A walk-behind tractor is one of the most useful household units. Even a simple and not particularly powerful machine can make caring for your garden and surrounding area much easier. At the same time, a walk-behind tractor is a piece of equipment that tends to break down. Let's look at the most common breakdowns of an agricultural unit, their causes and methods of eliminating them on our own.

The walk-behind tractor stalls: causes and solutions to the problem

A walk-behind tractor is a technique that has many functions and is a faithful and indispensable assistant on any plot of land. With the help of additional attachments, such a unit performs many different jobs. With prolonged use of this or that equipment, it begins to fail. If maintenance is carried out on time, malfunctions may appear only due to wear and tear of parts.

A frequently asked question among users of such equipment is “why does the walk-behind tractor stall under load.” In most cases, it turns out that the problem is in the engine. It is better to entrust troubleshooting of the walk-behind tractor to a specialist, but if you also understand this matter, you can repair it yourself.

If you nevertheless encounter a problem when your equipment does not start or starts, but sneezes and stalls when the air damper is opened, you need to immediately find out what the reason is and repair it.

Possible causes of motorcycle breakdowns

The main problems of the walk-behind tractor engine

It is impossible to give an answer to such a seemingly simple question offhand. There are many reasons why the walk-behind tractor becomes capricious and stalls during operation. Conventionally, they can be divided into several groups:

- problems with fuel supply;

- malfunction of the engine starting system;

- control and automation malfunctions;

- problems with the muffler, cooling, etc.

If you notice problems in the operation of the walk-behind tractor, then the main thing you must understand is that there are problems that you can easily fix with your own hands, even if you are not particularly versed in technology, and there are situations when it is impossible to do without a competent specialist and appropriate equipment. The most important task for you, as the owner, is to quickly and correctly determine why your walk-behind tractor is stalling and make the right decision.

Malfunctions of walk-behind tractors - why they stall, do-it-yourself repairs

The walk-behind tractor is a useful household unit that greatly simplifies land and house work. Like any other equipment, units can break down. But it is quite possible to repair a walk-behind tractor engine yourself, following simple recommendations.

Why does the walk-behind tractor stall under load?

Starter repair

The starting device plays a major role in starting the engine. There are two types of starter - spring and manual. The most common problem is the destruction of the ratchet mechanism, breakage of the starter spring, breakage of the starter cord. In this case, repairing a starter on a walk-behind tractor comes down to replacing all defective parts. Repairing a recoil starter can also consist of simply fixing a loose attachment point.

How to start a walk-behind tractor and what to do if it stalls: we outline all the nuances

/ Motoblocks /

Reanimation of a walk-behind tractor after winter and the most common failures of walk-behind tractors.

I tried to start the walk-behind tractor after winter, but the walk-behind tractor would not start.

How to start a walk-behind tractor if it does not start can only be guessed at the beginning, because there may be several reasons:

— wire break; — there is not enough gasoline in the tank and it is not absorbed;

— the spark plug is dirty.

Why does the walk-behind tractor stall under load?

A fairly common problem is that the equipment stalls after 5 minutes of operation. Often the reason is a fuel supply failure and ignition problems.

If the equipment stalls during operation, you need to check how well the fuel is supplied:

- The candle is taken out and examined. It is overdried - this indicates a lack of fuel;

- There must be enough fuel in the gas tank for the normal functioning of the machine;

- The condition of the fuel valve is inspected. It may simply be blocked. Sometimes it is enough to open it for further use of the unit.

The walk-behind tractor starts and stalls if there is a problem with the ignition. First you need to check the spark plugs. Wet elements indicate breakdown. It is necessary to re-adjust the ignition system of the equipment.

Resetting is done as follows:

- The cover is removed, which protects the parts of the ignition system;

- The engine flywheel rotates until the contacts in the magneto open;

- A special feeler gauge measures the gap from the “anvil” to the “hammer”;

- The flywheel rotates until the piston is compressed. The latter must reach its peak;

- The flywheel turns again until a characteristic knocking sound is heard, which will indicate the operation of the overrunning clutch;

- The flywheel turns in the other direction until the mark of this element coincides with the mark on the body of the unit;

- The gap from the interrupting contact to the cam is set to 0.3 millimeters;

- The cam is fixed with a screw, which is located above the element, and a protective cover is installed in the equipment body.

If the above steps are performed correctly, the walk-behind tractor will not stall under load. When tilted, equipment may stall if there is not enough fuel in the gas tank. The unit must be installed straight and the starter cable removed. If the engine starts, you need to fill the tank with fuel.

Possible causes of motorcycle breakdowns

All walk-behind tractor malfunctions can be divided into two

- the reason lies in the engine;

- problems in other mechanisms and components.

