The main difference is the connection

In the case of straight polarity, the welding cable is connected to the positive terminal of the machine, so that electrical charge carriers flow to it through the workpiece. The negative pole of the influx of charges is formed in the area of the welder’s main tool – the holder with the electrode.

The described difference in direct and reverse polarity of connection to inverters has a significant impact on the temperature regime in the welding zone.

Thus, direct connection increases the temperature at the anode pole of the arc discharge ("+" sign) compared to the cathode contact ("-" sign). This effect determines the possible scope of application of direct polarity when carrying out welding work.

The direct direction of the current ensures the release of significant amounts of thermal energy from the workpiece. As a result, direct polarity can be used for cutting large metal structures and massive steel products with thick walls.

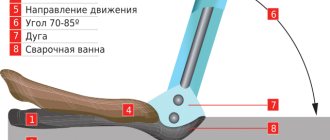

When turned back on, the picture of the distribution of the released thermal energy is completely different. In this case, excess heat is observed on the electrode of the welding inverter, and on the side of the workpiece being processed, its level noticeably decreases.

That is why reverse polarity is used in cases where it is necessary to minimize the risk of workpieces being rejected, as well as when carrying out jewelry-calibrated, precise work.

Reverse polarity is also used when welding thin-sheet materials and steels of varying degrees of alloying that are sensitive to overheating. The most widespread is the use of reverse switching current when working under submerged arcs, as well as in an environment of inert gases.

Requirements for welding cables

The wire must ensure the supply of current to the arc site with the minimum possible losses. That's why they are made of copper - the strand has the highest conductivity of the available metals. To prevent the cable from being heated by the passing current, its cross-section is made large enough.

In addition, the welder is required to hold the electrode at different angles and often make complex movements with it. The wire should not hinder the movements of the welder’s hand. In addition, when assembling complex building and industrial structures, it is necessary to weld in hard-to-reach places. Therefore, the cable must be flexible, and the insulation material must be elastic and resilient.

Since metal structures, among which welding work is carried out, are conductors of electric current, the insulation must be strong, durable and withstand high voltages.

Also, the insulation must have high resistance to tearing, compression and torsion, resistant to extreme temperatures and aggressive environments.

Welding inverter in operation

During use, the wire is repeatedly wound into coils and unwound back. All of the above requirements are met by stranded copper wire of large cross-sections insulated with oil- and petrol-resistant rubber.

What does welding polarity affect?

Working with rutile electrodes is possible in both types of polarity. The manufacturer recommends cooking analogues of the UONI type at minus. The heating of the part depends on the welding polarity.

With direct feeding, the workpiece heats up more, allowing the seam section to be made deeper.

With reverse polarity, the element being processed heats up less, and the temperature is concentrated at the end of the electrode. The second mode is focused on processing thin metal and products sensitive to overheating.

Features of forward and reverse welding

The direct polar method is designed for:

- rolling installation from special steels using fusion method;

- non-consumable tungsten welding using surfacing wire;

- working with fluid materials;

- cutting workpieces using welding fixtures.

The thermal balance of the arc determines the nature of the distribution of thermal power.

If you accidentally change the pole, the working process with direct current will be delayed, the seam will become wide, and the rate of burning of consumables will increase. Reverse polarity is appropriate for carefully welding the workpiece, without allowing burns. This method is used for processing non-ferrous metals during flux welding.

Advantages and disadvantages of different methods

Knowing what direct and reverse polarity are when welding, you need to take into account the advantages and disadvantages of both methods. This will allow you to change the connection of the terminals and achieve better results.

Advantages of direct polarity over the reverse method:

- obtaining a narrow seam bead;

- deep welding of the part;

- presence of a stable electric arc;

- a wide range of consumables with different types of coatings.

Flaws:

- metal splashing;

- increased risk of burning through workpieces;

- the appearance of residual stress in places of heat treatment.

The advantage of direct polarity is deep welding of the part.

The advantage of negative polarity is that the circuit is suitable for accurate processing of thin and special alloys.

The disadvantages include:

- the need to use electrodes that are resistant to overheating;

- shallow depth of the suture bead;

- maintaining a short arc.

Welding with direct and reverse polarity current

Welding with straight polarity means that in its process, current is supplied from the welding rectifier to the workpiece with a positive charge. In this case, the “plus” terminal of the device is connected to the product using a cable. Accordingly, a negative charge is supplied to the electrode connected to the minus terminal through the electrode holder. The anode, which is the positive pole, has a higher temperature than the cathode, which serves as the negative pole. Therefore, the use of electric currents of direct polarity is advisable in welding workpieces with thick walls. It is also justified for cutting metal products and in other situations that require the release of a significant amount of heat, which is what characterizes this type of connection.

When welding with reverse polarity current, the opposite connection order is required. The negative charge from the negative terminal is applied to the structure being welded, and the positive charge from the positive terminal is directed to the electrode. With a given polarity of the welding electric current, in comparison with a direct connection, a larger volume of heat is generated at the electrode end with relatively less heating of the workpiece, which facilitates “delicate” welding.

It is used when there is a possibility of burning through the workpieces. Therefore, welding with reverse polarity electrodes is suitable for working with stainless and alloy steels, other alloys that react to overheating, as well as for joining thin-sheet metal structures. No less effective is connecting reverse polarity in the welding process using an electric arc, gas protection and flux-cored welding.

