27.09.2019

A mobile boring machine for processing holes is a highly productive, economical and easy-to-use equipment. It is consistently popular among specialists, despite the fact that it finds its application in a rather narrow field. Let's consider its types, features, operating modes, and tasks to be solved. Maximum useful information so that you can form your own impression.

In modern domestic industry, the most popular units are the Pioneer (1, 2) and Sarmat (200, 600) series, which have been tested by practice in real production conditions and have received a sufficient number of reviews from specialists. The high quality of their components, as well as the accuracy of delivery, assembly and commissioning are known and beyond doubt.

Options for processing parts using a mobile machine:

The main actions that can be taken are as follows:

- • thread cutting;

- • boring technical holes;

- • their subsequent processing directly on the metal structure.

Now let's look at each type of work in more detail.

Threading

It works like this:

Due to constant movement, the tool moves along a guide along the rotating part. With its pointed end, it draws a helical line with a certain angle of rise/increase (which depends on the frequency of the electric motor and the feed rate). In this way, a screw-type pattern is formed, that is, a thread, with a characteristic pitch and profile of one of the following types:

- • rectangular;

- • triangular;

- • trapezoidal;

- • round;

- • stubborn.

All operating parameters can be set using CNC during setup of the boring machine, and then changed if necessary. Threaded connections are easy to manufacture and are reliable, they allow you to join two elements with high precision, withstand significant axial stresses, and have a self-braking effect - they have quite a number of relevant advantages.

Planar milling

As the main working tool, you can install a cylindrical cutter with a special configuration of the cutting part. During rotation, it will evenly remove material over the entire surface at once. This process is completely controlled, making it easy to remove a strictly defined volume of metal and at the same time ensure the necessary smoothness.

Please note that for edges and vertical planes, blades with a different tooth profile are used - corner and end, respectively.

Boring technical holes

It is performed either for additional processing of the workpiece after forging or casting, or for adjusting previously prepared seats (if after stamping, forging or casting their surfaces do not meet the specified requirements).

The features are as follows:

- • The main tool in this case is a carbide cutter, which makes it possible to achieve processing accuracy of H7, with a finish of Ra = 1.6-2.5 microns.

- • Rotation of the part during the process makes it possible to ensure the straightness of the expansion, completely coinciding with the axis of movement of the spindle (withdrawal is minimized through the use of guide bushings).

- • The electric motor supports high speed (up to 3000 rpm, depending on the specific model).

With such features, even fine boring is possible, and this is especially important for non-rigid bodies, for which it is important that the resulting clamping forces and deformations be small (or better yet, minimal).

Machining holes in metal parts

In general, it is a whole set of technological operations - drilling, countersinking, countersinking and countersinking. In our situation, it helps to perform the following tasks:

- • bring the shape and geometry of the space for a bolt, screw or other element to the required values;

- • reduce the degree of roughness of internal edges and surfaces (bring it to 1.6-2.5 microns);

- • increase the accuracy of parameters.

To solve each issue, different tools installed on the boring bar can be used, and some of them require special operating conditions. So, countersinks need low spindle speeds (up to 100 rpm).

Although there are general rules for processing holes on boring machines - and they are formulated as follows:

- • any deviations are selected only according to special tolerance tables;

- • the reliability of fixation of housings and other voluminous or complex-shaped parts must be constantly monitored;

- • all technical processes are carried out in accordance with labor safety standards when working on plumbing equipment;

- • the quality of the result is checked without fail - using special calibers.

Seats, the diameter of which needs to be increased or the roughness of which needs to be reduced, can be created in the thickness of the material by any method, including the method of punching or casting.

Reaming holes on a machine

This is a procedure for expanding already drilled elements while simultaneously improving the degree of surface cleanliness. In theory, it can be done manually, but with high-performance equipment, the machine method looks much preferable.

The cutting tool mounted on the boring bar is called a reamer. It can be cylindrical or conical, fine or rough. When using it, that is, when performing an operation to increase the diameter, you should adhere to the following recommendations:

- • choose tolerances not arbitrarily, but according to current tables of deviations;

- • pay attention to the material of the part - cast iron can be processed dry, steel - only with the use of cutting fluids;

- • it is better to perform reaming on a portable machine for boring holes immediately after drilling;

- • subsequent calibration is required to check the quality of the result;

- • rough expansion must precede finishing expansion.