Why does the walk-behind tractor work intermittently?

Among other typical malfunctions of a walk-behind tractor, a number of such breakdowns can also be identified:

- The engine of the unit backfires - this indicates the use of low-quality fuel to refuel the unit. In this case, you will have to not only replace the fuel, but also thoroughly rinse the fuel pump and fuel supply hoses;

- The walk-behind tractor operates jerkily - the reason for this lies in insufficient warming up of the engine. Be sure to turn off the engine, wait for it to cool completely, and start the engine again, giving it at least 10 minutes to warm up completely;

- The motor of the walk-behind tractor does not noticeably pull, the engine power has decreased - in this case, you need to check and, if necessary, clean the air and fuel filters. Another reason for this breakdown lies in the wear of the magneto of the ignition system. It is best to replace the part immediately without attempting to restore it.

The owner of both gasoline and diesel walk-behind tractors equally often encounters this kind of malfunction. In any case, you must immediately stop working with the machine and repair the breakdown as quickly as possible.

Repair sequence

1. Check the integrity of the wire running from the button (On / OFF) on the walk-behind tractor control levers to the spark plug.

Checking the integrity of the wire

2. Remove the spark plug and clean the contact with sandpaper. Check the gap between the contacts.

Unscrew the spark plug

When I was assembling the walk-behind tractor and cutters, I left the keys in the box and forgot, so for a long time I looked for the ring wrench that was included in the kit.

Having unscrewed the spark plug, I discovered carbon deposits - apparently the quality of the gasoline is not very good.

3. Screw the spark plug back in.

The walk-behind tractor does not start - we bleed the fuel supply system

A murmur was heard in the tank. After this operation, the walk-behind tractor sneezed and started up.

I think that the fuel filter still needed to be washed, because... there may have been a blockage in it that was blocking sufficient fuel from entering the combustion chamber.

In any case, at the moment the walk-behind tractor has started up and is working, and I hope you will also be able to start the walk-behind tractor if it doesn’t start for you. In my case, the walk-behind tractor did not start even after stripping the spark plug. So I opened the fuel wire flap and blew into it .

The easiest ways to revive a walk-behind tractor:

This problem

and can occur with both old and new equipment. In this case, you will need to troubleshoot the engine of the walk-behind tractor.

One of the possible reasons is the absence of a spark between the electrodes or its breakdown (breakdown). In this case, it is necessary to replace the spark plug with a new one.

If there is a spark, but the engine does not start, check the spark plug insulation. If the spark plug gets wet, the tip (or rather its insulator) may be faulty. Remove the screen and install a new tip.

A frequent failure of a walk-behind tractor is popping noises and the emission of flame from the muffler (the engine does not start). The reason for this may be deformation of the flywheel key. Replace it by disassembling the starter ratchet. Open the clutch housing, remove the flywheel, remove the old key, install a new one and tighten the housing.

If the starter cord is pulled out without effort when starting, the cylinder seal may be worn out or the gasket between the filter and carburetor may not be installed correctly. To resolve, replace the seals and check that they are properly secured.

The walk-behind tractor also stalls after winter or after a long period of inactivity. In this case, gasoline does not enter the carburetor. The cause of the malfunction is the locking needle. Sediment and tar formations accumulate near it and prevent it from opening when the engine starts.

Poor quality or inappropriate gasoline may cause engine malfunction. In this case, the spark becomes wet and requires replacement of the tip. If you notice an odor uncharacteristic of fuel, replace it.

What if the walk-behind tractor starts poorly and stalls?

After starting, the walk-behind tractor periodically turns off with popping noises. Make sure the spark plug is dry. If a conductive substance appears on it, this may cause a lack of spark between the electrodes. The spark plug can be replaced with a new one or the old one cleaned. To do this, it is washed, blown and calcined.

The engine started for a few seconds and then died again. Check the permeability of the sump. If the faucet is clogged, it needs to be blown out and cleaned (using gasoline). Water may also get into the fuel. In this case, you need to drain it and fill in a new one.

Starter repair

The starting device plays a major role in starting the engine. There are two types of starter - spring and manual. The most common problem is the destruction of the ratchet mechanism, breakage of the starter spring, breakage of the starter cord. In this case, repairing a starter on a walk-behind tractor comes down to replacing all defective parts. Repairing a recoil starter can also consist of simply fixing a loose attachment point.

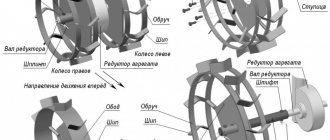

Gearbox repair

An increase in extraneous sound in the gearbox also indicates a possible breakdown. This noise can appear when using low quality oil, or when there is simply not enough of it in the gearbox.