Regardless of the power supply polarity used, there are a number of general factors that should be taken into account. If direct current is used, the resulting seam will be neater, without a lot of metal spatter. This is explained by the absence of frequent changes in polarity when working with direct electric current, which distinguishes it favorably from alternating current.

If consumable electrodes are used for welding, then due to the different heating of the anode and cathode, the method of connecting the electric current can affect the volume of molten electrode metal transferred to the product. To prevent possible burns of the workpieces being welded in the area where the power cable is connected, no matter what charge (positive or negative), it is necessary to use a clamping clamp.

What it is?

When working with direct electric current, the electric welding process can be carried out using electric current with direct or reverse polarity.

When performing electric welding, the term “straight polarity” means that the electric current passes from the rectifier of the welding device to the surface of the workpiece with a positive charge. The positive terminal of the welding device is connected to the workpiece via a special electrical cable, and a negative electric charge passes through the electrode holder, which is connected to the negative terminal. Features of the electric welding process in this version are that the positive pole of the anode has a temperature significantly higher than the cathode, which serves as the negative pole. For this reason, the use of electric current with straight polarity is widespread when performing welding work on parts with thick walls. In addition, this method is also used for cutting metal, as well as in cases where the generation of a large volume of thermal energy is necessary to perform a particular process. As for performing the welding process using electric current of reverse polarity, to carry out welding work it will be necessary to change the connection order in the opposite direction. In this case, the negative charge of the terminal with the “-” sign will be applied to the working surface of the workpiece, and the positive charge from the terminal with the “+” sign will be directed to the welding electrode.

A feature of the reverse polarity of the welding electric current is that the entire potential of thermal energy falls on the electrode end of the rod, while the workpiece itself heats up much less. This version of electric welding allows you to carefully align the edges of the workpieces, minimizing the risk of through burning. Reverse polarity electric welding is used to work with alloyed or stainless steel grades of metal, with thin-walled parts, and in addition, it is suitable for those metals whose overheating during welding is extremely undesirable. Making a weld with electric current of reverse polarity is also effective for welding using flux or shielding gases.

Differences in welding modes

When welding with constant current, a thermal spot with a high temperature appears at the tip of the consumable. Depending on the pole connected to the electrode, the welding mode is selected. For example, if a positive terminal is connected to the electrode, an anode spot with a temperature of 3900 degrees Celsius will form at its end; if a negative terminal is connected, the spot will be cathode, and its temperature will reach 3200 degrees Celsius. This is the main difference between the two methods.

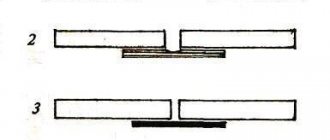

Connecting welding cables with different polarities.

When welding with direct polarity is used, the main part of the temperature load is received by the metal part. As a result, it is easy to deepen the weld seam. In the case of reverse polarity, the heat is concentrated at the end of the electrode. In this case, the parts at the joints heat up less, which is advisable for welding workpieces of small thickness.

The work involves heating the metal until it melts, that is, the formation of a weld pool, the state of which is influenced by the choice of welding mode with reverse or direct polarity:

- If the current is too high, the electric arc will begin to push away the heated metal. In this case, the parts cannot be connected;

- if the voltage is insufficient, the metal will not heat up to the desired state.

With straight polarity, a spreading medium is created in the bath, where you can guide the electrode, directing the weld and controlling its depth. The final result depends on the speed of the electrode. The smaller it is, the more heat enters the welding zone and the better the metal warms up. The depth and width of the weld depend on the mode used.

Interesting: Welds - defects and their elimination

Diagram for connecting poles with reverse polarity.

Important! The higher the current and driving energy on the arc, the deeper the penetration. The greatest penetration depth can be achieved using the reverse polarity welding mode.

As for the choice of consumables, it is recommended to use clean uncoated metal rods for welding in reverse polarity mode, and carbon electrodes for direct welding.

Text of the book “Occupational safety during welding work”

2.3. Electric welder's workplace

Welding station. The workplace

of an electric welder is a section of the production area assigned to a worker or team, equipped in accordance with the requirements of the technological process being carried out with certain equipment, tools, devices, etc.

When servicing a workplace you must:

♦ receive shift assignments, orders and drawings in a timely manner;

♦ maintain equipment in working order;

♦ deliver materials, workpieces, electrodes, etc. to the workplace in a timely manner;

♦ control the quality of manufactured products;

♦ maintain proper order in the workplace.

A specially equipped workplace for welding is called a welding station

(Fig. 2.1).

When welding small structures, a stationary welding station is equipped in a cabin measuring 2 × 2.5 m. Working cabins are used to protect welders from arc radiation at permanent welding locations. Their walls can be made of non-flammable and non-electrically conductive materials, for example, asbestos sheets.

Rice. 2.1.

Stationary welding station for manual arc welding:

1 -

welding current source;

2 —

table for electrodes;

3 —

tool box;

4

– switch;

5, 6 -

exhaust chambers;

7 – electric holder; 8

– welder’s chair;

9 -

welding wires

When using plywood or tarpaulin, they are impregnated with a fire-resistant compound, for example, a solution of potassium alum.

