The excellent physical characteristics of profile pipes make them a universal material for the manufacture of various structures. With a relatively low weight, they have high values of resistance to bending and compression, and excellently withstand constant and multidirectional variable forces.

Profile pipes are much easier to weld and cut than traditional round pipes, and they also look more attractive. From such pipes you can make a comfortable and reliable bench, spending very little time and effort on the work.

Do-it-yourself benches from a profile pipe

Garden bench for a summer house or country house

The metal garden bench has become an integral part of our lives; not a single dacha or private house can do without it.

Relaxing and enjoying nature in the fresh air thanks to the bench becomes comfortable. And if it has beautiful forged elements, it becomes a real decoration of the garden, blending harmoniously into the surrounding landscape.

By creating a bench with your own hands, you can save your budget. Finished industrial products cost a lot, but everyone wants to create beauty with convenience. In addition, the work process itself brings a lot of pleasure, allowing you to later be proud of what you have done with your own hands.

Decor for country benches made of metal

Since just a metal frame and boards are boring, craftsmen strive to diversify their products with interesting additions. Most often, forged elements act as such additions. They simultaneously serve as decoration for outdoor furniture and at the same time increase the rigidity of the structure by creating additional support points.

For example, in this model, curls of square rod act as side rails and support wooden armrests.

Here, a curved profile pipe completely replaces the standard sidewall and back support elements.

This model doesn’t have any decor as such, but polished stainless steel with a rod crosshair on the side looks elegant on its own.

The creators of such products prefer minimalism, so they do not decorate the benches. The shape of the models, the use of only brushed metal or the original design are interesting.

Variety of metal benches

As a rule, they are made from a regular profile pipe. Such rolled metal has many advantages, including high strength, quality, ease of use and affordability.

1) From a profile with wood

The most common type, recognized for its versatility. A profile pipe or other type of rolled material serves as a strong frame. And the wooden seat and back are a pleasant “warm” material that makes it comfortable to sit on.

2) Metal

Made entirely of metal, it is reliable and durable. In terms of convenience, it is inferior to the previous one, since the metal gets very hot in the summer and freezes in cold weather.

But such benches add a special chic to the design of the garden plot. They can be decorated with decorative pillows, blankets, bedspreads, or even a beautiful mattress. This will not only add beauty, but also add comfort when sitting.

Types of structures:

- With or without a back , they are either entirely metal or with wooden parts.

- With or without armrests , their main function is auxiliary when sitting on a bench or when lifting.

- Wide or narrow , long or compact.

- Combined with a table into a single structure.

- With a different number of legs : 2, 4 or 6 (depending on the model, for example, the 5th and 6th leg is additionally mounted in the middle with an increased seat length).

- With canopy or other additions.

- Built into the interior or surrounding landscape. For example, around a pillar, flower bed.

- Welded or assembled using fastening bolts.

Which one to make depends on your wishes, budget, and choice of functions assigned to the bench. But in any case, it can always be decorated with artistic forging. With a little imagination, it’s easy to achieve originality.

Pros and cons of profile pipes

The cross-section of a profile pipe can be of several types:

- rectangular;

- square;

- diamond-shaped;

- oval.

Low alloy and carbon steel is used for production. The profile pipe is used both in industry and in private construction. This material is easily bent, welded and cut. Using a profile pipe, you can assemble an arch, gazebo, bench, gate, fence, carousel and swing. The profile pipe is characterized by the following indicators:

- the final weight of the structure will be small;

- reasonable cost;

- resistance to mechanical and physical stress.

It is extremely easy to work with such materials, which even a novice master can do. A high degree of stability is inherent in materials with an oval or round cross-section. It is this type of profile pipe that is recommended for use in the manufacture of benches for the private sector. Pipes should be selected thin-walled 1-4 mm. This is the easiest material to work with.

The process of bending a profile pipe

The cost is affordable, and the bench itself will be lightweight, which will allow you to move it if necessary. The susceptibility of the material to corrosion is considered a significant drawback, which makes it necessary to coat the product with polyurethane, epoxy, alkyd or oil paint. Pre-priming is required. With proper care, the bench will last a long time.

How to make a forged bench with your own hands

Forged elements are very popular. And this is well deserved: the products look much more attractive. To make such a bench yourself, you don’t need to have super professional skills.

At first, it is enough to start with simple things. You also need to have at your disposal special tools for making blacksmith decoration - cold forging machines. The most necessary ones are Snail, Gnutik, Torsion Bar + Basket.

Basic Rules:

Despite the fact that the sizes are selected individually, several points must be observed to make the bench comfortable.

- The length is calculated at the rate of 0.6 m per person.

- Width – minimum 30 cm.

- Back height – minimum 30 cm.

- The angle between the seat and back is from 105 to 120 degrees.

- The height is determined by the length of the tibia (to the popliteal fossa). The standard is 38-45 cm.

If the height of the bench is more than 45 cm, then the legs will hang down. And if it is less than 30 cm, then when sitting your knees will be bent at a right angle, which is not at all comfortable.