Such a repair of the walk-behind tractor gearbox will consist of filling in a sufficient amount or replacing it with high-quality oil recommended by the manufacturer. The gearbox may also fail due to wear of the bearings and gears, which would be best replaced.

Don't forget to check if the chain tension is good and if there are any oil leaks.

| Share on social networks: |

Source: https://arendavlg.com/motobloki/glohnet-motoblok-prichiny-i-puti-resheniya-problemy.html

Fuel supply problems

If during operation the walk-behind tractor stalls and does not start again, then most likely the problem is in the engine or in the starting system. The first thing to do in this situation is to carefully inspect the spark plugs. Dry spark plugs mean that fuel does not have access to the engine cylinders.

In such a situation, first of all, check the presence of gasoline in the tank. It is possible that due to your forgetfulness, the walk-behind tractor has used up all the gasoline, and it simply needs to be refueled for further work. If everything is fine with gasoline, check the fuel valve - it may be closed. There is nothing complicated in this situation either - just open the tap and the engine will come to life again. It also often happens that during operation the walk-behind tractor stalls due to a strong roll. You need to place it horizontally. If the engine starts in this position, it means that there is little gasoline in the gas tank and when tilted it simply does not come out of the gas tank; you need to refuel.

The next thing that often happens is that the drain hole in the gas tank plug becomes clogged. You need to clean it, and the problem will be solved. It often happens that some kind of rubbish has gotten into the fuel system, especially considering the quality of gasoline today. In this case, you need to remove the fuel tap, drain the gasoline from the tank and rinse everything thoroughly, and then disconnect the connecting hose from the carburetor and thoroughly blow it out.

The walk-behind tractor starts and stalls - faults, repairs, video

The “heart” of any gasoline-powered vehicle is the engine. Walk-behind tractors are no exception to this. Their motor part creates a working stroke, power potential, and declared productivity, which together make it possible to perform certain agricultural operations.

But often it is this working node that is the most vulnerable. Low-quality fuel, severe overloads, lack of regular diagnostics and many other reasons cause serious malfunctions, the timely detection and repair of which will determine its further performance. This article will be devoted to what types of breakdowns are most often characteristic of walk-behind tractor engines, and which ones can be diagnosed and fixed at home.

The walk-behind tractor starts and stalls: causes of malfunction and mechanisms for eliminating them

Owners of either brand new or used motor cultivators are not insured against a situation where the walk-behind tractor starts but immediately stalls at idle.

It can be caused by a number of factors:

- problems in the ignition system:

- loose or broken electrical contacts;

- spark plug malfunction. They can be installed only after unscrewing and external inspection. If the candle:

- dry - the cause of the malfunction lies in the carburetor, where gasoline is not supplied. It may occur due to clogging of its filter or a separate jet;

- wet - the engine does not develop speed due to an excess of fuel;

- covered with soot - the fact of its failure, which may result in the failure of an ignition spark to form. Testing with electrodes will help you finally verify this;

- after replacing or cleaning the spark plug, the electronics are examined - the integrity of the connections and the wires themselves, which may need repair due to strong vibration;

- shortage or poor quality of fuel . Often the engine does not gain speed due to an incorrectly prepared fuel mixture or debris in the carburetor. In this case, the repair begins with removing it from the walk-behind tractor body and cleaning it from dirt particles. At the same time, they change the fuel, after draining the old one and washing the fuel tank and supply hoses.

- Another reason that the walk-behind tractor starts up and immediately stalls, related to gasoline, may be depressurization of the gas tank itself. Very often this is observed after a long period of inactivity (for example, after winter), when the walk-behind tractor has not been used for a long time and has been stored with gross violations. After repairing or replacing the entire fuel tank, the functionality of the device is usually restored;

- cool weather, which often causes diesel equipment to stall. Therefore, in early spring, experts advise turning on the walk-behind tractor only after pouring hot water into the radiator;

- gearbox malfunction. The fact that the cultivator does not develop speed and stalls at idle is indicated by a characteristic knocking noise from the gearbox, which occurs against the background of a lack of lubricant.

Why does the walk-behind tractor stall under load?

The problem when the walk-behind tractor operates with periodic stalls and does not develop speed is perhaps the most common among gasoline and diesel units. If the walk-behind tractor starts and stalls, the main reasons for this phenomenon should be sought in the fuel supply and ignition systems, malfunctions of which may appear after 5 minutes of operation.