Standard reamers consist of a intake part (with grooves and a cutting edge of a certain profile), a calibrating part, a neck, a shank and a square. With their help (with accuracy class H7 and surface roughness Ra = 0.4-0.8 microns) it is possible to obtain a seat with a diameter of 1-300 mm. Although the same “Pioneer-2” supports 400 mm, and the surfacing “Sarmat NK 450” supports 450 mm. In their case, combined type tools are installed on the boring bar, combining the advantages of cylindrical and conical ones.

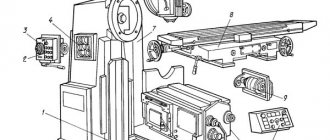

Special attachments for machines

Any processing of holes using boring equipment cannot be done without special equipment. First of all, the heads that fit into some other parts are of great importance. The head itself should consist of a shank holder known to everyone. The holder is made of solid metal material and is placed on the groove to assist the movement of the cutter.

In addition to the holder, there is also an element in the head that is triggered automatically. This is what allows the head to work and the slide to move. It is necessary to justify the presence of another device in the operation of boring equipment, which helps to bore all parts efficiently, efficiently and, most importantly, quickly. But for this, such a device must be firmly fixed on the table, even on both sides, using, for example, bolts. In this case, the head needs to be adjustable. This type of head is almost always square in shape. Small screws in the machine are needed to help set up and adjust the head. But there is a word of warning: not all types of boring equipment may have heads.

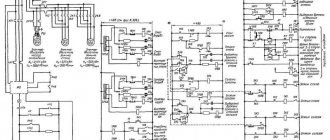

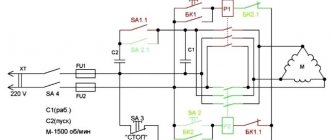

Features of the design of a mobile boring machine and its control circuits

The function of the supporting element is performed by the frame, on which there are round guides.

- Racks (optional) and/or a slide with a table (required) move along the latter, and a boring bar is already attached to it.

- The cutter is inserted into this shaft and securely fixed.

- An electric drive (drill or servomotor) ensures the movement of moving elements.

This is what the structure looks like in the most general case; in a specific situation, it can be equipped with additional elements, depending on the model and type of equipment, as well as on the tasks being solved. The principle of its operation is always simple:

- • due to the energy received from the drive, the boring bar makes rotational and translational movements, together with the part fixed to the racks;

- • upon contact, a tool (reamer, cutter or similar) applies a thread to the surface of the workpiece, removes metal, cleans and expands the hole - performs its function;

- • by changing the speed and switching the feed, you can adjust the mode and influence the final result.

Features you should pay attention to when purchasing:

- • diameter, length, working stroke of the boring bar, the ability to adjust these parameters;

- • type, power, type of engine power supply;

- • maximum distance of movement along the axes;

- • permissible weight and dimensions of parts;

- • depth and quality of processing accuracy;

- • speed range and feeding method.

In order not to doubt that all real parameters correspond to the declared ones, it is worth ordering equipment from its direct manufacturer (and the purchase cost in this case will be cheaper). In such conditions, purchasing equipment from is also convenient because, as a direct manufacturer, it is ready to provide comprehensive advice.

Control diagrams for boring machines are presented below, along with a description of the features of certain types.

Variety of boring equipment

But not only coordinate machines have their own characteristics, but also other types of boring equipment have individual technical characteristics. This includes speed, which is increased, and procedures that perform cutting actions, and small feeds. All types of machines are divided according to their characteristics into single-spindle and multi-spindle .

They can be horizontal or vertical, as well as one-sided or double-sided. Diamond machines can be found at various plants, the main focus of which is the creation of products for aviation, automobiles and agriculture. Such equipment only works with those products that are processed using special cutting tools that have carbide and high-precision characteristics. They allow cutting of a wide variety of parts: cylindrical blocks, engine liners required for vehicles, block heads and connecting rods.

