Electric contact pressure gauges DM, EKM

Electrical contact pressure gauges (DM, EKM), pressure and vacuum gauges (DA), vacuum gauges (DV) (hereinafter referred to as “pressure gauges”) (Fig. 1, 2) complete with signaling device MS-3-…

are designed for measuring excess and vacuum pressure of non-crystallizing liquids, steam and gas, parts that are not aggressive to the materials in contact with the medium being measured, discrete control of electrical circuits of auxiliary and control devices (if the nominal, that is, threshold, value is exceeded, the electrical circuit is closed or opened) and supplying light and sound signals. Set of pressure gauge with signaling device MS-3-…

can be used to control pressure in technological systems of oil, chemical, food and other industries.

A pressure gauge set with a signaling device, for example, can be used to monitor the tightness of the interwall space of a double-walled tank (Fig. 3), as well as for double-walled fittings at gas filling stations and gas stations.

Device, principle of operation

Pressure gauge design: Pressure gauges are manufactured on the basis of non-explosion-proof instruments: - DM (DA, DV) ... - pressure gauges with sliding contacts (manufacturer OJSC Manotom, Tomsk) - fig. 1;- EKM... - pressure gauges on microswitches (manufacturer: NPO YUMAS LLC), Moscow - fig. 2. Explosion protection of pressure gauges is achieved by modifying them and using them together with the MS-3-...

, which performs the functions of an intrinsic safety barrier. Modification of pressure gauges does not concern their measuring part and consists of bridging the contacts with diodes, carrying out additional checks and marking. Operating principle: Setting pressure thresholds is carried out by moving the “signal” arrows of the pressure gauge. In normal condition, the electrical contacts of the pressure gauge are short-circuited.

When the threshold pressure is reached, the contacts open and current flows in one direction - through the diode that shunts the contacts. The MC-3-... signaling device reacts by lighting up the corresponding LED, sounding a sound signal and switching the output relay (see sections “MC-3-2R signaling devices”, “MC-3 signaling device”).

Protection against false alarms is provided by the signaling device controller MS-3-…

, which carries out a logical transformation of the pressure gauge pulse signals arising from contact bounce during vibration or unstable contact.

Designation, options

The designation, design options, and technical parameters of the devices are given in Table 1. Notes: 1) To monitor the tightness of double-walled light oil product storage tanks, a pressure and vacuum gauge DA2010/DA2005-Ex with a measuring range (-1...0.6) (kgf/cm2) is used, which allows recording the decrease excess pressure from 0.2 kgf/cm2 to zero.

2) To monitor LPG storage tanks, DM2010 (DM2005) or EKM-100 (EKM-160) pressure gauges are used with a measurement range from zero to the upper limit of pressure in the interwall space in normal and emergency modes. In this case, it is possible to both decrease the pressure - when the outer wall of the tank is depressurized, and increase it - when the inner wall of the tank is depressurized (Fig. 3).

Alarm options - see sections “MS-3-2R Alarms”, “MS-3 Alarms”.

Technical specifications

| Designation | Pressure gauge DM2010-ExDM2005-Ex | Vacuum gauge DV2010-Ex DV2005-Ex | Pressure and vacuum gaugeDA2010-ExDA2005-Ex | Pressure gauge EKM-100-Ex (EKM100NVm-Ex)EKM-160-Ex (EKM160NVm-Ex) | Pressure gauge EKM-100Vm-ExEKM-160Vm-Ex |

| Measurement limits (kgf/cm2) | From 0 to 1; 1.6; 2.5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 100; 1600 | -1 to 0 | From -1 to 0.6; 1.5; 3; 5; 9; 15; 24 | EKM100: from 0 to 4; 6; 10; 16; 25; 40EKM160: from 0 to 6; 10; 16; 25; 40; 60; 100; 160; 250; 400 | EKM100: from 0 to 4; 6; 10; 16; 25; 40EKM160: from 0 to 6; 10; 16; 25; 40; 60; 100; 160; 250; 400 |

| Accuracy class | DM2010 – 1.5 DM2005 – 1.5 (on request 1.0) | DM2010 – 1.5 DM2005 – 1.5 (on request 1.0) | DM2010 – 1.5 DM2005 – 1.5 (on request 1.0) | 2.5 (optional 1.5) | 2.5 (optional 1.5) |

