Icer

12549 0 0

Icer September 26, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Today I will talk about a special fastener for window and door structures, which builders call a window or frame anchor. This type of product differs from other options in a number of ways, and in order to choose the best option, you need to understand some of the nuances.

I will tell you what types of products there are, how they are designed and what you should pay attention to when choosing. We will also figure out how to carry out installation correctly.

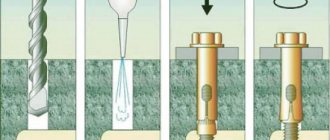

In the photo: using frame anchors you can quickly and securely secure windows and doors

Anchor - classification and scope of use

According to unconfirmed statistics, it is believed that Russia is capable of absorbing about 15 thousand tons of all kinds of anchors in one quarter, which is only three months. Our mounting element is almost at the top of this list. This is explained simply: this type of fastener is made so popular by its technical characteristics and a fairly wide range of applications.

But initially, such fasteners were intended for attaching window frames and door frames to a concrete and brick base. It is thanks to its purpose that such a dowel received the “frame” classification. Today, fasteners correspond to their immediate technical characteristics, and most of this type of dowels is used for installing metal-plastic windows and door frames made of various materials.

But thanks to its versatility, the use of the anchor did not end with the above tasks. As it turned out, such fasteners were ideal for mounting wooden beams and slats to various bases. For example, it is very convenient to use such an anchor when installing a wooden beam when installing a floor on a small area; in practice, it could be an ordinary balcony block, the floors of which you want to make of wood.

Peculiarities

The main difference between a frame anchor and any other anchor-type fastener is an elongated pin with a countersunk conical head. All this is necessary so that the three-dimensional structure of a window frame or door frame can be secured to a usually solid wall material. The fasteners are excellent for installing hollow structures, such as modern metal-plastic window frames or metal door jambs.

The purpose of fastening is to securely fix the frame in the opening. Since such structures, in addition to constant load, constantly experience variable dynamic influences (arising from their functionality), special requirements are imposed on the fasteners intended for their installation. It must be resistant to tearing and bending, while being tolerant of vibrations.

A metal anchor bolt and a spacer sleeve make it possible to combine all the requirements for such fasteners, which has significantly expanded the scope of application of frame anchors. Currently, they are purchased not only for installing a window or door, but also for installing various types of structures, decor, or hanging not very heavy equipment.

The appearance of frame anchors has caused the need for their standardization; as a rule, they comply with specifications, since during the development of GOSTs such fasteners did not exist at all. But the alloy (steel, stainless steel, brass, aluminum) used for their manufacture must strictly comply with GOST, which standardizes the products of metallurgical enterprises.

Dowel anchor as a key structural element

It will not be superfluous to know how this fastening technology works, which elements perform the main tasks in the operation of this mounting element. All the same technical characteristics warn us that this design is intended for light loads due to its weak holding properties. Therefore, fasteners may not be able to withstand objects that are too heavy; be aware that one such anchor can withstand a load of up to 30 kilograms.

The design of our fasteners includes a metal sleeve, which, using the expansion method, jams the fastener in the wall or floor; thanks to the ribs on the sleeve, it is not able to rotate during installation, thereby ensuring high-quality adhesion in the hole. The sleeve is pushed apart by a cone-shaped nut, which is screwed onto the base.

Also, for convenient installation, the stud has a head with slots for a shaped screwdriver. According to the installation rules, the cap must be hidden in the material and not stick out; for this, it is also made in the form of a cone and easily fits into a pre-prepared “slot”. Typically, all fasteners of this design are mounted with a wide cross-shaped screwdriver, which greatly facilitates installation in hard-to-reach places.

Frame metal anchor - making the right choice

Let us assume that you have already decided for what purposes you need fasteners, and now all that’s left is to buy the necessary part and carry out installation. But the choice of mounting bolts is also a crucial moment, especially since currently there are a large number of low-quality products, and if this concerns anchor fasteners, then we definitely need to take into account some points, namely:

- The material from which the fastener is made. The anchor can be made of various metals, as a rule, it can be ordinary steel, galvanized steel, stainless steel, and also brass. Depending on the application environment, you need to select the appropriate fastener.

- Hairpin length. In each individual case, the length is determined based on the tasks that the fastener must perform.

- Spacer quality. This is perhaps the main technological parameter of the entire fastener. The thickness of the bushing, based on existing requirements, must be at least 0.8 millimeters, and if the thickness of the metal of the bushing is less, you risk getting a poor-quality fastening.

As for the length and diameter of the working area of the bolt, there are certain standards: usually the count starts with a size of 8x72 millimeters, where 8 is the diameter of the sleeve, and 72 is the length of the stud. The maximum mounting length is 8×172 millimeters. In some cases, the diameter of the sleeve can be 10 millimeters; this is already considered reinforced fasteners; accordingly, the loads on such an anchor increase.

Do not forget to take into account the material in which you plan to install. Such a dowel will hold well in solid materials such as concrete and solid brick. In loose materials the holding force is much weaker.