If the walk-behind tractor does not develop speed and stalls spontaneously, you need to check:

- aerofilter - if it becomes clogged, its surface is cleaned, washed or blown with a vacuum cleaner.

- quality of refueled fuel;

- ignition system - its diagnosis begins with a spark plug, the external condition of which is used to judge the functionality of the ignition.

In addition to the spark plug, other ignition failures of the walk-behind tractor are:

- incorrect gap between electrodes;

- mechanical damage to the electrical circuit;

- unadjusted angle between the magnetic part and the coil.

Repairing them yourself is allowed if this is provided for in the user manual for a specific walk-behind tractor model;

- muffler - the engine stalls during operation and does not develop speed due to a clogged muffler. To free it from combustion products, it is soaked in water with detergents and, after washing, dried;

- carburetor, the settings of which may be incorrect;

- cylinder-piston parts, due to which the engine does not develop speed under load. This can only be checked with a compression gauge.

It also happens that the cultivator suddenly stalls when tilted in both directions or only to the left or right. Most often this occurs due to insufficient oil level. At the moment of tilt, the lubricant remaining sensor in the crankcase may be triggered, which automatically blocks the motor.

Why does the walk-behind tractor shoot into the muffler?

Often, if the engine system malfunctions, the walk-behind tractor not only does not develop speed, but also produces obvious, ear-piercing sounds emanating from the muffler. After this, it smokes and stalls, which clearly causes concern to users.

The cause of this problem may be:

- excessive intake of oil into gasoline or diesel, due to which its combustion is accompanied by the release of unnaturally acrid smoke. In this case, the repair consists only of cleaning the fuel system and refueling with high-quality fuel;

- failure to adjust the ignition or failure of its components - first of all, pay attention to the gap between the electrodes and, if necessary, set it in accordance with the operating instructions;

- incomplete combustion of fuel in the engine cylinder. In this case, repair of the walk-behind tractor engine begins with disassembling the entire cylinder-piston group, which is cleaned and checked for defects. It must be remembered that after such manipulations it will not be superfluous to reconfigure the carburetor.

What to do if the walk-behind tractor engine does not start well when hot?

If the walk-behind tractor does not develop speed when hot, fault diagnosis is carried out in the following sequence:

- after several unsuccessful startup attempts, the spark plug is examined as described above. If possible, it is better to immediately replace it with a new one in order to completely eliminate questions on this point;

- check the compression and vacuum level in the gas tank;

- in a dark room, see if the wiring is sparking;

- make sure that when heated, a spark is definitely formed. In addition to the spark plug, a faulty ignition coil can also prevent sparking.

Other causes of malfunction include:

- lack or incorrect filling of oil, due to which the triggered oil level sensor blocks the operation of the engine part;

- failure of the valve in the fuel tank, which is supposed to maintain gasoline pressure. As a result, its liquid contents do not flow into the carburetor.

Repairing walk-behind tractors, and especially their power plant, is a responsible matter that requires literacy and good dexterity. This applies not only to domestic favorites - the Neva, Cascade, Agro walk-behind tractors, but also imported ones, for example, Honda. But this does not mean that repairing them yourself is impossible. Having a minimum amount of knowledge and following our recommendations above, you can eliminate any malfunctions at home.

Source: https://pro-traktor.ru/motobloki/zavoditsya-i-glohnet.html

Preparing the walk-behind tractor for start-up

Difficulties with starting the engine can appear not only in used walk-behind tractors and cultivators, but also in new ones just purchased at the shopping center. For this reason, before starting a mini-tractor for the first time, you should read its instructions, then carefully examine all connections and, of course, check the oil level in the internal combustion engine.

You should study the annotation compiled by the manufacturer in order to find out what operating speed the engine has: four-stroke or two-stroke. This is important to understand, since modifications with a two-stroke engine (like the Mole cultivator) require a special combustible mixture, consisting of a mixture of fuel and oil in a special proportion.

Due to the mismatch of fuel, the special equipment will make noise, and the spark plugs and fuel line may also be damaged, which can lead to fuel pump failure, and this is a direct path to expensive repairs at a service station. You can determine whether the fuel is suitable for the motorcycle by the smoke that appears. If the quality of the fuel is poor, it will have a white tone, as happens when the car is tilted too much.

Fuel quality is also important for a diesel walk-behind tractor. It does not start in winter - or it starts, but soon freezes - if summer diesel fuel is poured into its engine, since at low temperatures it begins to thicken and clog the fuel line.

The start-up of motor vehicles both in the summer and in the winter must be carried out in the established order. For example, to start a Krot brand motor cultivator, the following procedure is carried out:

- open the gas tap;

- set the suction motor to the “Choke” state;

- turn off the ignition and turn the engine several times with a manual starter;

- start the motor again and move the motor to the “Run” state.

