A barn is a necessary building on a private farmstead in the city and village. You can’t do without it even at the dacha. Gradually, more and more tools, equipment, and building materials accumulate that need to be stored somewhere. A reliable shelter for all these things is a metal shed. If you know how to weld metal, it won’t be difficult for you to make it yourself. It turns out to be approximately equal in cost to wood, and much cheaper than brick.

Which type of shed to choose for your summer cottage?

Depending on the plans for the future development of the personal territory, the availability of free time and money, solve the household problem. premises on a summer cottage can be done using several methods:

- hire workers and erect a permanent building made of brick or foam concrete block, with a pitched roof and a utility room;

- pour a concrete foundation for the utility block with your own hands, purchase a five-ton iron container and place it at the dacha instead of a barn;

- build a simple building with a pitched roof from timber and boards.

Which option to choose is up to you.

Roof

A shed made of corrugated sheets can be equipped with both a gable and a pitched roof. More often they choose the first option - it can be easily insulated if necessary. This is the work plan.

- Arrangement of sheathing. The same timber used for the construction of the frame is used for it.

- Fastening corrugated sheets. If for the walls you can take a sheet of ordinary galvanized steel, then for the roof it is better to purchase material with a polymer coating - the roof is more exposed to precipitation. The corrugated sheet is again attached with an overlap, self-tapping screws, and preferably with a rubber gasket, to ensure greater tightness of the roof.

If the shed is supposed to be equipped with the utmost capital, steam and heat insulation is installed under the corrugated sheet roof, which is covered from the inside with a sheathing made of antiseptic-impregnated plywood.

Barn floor

Advantages and disadvantages of outbuildings made from profile pipes

Advantages of structures made of metal profiles:

- reliability. A metal frame for a shed, installed on a flat and dense base, will last for many years and will be subject to deformation. It will protect the contents from rain, street dirt and rodents.

- High fire safety.

- Beautiful view. A structure made from profile pipes will look great on the site.

- Economical. You don't need to spend a lot of money to build a metal shed. Also, a metal utility unit made by yourself will not require expensive maintenance.

Disadvantages of metal buildings:

- Freezing. If you are not going to keep animals indoors, then this point can be ignored. Some materials, for example, oil paint, cannot be left in a shed made of metal profiles for the winter.

- The appearance of rust. To avoid this problem, all structural parts must be inspected every year and coated with an anti-corrosion agent, especially attention should be paid to damaged areas. If you built an outbuilding yourself, then it is enough to periodically paint or prime the metal.

The final touch is the floor

In the most primitive version, the floor in the barn can be left concrete, that is, the foundation can be poured. In this case, you can cross out from the list of works the frame installed on the blocks after constructing the base of the shed. However, such a choice will make the building completely uncomfortable, and the humidity inside it will be unacceptably high. In addition, the conditions for storing the same fertilizers in a barn will be unsuitable. It is better to equip the flooring.

The most commonly used boards are nailed to the frame or fixed with self-tapping screws. They need to be laid end to end, but not too tightly, leaving technological gaps of about 2 mm for the wood to “breathe”. Some craftsmen prefer to use chipboards instead of boards. This is a more affordable option, but it will require laying transverse joists under the floor for fastening individual elements.

After completing the main work, a window is inserted into the barn and doors are hung.

As you can see, building a shed from corrugated sheets with your own hands is not so difficult. However, if you are not confident in your own abilities or are limited in time, you can always hire a team that will quickly and efficiently provide you with a utility unit.

Watch a video on the topic:

https://youtube.com/watch?v=videoseries

Metal barn: types and features of construction

Sheds come in different shapes and sizes, everyone chooses an option to suit their needs. However, most often outbuildings are divided into two main types, which differ precisely in design:

- Mobile . Such collapsible iron sheds are assembled with your own hands like a constructor using fasteners, grooves and other extras. details. They are easy to install and low maintenance. Mobile modifications are suitable for those who are still choosing a place for construction or are planning to move somewhere in the future. If you want such a metal shed built with your own hands, you can dismantle and move it.

