Copper and aluminum in the generator. We extract copper from the generator.

How much copper is from KAMAZ wiring? I sell spare parts.

How to disassemble the Kamaz generator rotor.

GENERATOR FROM VAZ. WE DISASSEMBLE THE STAR TO RECOVER THE COPPER. QUICKLY.

how to disassemble the anchor and remove the copper KAMAZ starter..

How to remove copper from a winding without any tools

HOW TO DISASSEMBLY AN ANCHOR FROM A GENERATOR PASSED 5000 THOUSAND COPPER

Generator G287 G288 Kamaz, Ural, Gas-66, K700-701. Repair

Has the price of light gone up? Make a 220-380V generator like this for your home. homemade Generator 220-380V.

Do-it-yourself analysis of the armature and stator

Choosing the “right” electric generator is not an easy task, especially if the buyer is based on such an irrational indicator as the price of the generator. When choosing such a complex device as a gasoline or diesel generator, it is better to remember the “golden” rule of any purchase: “A quality product is never cheap” or, as it is popularly reproduced: “A miser pays twice.” The fact is that the lion's share of the price of each generator falls on its main parts: the engine itself and its electrical part - the winding. The design of the engine and the materials from which the shaft, cylinder liner, bearing, armature are made, as well as such a seemingly not too weighty, but in fact extremely important element as the winding - this is what we pay for when buying a high-quality generator.

Parallel sections in coils.

Before using this type of winding, read on page 310 “Windings of Electrical Machines” by G. K. Gervais, 1989.

- If, with all the above calculations, it was not possible to reach the required wire, the calculation can be continued by dividing the winding coils into parallel sections. For example, let's take the winding of a 24-slot 3000 rpm motor.

- From Figure 6 you can see that there are 4 sections in the coil, the possible number of parallel sections is a=1c, a=2c and a=4c.

Rice. 7. Laying diagram with parallel sections in the coil.

- Since the sections in the coil are connected end to beginning, we will also connect parallel sections taking this into account.

Rice. 8. Winding connection diagram, number of parallel branches/sections a=2/2c

Rice. 10. Winding connection diagram, number of parallel branches/sections a=2/4c

- As the number of parallel sections in the coil increases, the number of conductors in the section increases, and the cross-section of the wire decreases by the number of times the parallel sections.

Non-ferrous metals in a car engine

For the manufacture of automobile engines, not only ferrous metals are used, but also non-ferrous ones. As you know, non-ferrous metals cost several times more than their counterparts. But where to look for them?

- Cylinder head. This engine part is quite massive. Aluminum, by its nature, is 50-60% lighter than steel. In order to reduce the weight of the engine and the car as a whole, the cylinder head is made of aluminum. Her weight is in the range of 10-15 kg.

- Pistons. Here the situation is not only in the masses (although in them too). The thermal conductivity of aluminum is several times higher than that of steel, so an aluminum piston provides a better compression ratio. Also, such pistons have better anti-friction properties. Depending on the number of pistons, the weight can vary from 0.7 to 2 kg.

Aluminum is also contained in the intake manifold, but, as a rule, it is not classified as part of the engine.

The average price of aluminum scrap ranges from 60-80 rubles/kg. So we have that with a little work, you can increase the income from engine delivery by 940-1360 rubles. In other words, twice as much. Agree that for the sake of such benefits, you can work a little.

Now let's approach this issue from the point of view of labor intensity. To remove all of the above elements, you will need basic knowledge about the structure of the engine and several hours of free time. If you have both, then feel free to get down to business.

ALUMINUM WINDING: PROS AND CONS

Aluminum is a light and soft metal; it also has good conductivity compared to other metals. But in addition to the conductivity of electric current, aluminum is also characterized by increased thermal conductivity, that is, it heats up much faster and stronger than copper, and this negatively affects the output power of the electric generator. One of the features of aluminum is its increased resistance to corrosion. Upon contact with air, aluminum oxide immediately appears, which coats the wire with a thin layer. This quality is indispensable in the manufacture of housings for various units, but, unfortunately, it has a negative effect in windings. The fact is that the oxide film makes soldering difficult, so the connected parts of aluminum are not very strong and not resistant to wear. Have you noticed how easy it is to break aluminum wires by twisting them in your hands? Aluminum windings will also crack easily. So, the only advantages of aluminum winding are low cost and light weight.

And the disadvantages should be counted:

1. Current conductivity is lower than that of copper. 2. Fast heating (under load, the generator output power drops). 3. Poor durability (reduced generator life). 4. Cools slowly.