Additional materials

1) Paint for metal. Primer enamels are often used, which are applied in several layers and do not require special surface treatment. Hammer effect paints are also popular; due to their decorative properties, they add zest to the finished product.

One of the main qualities of metal paint is that it must have anti-corrosion properties.

2) Materials for wood processing. There can be various combinations here. But the most necessary are: antiseptic impregnations, protective compounds and paintwork materials. Their main task is to increase the service life of the open-air bench.

3) Circle for an angle grinder. Metal always has to be cut to the required dimensions.

4) Brush for metal. Necessary for cleaning before painting, or during the creation of forging curls, to clean off scale. When stripping, all rust is removed and the metal is cleaned to a shiny state. On such a carefully prepared surface, the paint will last much longer.

5) Degreaser. Before painting, the metal frame is degreased. This gives higher adhesion of the applied paintwork material, plus improves the uniformity of application of layers.

6) Electrodes for welding. These are mandatory consumables, you can’t live without them.

7) Set of metal drills. You may not need to drill much, but you should have some in stock. Needed for attaching a wooden seat to a metal frame.

Bolts, self-tapping screws. Also useful for fastening the wooden part of the structure. Sometimes used to connect all parts, instead of welding. Tip: fasteners with rounded caps will help avoid damage to clothing in the future.

Bolts, self-tapping screws. Also useful for fastening the wooden part of the structure. Sometimes used to connect all parts, instead of welding. Tip: fasteners with rounded caps will help avoid damage to clothing in the future.

9) Sandpaper. The wood is treated with sandpaper of different fractions. This way it becomes smooth and pleasant to the touch. But if there is a planed board, then this consumable is crossed off the list.

10) Protective mask, gloves. We make sure to follow safety precautions and protect our main working tools - our hands and eyes.

You may need other small things, which can be easily bought at any hardware store or found in your garage.

Bench protective covering

Wood and metal are processed separately. It is better to use a primer for the frame. Ideally, red lead will be used, which will protect the metal frame from corrosion for decades. Especially when you consider that at the dacha such garden furniture is under the snow for six months.

The wood can simply be painted. But if you first dry it, let it dry for a couple of days, then apply varnish in two layers, then such a coating is guaranteed to protect the wood from environmental influences.

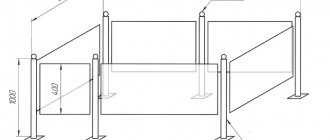

Two benches with a table on a rolled metal frame

In any case, color compatibility and design ideas are important. For example, if the frame is covered with Kuzbasslak, then it is better to varnish the wooden parts, this will emphasize the natural texture of the material.

To make the protection of the bars effective, the treatment is carried out before fixing to the frame.

Stages of work

1) Develop a design for a future product or find a ready-made sketch. The design can be taken either from a sketch or modified to suit your needs. Thus, the modified bench will stand out among others.

2) It is important to think through all the interfaces , angles of inclination, methods of fastening, and calculate possible loads. The correct drawing will make all subsequent work easier.

3) Record the dimensions of all parts , on the basis of which add the required amount of material to the estimate. The length of the curved elements is measured using a regular rope. To measure, forged elements are drawn with chalk on any flat surface, or with a pencil on whatman paper, on a scale of 1:1.

4) Prepare all material and tools for work. It is better to treat metal and wood immediately. A grinder removes rust from metal. If necessary, the wood is sanded to remove roughness. As a result, further work is simplified, because it is much more difficult to do in the finished product.

5) Before cutting the material, do not rush. It’s better to measure everything carefully and accurately . Make allowances for deviations (excess will be trimmed). Otherwise, during assembly there may be a mismatch of parts.

6) First of all, you need to make a frame . All cut and processed metal is welded one by one. Make sure everything is welded evenly.

7) Based on the sketch, forged elements are created using cold forging machines. Then the result is checked against the prepared stencil (drawing with chalk on a work surface or with a pencil on whatman paper).

All forged elements are laid on a stencil, and the excess is trimmed off. Alternately connected by welding. When working with a welding machine, you must follow safety precautions.

All forged elements are laid on a stencil, and the excess is trimmed off. Alternately connected by welding. When working with a welding machine, you must follow safety precautions.

9) Holes are drilled in the metal frame to attach the backrest.

10) All finished metal parts are welded according to the design in the project.

11) Increasing the rigidity of the bench . Plates with a diameter slightly larger than the cross-section of the pipe are welded to the legs. A longitudinal torsion bar can be welded to the base, this will add decor and increase stability.

12) Grinding of all excess in the welding areas. Welding beads, sharp edges, and burrs are removed.

13) The final metal frame is coated with paintwork , observing the order of application and drying stages.

14) Using a drill, holes are drilled to attach a wooden seat .

15) Treating wood with stain or other paints and varnishes.

16) Fastening the prepared wooden parts. You need to screw it securely, but not overdo it, so as not to push through the wood from the front side.

17) Finally, the forged bench is installed in the intended place. And we enjoy the result, which we made with our own hands!