The cabin frame is made of rolled steel profiles (pipe, angle). The floor must be made of fire-resistant material (brick, concrete). The walls are painted light gray with paints that absorb ultraviolet radiation well (zinc or titanium white, crown yellow). The illumination of the cabin must be at least 80 lux.

The cabin is equipped with local ventilation with an air supply of 40 m3/h for each worker. The ventilation suction must be located so that the gases released during welding pass away from the welder.

Welding of parts is carried out on a metal work table 0.5–0.6 m high for sitting work or 0.9–1.1 m high for standing work. Instead of a table, you can use a manipulator, tilter or other equipment that makes it easier to rotate the product when welding seams.

A rectifier, welding transformer or generator is used as a power source for the welding arc.

To turn on the welding current source, there is a switch or magnetic starter in the cabin.

Mobile welding stations are used for welding large-sized products (metal structures, vessels, pipelines), construction of buildings and structures, on a construction site, as well as during repair work. Such posts are located in mobile machine rooms made of a steel frame covered with sheet iron. The hall usually contains 1–3 welding machines, starting equipment, a cabinet for tools and welding cables, and a furnace for calcining electrodes.

Mobile machine rooms have welded eyes in the upper corners for securing with slings and moving along the height with a crane or loading onto cars and wagons, and at the bottom there are skids for moving over a short distance by dragging.

It is allowed to place mobile posts directly on the construction site, but always under a canopy. The welder's workplace during installation must be protected from rain, snow and wind, and also fenced with portable shields or screens (Fig. 2.2). Welding equipment located on sites must also be protected from rain and snow. Posts installed at a height of more than 2 m must be equipped with guardrails and ladders. To protect workers from arc radiation, folding shields are used.

Rice. 2.2.

Welder's workplace in the field

All areas where welding work is carried out in stationary or installation conditions must be well illuminated with daylight or artificial light.

Electrode holders.

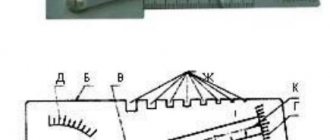

Welding electrode holders are the main tool of an electric welder; they are used to secure the electrode and supply current to it during manual arc welding.

Electrode holders must provide the ability to grip the electrode in at least two positions: perpendicular and at an angle of 115° or more to the axis of the electrode holder. It is necessary that the design of the electrode holder allows the electrode to be replaced in a time not exceeding 4 s. Current-carrying parts of the electrode holders must have reliable insulation with a resistance of at least 5 MOhm to prevent their accidental direct contact with the product being welded or the welder’s hands.

The handle insulation must withstand a test voltage of 1500 V at a frequency of 50 Hz for 1 min without breakdown.

The temperature of the outer surface of the handle during nominal operation should not increase by more than 55 °C. It is necessary that the cross-section of the handle at the place where the welder’s palm fits into a circle with a diameter of no more than 40 mm.

Electrode holders must have sufficient mechanical strength.

Additional welding tool.

This includes screw clamps, wire brushes, stamps, chisels and hammers. To connect the wire to the product, screw clamps such as clamps are used, into which the end of the wire is soldered with hard solder. The clamps must ensure tight contact with the work being welded.

Seams are cleaned and slag is removed using wire brushes - manual or electric.

Brands, chisels and hammers are used to mark seams, cut out defective areas, and remove splashes and slag.

Canvas bags are used to store electrodes during welding during installation.

300 mm long, suspended from the welder’s belt. In workshop conditions, glasses of similar length are used for this purpose, made from a piece of pipe with a diameter of 50–75 mm, with a welded bottom-stand.

Welding cables.

To supply current to the electrode holder and the product from the power source, flexible cables of the RGD, RGDO and RGDV brands are used. The length of the flexible cable to which the electrode holder is connected usually does not exceed 3 m; the rest of it can be replaced by cables of the KRPGN, KRPNT and KRPSN brands. It is not recommended to use a cable longer than 40 m, as this leads to a significant voltage drop in the welding circuit, which can adversely affect the quality of the weld.

A long cable may interfere with the welder's work. Welding equipment and welding cables must not interfere with free passage. The cable connecting the product being welded to the power source can be more rigid and less expensive, for example, PRN brand.

The cross-sectional area of the welding cable is selected depending on the welding current and permissible loads, usually at the rate of 5–7 A/mm2. For example, the cross-sectional area of a single-core cable for a welding current of 200 A should be 40 mm2.

The end of the cable is soldered into a lug, one side of which is made in the form of a bushing, and the other in the form of an ear with a hole - for putting on the terminal bolt.

For detachable connection of cables, connectors MS-2, MSB-2, M-315, etc. are used. Connector MS-2 is intended for cables with a cross-section of 35, 50 and 70 mm2 and consists of two parts, which are connected by inserts and secured by turning one of the parts . Disconnection is carried out in the same way as fastening by turning in the opposite direction. Before connection, a welding cable is attached to each half of the connector by wedging the cores of its exposed part between the nut body, inserts and cone. The connector is covered with rubber insulation. Other types of connectors are also used, which are fundamentally different from MS-2.

The cables are permanently connected using a special connector SSP-2, which consists of a current lead covered with insulating material and screws.

Connecting sections of a welding cable by twisting its bare strands, as well as connecting the cable to a welding machine without a special connector or tip is strictly prohibited, as this can lead to accidents or fire.