SOME NUANCES OF CHOOSING A WINDING

Based on the comparative characteristics of copper and aluminum, it is clear that the copper winding of the alternator is better and more reliable. It is so good that many buyers have already made the right conclusion for themselves and when buying a generator they are always interested: does the alternator have copper or aluminum windings? With all the obvious advantages of copper, it must be said that this article does not at all advertise the purchase of generators with copper windings. Reviews from many customers indicate that not everything is so bad with aluminum. There are excellent and reliable alternators with aluminum windings that last for more than 10 years without repair. Many quality brands pay a lot of attention to the issue of improving the conductivity of aluminum, making correct calculations of the wire cross-section and its interturn insulation. This increases not only the conductivity, but also the resource of the generator. Thus, if you need an inexpensive and not very powerful electric generator for infrequent use (for example, a reserve for a small home and office), then feel free to buy a synchronous generator with aluminum winding, saving money. Finally, a few more secret tips when choosing a generator winding. Since copper is more expensive and in high demand, some unscrupulous manufacturers even resort to deliberate deception. They lightly tint the aluminum winding, passing it off as copper. The situation is bad because you will not be able to look at the insides of the generator and touch them. Although, even in this case, few will understand what kind of metal is at hand. You have to take the seller's word for it. And then, when the generator “dies,” already during repairs, you can see whether you were deceived or not. To avoid falling into this trap, be careful when choosing a generator:

- buy generators only from reliable and stable brands;

- On the Internet, look only for official dealers of the manufacturer.

Preparing to measure the electric motor before rewinding.

In preparation, before starting measurements, you should thoroughly clean the stator core (and, if necessary, the rotor) from dirt and oil, remnants of the old winding and its insulation, layers of varnish, paint, rust, etc. When cleaning the core stator, you should not use a file even with a fine notch. It is best to use only a rag soaked in kerosene; as a last resort, firmly adhered particles are removed with a scraper. It is convenient to wipe the inside of the grooves with a rope dipped in kerosene. After cleaning, the core is wiped dry with a clean rag.

Source

Functions performed

So, what is a generator for? First of all, in order to provide all VAZ 2110 equipment that runs on electricity with energy. Perhaps someone thinks that this is the battery's task. Not really, because the battery is needed to maintain functionality when the engine is not running (it starts the engine, supports the alarm, music system while parked, etc.).

But when the engine has already started, with the help of the battery, the generator comes into play. During the trip, it is he who supports the operation of all electronics, air conditioning, audio (or even video systems), and everything else that you have added to your VAZ 2110.

Another equally important function of the generator is charging the battery. This also happens when the engine is running. And if it weren’t for this device, the battery would not be able to cope with its tasks, and it would have to be charged all the time.

Considering that today on the VAZ 2110, in addition to the standard layout, many additional energy consumers are installed, it happens that the generator voltage is not enough. In this case, it makes sense to install a 120 amp generator.

VAZ for scrap metal

First Scrap Company is no longer the only one accepting old machines. By concluding a deal with us, you will not have to tediously wait for funds to arrive. We work around the clock and are ready to immediately accept your order.

Attention: renting a car for scrapping is not only a profitable solution, but also the right one from the point of view of protecting the environment.

How we are working

First, the car is sent to a metal processing plant. This is where they begin to separate the old batteries, rubber and wiring from the car. After this, the parts are sent to the dismantling workshop. If there is any remaining gasoline in your car, it will definitely be drained into a container intended for this purpose. A completely disassembled car is just a pile of metal that will be sent to metal shredding equipment.

All that is left of the car melts. Recycled materials will only be an excellent source for the production of brand new car bodies. When considering selling a VAZ 2106 for scrap metal, you can:

- earn;

- clear the surrounding area of debris;

- contribute to improving the environmental situation;

- assistance in obtaining recyclable materials.

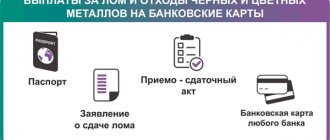

Documents required for scrapping a car:

- You must have a civil passport with you;

- passport of the car that was going to be scrapped;

- traffic police document for waste disposal.

If you cannot deliver the car to the collection point yourself, we will do it for you, using special equipment for its delivery. We have a fleet of vehicles for this!

The most frequently asked question is how much does a VAZ cost for scrap? We answer:

| VAZ model | Vehicle weight | Block | Metal weight |

| 2101 | 955 kg | thirty% | 668 kg |

| 2105 | 955 kg | thirty% | 668 kg |

| 2106 | 1045 kg | thirty% | 731 kg |

| 2107 | 1060 kg | thirty% | 742 kg |

| 2109 | 945 kg | thirty% | 661 kg |

| 21099 | 950 kg | thirty% | 665 kg |

All data shown in the table are approximate. For more detailed information, please contact our manager.

Prices at the First Metallurgical Company will be the most favorable for buyers. Our company officially and with great responsibility approaches the determination of cost, which consists of the following factors:

- how much does the car weigh;

- what is the quality of its metal;

- there are machine parts;

- the shape of the machine itself.

Having an engine significantly increases the cost of a car because it contains a significant percentage of steel. Cast iron and steel are present in significant quantities in the car chassis. Nickel and copper are found in automotive electronics. In this regard, it can be said that a more complete set of your car will bring more money upon delivery.

Why is it profitable to cooperate with us?