| Response variation (+-%) | 2.5 (1.5 for accuracy class 1.0) | 2.5 (1.5 for accuracy class 1.0) | 2.5 (1.5 for accuracy class 1.0) | 4 (2.5 for accuracy class 1.5) | 4 (2.5 for accuracy class 1.5) |

| Ambient temperature range Wed, deg, C | -50…+60 | -50…+60 | -50…+60 | -50…+60 | -50…+60 |

| Degree of protection against water and dust according to GOST 14254 | IP53 | IP53 | IP53 | IP54 | IP40 |

| Explosion protection marking | 0Ex ia IIB T6 Ga | 0Ex ia IIB T6 | 0Ex ia IIB T6 | 0Ex ia IIB T6 Ga | 0Ex ia IIB T6 Ga |

| Case diameter | DM2010-Ex – 100 mm DM2005-Ex – 160 mm | DV2010-Ex – 100 mmDV2005-Ex – 160 mm | DA2010-Ex – 100 mmDA2005-Ex – 160 mm | EKM-100-Ex – 100 mm EKM-160-Ex – 160 mm | EKM-100-Ex – 100 mm EKM-160-Ex – 160 mm |

| Mater. details: - housing - fitting | - steel; - brass. | - steel; - brass. | - steel; - brass. | - stainless steel steel; - brass. | - steel; - brass. |

| Thread | M20x1.5-Bg (default); G1/2-B; R1/2 | M20x1.5-Bg (default); G1/2-B; R1/2 | M20x1.5-Bg (default); G1/2-B; R1/2 | M20x1.5-Bg (default); G1/2-B | M20x1.5-Bg (default); G1/2-B |

Source: https://www.nppsensor.ru/product/155

Electric contact pressure gauges

Electric contact pressure gauges are used to control valves, pumps, and other active components of pipeline systems in order to control the pressure in them. Abbreviation for ECM. Can be used as a complete replacement for a pressure switch.

Design

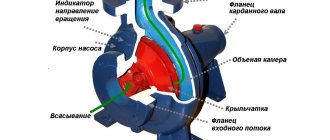

The entire device is assembled in a cylinder-shaped housing. The pressure gauge consists of a sensing element, a dial, a pointer and control contacts.

For most models, the sensing element is a Bourdon tube. The arrow is rigidly fixed to its free end and moves with it. In overpressure thermomanometers, the role of the sensitive element is performed by a bimetallic spring.

Principle of operation

The operating algorithm of an electric contact pressure gauge is simple. The arrow plays the role of a moving contact, moving when the pressure changes. One or two fixed values of the last value are set on the device. When the arrow reaches them, the circuit closes or opens. And, accordingly, turning on the active component or turning it off.

ECM classification

According to their layout, pressure gauges are usually divided into groups, one or two contact. The first ones, when triggered, close the circuit or open it. This is, respectively, version I or II (in accordance with the provisions of standard 2405-88). Such pressure gauges are used quite rarely. The latter have settings for two pressure values. These devices are divided into 4 versions (according to the same GOST):

- III – have a pair of normally open contacts;

- IV – equipped with two normally open contacts;

- V is a more complex option. The first contact, marked blue, opens when the minimum pressure is reached. The second contact is red, designed to close the circuit when maximum pressure is reached;

- VI – works in a mirror manner relative to the previous version. When the minimum set pressure is reached, the circuit closes. At maximum, it opens.

ECM device

The ECM is a cylinder-shaped device very similar to a conventional pressure gauge. But unlike it, the ECM includes two arrows that set the setpoint values: Pmax and Pmin (their movement is carried out manually along the dial scale). A moving arrow showing the real value of the measured pressure switches contact groups that close or open when it reaches the set value. All arrows are located on the same axis, but the places in which they are fixed are isolated and do not touch each other.

The axis of the indicator needle is isolated from the parts of the device, its body and scale. She rotates independently of others.

The bearings with which the arrows are attached are connected to special current-carrying plates (lamellas) connected to the corresponding arrow, and on the other side these plates are brought out into the contact group.

In addition to the above components, the ECM, like any pressure gauge, also has a sensitive element. In almost all models, this element is a Bourdon tube, which moves along with a pointer rigidly fixed to it; also, a multi-turn spring is used as this element for sensors that measure medium pressure more than 6 MPa.