The cables are connected to the power source using copper cable lugs or an MS-3 coupling. For quick and reliable grounding of welded parts, use inventory clamps or special grounding terminals. The return cable is connected to the product to be grounded using grounding terminals of the KZ-2, KZP, KZP-12 types.

To connect the welding wire to the product, spring or screw clamps are used, into which the current-carrying wire is soldered with high-temperature solder or secured mechanically.

During prolonged continuous operation, the welding machine, cable and electrode holder overheat. The cable cross-section is selected taking into account the possibility of its heating during operation up to 80 °C.

To eliminate overheating, two welding machines are installed, which are turned on alternately every two hours of operation. The same is done to prevent overheating of the electrode holder.

Welding cables are transferred rolled into a coil.

Defective welding cables must be repaired or replaced in a timely manner.

The welding wire can be laid through door or window openings (Fig. 2.3). In this case, the wire is enclosed in a metal pipe.

All work on installation, repair and monitoring of electric welding machines must be performed by an electrician with a qualification group in electrical safety of at least third. The welder is prohibited from connecting the electric welding machine to the power source, replacing fuses and making any repairs to the electric welding machine.

All electric welding equipment must be protected, and the rotating parts of welding generators must be equipped with guards.

Rice. 2.3.

Protection of welding wires from mechanical damage

Mobile welding machines with an internal combustion engine must be serviced by a mechanic who has a certificate of admission to this work. These devices are grounded with a metal pin driven into the ground and connected to the body of the device. The number of pins, their diameter and length are determined by calculation, based on the fact that their resistance should not exceed 4 ohms.

If it is not possible to provide protective grounding, then it is necessary to use a residual current device.

There must be a secure lock on each box of the switch switch (ISR) to which the welding machine is connected. On the box you must write in indelible paint:

"Life threatening. Voltage 380 V. Responsible

_________».

On the inside of the box door there is a diagram for connecting the transformer, indicating its power and the permissible current strength of the fuse links.

Electric welding installations are registered by the organization's chief mechanic. He has installation passports and operating instructions. All welding transformers, devices and converters must have serial and inventory numbers under which they are registered in the chief mechanic’s journal.

Each electric welding machine is connected to an individual switch with a wire of the appropriate cross-section, and the distance between the machine and the wall must be at least 0.5 m.

It is strictly forbidden to connect the welding machine directly (without a switch) to a power or lighting electrical network.

The device should be connected to the network in accordance with the markings of the terminals on the terminals.

Controls for electric welding machines (switches, batch switches, buttons, starters, etc.) must have reliable latches or guards that prevent their spontaneous or accidental activation (disconnection).

When using several welding transformers simultaneously, they must be placed in such a way that the distance between them is at least 0.35 m, and the width of the passages is at least 0.8 m.

Electric welding work is allowed if the requirements of the fire safety instructions are met and with the mandatory approval of the type of work with a representative of the State Fire Supervision. When working in fire-hazardous premises, electric welders undergo training in fire safety rules, upon completion of which the fire inspection authorities issue a control certificate.

Electric welding work is prohibited in places where there are flammable substances and materials. Hot work areas and placement of electric generators must be cleared of flammable materials within a radius of at least 5 m. Electric welding work in refrigerators under construction can only be carried out in chambers and compartments freed from combustible materials.

To connect the grounding wire on the body of the electric welding machine, in an accessible place, it is necessary to install a bolt with a diameter of 5–8 mm and label it “Earth”. Above the terminals of welding transformers there must be visors and the inscriptions: “High side” and “Low side”.

The return wire can be a steel bus of any profile, a welding plate, a rack or the welding structure itself if their cross-section ensures that the welding current flows safely, from the point of view of possible heating.

The individual elements of the return wire must be connected to each other with bolts, clamps or clamps.

The electrical wiring between the welding machine and the electrode holder must be made of wire in accordance with the state standard, taking into account the current strength and compliance with safety conditions.

It is necessary to take measures against damage to the insulation on wires (cables) and prevent their contact with water, oil, steel ropes, hoses with flammable gases and hot pipelines. The use of electric welding wires with damaged braiding or insulation is prohibited. If it is not possible to replace the damaged wire, then it is necessary to enclose it in a rubber hose.

The length of the wires between the power supply and mobile welding machines should not exceed 10 m, and the wires should be protected from mechanical damage.

Welding wires should be connected by hot soldering, welding, using couplings having an insulating sheath, and the places of soldered and welded connections of the wires should be carefully insulated.

When moving the welding machine, it must be disconnected from the electrical network.

Before starting work, the electric welder must check the insulation of the electric wire and electrode holder, the presence and correct grounding of the welding machine body, the secondary winding of the transformer, the part being welded and the switch casing (Fig. 2.4), and the reliability of the connections of the electric wires to the machine. This ensures the electrical safety of the welder and auxiliary workers in the event of a breakdown of the insulation of the primary winding of the transformer and voltage transfer to the secondary winding.

An increased danger occurs when replacing an electrode when the welder touches it or exposed parts of the electrode holder with his hand. Therefore, it is strictly forbidden to touch the part being welded with the other hand.

Rice. 2.4.

Grounding equipment at the welder's workplace

It is also necessary to make sure that there are no flammable substances in the workplace (the distance from the place of electric welding work to flammable objects must be at least 10 m, and if the wind is directed towards flammable substances, at least 20 m).