It is our company that will pay a high price for your scrap metal! We will come to you exactly at the agreed time, because we value our time and the time of our clients. He is conscientious and works seven days a week and on holidays. Our specialists are highly qualified and experienced in performing similar work. Contact us to scrap your VAZ 2107! We will prepare the necessary accompanying documentation and pay immediately on the spot.

CLEAR ADVANTAGES OF COPPER WINDING

So, copper. The most malleable and ductile (after gold) metal. It has such unique qualities as high conductivity at low temperatures, strength and endurance. Copper is a heavy metal and quite expensive. But we have already said that it is better to buy an expensive generator once than several cheaper ones. Let’s say right away: only the copper winding of a generator can withstand increased loads without damaging its structure, which means that the service life of a generator with a copper winding is incomparably longer. The conductivity of copper wire is 1.7 times higher than that of aluminum wire, while its resistance (in Ohms) is lower and, accordingly, less heating. Let's summarize, what should be considered as the advantages of copper winding ?

1. Increased service life. 2. Doesn’t overheat too much during heavy loads. 3. High conductivity. 4. Short circuit resistance. 5. High strength. 6. Greater heat transfer (cooling occurs faster). The disadvantages of copper winding , in addition to its expensive cost, also include weight - it adds to the overall weight of the generator, but not significantly.

Popular models of generators with copper winding:

Typical customer review:

“The Iron Angel generator can be classified as budget, but the quality of the build and materials is very pleasing. Unlike more budget options, its generator winding is made of real copper. It starts my boiler, and I’m not afraid to connect a computer and expensive household appliances to it. I had a bitter experience with cheap Chinese junk, so these smart guys disguise the aluminum stator winding as copper, paint it copper-yellow. I found such a miracle of technology more in service than in work. I spat and gave it away for spare parts for pennies. Regarding the Dutch manufacturer, I can say that this is price-quality.” ©Victor

WHAT IS A WINDING AND WHY IS IT NEEDED?

In order to excite an electromotive force in sections of the stator (the immovable part located in the generator), it is necessary to create a variable magnetic field structure. Such a field is created due to the rotation of a magnetized armature (rotor). Magnetization occurs using a winding - a metal wire wound around the rotor and stator. With a change in the magnitude of the electric current, the structure of the magnetic field and, of course, the output voltage of the stator are affected. Using a simple electrical circuit with a reverse effect on voltage and current, the process is regulated. As a result, a synchronous alternator can cope with short-term overloads, and is limited only by the resistance in its own windings. In other words, its starting processes are much easier than those of an asynchronous one.

That is, a metal winding is needed to create electromagnetic excitation and subsequent creation of the necessary magnetic field. In this case, only two factors affect the generator resource:

- Winding quality: the more turns, the higher the calculated power of the electric generator. The size of the cross-section of the wire also affects the power of the generator.

- The metal from which the winding is made. It can be copper wire or aluminum.

It is also worth noting that in modern devices the winding is covered with a layer of varnish insulation, which is classified using letters. The closer the letter is to the end of the alphabet, the better the class, therefore, the heat resistance is higher and it withstands heat better (also affects the price). Many people, before purchasing a synchronous electric generator, wonder about the structure of the winding, wondering whether to choose a generator with copper or aluminum winding. Let's consider the positive and negative sides of both, since the winding is one of the key points when selecting a generator.

Electric motor scrap, copper disassembly and price per 1 kg of scrap

Sooner or later, the electric motor finally fails and must be scrapped. The difficulty lies in the fact that these products consist of heterogeneous quantities and assortments: copper, cast iron, electric steel. Therefore, it is irrational to directly hand over scrap electric motors to a collection point: some preparation is required.

Difficulties in disassembling an electric motor for scrap and solving the problem

We invite you to read the real story of our subscriber about his experience in extracting copper from scrap electric motors - Copper and the AIRХМ132S6У3 electric motor.

Electric motors that are subject to scrapping differ in power, size and type, and, therefore, have different designs.

For example, based on their size, motors can be divided into small, with a power of up to 3 kW, medium, with a power of up to 10 kW, and larger. The design of AC and DC motors also differs.

Many Vtorchermet bases offer their services for engine dismantling. However, with proper qualifications, such work can be done independently. Moreover, it is possible to simultaneously sort parts made from different metals and alloys. There are several cutting methods before scrapping an electric motor. The simplest is considered to be opening the housing, separating the stator from the rotor, and then subsequently sorting the parts. For this purpose, mechanized separation can also be used, but in such situations it is ineffective, so many works are performed manually. In addition, it is impossible to remove aluminum and/or copper windings, and the majority of non-ferrous metals and special steels do not change their type at all. For example, electrical steel plates remain in the insulation layer, and the shaft is often not removed.

Video - removing copper (windings) from the stator of an electric motor:

How to disassemble an electric motor for scrap quickly and efficiently? The optimal solution is disassembly, during which the front part of the stator and rotor windings is cut off with a circular saw, and then the insulation is burned. After this, removing the copper wires is quite easy. Then the frontal part is fired, and the copper winding is pressed.