- Stationary . The welded model is installed by welding the frame parts. It is more reliable, has a longer service life, but it cannot be completely disassembled and moved. Therefore, welded frames are mounted on a pre-selected site, taking into account the placement of other buildings on the summer cottage.

Peculiarities

The functions of a shed are limited to storing things and ensuring order. It is very important that the outbuilding is durable. The roof must cope with the load in the form of snow, and the walls and doors must be protected from penetration into the premises. Metal boxes have all these qualities, while having a beautiful visual appearance. Read more about the features of such outbuildings:

- Compared to wooden models, galvanized metal sheets, which are used in the latest designs, do not rot or leak water. This allows you to store things indoors on a permanent basis without worrying that mold or rust will soon appear.

- If we compare a shed made of metal profiles and a plastic box, then the first option wins in the comparative analysis, thanks to the following advantages: the outbuilding is mounted on the surface of the earth, which means it will be subject to various influences. Plastic buildings will not be able to withstand very hot summers or cold winters without deformation. Overheating can cause plastic materials to lose their beauty. Plastic is also quite sensitive to sub-zero temperatures. For metal sheds this is not a problem: profile pipes can withstand any frost or heat.

- Concrete and brick sheds are considered competitors of outbuildings made of metal, but their construction takes too much effort. A barn made of brick and concrete mixture will be built using small house technology, starting with the creation of a project and pouring the fundamental structure.

Why is it worth buying a change house for a summer house or construction site?

- Speed of installation - you can buy and install the structure within one day;

- Convenience and functionality - this is a full-fledged compact house with a kitchen, bathroom and shower;

- Wide selection of models - from standard to exclusive;

- Favorable price-quality ratio. You can buy a change house from us inexpensively, because... You purchase the house directly from the manufacturer;

- Attractive appearance;

- Durability;

- If necessary, the structure can be dismantled and transported to another location.

We offer a wide selection of country and construction trailers with delivery throughout Moscow and the region. You can choose a model in our catalog according to your preferences or order a change house according to your drawings.

Choosing a place to build a shed on a summer cottage

If you want to build a shed from pipes, you need to choose the right place, and for this you should take into account some nuances:

- Prefabricated models usually look aesthetically pleasing, so they do not have to be installed at the edge of the site.

- The outbuilding must have open access. If you want to safely remove your equipment, clear the road.

- The barn needs to be built on a flat area, then it will be stable. It is advisable not to install a metal profile box in a low area, where moisture will collect after the onset of spring.

- You also need to think about the function of the shed when choosing a site. If you will store garden tools and special equipment in an outbuilding, then there is no better place than the path from the cottage to the garden or field. If you will be keeping animals in a building, it is better to choose a place away from the house.

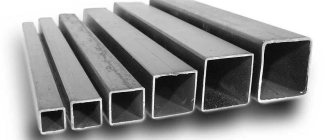

Features of the metal profile

Main features of the metal profile:

- It is easy to work with and does not require the use of special equipment.

- Galvanized steel and polymer coating protect the structure from moisture.

- Thanks to its light weight, it is easier to make a frame and build a fundamental structure for the utility unit.

- A metal shed, due to the large selection of colors, will easily fit into the exterior of your site.

However, metal profiles also have disadvantages:

- Passes all sounds.

- Due to damage to the protective layer, the material may begin to rust, but if you remove sources of fur in a timely manner. damage, then everything will be fine.

At what distance from the fence can you build?

If the barn will be used exclusively as a warehouse or workshop, the regulations allow construction at a distance of 1 m from the boundaries of the site. But in the case of keeping animals or poultry, everything is much stricter:

- must be at least 4 m from the fence;

- from a residential building (both your own and a neighbor’s) - 12-15 m;

- from a well or well for drinking water - 30 m.

If the building is located on the north side, this protects the area from cold winds. In addition, it will not cast a shadow on the area suitable for summer cottage plantings.