Electric welding work is not allowed during a thunderstorm, rain or snow.

When performing surfacing work, the surfacing head should be moved after turning off the current.

When welding in a confined space and outdoors after rain or snow, the electric welder must use dielectric gloves, galoshes and a mat.

The electric welding machine must be checked regularly, at least once a month:

♦ for absence of short circuit of primary and secondary circuits to the housing;

♦ integrity of the grounding wire;

♦ insulation resistance of supply wires (not less than 0.5 MOhm);

♦ no exposed sections of power wires.

Upon completion of welding work, it is necessary to restore order in the workplace.

The mobile welding station must have a carbon dioxide fire extinguisher, felt or felt, shovel, crowbar and axe.

2.4. Working in particularly hazardous conditions

The organization of the workplace requires special attention when working inside tanks, boilers, wells and other confined or cramped spaces, as this poses a risk of gas poisoning and electric shock.

Welding and surfacing work in closed containers, carried out with a special permit from the enterprise administration, is allowed only to male persons at least 20 years old with a safety qualification group of at least 2 and who do not have medical contraindications. The welder must carry out work under the supervision of an observer located outside the tank.

It is prohibited to carry out work inside containers containing toxic, flammable and explosive substances without observing appropriate safety measures. Each container must be ventilated before starting work (with at least five air changes). During work, air must be removed from the welding zone or clean air must be supplied under the welder’s mask.

Oxygen should not be used to ventilate confined spaces.

The containers must be grounded, and the electrode holder must be interlocked with the open circuit voltage limiter of the current source. To insulate from the metal being welded, dielectric mats and mats, helmets and gloves made of dielectric material should be used.

The internal surfaces of containers must have a temperature no higher than 35 °C. At higher temperatures, it is necessary to use heat-insulating mats, shields, and personal protective equipment. Work inside containers at air temperatures above 40 °C must be carried out using special protective measures and personal protective equipment. In addition to PPE, welders working inside tanks must be provided with rescue equipment.

When welding large-sized heated products, operator panels must be placed in cabins made of thermally insulating material and equipped with air conditioning, and remote control of the process must be used. If it is impossible to automate the heated welding process, it is necessary to use heat-insulating mats (asbestos, etc.), thermally insulating water-cooled suits, and take breaks during work, spending them in rest areas with optimal meteorological conditions.

When manual arc welding with alternating current in particularly dangerous conditions inside a metal container, in the open air, as well as in rooms with increased danger), locking devices are used when changing electrodes. They allow you to change electrodes when the welding circuit voltage is turned off or reduced to a safe value (12–14 V). They carry out the work wearing canvas gloves. During welding breaks, the electrode holder is suspended on a tripod or hook.

An electric welder working in closed vessels is provided with a hose gas mask PSh-2 or PSh-1, a life belt with a strong rope attached to it, rubber insulating mats on a felt or other lining that does not conduct heat well, a helmet made of dielectric material and overalls with rubber armrests and knee pads.

Before starting work in a hazardous area, an air sample is taken. During operation, the blower supplies clean air to the work area.

Containers to be welded that have been filled with petroleum products and other flammable and combustible liquids must be washed and steamed.

When performing welding work at height, the worker must have a safety belt and a tool bag. If welders simultaneously work at different heights along the same vertical, means must be provided to protect people below from falling drops of molten metal and slag. A dense platform covered with sheets of roofing iron or asbestos is installed under the welding site.

When performing work in particularly hazardous rooms and tanks, the electric welding machine must have an electrical interlock that ensures automatic shutdown of the welding circuit when replacing the electrode in idle mode.

It is prohibited to weld on vessels under pressure, as well as inside vessels that have not been cleaned of flammable, explosive, combustible and toxic materials (after cleaning, such containers must be checked for the absence of hazardous and harmful substances). In addition, it is not allowed to weld freshly painted structures and pipelines until the paint has completely dried.

Welders working on construction sites are required to wear hard hats to protect their heads from falling objects, electrical shock and the elements. A balaclava is worn under the helmet.

Features of welding when using straight polarity

When working with a DC welding machine and using the method of connecting a straight polarity circuit, you should take into account the following features of the process:

- The seam of the welding joint is deeply penetrating, narrow in width, stronger in quality;

- Almost all types of steel can be welded, the thickness of which starts from three millimeters and above;

- When using tungsten rod for non-ferrous metals, only straight polarity welding method can be used;

- The welded arc is stable and resistant to breakdowns, making it easier to control the work process and get a beautiful seam;

- Electrodes designed for use in alternating current welding are not suitable for working with this method;

- When using a welding machine as a cutter, the workpiece is easier to cut.

Features of reverse polarity when welding

Metal welding with this method of connecting equipment has the following characteristics:

- The seam of the welding joint is less deep in penetration into the metal, with a more pronounced width;

- The method is most suitable for joining medium-thick workpieces or thin sheets of metal;

- During operations with thick workpieces, the seam becomes brittle under the influence of loads;

- Electrodes whose structure is destroyed when overheated are not suitable for work;

- The electric arc is less stable, especially when operating at low currents, which leads to uneven connections;

- When welding high-alloy steels, it is necessary to strictly follow the technological process of the work cycle.