Conditions often arise when the power apparatus starts up easily, but after a couple of seconds it freezes. In this case, you should check the permeability of the sump. If the reason is that the tap is clogged, then clean it with gasoline.

Starting a motorcycle with a diesel engine will be somewhat more difficult. Starting a diesel engine begins with “de-airing” the fuel path, that is, by ridding it of air accumulations. For this:

- open the fuel supply valve;

- untwist the connections of the outlet channel until fuel appears;

- twist the connections and blow through all the nozzles.

If after the operations the motor does not function properly, and the special equipment begins to smoke, then the reason is the old lubricant, and it must be completely changed. The unit does not start due to insufficient volume of oil fluid, so do not forget to control this parameter.

Starting a motor cultivator after winter or prolonged downtime also has its own nuances. In order to bring the unit into working position, perform the following manipulations:

- open the gas tap;

- check whether the power is turned on;

- check the presence of lubricant;

- let the gas reach about half way.

Before putting the motorcycle into operation, all connections are checked, including transmission sections, clutch, starting mechanisms, and, if necessary, they are adjusted.

Repair: why the walk-behind tractor stalls under load, shoots into the muffler, works intermittently, and more

A walk-behind tractor is one of the most useful household units. Even a simple and not particularly powerful machine can make caring for your garden and surrounding area much easier. At the same time, a walk-behind tractor is a piece of equipment that tends to break down. Let's look at the most common breakdowns of an agricultural unit, their causes and methods of eliminating them on our own.

The walk-behind tractor starts and stalls - causes and repairs

Repairing walk-behind tractors if they start and, after a few seconds, stall, must begin by searching for the main causes of this malfunction. To do this you need to inspect:

- Plugs, wires and electrodes - in most cases, the unit starts and immediately stalls due to too large a gap between the electrodes of the ignition system, poor contact between the wires, and a dirty spark plug. Repairs should begin by cleaning the spark plug. If this does not help, then you need to check the integrity of the wires. If this does not bring the desired result, then you will need to re-adjust the gap between the electrodes of the ignition system;

- Carburetor for contamination and sufficient fuel supply - if you used low-quality gasoline and added too much motor oil to it, you will need to replace the fuel and reduce the amount of oil. In addition, you need to dismantle, disassemble, and thoroughly clean the carburetor;

- The presence of gasoline in the fuel tank - if the walk-behind tractor does not gain speed, this often indicates a lack of fuel necessary for the proper operation of the engine. Very often, owners of walk-behind tractors are faced with a problem in which gasoline spills through a small hole or crack in the fuel tank of the machine. In this case, you need to try to repair the defect, and if this fails, you will need to completely replace the walk-behind tractor tank.

Another less common cause of a breakdown, in which the walk-behind tractor does not develop speed, is a malfunction of the gearbox, which is indicated by an extraneous sound from the gearbox. To fix the breakdown, you need to replace the oil that you use to lubricate the unit.

Walk-behind tractor engine is difficult to start when hot

The question of why the motor of a walk-behind tractor stalls when heated is quite simple to solve. The whole essence of the problem lies in the excess air supplied to the carburetor of the walk-behind tractor. Part of it is mixed with a mixture of gasoline and motor oil, and the second part cools the carburetor.

As a result, the carburetor temperature becomes much lower than the temperature of the unit’s engine. This problem is observed only during the operation of the walk-behind tractor. When its engine is turned off, the carburetor, on the contrary, is heated by the hot walls of the engine.

As the carburetor of the walk-behind tractor heats up, the remaining fuel begins to actively evaporate, filling all the voids in the walk-behind tractor, including the air filter and the intake manifold. This leads to the complete disappearance of fuel, which is why the walk-behind tractor will not start when the engine is hot.

To fix this problem, it is necessary to follow a certain algorithm every time you start the walk-behind tractor “hot”. Your main task is to ensure that the mixture combines so that the engine can start. To do this you will need:

- When starting a hot engine, squeeze the throttle trigger halfway;

- Do not try to press the gas trigger over and over again, otherwise you will only aggravate the situation, since when you press the gas trigger frequently, the fuel pump will supply new portions of fuel to the carburetor, which will lead to flooding of the engine;

- After several attempts to start with the gas trigger pressed halfway, you will start the engine of the walk-behind tractor, after which you will need to rev it up 2-3 times and continue working.

This procedure will eliminate the increased load on the hot motor, due to which the main parts and mechanisms of the walk-behind tractor will not be subject to excessive wear.