When choosing a location for a shed, you need to remember fire safety. The fire gap is 15-18 m for wooden buildings, 9-12 for buildings with wooden floors and 6-8 for buildings made entirely of brick or concrete.

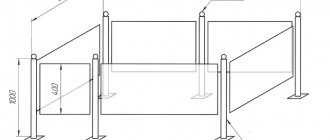

Drawings and diagrams of the barn

A barn is a capital building, so the drawing is considered the basis for everything, calculation of materials, construction, and so on. When creating, you need to take into account the dimensional characteristics of blocks, sheets, and measured products.

A drawing of a barn for a summer residence made of metal profiles must be made in several projections, preferably all four facades, if there are any differences. It is necessary to indicate the dimensions of the shed along the axes, height, dimensions of openings, and wall thickness. The layout of the main structural elements and other technical details are highlighted. moments. You can download the diagram from the Internet and customize it for yourself.

Greenhouse made from plasterboard profile

Many who do construction and repairs with their own hands have obviously worked with drywall, and, of course, paid attention to the ease of working with profiles. Such elements have great advantages: galvanized steel is protected from corrosion, has quite high strength, looks quite decent and can be easily processed (cut, bent, etc.). Due to its numerous functions, such material is very suitable for building a greenhouse. Have you always wanted to arrange it in your garden plot? Then it’s time, especially if you have already worked with this material, then you have only the best impressions. The process itself is elementary simple, and now we’ll look at how it’s done.

What is this article about?

Instructions on how to build a barn with your own hands

Before building a metal shed with your own hands, you need to prepare the site:

- clear the area of debris;

- cut down bushes, remove roots and other vegetation;

- level the ground.

Building materials, cement mixture, insulation and everything that is afraid of moisture must be covered under the roof. Concrete mixers, tools, stepladders and other items should also be stored under a shelter.

Required tools and materials

To build a utility block for your dacha with your own hands from corrugated sheets, prepare the following:

- welder;

- vibrator;

- drill-driver and rivet gun;

- grinding machine;

- construction level, plumb line, tape measure.

A portable structure made of profile pipes, like a collapsible one, is created from wall frames. They are welded separately. Bolts are used for connection. A profiled sheet is used for cladding. It is quickly and easily installed by hand. The roof can also be made from corrugated sheets. Racks made of round pipes with a diameter of 61 mm can be useful for work. This was a list of materials for the frame part. But for concreting you will need to prepare:

- 16 bags of cement composition;

- 7 tons of gravel;

- moisture insulation (1 roll);

- self-tapping screws, rivets, electrodes for welding;

- wooden slats for the sheathing: 50 by 25 mm - 3 pieces, 6 m each.

Advantages of using profiled sheets in construction

High strength, anti-corrosion properties and rigidity, combined with a variety of sizes and low weight, have ensured the popularity of corrugated sheets in the construction of various types of premises.

Even a non-professional can install profiled sheets

The main advantages of using profiled sheets include the following:

- durability;

- resistance to corrosion;

- rigidity;

- light weight;

- versatility;

- ease of self-installation;

- availability of component materials;

- ease of transportation and storage;

- low price;

- wide choice of sizes;

- high aesthetics of the coating.

The corrugated roof is not subject to corrosion

The use of profiled sheets speeds up the time and overall costs of DIY construction. A small number of joints ensures the reliability and tightness of the structure, and the low weight allows even beginners to attach the corrugated sheet.

Like many repairs, covering the roof with corrugated sheets is best done by two people. It is first necessary to clarify the dimensions of the area that needs to be covered with corrugated sheets, make sure that the slopes are rectangular in shape and check their flatness using a level. Then decide on the color, shape, thickness and brand of corrugated sheet, as well as select the necessary tools and components.