Pros and cons of the two methods

Both methods of welding metal have their pros and cons. Using a direct polarity connection diagram, the following operating features can be identified:

- the result is a deep, strong welding seam that is narrower;

- the stability of the welding arc is noted, which allows complete control of the entire process;

- the ability to weld any metal with a thickness of 3 mm or more;

- when using a welding machine, the workpiece lends itself well to cutting;

- individual selection of electrodes is required. Consumables for AC welding are not suitable for this method. Tungsten rods can be used to join non-ferrous metals.

Welding metal using the reverse polarity method is characterized by:

- obtaining a less deep but wider weld seam;

- a less stable electric arc, especially at low voltage, which can cause an uneven connection;

- possibility of welding medium-thick workpieces and thin metal sheets:

- the need to choose electrodes with a structure that does not collapse when overheated.

When using the reverse polarity method, welding high-alloy steels must be carried out in strict accordance with the technological process.

What does polarity mean when welding?

In inverter welding machines, inscriptions are used to indicate polarity

. Considering the issue of polarity, it is clear that welding in this case is carried out with a constant voltage current. The welding inverter terminals, where the power cables of the electrode holder and ground are connected, are marked with “+” and “-”. Usually, when connecting such a device and starting to operate it, many, guided by the instructions or recommendations of a familiar specialist, do not think about why they hang this particular wire and not another wire on a specific terminal.

But there is still a difference, and here lies the unambiguous physical law of motion of charged particles - electrons. Electrons, having a negative charge, always move from minus to plus in any circuit, including an inverter. When welding, you can connect the electrode to both the positive and negative terminals - everything will work. But the electrons in both cases will move in different directions along the circuit, this will affect the process and the final result.

Direct polarity connection

If the circuit is assembled in such a way that the plus from the inverter goes to the steel workpiece (the part being welded), then through the arc gap, the welding electrode to the minus of the inverter, then such a connection is called direct polarity when welding. In this case, the anode is the part, and the cathode is the electrode. The connection point on the part will heat up more than the tip of the electrode, approximately 700 degrees Celsius.

Reverse polarity connection

The connection diagram for the cables of the welding machine, when the plus from the inverter comes to the welding electrode, then through the arc gap hits the work piece and the minus of the inverter, is called reverse polarity during welding. Here the electrode will heat up more strongly, since the anode spot will be on it, and the cathode spot will be in the area where the steel workpieces are connected.

How to properly connect a welding inverter

Many novice welders do not know that an inverter can be used to weld in different ways. They still use it this way, the standard connection is positive to the electrode and negative to the metal.

However, if you connect the inverter differently, the electrode to the minus, and the metal to the plus, you can achieve better deepening of the weld. In simple words, with this connection of the inverter, the main temperature will fall on the metal, as a result of which the workpiece will warm up better.

Well, and, on the contrary, with a “standard” connection of the inverter, when the electrode is connected to the plus and the metal to the minus, it will be possible not to burn through the thin workpiece. How does it work and what is the point? How to connect the inverter correctly, positive to electrode or negative? Read in this review.

What criteria should you use to choose polarity?

When choosing the type of connection for a welding machine, you need to pay attention to a number of important criteria. This will prevent defects or excessive consumption of materials and ensure the required strength of the connection.

Sheet metal thickness

Parts whose thickness does not exceed 3 mm are often burned through. To weld such workpieces, a reverse-polar scheme is used, providing an anode thermal spot at the edge of the electrode. This approach is appropriate when processing non-ferrous, alloyed materials.

Types of metals

The positive terminal is responsible for the final heating of the products and the holder. The cathode generates less heat than the anode. When machining refractory steels, it is better to use direct connection when the temperature reaches 4000 °C. For metals that change characteristics when overheated, connect the negative terminal. With direct-polar processing, the seam deepens; with “reverse” processing, it concentrates on the surface.

Types of electrodes

When choosing the brand of electrodes, take into account the type of current. Any variety is suitable for alternating voltage, since polarity does not play any role in this case. For varieties OK, OZS, MR, reverse connection is recommended. UONII and similar modifications are designed for a direct circuit. Manufacturers' recommendations are indicated on the packaging. Many welders prefer universal analogs to other options.

Additives and other consumables

Refractory electrodes used to create an arc are often used with straight polarity. Working with surfacing wire involves the use of only tungsten elements. Coal analogues are unstable to high temperatures, become brittle and crumble.

How to choose the length and cross-section of the welding cable

Today we will talk about welding cables. More precisely about their length and cross-section.

If there are one and a half meter scraps on your welder, this does not mean at all that they should be like that. Although, if it is written in the passport that you cannot install longer wires, then we have to disappoint you - you bought a low-quality inverter! But this is now commonplace (customer deception) and even experienced welders sometimes make mistakes when buying a “pig in a poke.”

The length of the welding cable can be different; it is selected in each specific case separately. Some people manage to carry the device on their shoulder; this is not a very good practice, since there is still high voltage inside the device. Most often, this is practiced by amateurs who do not know what normal work is (this is when you have one holder in your hands and do not need to carry all the equipment with you all the time).

The recommended cable length according to the textbook should not exceed 40 m. Despite this, there are examples of using a 16mm 2 x 50m cable on a 400A transformer and no losses, interruptions in ignition or problems with arc burning are observed.

Battery polarity

Polarity refers to the arrangement of current-carrying elements on the top cover or front side of the battery. In other words, this is the position of the plus and minus. The current leads are also made of lead, as are the plates inside.