Horizontal lathes are varieties of already known coordinate equipment. They differ in the movement and location of the spindle. Boring equipment is used quite rarely nowadays.

Main types

Depending on the purpose and specifics of the design, there are 4 options, each of which is worth considering in more detail.

Coordinates

Equipped with universal tables that can rotate. This design solution allows you to process any parts, even large-sized or non-standard ones. Stamps, templates, and conductors are made using such equipment.

Peculiarities:

- • have a set of additional devices – mechanical, optical, electronic – which ensures high accuracy of the location of functional units;

- • processed without displacement of the cutting tool;

- • the boring bar moves in a horizontal plane;

- • can be single- or double-post.

Diamond

Designed for cutting threads, expanding holes and performing other technological operations on workpieces made of especially strong metals. They can also mill the surfaces of cylindrical and conical objects. They are relevant in the field of instrument making - with their help they produce particularly precise equipment.

The design does not differ in anything fundamental; the diamond model is original only in the design of the cutting part of the tool, which can be rectangular or square, with a threaded, grooved, pass-through or scoring profile.

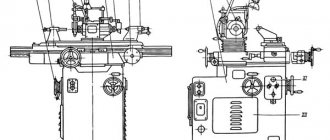

Portable lathes

They are a classic solution for factories. They can be precise and provide high accuracy in creating the required diameter and a low degree of roughness of the seat. Their advantage is their comparative rigidity - during operation they most effectively resist elastic deformations, which makes it possible to maintain serious speeds of rotation of the boring bar.

They are capable of performing a wide range of tasks, but this category usually includes stationary rather than mobile equipment.

Horizontal boring mobile machines

One of the most common types. Despite the availability and development of high-precision coordinates, they retain their popularity due to a key design feature. Their spindle is not only located in one plane (which gives the name to the whole type), but can also extend. This solution allows you to expand the diameters even in hard-to-reach areas of frames, booms and other similar metal structures.

Another nuance is that the workpiece, and not just the tool, performs rotational-translational movements. This expands the feeding capabilities, especially when combined with the use of additional components, such as spindle heads.

, a world leader in the production of mobile machines for machining, offers, in addition to boring and surfacing equipment, a wide range of different mobile machines and devices for the remanufacturing of flanges and pipeline valves, safety valves and shut-off valves, as well as portable milling machines and mobile lathes for processing fixed shafts.

Machines for processing flanges.

Restore the surface of the flange or cut a groove on the flange, prepare places for the seal, chamfer for welding and much more - you can confidently do all this directly at the location of the fittings. The fleet of flange processing machines includes

models with diameters from 25 mm to 3050 mm.

A characteristic feature of all machines without exception is their very simple installation on the workpiece.

Small-sized machines can be quickly mounted on the workpiece thanks to built-in mandrels. Larger machines are mounted using separate supports or racks and clamps, to which the machine frame is directly attached.

All machines are made on the basis of rigid frames with joints designed for harsh working conditions, lubrication units are sealed, and compact drives have an optimal weight/power ratio.

| Options | FF 1000 | FF 2000 | FF 3000 | FF 4000 | FF 5000 | FF 6000 | FF 8000 |

| Flange diameter | 50-305 | 25-65 | 38-305 | 75-480 | 130-610 | 355-1525 | 760-3050 |

| Int. Ø for installation | _ | 25-50 | 38-172 | 75-320 | 130-460 | 355-1525 | 760-3050 |

| Ext. Ø for installation | 50-305 | _ | _ | _ | _ | _ | 1070-3380 |

| Type of drive * | R | R | R | R | R | R,N | R,N |

| *E-electric; P-pneumatic; H-hydraulic; | |||||||

| Model FF 1000 – external flange mounting. Processes flanges with a diameter of 50 mm to 305 mm. It is equipped with a turning head with diameters of 200 mm or 300 mm. The supplied mounting sockets or adapter plates allow the machine to be mounted on the outside diameter of a flange in 30 minutes. Or even less. The power module uses a 0.91 kW air motor with a reduction gearbox to provide significant torque to the tool head. Automatic radial feed is carried out from the center to the outer edge of the flange. Vertical feed (25 mm), equipped with a manual drive (electric if desired), all power modules are made using bearings designed for harsh operating conditions and in a lubricant-tight design. | |