Frame dowel dimensions

| Designation | Max. thickness of the attached object (mm) | Anchor hole diameter (mm) | Min. anchorage depth (mm) | D, Anchor diameter* (mm) | L, Nominal anchor length (mm) |

| MF 8/72 | 42 | 8 | 30 | 7,8 | 88 |

| MF 8/9 | 62 | 8 | 30 | 7,8 | 108 |

| MF 8/112 | 82 | 8 | 30 | 7,8 | 128 |

| MF 8/132 | 102 | 8 | 30 | 7,8 | 148 |

| MF 8/172 | 142 | 8 | 30 | 7,8 | 168 |

| MF 10/52 | 22 | 10 | 30 | 9,8 | 68 |

| MF 10/72 | 42 | 10 | 30 | 9,8 | 88 |

| MF 10/92 | 62 | 10 | 30 | 9,8 | 108 |

| MF 10/112 | 82 | 10 | 30 | 9,8 | 128 |

| MF 10/132 | 102 | 10 | 30 | 9,8 | 148 |

| MF10/152 | 122 | 10 | 30 | 9,8 | 168 |

| MF 10/182 | 152 | 10 | 30 | 9,8 | 198 |

| MF 10/202 | 172 | 10 | 30 | 9,8 | 218 |

Rules for mounting the fastening element

Let's now look at the basic rules for installing our dowel using a specific example. After all, compliance with all technical conditions for installing the anchor determines how the structural element we have secured in the future will hold, be it a door frame or a wooden beam on which we are going to hang a heavy carpet. First of all, we need to prepare the tool with which we will carry out the installation.

To do this, we will take a hammer drill, a drill for it, with a diameter of 8 millimeters, and we will also need a Phillips screwdriver to tighten the fastening pin, and also prepare a hammer, we cannot do without it. As an example, we will look at installing a window frame and then using our frame fasteners. So, let’s get started and go through all the steps of installing a window unit step by step.

Plug for frame dowel in Minsk and Brest: buy wholesale, find out prices

At VISMA-Stroy you can buy caps for frame dowels in bulk at a competitive price. What are the plugs for? Their main purpose is to protect the dowel body from external influences, mainly condensation on the windows, which oxidizes the material. Thus, it helps protect the fastener from rust.

The plug can be easily attached to the dowel. In addition, they are available in various colors.

You can find out the prices for frame dowel plugs in our price list. Orders for the supply of frame dowels complete with plugs are being accepted now. We are ready to complete any quantity to order

How to properly install the fastening element - step-by-step diagram

Step 1: Install the frame into the opening using spacers

Before you start drilling holes and permanently securing the window block, the frame itself must be correctly positioned on spacers, align the window block relative to the vertical plane and, accordingly, the horizontal one. To do this, we use pads under the frame and wedge the frame on both sides with wedges. We hammer the wedges in as tightly as possible so that the frame stands firmly in the window opening. The building level will help us check the evenness. If deviations are observed, then with light blows of a hammer we remove these defects, moving the frame in the desired direction.

Step 2: Mark the attachment points, make a “hidden”

Now that we have firmly fixed the frame, we need to mark the places where our mounting bolts will be located. Usually four fasteners are enough for a small kitchen window, but if you have to deal with a wide window opening, the number of fasteners can be increased. According to the standard, the installation location of the dowels is 30 centimeters from the upper and lower corners of the window block. If this standard does not suit you, you can change it. Regarding the “sweating”, some window frames already have it, but if you do not have such a recess, make it yourself by drilling a hole to the height of the dowel head.

Step 3: Mounting the Fastener

Then everything is simple, if you have a wooden frame, then with the drill that we have prepared, we drill through the frame, while going deep into the concrete to the required distance. Then we insert our bolts around the entire perimeter into the finished holes and tighten them with a Phillips screwdriver. The fastener will be released from both sides into the concrete and window frame, on one side by a cone-shaped nut, on the other by a cap. After all the bolts are tightened, seal the cracks around the perimeter of the window with foam, and the installation of the window unit is complete.

How to attach?

To install a frame or door jamb, in addition to a set of anchors, you cannot do without some tools:

- a hammer drill with a set of drills for drilling wall material and for drilling a hole in a metal structure;

- hammer;

- a Phillips screwdriver or a corresponding bit for installation on a screwdriver; some craftsmen make do with the same hammer drill in drill mode at low speeds;

- building level;

- pencil.

Fastening the frame with anchors step by step is as follows.

- The frame must be wedged in place, making sure to adjust the vertical and horizontal levels. Wedges can be wooden or plastic. To install them you will need a hammer.

- Marking the frame for holes. It is customary to drill at a distance of 30 cm from the corners, but this is not an unshakable truth; sometimes you have to take into account the features of the wall and change the standard distances; as a rule, this does not affect the quality of the frame installation. In the places chosen for drilling, it is necessary to make a countersunk hole for the anchor head.

- Holes are drilled in the designated locations. Next, after changing the drill, you need to drill through the wall material to a depth sufficient to install the fasteners.

- Clean the drilled hole, removing debris, dust and splinters of material.

- Insert the anchor into the drilled hole. You may have to use a hammer, but this should be done without excessive force.

- Use a Phillips screwdriver or bit to tighten the anchor.

- When installing the next anchor, check the position of the frame with a level - if no displacement has occurred, perform all the operations described above.

To install a small fixed frame with a side of less than 1 m, 4 dowels are sufficient. Typically, to install frames, two anchors are used on each side of the frame.

In the next video you will find examples of installation of various anchors.