Example drawings

Photos of forged bench options

Advantages of cold forging

The forging method can be either cold or hot. But cold forging, unlike hot forging, has its advantages:

- Less energy-consuming process : the technology for manufacturing forged elements is much simpler. There is no need to preheat the metal and carry out additional operations: tempering, annealing or hardening.

- There is no need to create special conditions . Unlike hot forging, where you need a furnace for heat treatment of metal, a forge, an anvil, various hammers, tongs, a container for cooling the metal, and a large room. In addition, working with hot forging requires certain skills.

- During cold forging, the metal does not change its chemical properties , which is why it remains very durable.

- With cold forging machines, it’s easy to master the creation of beautiful forged elements. Even a beginner can handle it.

- Hand-made cold forging looks no worse , it is exactly the same original work with its own characteristics. You can make beautiful forged products that are in steady demand not only for summer cottages. For example, a bench will look interesting in a composition with a hanger in the hallway of a city apartment. Forging looks great in homes, interiors, commercial buildings, and on city streets.

- The scope of application of cold forging is varied : benches, forged gratings, railings, fences, fences, gates, barbecues, canopies, gazebos, canopies, furniture parts and the furniture itself, for example, a forged bed, interior items - forged frames for pictures, mirrors, clocks, stands for indoor flowers, fireplace grates, lamps and much more.

Snail machine for cold forging “TR-U1”

6,000 rub.

More about the machine

10 in 1 cold forging machine “TR-U2”

from 34,000 rub.

More about the machine

A bench carefully assembled with your own hands is practically no different from an expensive industrial model. And if you carefully process and paint the welds, then 99 percent of people will not see any difference.

Other options for metal benches

Creative solutions

Custom benches can be made from any handy scrap metal. Here you can not be limited in design ideas, I use my imagination to the maximum. The main thing to remember is that in the end you want to see comfortable, practical furniture, or a futuristic installation.

But creative solutions can be practical and give new life to old items. For example, a bench from an old cast-iron bathtub, or from an unnecessary metal bed. They will undoubtedly stand out in the garden.

Simple solutions

Simple cheap benches can be welded from reinforcement or steel angle. But bending reinforcement with an angle is more difficult. Here you can do it without a drawing, assembling parts by eye. The main thing is to maintain standard sizes so that later it will be comfortable to sit.

Modern minimalism

Simple but at the same time original shapes, lack of decor, asymmetry, curved contours. All this, done in the same style or using only one material, looks great in modern landscapes.

Raw materials for frame

Depending on the type of metal base, the following types of garden benches are distinguished:

- forged;

- from a professional pipe;

- from the corners;

- from scrap metal.

Materials for manufacturing: profile 25x25 - 6 meters, timber 60x20 and 80x40, 5 meters each.

What kind of bench should I make?

Making a choice is sometimes difficult, since there are many different designs with interesting designs. But when deciding, two main factors are taken into account:

1) What is it for? To sit on it with a group, or relax in solitude, or drink tea with your wife? Or maybe especially for children and grandchildren?

2) How often will it be used? Daily or occasionally?

Based on the answers, it will be clear which bench to make. But first of all, the basic requirements must be met:

- Convenience . For example, the presence of a backrest on which you can lean back and relax.

- Safety . A garden bench should be strong and well finished. Therefore, use only high-quality materials.

- Reliability . It must be resistant to changes in humidity and temperature. And for this, high-quality material is also selected, all stages of processing are observed.

- Sustainability . When sitting on a bench, it should not tip over. Stability is achieved in various ways, for example, fixation with anchor bolts, provided that it is installed on asphalt or concrete.

To increase stability, it is better to make the legs of the bench with a slight slope (8 - 15 degrees).

A hand-made forged bench can be installed not only in recreation areas of a country house or private home. It can also be installed at the entrance to the house, where the bench will serve as a waiting area or serve well for shopping bags.

Preparation for production

Regardless of the type of blanks (corrugated pipes or corners), before welding them, you should take measurements and prepare a sketch of the future bench. Such forethought will allow you to obtain a strictly verified frame base and estimate the approximate amount of starting materials.

You can weld a bench only if you have welding equipment and the ability to use it. It is necessary to take into account the features of metal welding technology and worry about preparing consumables (electrodes, various additives) in advance.

The level of classification of the welding performer is also important, on which the quality of the future bench ultimately depends. Even when manufacturing such a simple structure, handling metal workpieces during welding requires increased attention and the correct choice of current mode.

When preparing for welding, you should worry about the safety of the activities being carried out and prepare the workplace in compliance with basic safety requirements.

How to care for a wrought iron bench

Maintenance is kept to a minimum . If initially everything is done correctly, then it will serve for a long time, maintaining its strength and impeccable appearance.

1) The most banal thing: use the bench carefully to avoid chips that can occur under strong mechanical stress. But even if this happens, the chips are treated with an anti-corrosion compound.

2) Periodically clean the bench from dirt.

3) Regular wax will help maintain the attractiveness of forged parts. Applying wax once a year will prevent clogging with dust and dirt.

Required Tools

- saw (for cutting wood if it is too long);

- screws;

- roulette;

- manual grinding machine;

- pencil;

- eye and ear protection.