| Model FF 2000 - internal flange mounting. Processes flanges with diameters from 25 mm to 65 mm using a specially shaped head. Special tools for removing chamfers, bevels and a counterboring tool are supplied additionally. The machine is an ideal equipment for processing small flanges in confined spaces. The machine is reversible. The feed is approximately 0.13 mm per revolution. A pneumatic drive is used with a 0.7 kW motor, which includes an oil and air controller. Three cores ensure reliable self-centering installation of the machine inside pipes from 25 mm to 50 mm. The weight of the machine is 6.4 kg. | |

| Model FF 3000 - internal flange mounting. Processes uneven flange surfaces with diameters from 38 mm to 305 mm. The head, available on request, chamfers pipes with a diameter from 38 mm to 160 mm in outer diameter. A special quick release system allows you to instantly switch from chamfering to flange processing. The machine is low profile, compact, weighing just 16 kg and can be installed on the workpiece in less than 10 minutes using a self-aligning, hand-attached cam-type holder. The machine is equipped with an independent feed system along two axes. A pneumatic drive is used with a 0.6 kW motor, which includes an oil and air controller. The delivery set includes 2 miter tips and a case for carrying equipment. | |

| Model FF 4000 - internal flange mounting. Processes uneven flange surfaces with diameters from 75 mm to 480 mm. On request, a head for removing external chamfers of pipes with a diameter of 90 mm to 325 mm is available. A special quick release system allows you to instantly switch from chamfering to flange processing. The machine is low profile, compact, weighing just 26 kg and can be installed on the workpiece in less than 10 minutes using a self-aligning, hand-attached cam-type holder. The machine is equipped with an independent feed system along two axes. A pneumatic drive is used with a 1.08 kW motor, which includes an oil and air controller. The delivery set includes 2 miter tips and a case for carrying equipment. | |

| Model FF 5000 – internal flange mounting. Processes flanges with diameters from 130 mm to 610 mm. The lightweight 4-jaw clamping device allows the machine to be installed and centered in less than 12 minutes on the inside surface of a flange with a diameter of 130mm to 460mm. The machine is mounted on the flange body using only one tightening bolt. The low profile ensures that the machine is only 190 mm above the flange surface. Automatic reversible radial and axial feed are adjustable through the use of a single mode selector, which is located at the end of the machine bed in a place safe for the operator. | |

| Model FF 6000 – internal flange mounting. Processes flanges with a diameter of 355 mm. up to 1070 mm, or up to 1525 mm, using additional equipment. Individually adjustable 8 jaws allow you to quickly install the clamping device on the inner surface of the flange and perform rigid alignment of the machine. The machine is also used to prepare surfaces for welding, process chamfers, etc. For this purpose, a tool head mounted using a swivel joint is used, rotating at an angle of 45° in any direction. Smooth, precise machining is achieved through heavy-duty rotating guides that are precisely balanced on center and the use of harsh-duty spindle bearings. The 1.09 kW air motor and reduction gear provide a torque of 798 Nm. | |

| Model FF 8000 – internal/external flange mounting. Processes flanges with diameters from 760 mm to 3050 mm. A portable machine for processing large diameter flanges is installed directly on vertically located fittings, both from above and below, horizontally located - both from the outside and from the inside. The system for external fastening is supplied upon a separate request of the Customer. All guides are movable and dovetailed for easy positioning. To ensure high quality of the processed surface, the machine is carefully balanced. For longitudinal and transverse movement, two pneumatic motors with a power of 1.09 kW are used. At the Customer's request, the machine can be equipped with hydraulic motors. Additional accessories include grinding and polishing heads, various devices for mounting the machine, etc. |

Popular models of mobile boring machines and their characteristics

Today, both foreign and domestic brands are widely represented on the Russian market. Foreign brands usually have a high cost, so it makes sense to look for more practical options in terms of price/quality ratio. The “Pioneer” series from Izhevsk has proven itself well. You can buy equipment at quite affordable prices; in addition, the manufacturer is always ready to provide detailed advice and help you choose a mobile boring machine with the right one, as well as additionally equip the device depending on your needs.