Device Application

Welding machine vd 306 is designed for welding metal workpieces made of medium-carbon and low-carbon steels. With it you can carry out manual electric arc welding with direct current. It is possible to cut and weld metal.

Welding rectifier VD-306

The VD 306 rectifier is used at automotive repair stations, small workshops, construction sites, in domestic conditions, etc. A distinctive feature of this model is the ability to create a high-quality seam with unstable power supply voltage.

VD 306 can be used at ambient temperatures from -40 to +40 degrees. The maximum air humidity at which you can safely use a welding machine is 80%. The device can be used both indoors, which have natural ventilation, and outdoors. The manufacturer does not recommend using the device in rooms with a high dust content, as well as in an environment of aggressive gases.

The lineup

Marking VD-306 means arc rectifier, 30 A rated current, model version 6. The unit has been operating for several decades in various conditions where other welding machines cannot withstand and quickly break down. Therefore, modernized devices have been created on its basis. The VD-306 series has many modifications . The most popular models among welders:

- VD-306D for large-scale production and work in field conditions;

- rectifier VD-306Sh operates from a network of 380 W and consumer 220 W;

- the improved VD-306M1 allows you to cook additionally with alternating turns;

- VD-306I is an upgraded modern inverter device based on a rectifier.

In addition, there are models made in various climatic versions for work in northern and tropical conditions.

Design of the VD 306 unit

The welding rectifier VD 306 is connected to a three-phase power supply network with a voltage of 380 volts. The device has one range of adjustment of operating settings. The power transformer has movable windings. This allows you to adjust operating parameters by moving the magnetic shunt.

The model is made in a metal case. This protects its parts from damage from sparks and prevents electric shock to the operator. For convenient movement, the straightener is equipped with wheels. To make the process easier, a power supply indicator is installed on the front panel of the case.

The rectifier for welding vd 306 consists of the following elements:

Welding machine VD-306 - device

- Metal body.

- Magnetic shunt.

- Cooling Fan.

- Ammeter.

- Rectifier block.

- Power transformer.

- Connectors for connecting welding cables.

- Switch.

- Power cord for connecting to a 380 volt network.

The product is powered by alternating current. The rectifier block allows you to convert alternating current into direct current. This makes it possible to obtain DC electric arc welding.

During use, the internal parts of the device become hot. To avoid overheating and failure of components, VD 306 is equipped with an electric fan. It carries out forced cooling of parts.

To avoid electric shock to the operator, a grounding clamp is installed on the product body. The clamp is attached to the device body using a bolt.

Internal structure of the device VD-306

Design and principle of operation of a welding rectifier

The rectifier components include:

- Primary winding.

- Rectifier block.

- Cooling system.

- Control equipment unit, including a current stabilizer and automatic fuses.

- Protective housing with trolley.

- Control Panel.

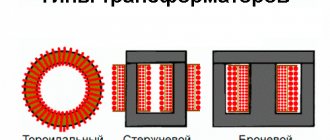

The operation of the welding rectifier is as follows. The primary current from the network enters the input winding of the transformer. If a saturation choke is used as a rectifying device, then an electromagnetic field is first formed in its circuit, inducing the corresponding excitation current. This current is stabilized and transmitted through the rectifier unit to the electrode holder to initiate an electric arc.

Depending on the purpose, other rectification schemes can be used. For example, using power diodes (this is how current rectification is realized in VDU-504) or using thyristors. A thyristor current rectifier allows you to set the current value not stepwise, but smoothly, which is much more convenient.

Since semiconductor elements heat up intensely during operation, they are structurally enclosed in a ventilated housing. The straightening process itself can be organized according to various schemes:

- Conventional smoothing of current ripples (for low powers);

- Bridge, where current ripples are smoothed out in all three phases, and the oscillation frequency increases from 60 to 300 Hz;

- Ring, with two secondary windings (at the same rectification frequency, requires a more complex transformer device);

- Six-phase, with a symmetrical choke, due to which the pulsation frequency is halved (used for the most powerful models of welding rectifiers).

