Technical oxygen

According to GOST 5583-65, two main types of similar gas are produced on a production scale , which are then used in various industries - these are the first and second grades, the composition is indicated in the table.

Substances more contaminated with impurities can be used by private companies , but they are unsuitable for serious production tasks.

Receiving process

Industrial production of oxygen is based on the separation of air at low temperatures : first, compression occurs in a compressor, then the heated substance is cooled to room parameters so that expansion and a sharp decrease in internal temperature occur;

then compressed to 10-15 MPa. As a result of several similar cycles, liquid air is obtained, from which nitrogen evaporates during distillation, and oxygen accumulates in the residue.

The second industrial method is water electrolysis , in which the molecular component is decomposed and the result is pure oxygen.

Areas of use

Oxygen is used in many areas of human activity:

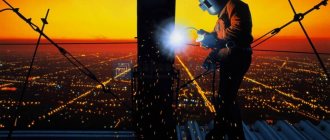

- Metallurgical - welding and cutting of metals.

- Medical institutions.

- In the form of fuel for rockets.

- In agriculture.

- Water purification and disinfection.

- Synthesis of chemical compounds, for example, in the production of explosives.

Oxygen cylinders are used for welding and gas welding processing of surfaces made of various metals before and after similar processes. For cutting metal, its use has no alternative, because only oxygen gives the highest possible temperature of the fiery jet, capable of burning through any composition of metal parts and structures.

The minimum purity of oxygen for industrial use is 99.2% , and for domestic use they use a budget option with 92%.

Main settings

The liquid substance oxygen is colored blue; when it freezes, it changes to blue . O2 dissolves better than all gases in water and does not form oxides with inert gases, so similar mixtures are used in industry.

The physical properties are:

- The composition in the air is up to 21%.

- In the gaseous state it has no color, smell or taste.

- Dissolves in organic substances, absorbed by coal and metals in powder form.

- Boils when frozen below -183 0 C.

- The density under normal conditions is 0.0014 g/cm 3 .

Safety precautions

The oxygen cylinder design is very simple, but reliable. The main thing is to accurately observe the parameters of the gas pumped inside so that the container does not rupture. During operation and storage, some very strict requirements must be observed.

- If an oxygen cylinder is used in a stationary welding station, then it is installed vertically and secured with a rigid clamp.

- Before installation, the gearbox must be inspected for the absence of grease and oil stains.

- The fitting must be purged, after which the gearbox itself is screwed on.

- After complete extraction of gas, it is necessary to leave some oxygen inside under a minimum pressure of 0.5 kg/cm². The reason is so that filling stations can analyze previously filled gas and compare it with what is available.

- Oxygen must not be transported with other flammable gases.

- At sites, oxygen cylinders must be transported in special trolleys on soft rubber wheels.

- The distance from the installed oxygen container to an open flame source or welding machine is at least 5 meters.

- There must be protection from precipitation and sunlight during prolonged use outdoors.

- If the valve of an oxygen cylinder is frozen, then it should only be thawed with a clean rag soaked in hot water.

- Cylinders should be stored in metal boxes with holes; a lock must be attached.

- A small cylinder must be carried in a special metal box, which is equipped with a handle and a strap for carrying on the shoulder.

Refilling with oxygen is a complex process, because it is the gas that is pumped into the welding cylinders. And it reaches the distribution station in a liquid state. Such oxygen is much safer than gaseous oxygen, but it evaporates quickly and in large quantities, which is not profitable financially. But manufacturers take such losses because safety comes first. Moreover, liquid oxygen is transported in large quantities (road and rail tanks). If such a volume catches fire and explodes, the losses will be several times greater.

Gas is pumped into cylinders using pumping and pumpless methods. In this case, filling does not occur with supercooled oxygen. When performing any actions with a cylinder, it is very important to comply with accuracy and safety requirements. The most vulnerable point is the valve; most often it is the valve that fails because it is subjected to repeated opening and closing.

It cannot be repaired, you can only replace it with a new one. Doing this with your own hands is prohibited; such an operation can only be carried out in a factory setting. Here it is important to follow the installation rules, which are based on pressing, that is, screwing in under a certain pressure. Then the cylinder itself with the valve is checked with test pressure. By the way, testing is hydraulic. Water is pumped inside the cylinder under a pressure of 225 or 300 kg/cm², which remains there for 5 minutes. After which the pressure is reduced to working pressure - 150 or 200 kg/cm².

It should be noted that the same technology is used to check the cylinders themselves to detect leaks. If nothing is found: all joints and walls have not become wet, then the test was successful and the device itself can be used further.

How to find out the volume of a gas cylinder and how much oxygen is in cubic meters

Often, all the characteristics and material about the company that manufactured the product are indicated on a steel label attached to the top of the container, which contains data on the volume. It is written in a standard unit - liter, but the mass of gas per meter cubed can vary depending on the type of gas.

Oxygen-containing containers can be of medium or small capacity.

In order to find out the remaining mass of gas in cubic meters, it is necessary to find out the initial pressure of the gas cylinder, the readings of which are on the pressure gauge. It is necessary to calculate an indicator for measuring volume based on the data from the pressure gauge and tables.

By multiplying the value of the standard volume, which is measured in cubic decimeters. The weight of the full cylinder volume is indicated on the label.

Scope of use

Compressed oxygen is a popular gas, the scope of which depends on the type of raw material. The medical substance is used during the resuscitation of patients. The element has a beneficial effect on the heart and lungs, so therapeutic procedures are often prescribed for health problems. The component is taken to saturate cocktails during oxygen starvation.

Technical gas heats up quickly and maintains high temperatures for a long time. The resulting continuous jet burns through metal of any density, which allows you to cut or solder parts. The characteristic is useful both in construction and in domestic use. In metallurgy, the substance increases the efficiency of furnaces, thereby improving the quality of the finished product.

How to find out the amount of oxygen in a cylinder and how many kilograms are in an oxygen cylinder

This gas is mainly needed for welding work. Gas welding allows you to create neat and high-quality seams.

For a full container of oxygen, there is no need to calculate when the contents will run out. And if the container has been used, it will be problematic to determine the amount of oxygen in the remaining gas cylinder. Often the definition is based on the fact that one liter of oxygen weighs 1.13 kg. Therefore, to calculate the mass of a gas, you need to multiply the volume by a factor of 1.13. However, there are special tables for welding.