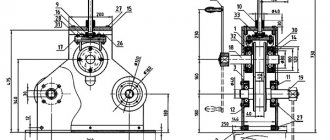

How to cook metal without causing any problems

Let's consider the solution to this problem:

Sequential passage of welding seams. If you need to weld thin sheet metal, then in order to avoid its deformation, it would be advisable to use a reverse-step weld, no more than 300 mm. After the metal has cooled, you can weld the remaining cracks. Thus, thin sheet metal will not lead.

More precisely, there will be deformations, but the previously made, “short” seams will compensate for them. In addition, in some cases, when welding thin metal, it is best to use tacks first, and only then weld the seam.

Preliminary bending of workpieces to be welded. Another method that will reduce the deformation of thin metal involves bending the workpiece in the opposite direction from the stresses during welding. Thus, after the welding is completed, the metal workpiece will return to the desired position under the influence of deformation.

Price of finished products

In addition to the fact that you can make trusses yourself, you can also buy them ready-made. But, if you want something sophisticated, then it will be difficult for you to make a purchase, since everything is designed for standard projects. If you are ready for what they will offer you, then agree to standard solutions, but be prepared to overpay.

On average, if a lean-to farm structure costs around 1,500 rubles at cost, then specialists charge from 1,000 rubles per linear meter. With the required number of crossbars that we indicated in the calculation, the finished product will cost at least 4,000 rubles per unit.

Thus, for only 5 of our trusses necessary to arrange a 6 by 4 m shed, we will have to pay 20,000 rubles. The price of a shed farm is steep and not affordable for everyone. Otherwise, be prepared to pay for the construction of the canopy itself. The work will include concreting, carpentry, purchasing metal for poles, as well as other types of tasks solved.

In any case, buying a ready-made option is expensive, since you overpay up to 300%. There is no difficulty in welding a truss for a canopy yourself, especially if you have at least once worked with welding equipment. A modern inverter allows you to solve complex problems, even if you are a welding novice.

Buy the right electrodes, don’t skimp on metal, watch what others are doing, because today the Internet is full of different options for arranging farms and sheds in general. Remember that a canopy without trusses is flimsy and will not be able to withstand the load of snow in winter.

How to sheathe the structure of a utility block

Initially, you need to determine the conditions in which the shed will be used. In regions with high humidity and harsh winters, it is necessary to cover utility blocks with wear-resistant metal sidings or clapboards and slabs. In warm regions, to provide a rustic design design (that will remain after many years), slabs (the sides of a log) or old wooden sleepers will do.

A cheap and practical way to cover a shed is with ordinary boards, which the owners can later paint to their liking. You can also simply coat a regular board with stain and varnish. In any case, you first need to put plywood or OSB boards on top of the frame.

On a note! Before covering the shed with wood materials, they must be treated with an antiseptic. Re-treatment will have to be carried out after 2-5 years

Change house 6x3

Wooden ones differ from their non-mobile counterparts in the lack of decorative finishing, simpler interior decoration, and a thick frame. For the main beams of the frame, timber 150x100 mm or more is taken. The installation of such structures does not require special preparation and rigid fastening to the ground. The construction of a cabin is not very complicated technologically and does not require special training or expensive rare tools, but an inexperienced builder should not hope that everything will go quickly and without problems. The number of required installation operations is quite high; it can take a month or more to fully master them during the construction process.

The walls are provided with hydro- and thermal insulation and sheathed with corrugated sheets on the outside and chipboard on the inside. If necessary, electricity, water supply, and heating can be installed in the trailer. The disadvantages of this model include the highest price of material for all frame options, high weight, the need to monitor the condition of the skin and tint it, and a large amount of welding work. On the one hand, self-construction of a change house is a rather lengthy and costly task, and many will abandon this in favor of factory-made solutions. On the other hand, this is a good way to save money by building a shed from cheap materials, or, conversely, to build a much better one for the same money.

The standard drawing of a 6x3 construction cabin provides for the presence of 3 rooms - the main one, 3x4.5 in size, equipped with heating and other amenities, a 1.5x1.5 m corridor, which serves as a temperature lock, a storage room/toilet, 1.5x1.5 m in size. The roof for all models is made of corrugated sheets.