All of the above methods will help to effectively cope with typical breakdowns of the most famous manufacturers of walk-behind tractors. They are equally successfully used by owners of agricultural implements of the Honda, Agro, Cascade and Neva brands.

Repair: why the walk-behind tractor stalls under load, shoots into the muffler, works intermittently, and more Link to the main publication

Source: https://o-motoblokah.ru/motobloki/remont

How does it work?

To understand breakdowns and fix them, it is important to understand how everything works in a normal situation. For greater simplicity, we will focus only on models with internal combustion engines. Previously, there were two-stroke walk-behind tractors, but now they are increasingly being replaced by four-stroke analogues. Diesel devices are also gaining popularity. As for the transmission, it can be configured in three different options.

The traditional approach involves the use of a gear transmission. Despite a decent level of reliability, this device takes up a lot of space. The force is transmitted using either a cone or a cylinder. Light walk-behind tractors are mainly equipped with a worm-gear transmission. A typical operating principle of a walk-behind tractor controller contains:

- a device that monitors the number of revolutions;

- a rod connecting this device to the throttle valve;

- spring.

The control unit operates on the basis of pneumatic or mechanical connection. “Pneumatic” means the presence of a kind of wing that reacts to the speed of the air flow. Centrifugal options involve placing a special camshaft inside the crankcase. It is complemented by small weights and an easily moving rod. The rod is made of wire, and the sensitivity of the spring determines how accurately the speed values will be maintained.

The role of the valve timing mechanism is to supply a mixture of fuel and air into the cylinder. But the same device also ensures the removal of exhaust gases. To influence the compression ratio, a decompressor is used. Gasoline engines are necessarily equipped with carburetors, which are responsible for preparing the fuel-air mixture. Regardless of the type of fuel, the starting device plays an important role.

The walk-behind tractor stalls: causes and solutions to the problem

A walk-behind tractor is a technique that has many functions and is a faithful and indispensable assistant on any plot of land. With the help of additional attachments, such a unit performs many different jobs. With prolonged use of this or that equipment, it begins to fail. If maintenance is carried out on time, malfunctions may appear only due to wear and tear of parts.

A frequently asked question among users of such equipment is “why does the walk-behind tractor stall under load.” In most cases, it turns out that the problem is in the engine. It is better to entrust troubleshooting of the walk-behind tractor to a specialist, but if you also understand this matter, you can repair it yourself.

If you nevertheless encounter a problem when your equipment does not start or starts, but sneezes and stalls when the air damper is opened, you need to immediately find out what the reason is and repair it.

Possible causes of motorcycle breakdowns

Possible causes of motorcycle breakdowns

All walk-behind tractor malfunctions can be divided into two categories:

- the reason lies in the engine;

- problems in other mechanisms and components.

Engine repair

Engine repair

If your motorcycle malfunctions, you need to look for the source of the breakdown. Repairing a walk-behind tractor engine involves several points:

- checking spark plugs, electrodes and wires;

- inspect the carburetor for contamination and fuel supply;

- checking the presence of fuel in the engine tank and inspecting the valve on it.

To begin with, it is better to check the spark plugs: inspect their cleanliness to see if there is carbon deposits on them. Check how tightly the end of the wire fits - if it comes off a little, then you need to press it tighter. Next, the electrodes are inspected and, if necessary, the gap between them is adjusted. It is also necessary to check all wires for oxidation and proper insulation. If you notice damaged wires, they should be replaced immediately, otherwise the spark will disappear altogether.

Also, a breakdown in walk-behind tractors with a gasoline engine may also occur in the carburetor. To correct possible problems, it is enough to clean it correctly and carefully. To do this, you need to disassemble it and, following the manufacturer's instructions, remove contamination.

At the end of the procedure, the part is reassembled and reconfigured. Good carburetor performance also depends on the quality of the gasoline you filled in. If you doubt the quality of the fuel, you should not take risks - thereby you will reduce the likelihood of a quick carburetor failure.

Carburetor repair is not difficult for an experienced person.

Starter repair

Starter repair

The starting device plays a major role in starting the engine. There are two types of starter - spring and manual. The most common problem is the destruction of the ratchet mechanism, breakage of the starter spring, breakage of the starter cord. In this case, repairing a starter on a walk-behind tractor comes down to replacing all defective parts. Repairing a recoil starter can also consist of simply fixing a loose attachment point.

Gearbox repair

Gearbox repair

An increase in extraneous sound in the gearbox also indicates a possible breakdown. This noise can appear when using low quality oil, or when there is simply not enough of it in the gearbox.