Direct and reverse polarity

There are two common layouts:

- straight polarity;

- reverse polarity.

Straight

During the Soviet period, all domestically produced batteries were with straight polarity. The pole terminals are arranged according to the diagram - plus (+) on the left and minus (-) on the right. Batteries with the same circuit are still produced in Russia and the post-Soviet space. Foreign-made batteries that are made in Russia also have this terminal arrangement.

Reverse

On such batteries, the minus is located on the left and the plus on the right. This arrangement is typical for European-made batteries and therefore this polarity is often called “Europolarity”.

Accumulator battery

The different position schemes do not provide any special advantages. It does not affect the design and operational features. Problems may arise when installing a new battery. A different polarity will force the battery to change position and the wire may not be long enough. Also, the driver can simply mix up the contacts, which will lead to a short circuit. Therefore, it is important to decide on the type of battery for your car when purchasing.

How to determine?

It's not that hard to find out. First you need to turn the battery with the front side facing you. It is located on the side where the stickers with characteristics and logo are located. Also, the pole terminals are located closer to the front side.

On many batteries you can immediately see the “+” and “−” signs, which accurately indicate the polarity of the contacts. Other manufacturers indicate information in the markings or highlight the current leads in color. Usually the plus is red and the minus is blue or black.

In the marking, reverse polarity is indicated by the letter “R” or “0”, and direct polarity by the letter “L” or “1”.

Is it possible to install a battery of a different polarity?

This question often arises among those who inadvertently bought a battery of a different type. Theoretically, this is possible, but it will require costs and unnecessary red tape with installation. The fact is that if you buy a battery with reverse polarity for a domestic car, then the length of the wires may simply not be enough. You can't just lengthen the wire. It is necessary to take into account the cross-section and diameter of the terminals. This may also affect the quality of current transmission from the battery.

The best option would be to replace the battery with another one with a suitable contact arrangement. You can try to sell the purchased battery so as not to be at a loss.

Selecting a cross-section when extending a cable

If it is necessary to extend the cable, it is important to adhere to the principle of maintaining its total resistance. According to the laws of electrical engineering, for a cylindrical conductor the resistance is directly proportional to its length and inversely proportional to its cross-section.

Roughly speaking, if the wire has become twice as long, then the cross-section of the welding cable should be twice as large.

If the increase in length is not multiple, then the cross-section of the new cable can be determined by the formula:

S2=L2/L1×S1,

where S2 and L2 are the cross-section and length of the new cable, and S1 and L1 are the old cable.

What can happen if you mix it up during installation?

If the polarity is reversed, the following can happen:

- blown fuses, relays and wires;

- failure of the generator diode bridge;

- burnout of the electronic engine control unit, alarm system.

The simplest and cheapest problem can be a blown fuse. However, this is their main function. You can find a blown fuse with a multimeter by “ringing”.

If you mix up the contacts, then the generator, on the contrary, consumes energy from the battery rather than providing it. The generator winding is not designed for incoming voltage. The battery may also be damaged and fail. The simplest option would be to burn out the desired fuse or relay.

A big problem can be the failure of the electronic engine control unit (ECU). This device requires correct polarity despite its built-in protection. If the fuse or relay does not blow out in time, then the ECU will most likely fail. This means that the car owner is guaranteed to face expensive diagnostics and repairs.

Most devices in a car's electrical system, such as a car radio or amplifier, are protected against polarity reversal. Their microcircuits contain special protective elements.

When “lighting” from another battery, it is also important to observe the polarity and sequence of terminal connections. Incorrect connection will cause a short circuit at 24 volts. If the wires have a sufficient cross-section, they may melt or the driver himself may be burned.

When purchasing a new battery, carefully read the labeling and ask the seller for all the characteristics of the battery. If it so happens that you purchased a battery with the wrong polarity, then it is best to replace it or purchase a new one. Extension of wires and changing the position of the battery should only be done as a last resort. It is better to use a suitable device than to spend money on expensive repairs later.

Selecting an inverter and its operation

To quickly switch polarity when working with thin and thick metals, the inverter must have reliable power cable connectors. The flimsy thin pins in the connector and the low rim for fixing quickly wear out from frequent rearrangements. Then there will be a backlash, the cable sockets will dangle, increased resistance and overheating will form. The welding current will drop, and an electric arc may even form between the connector and socket.

Select reliable MMA inverters with durable sockets so that when changing polarity, nothing wears out or dangles. If you already have an inverter and its connectors are worn out, you can replace them with stronger ones by choosing from a catalog of connecting cable connectors.

Welding thin metal with a 1.0-1.5 mm coated electrode is a difficult task for a beginner. RDS inverters with the “Anti-stick” function will help you cope with it without burns. When the tip of the electrode is immersed in the weld pool, the machine “feels” this and turns off the welding current. As a result, there is no holding force; you do not need to tilt the holder left or right to lift the electrode from the surface. The coating of the consumable does not crumble in this case.

The Arc Force function also helps when welding thin metal with reverse polarity. When the electrode is about to stick, the inverter automatically increases the current by 10A, maintaining the electric arc. As soon as you have restored the air gap, the device itself reduces the current strength to its previous value, eliminating burn-through.

