instructions for organizing and carrying out fire hazardous work” of Appendix No. 32 PB 03-428-02 “Safety Rules for the Construction of Underground Structures”.

We are underground builders and this document is binding for us, but remember which regulatory documents are the basis for you. Below are examples of several such documents by department.

“On permanent places for welding and hot work”

This is the order that is issued not by the chief welder’s service, but by the labor and industrial safety service (or whoever calls it?).

Since, in accordance with clause 372 of the Russian Federation PPR, hot work includes not only gas and electric welding work, but also cutting metal with a mechanized tool with the formation of sparks, and work with a blowtorch, then these works are formalized by the person responsible for fire safety in the form permit for hot work.

And our TB specialists are responsible for fire safety!

According to constant

and

temporary

places for hot work, almost the same thing is written in a variety of regulatory departmental documents:

These documents are mostly old, their status is not always determined. Therefore, look for yourself according to your departmental affiliation. Here are a few offhand:

Do not under any circumstances confuse permanent and temporary hot work locations.

with

stationary and mobile welding stations

!

These are completely different concepts, unrelated to each other, found in different NDs and requiring completely different organizational approaches!

If possible, try not to contact stationary posts at your enterprise. We have them registered only for the NAKS certification point at the metal structures plant. If you have questions, write, I will explain.

Link to download the Order for welding work (sample) in pdf format.

Order on assigning a mark to a welder: sample, form

Clause No. 8 of the FNP states that after brand codes are assigned to welders, they are assigned to these specialists. The order is signed by the organization performing the welding work. We bring to your attention a sample order for a welder's mark.

Nothing complicated, as you can see. In addition, the order to assign a personal brand is usually written in free form. It may indicate the types of structures being welded and other powers of the welder.