Such a repair of the walk-behind tractor gearbox will consist of filling in a sufficient amount or replacing it with high-quality oil recommended by the manufacturer. The gearbox may also fail due to wear of the bearings and gears, which would be best replaced.

Don't forget to check if the chain tension is good and if there are any oil leaks.

Diesel engine repair

Diesel engine repair

Malfunctions in a diesel engine are the same as in a gasoline walk-behind tractor. Any type of equipment needs timely repair. Diesel engines are distinguished by power and endurance. A walk-behind tractor with such an engine can cultivate a lot of land.

And with a larger volume of work, you need to clean all possible parts more often. Another feature of a diesel engine is that at very low temperatures the fuel freezes, and before starting such equipment, you need to check the condition of the fuel.

Possible problems with a diesel engine:

- fuel is frozen;

- wear of parts;

- weak injection pressure;

- incorrect valve clearance;

- contamination on parts.

Repairing a diesel walk-behind tractor is quite difficult to do on your own. If you have even the slightest doubt about your abilities, it is better to entrust the repair to specialists.

Source: https://pro-motobloky.ru/motobloki/pochemu-glohnet.html

The walk-behind tractor does not develop speed: the reason

Auto mechanic, specializes in agricultural equipment

Two-wheeled, mechanical devices of this type, such as a walk-behind tractor or cultivator, are in great demand among farmers, gardeners and cultivators. They minimize human physical labor and help cultivate the soil, remove grass or snow, and transport small loads.

Like any other mechanical unit, a walk-behind tractor can fail and cause a lot of inconvenience to the owner. Careful care of the device and following all operating rules specified in the instructions for use can minimize the likelihood of breakdown. However, no matter how high-quality the walk-behind tractor is, there are parts and elements that become unusable before others. And such an element is the engine.

The walk-behind tractor fails for certain reasons

Malfunctions of walk-behind tractors - why they stall, do-it-yourself repairs

The walk-behind tractor is a useful household unit that greatly simplifies land and house work. Like any other equipment, units can break down. But it is quite possible to repair a walk-behind tractor engine yourself, following simple recommendations.

Why does the walk-behind tractor stall under load?

Why does the walk-behind tractor stall under load?

A fairly common problem is that the equipment stalls after 5 minutes of operation. Often the reason is a fuel supply failure and ignition problems.

If the equipment stalls during operation, you need to check how well the fuel is supplied:

- The candle is taken out and examined. It is overdried - this indicates a lack of fuel;

- There must be enough fuel in the gas tank for the normal functioning of the machine;

- The condition of the fuel valve is inspected. It may simply be blocked. Sometimes it is enough to open it for further use of the unit.

The walk-behind tractor starts and stalls if there is a problem with the ignition. First you need to check the spark plugs. Wet elements indicate breakdown. It is necessary to re-adjust the ignition system of the equipment.

Resetting is done as follows:

- The cover is removed, which protects the parts of the ignition system;

- The engine flywheel rotates until the contacts in the magneto open;

- A special feeler gauge measures the gap from the “anvil” to the “hammer”;

- The flywheel rotates until the piston is compressed. The latter must reach its peak;

- The flywheel turns again until a characteristic knocking sound is heard, which will indicate the operation of the overrunning clutch;

- The flywheel turns in the other direction until the mark of this element coincides with the mark on the body of the unit;

- The gap from the interrupting contact to the cam is set to 0.3 millimeters;

- The cam is fixed with a screw, which is located above the element, and a protective cover is installed in the equipment body.

If the above steps are performed correctly, the walk-behind tractor will not stall under load. When tilted, equipment may stall if there is not enough fuel in the gas tank. The unit must be installed straight and the starter cable removed. If the engine starts, you need to fill the tank with fuel.

Why does the walk-behind tractor work intermittently?

Why does the walk-behind tractor work intermittently?

There are other faults that are worth considering:

- The walk-behind tractor engine is running backwards. The reason is often the use of bad fuel. It will not be enough to replace the fuel. The pump and fuel supply hoses are washed;

- The equipment works in jerks. The engine does not warm up completely. You need to turn off the engine and wait for it to cool completely. Then restart it and warm it up for at least ten minutes;

- The engine does not pull, therefore the engine power decreases. The filter system is checked and cleaned. The problem can be caused by wear of the ignition magneto. In this case, the part is replaced.

Owners of both gasoline and diesel vehicles may encounter such problems. Regardless of the specifics of the breakdown, you must urgently stop using the unit and start fixing the problem.

Why does the walk-behind tractor shoot into the muffler?

Why does the walk-behind tractor shoot into the muffler?

Sometimes the operation of equipment is accompanied by unusual sounds from the muffler. The walk-behind tractor smokes and stalls. To eliminate such a malfunction, it is necessary to first determine what caused it.