Electric contact pressure gauge - connection diagram, types, principle of operation

In water and gas supply, in the oil and gas, chemical industries, electrically driven valves are used to control the flow of liquid or gas.

The electric drive operates a mechanism that closes or opens the valve. The use of electrical control makes it easy to implement automatic control.

What kind of sensor is this and when is it used?

An electric contact pressure gauge is a sensor that is used to measure excess and vacuum pressure in various media (liquid, gas, steam), is used as a direct-acting signaling device and allows you to control production processes, while a special condition for the medium is to prevent its crystallization.

The ECM is used to issue control signals to actuators that maintain pressure values in the pipeline, as well as compressor units, hydraulic systems, pneumatic equipment or household autoclaves at a certain value.

https://www.youtube.com/watch?v=aFUQM_q5Ru4

The electrical contact pressure gauge is popular in many industries and infrastructure systems:

- Energy;

- Metallurgy;

- Oil and gas and petrochemical industry;

- Water supply systems;

- Mechanical engineering installations;

- Heat generation and distribution.

ECMs are also in demand in safety automation systems of thermal power plants, central heating stations and boiler houses.

Types of sensor models

There are many manufacturers involved in the production of electrical contact pressure gauges; some offer a fairly wide range of models; the list below is divided according to various manufacturing plants:

- TM (TV, TMV), 10th series;

- PGS23.100, PGS23.160;

- EKM100Vm, EKM160Vm;

- TM-510R.05, TM-510R.06, DM2005Sg and its analogue TM-610.05 ROSMA.

All of the listed models are divided into pressure gauges with microswitches and with magnetomechanical contacts. Manufacturers also produce devices that are explosion-proof and vibration-resistant or liquid-filled (filled inside with dielectric oil, most often glycerin) so that the readings of the pressure gauge needle do not jump when there is increased pulsation of the measured medium. Glycerin inside the ECM will prevent the needle from moving quickly.

Operating principle of electrical contact pressure gauges

The principle of operation of the ECM is that a moving contact closes or opens a certain set value. The movable contact of an electric contact pressure gauge is a pressure indicating arrow, which rotates when the pressure in the measured medium changes. The setpoint (adjustable) value is set manually using two arrows (minimum and maximum value). These pressure gauge needles are stationary after setting the values.

What kind of sensor is this and when is it used?

An electric contact pressure gauge is a sensor that is used to measure excess and vacuum pressure in various media (liquid, gas, steam), is used as a direct-acting signaling device and allows you to control production processes, while a special condition for the medium is to prevent its crystallization.

The ECM is used to issue control signals to actuators that maintain pressure values in the pipeline, as well as compressor units, hydraulic systems, pneumatic equipment or household autoclaves at a certain value.

The electrical contact pressure gauge is popular in many industries and infrastructure systems:

- Energy;

- Metallurgy;

- Oil and gas and petrochemical industry;

- Water supply systems;

- Mechanical engineering installations;

- Heat generation and distribution.

ECMs are also in demand in safety automation systems of thermal power plants, central heating stations and boiler houses.

Types of sensor models

There are many manufacturers involved in the production of electrical contact pressure gauges; some offer a fairly wide range of models; the list below is divided according to various manufacturing plants:

- TM (TV, TMV), 10th series;

- PGS23.100, PGS23.160;

- EKM100Vm, EKM160Vm;

- TM-510R.05, TM-510R.06, DM2005Sg and its analogue TM-610.05 ROSMA.

All of the listed models are divided into pressure gauges with microswitches and with magnetomechanical contacts. Manufacturers also produce devices that are explosion-proof and vibration-resistant or liquid-filled (filled inside with dielectric oil, most often glycerin) so that the readings of the pressure gauge needle do not “jump” with increased pulsation of the measured medium. Glycerin inside the ECM will prevent the needle from moving quickly.

Application of an electrical contact pressure gauge – UAM Pressure Gauges

Electric contact pressure gauge (signaling) for water supply systems. Operating principle, application, design, markings and types.

Ensuring pressure control in water supply systems and similar types of systems is a necessary component for the normal operation of water supply systems. There are equipment options that solve this problem by providing control of system components, in particular the pump. For this, a pressure switch or electric contact pressure gauge is used. In this article you can familiarize yourself with the nuances of the operation of a pressure switch and an electric contact pressure gauge, the advantages and disadvantages of each of them.