Wire for connecting to the network

To power any device, a wire of the same cross-section as the welding cable is not required, since the current value is several times less. The set of household inverters includes a multi-core flexible cable with a cross-section of 2.5 - 4 mm² and a length of 3 - 5 m. For a grounded socket, it must have three cores.

If the socket is located far away at the work site, the device is connected through an extension cord with a cross-section of at least 2.5 mm², provided that the distance does not exceed 20 m. For a length of up to 60 m, it is better to take a carrier with a coil with a cross-section of 4 mm². To connect three-phase equipment in production, a power cable with four copper cores with a cross-section of 4 - 6 mm² is used, for aluminum - no less than 16 mm².

The recommendations given will help you make the right choice. However, welding cables are expensive, so before going to the store you need to determine exactly what length and cross-section you need. Why buy extra if it won't be used.

Source: svarkaprosto.ru

Patterns of choice

Why is reverse polarity chosen for some jobs, and direct polarity for others when welding? Let's answer this question by considering the thermal features of the process using reverse direction.

When a welding arc burns on a workpiece, a pair of areas called anode and cathode spots appear at the end of the electrode. The difference in their temperatures sometimes reaches 800 degrees Celsius (in favor of the anode). That is, the amount of heat generated on the workpiece during operation is quite large, and the method is more suitable for high-quality welding of seams.

It is noteworthy that when operating with direct current of straight polarity, the combustion rate of the electrode metal is 20-40% lower. But for alternating current, observing polarity is not relevant at all - its peculiarity is that the direction of the current changes 100 times per unit of time.

What equipment to use

The reverse direction is required in work with special installations. The specificity is that the machine feeds the wire at a certain speed to the workpiece, so several types of welding can be selected.

For example, in a protective gas environment (when argon or carbon dioxide is used), or using powder-treated wire. Reverse direction of current is applicable when working with gases, direct - when the process is performed with cored wire (also known as flux-cored wire).

Semi-automatic welding involves a number of process changes. Firstly, the connection of the “holder” and “ground” changes - on the first “plus”, on the second “minus” (reverse). This is done so that the flux burns out completely, and the welding process occurs inside the resulting gaseous cloud. The metal will heat up less, and the splashing of droplets will be minimized.

The straight line is used for welding non-ferrous metals, when the working consumable element is a tungsten electrode. In this way, an increase in temperature in the heating zone is achieved, which can be critical for, for example, aluminum.

When working with alternating current, the user’s task is to change consumables in a timely manner. Professionals or advanced amateurs prefer direct current as a reliable guarantee of high-quality welding. Working with an inverter allows you to choose one of two known options. Direct and reverse polarity when welding are used in methods, each of which has its own advantages and disadvantages. The choice of direction is dictated by a number of factors, the main of which are the material of consumables and the equipment used.

Rules for choosing polarity

The main criterion for choosing direct or reverse polarity when welding is the electrode coating material. For example, carbon consumables heat up very quickly when the elements are connected in the opposite way and, as a result, are destroyed. A wire that does not have any coating burns well with straight polarity, but does not burn at all when using alternating current.

The dimensions and shape of the resulting seam also depend on the location of the poles. For example, deeper penetration is possible with a constant reverse current, which is due to increased heat generation at the anode and cathode.

It is important to remember that the faster the welding process is carried out, the smaller the width of the seam and the depth of penetration become.

Which one should I use?

One of the important criteria on which the choice of electric welding polarity is based is the composition of the welding electrode coating. Depending on the electrode material, the electric welding mode is selected. For example, black carbon rods, which tend to heat up quickly, are not suitable for reverse polarity welding. Such electrodes will quickly collapse, and the electric welding process will be constantly interrupted; in addition, they are not suitable for thin metal.

The correct selection of the electrode in this case depends on the composition of the workpiece material. If you take an uncoated electrode, then when electric welding under conditions of direct polarity it will melt and burn well, but if you work with such wire under alternating electric current conditions, the uncoated electrode will not burn. The strength and appearance of the weld depends on the polarity of the poles. To obtain the deepest penetration of metal, you will need to use technology using direct current with reverse direction. With this arrangement of poles, the maximum gain of thermal energy will be in the anode region.

The use of electric welding with reverse current direction is considered the most popular. The welding machine can feed welding wire at a certain speed, which will determine the choice of certain welding technology options. Reverse polarity electric current is used for working in shielding gases, and forward polarity welding is used when working with flux-cored welding wire.

The direct direction of electric current is used to work with non-ferrous metals, when a tungsten electrode is used for welding metal.

The forward and reverse direction of the electric current is selected based on a number of factors, the main ones being the composition of consumables, the equipment used, the type of metal of the workpiece and its thickness. Regardless of which polarity of electric current is selected, there are certain nuances that are important to consider.

It is known that using constant electric current, it is possible to obtain a welded joint without the presence of large scale formation due to spatter. The cooled seam is neat and durable. Such characteristics of the seam are explained by the fact that when working with direct current, there is no frequent change of polarities, in contrast to working with an alternating type of electric current supply.

In the case when consumable-type electrodes are used for the welding process, due to the difference in heating between the cathode and anode, burn-through of the surfaces of the workpieces is possible. To avoid burning through the workpiece in the area where it is connected to the electrical cable, use a clamping clamp.

The charge carried by the cable does not play a role - in both cases, the clamp acts as additional protection for the workpiece.