Such problems may occur in the following cases:

- Excess motor oil in fuel. The remaining fuel is drained, the fuel pump and hose system are washed, and new fuel is added;

- Incorrectly set ignition. It is necessary to check how correctly the gap between the electrodes is set;

- The fuel in the engine cylinder does not burn completely. In this case, it is necessary to disassemble the piston system, thoroughly wash and dry the cylinder, and adjust the carburetor.

In the above cases, it is not difficult to repair walk-behind tractors yourself. It is important to strictly adhere to the algorithm of actions.

Why does the walk-behind tractor start and stall?

Why does the walk-behind tractor start and stall?

If the equipment starts and immediately stalls, this may indicate the following problems:

- There may be a large distance between the electrodes, problems with contacts in the electronics, or the spark plug may be dirty. First, the candle is cleaned. Then the integrity of the wires is checked. The normal distance between the electrodes is set;

- The carburetor may become dirty, too little fuel is supplied. Sometimes it is necessary to change the fuel and reduce the amount of oil. The carburetor is dismantled, disassembled and thoroughly cleaned;

- If the unit does not pick up speed, this indicates a lack of fuel. Gasoline may simply spill. The defect must be eliminated or the fuel tank replaced;

- The walk-behind tractor does not develop speed when the gearbox breaks down. This is indicated by the presence of extraneous sound from the gearbox. The malfunction can be eliminated by replacing the oil that lubricates the components.

Faulty engine systems at startup

In this case, if when checking the spark plugs they were wet, that is, fuel flows normally, but the engine does not start, the problem may be as follows:

- Ignition system failure:

- A characteristic carbon deposit occurs on the electrodes of the spark plugs (it is necessary to clean the spark plugs with sandpaper, after which they should be washed with gasoline and dried);

- The gap between the electrodes does not correspond to the manufacturer specified in the engine manual (the gap is adjusted by folding the side electrode to the required size);

- Damaged spark plug insulators or high voltage wiring (faulty spark plugs and wiring must be replaced);

- The STOP button is locked to ground (the circuit must be closed for normal engine starting);

- The contacts in the spark plug squares are broken (the contacts must be put in order);

- The gap between the magnetic shoe and the starter does not correspond to the standard value (the gap needs to be adjusted);

- Defects in the stator of the ignition system (the stator needs to be replaced).

- Air passes through the carburetor seals, spark plugs, spark plug heads and cylinders, and through the connection between the carburetor and the engine cylinders.

Gearbox repair

An increase in extraneous sound in the gearbox also indicates a possible breakdown. This noise can appear when using low quality oil, or when there is simply not enough of it in the gearbox. Such a repair of the walk-behind tractor gearbox will consist of filling in a sufficient amount or replacing it with high-quality oil recommended by the manufacturer. The gearbox may also fail due to wear of the bearings and gears, which would be best replaced. Don't forget to check if the chain tension is good and if there are any oil leaks.

Diesel engine repair

Malfunctions in a diesel engine are the same as in a gasoline walk-behind tractor. Any type of equipment needs timely repair. Diesel engines are distinguished by power and endurance. A walk-behind tractor with such an engine can cultivate a lot of land. And with a larger volume of work, you need to clean all possible parts more often. Another feature of a diesel engine is that at very low temperatures the fuel freezes, and before starting such equipment, you need to check the condition of the fuel. Possible problems with a diesel engine:

- fuel is frozen;

- wear of parts;

- weak injection pressure;

- incorrect valve clearance;

- contamination on parts.

Repairing a diesel walk-behind tractor is quite difficult to do on your own. If you have even the slightest doubt about your abilities, it is better to entrust the repair to specialists.

Main malfunctions of outgoing units

Diesel and gasoline engines have different engine life. For the first, the normal value is 4000 m/h, but the second can only provide 1,500 m/h. Despite this, diesel models of walk-behind tractors are not in great demand. After all, they are much more expensive when purchased and during operation. Therefore, most likely, you are working with a walk-behind tractor equipped with a gasoline (carburetor) engine.

All breakdowns that may occur during the operation of mini-agricultural equipment can be divided into two categories:

- Engine faults:

- Problems at startup;

- Malfunctions.

- Malfunctions of other components and mechanisms:

- Clutch malfunction;

- Gearbox failures;

- Chassis problems;

- Control and automation failures;

- Malfunctions of walk-behind tractor systems (cooling, lubrication, etc.).

In many ways, the success of repairing a suddenly broken car depends on the correct diagnosis. As far as maintenance is concerned, it is carried out to identify minor faults that later lead to major faults.