Pros and cons of an electrical contact pressure gauge relative to a pressure switch

The advantages of an electric contact pressure gauge are that they are assembled in a single housing for switching contacts and for a control pressure gauge. This is convenient because this design does not require additional tees for assembly. Although you can find a pressure switch option that has a built-in pressure gauge.

Perhaps one of the main advantages of a pressure gauge is the ease of setting up the device and accurate visualization of response limits based on pressure indicators. The design of this type of pressure gauge allows you to set the lower and upper limits at which the mechanism will operate. This is achieved without the use of special-purpose keys, only with the help of contact arrows.

In this case, as a result, we get visual pressure gauge settings. The relay does not have this capability.

The disadvantages of an electrical contact pressure gauge are small switching currents, on average 0.3-0.5 A. This does not allow connecting powerful controlled devices without additional equipment. To do this, they use powerful relays, which in turn require an additional power source to operate.

It is this feature that determines the fact that the electric contact pressure gauge is called a signaling one. When changes occur, it signals this, and a power relay serves as the executing device.

The second disadvantage of this pressure gauge is its high cost relative to the pressure switch. On average, the price may differ by 2-3 times, not in favor of the pressure gauge.

The scope of application of the signaling pressure gauge is heat supply, water supply, ventilation systems, mechanical engineering, etc.

In particular, they are widely used to turn on pumping stations that supply water.

General information about the electrical contact (signaling) pressure gauge

An electric contact pressure gauge is used to determine the excess pressure of the working medium. The medium being measured must be non-aggressive, non-crystallizing (liquid, steam, gas, including oxygen). These are devices with an electrical contact group. When a certain pressure limit is reached, both upper and lower, the pressure gauge mechanism triggers the group of contacts.

Uses, advantages and disadvantages of electrical contact pressure gauges

Household use of electric contact pressure gauges is limited to water supply systems: the products provide pressure stabilization in individual circuits. Sometimes such devices are used in compressors equipped with compressed air receivers. When the pressure drops below the set level, the ECM sends a command to turn on the pump for boosting. Experts attribute the following qualities to the advantages of pressure gauges equipped with an electric contact mechanism:

- Convenient layout that combines an electrical contact pressure gauge and a switching unit in a single housing.

- Possibility to adjust pressure sensitivity.

- Clear visualization of settings.

Among the disadvantages, low switching currents are usually mentioned (because of this, it becomes necessary to connect powerful pumps and valves through additional relays). However, despite these disadvantages, the simplicity and accuracy of the operation of pressure gauges determines the stable demand for such products.

Electric contact pressure gauge

An electric contact pressure gauge is an obsolete, but simple and reliable device for controlling an electrical load depending on the measured pressure. It is a regular pointer pressure gauge, supplemented by two arrows that set the value of the on pressure (Rvkl) and the shutdown pressure (Rotkl), and contact groups that are closed or opened by the main arrow. Such devices are used in compressors and constant pressure systems.

Uses, advantages and disadvantages of electrical contact pressure gauges

The devices are very popular in various industries and infrastructure systems:

- Technological installations.

- Machine tools.

- Heat generation and distribution.

- Water supply networks.

- Compressor technology.

- Industrial refrigerators.

Electrical contact devices have a number of important advantages compared to their functional competitor - pressure switches. These include:

- No separate connection is required to connect the pressure gauge.

- Easy to set response limits, no special tools required.

- Clear visualization of settings.

The device also has disadvantages:

- The small limit current that an electrical contact device can switch. This limits the load power. For heavy loads, the pressure gauge will only be a signaling element; it must be used to control more powerful switching devices.

- High price. It costs about three times more than a relay. (But you don’t have to spend money on a separate pressure gauge).

A contact pressure gauge is convenient to use in cases of low load power and the absence of a modern electronic automation system.

Electric contact pressure gauge device

Structurally, the device is a modified dial pressure gauge. The differences are as follows:

- The indicator arrow axis is isolated from the body, parts of the electrical contact device and the scale.

- Two arrows have been added to the dial, setting (Rvkl) and (Rotkl). They can be moved along the scale.

- These arrows are on the same axis with the main indicator arrow, their attachment points are isolated from each other,

- The indicator arrow rotates independently of the settings.

- Current-carrying lamellas are connected to the pointer mounting bearings and are electrically connected to the corresponding pointer. On the other hand, the lamellas are brought out into the contact group.

- The wires can be mounted to terminals inside the housing, or they can be brought out in a bundle with a mounted connector at the end.

Sometimes the arrow specifying (Rvkl) is made blue, and the arrow for (Rotkl) is red. But for most models, both hands are blue, and they are distinguished by their position on the scale: (Rvkl) is always to the left. The equipment is connected to the electrical contact pressure gauge depending on its version.

For different consumers and switching circuits, several types (versions) of the device are available:

- Single contact normally open.

- Single contact normally closed.

- Two-contact, both normally closed.

- Two-contact, both normally open.

- Two-contact, one normally closed, the other normally open.

- Two-contact, one normally open, the other normally closed.

By selecting the desired design option, you can do without additional inverting relays, which complicate and increase the cost of the electrical circuit of the equipment and increase the likelihood of its failure.

Connection diagram for electrical contact pressure gauge

The most popular device circuits among consumers are two-pin.

In widely used domestically produced devices of the DM series, the version is determined by the colors of the setting arrows:

- Version 3 (Rvkl) - blue and (Rotkl) - red.

- Version 4 (Rvkl) - red and (Rotkl) - blue.

- Version 5 - both arrows are blue.

- Version 6 - both arrows are red.

The device has four numbered terminals:

- General.

- (Rvkl).

- (Rotkl).

- Earth.

The pins are marked on the connector located on the device casing; there is no marking on the mating part of the connector.

Do-it-yourself electric contact pressure gauge

The design of an electric contact pressure gauge is based on a conventional dial pressure gauge for measuring pressure. If a suitable device is not at hand, or its cost seems too high, then you can try to make such an electrical contact device yourself.

To do this you will need:

- Working dial gauge.

- Two tin strips measuring 3x15 mm.

- Wiring of different colors.

- Double-sided tape, the thinnest available.

- Soldering iron, solder, rosin or soldering acid.

- Drill.

- Pliers, awl, vice.

The sequence of manufacturing operations is as follows:

- Using an awl or a thin screwdriver, pry off the retaining ring that secures the glass.

- Remove the ring, glass and sealing gasket.

- Secure the case in a vice through gaskets, drill two holes in it so that the wires pass through them with a small gap.

- Cut two tin strips and bend their ends so that the length of the short part is greater than the distance from the arrow to the dial.

- Solder wires to the other end of each strip, carefully tinning the soldering area.

- Place the strips on the dial so that the arrow touches the curved part in the place corresponding to (Rvkl) or (Rotkl).

- Check the quality of the contact with an ohmmeter or test light.

- Glue the plates to the dial with double-sided tape.

- Lead the wiring through the holes.

Next, install the sealing gasket and glass in place and secure it with a retaining ring. The common wire can be connected to any metal part of the device. The DIY contact pressure gauge is ready for use. The degree of electrical safety of such a technical solution remains in doubt, so it is better to avoid touching the conductive parts of a running installation.

Source: https://stankiexpert.ru/tehnologicheskaya-osnastka/prisposobleniya/ehlektrokontaktnyj-manometr.html

ECM electric contact pressure gauge operating principle - all about electricity

Electric contact pressure gauge (signaling) for water supply systems. Operating principle, application, design, markings and types.

Ensuring pressure control in water supply systems and similar types of systems is a necessary component for the normal operation of water supply systems. There are equipment options that solve this problem by providing control of system components, in particular the pump. For this, a pressure switch or electric contact pressure gauge is used. In this article you can familiarize yourself with the nuances of the operation of a pressure switch and an electric contact pressure gauge, the advantages and disadvantages of each of them.

Advantages and disadvantages

Like any technical devices, ECMs have their advantages and disadvantages.

Flaws:

- Limitation of load power due to too low value of the limiting switching current, which has a range from 0.3 to 0.5 A (ECM with sliding contacts) to 1 A (contacts with magnetic preload);

- High cost, compared to a pressure switch, the price can be two or three times more.

Advantages:

- Visualization of settings is clear and understandable;

- Setting the response limits is quite simple and does not require special keys, special knowledge or a lot of time;

- Assembly in a single housing, which eliminates the need to use additional tees when connecting.