The functionality of rectifier units depends on the electric welding method used. For manual welding, a falling current-voltage characteristic is used, which is achieved either by increasing the resistance values on the transformer windings, or by inversion - using the feedback principle . Each of the schemes has its own limitations. When the resistance increases, it is necessary to use ballast rheostats. In turn, welding inverters are characterized by low processing currents and cannot operate with long duty cycle values.

Characteristics of the welding machine

The rectifier has the following technical characteristics:

Welding machine VD-306 - technical characteristics

- The rated welding current during operation is 315 amperes.

- The power supply is three-phase.

- Power supply voltage is 380 volts.

- Frequency – 50 Hz.

- Primary current strength is 36 amperes.

- Operating voltage is 32 volts.

- Idling - 69 - 70 volts.

- The operating voltage range is from 22 to 32 volts.

- The adjustment range is from 45 to 315 amperes.

The duration of switching on of the rectifier during operation is 60%. The total weight of the installation is 104 kilograms. The device has the following dimensions - 560x510x660 millimeters (length, width, height).

Classification and labeling

All versions of welding rectifiers are divided according to the following parameters:

- According to the phase of the current used: single or three phase. The former are compact, but do not allow smoothing out significant voltage ripples and obtaining significant processing currents at the output, therefore they are used mainly for welding machines for household use.

- According to the method of controlling the strength of the welding current.

- According to the type of current-voltage characteristic.

- According to the current rectification circuit. It can be single-phase (used in low-power devices), three-phase or six-phase (the latter is used in high-power units exceeding 1000 kVA). In turn, three-phase rectification can be implemented using bridge or ring circuits.

- Depending on the number of posts served - single-post or multi-post.

The marking of welding rectifiers is regulated by the requirements of GOST 13821-77 (for single-station units) and GOST 18142-85 (for semiconductor units). It includes the letters VD (arc rectifier), the third letter U (universal), or M - multi-station. This is followed by the value of the welding current in amperes multiplied by 10, and (optionally) the series number. Thus, for example, the universal welding rectifier type VDU-504 is designed to produce direct current up to 500 A.

GOST 13821-77 establishes the following relationships between the energy characteristics of a welding rectifier and the duration of its continuous operation. In particular, in the range of welding currents 400...630 A, the minimum operating voltage cannot be less than 24...25 V, and duty cycle - more than 60%. At currents of 800 A or more, the minimum voltage is 26...34 V, and duty cycle can reach 100%.

Preparation for use and welding

Before you start welding metal, you need to prepare the device for work. To do this, you should perform a number of actions, such as:

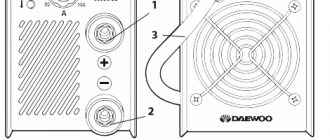

Front panel of welding rectifier VD-306

- Remove dust particles from the housing and live parts. You can do this with compressed air;

- Connect the cables to the appropriate connectors;

- Connect the grounding cable;

- Connect the power cord to a three-phase network.

After turning on the unit, it is necessary to determine whether the forced cooling fan is rotating. If there is no rotation, you must turn off the device.

Immediately before starting welding, you should configure the rectifier VD 306. The current strength is regulated by the control handle. The installation should be adjusted based on the thickness of the metal workpieces and the diameter of the welding rods. During the working process, the current strength can be controlled thanks to the built-in ammeter.

ATTENTION: To avoid overheating and damage to parts of the device, you should periodically turn off the unit.

Preparing the device: rules of use

Before starting work, you should inspect the integrity of the housing, insulation of cables and hoses. Check all contacts, terminals, clamps. After this, you should connect the case grounding and turn on the device.

Before starting work, you should set the settings and make a test seam. after that you can start working.

Welder of the 5th category of the central steelworks plant of Large-sized metal structures Bogdanov S.D.: “Dust settles on the windings and microcircuits of the equipment and leads to overheating and disruption of operation. If there is a compressor on site, the rectifier should be blown with a stream of compressed air through the air intake slots before operation. If work is carried out outdoors with normal dustiness, cleaning should be done once a week. Welding in an industrial enterprise with a large number of stations requires daily maintenance of the device. After this, you can begin checking connections and terminals. If there is no compressor, the dust is removed with a soft brush.”

Safety precautions

The welding rectifier is a device operating from a three-phase power supply. In this regard, some precautions must be observed during the welding process:

Characteristics of the rectifier VD-306

- Before starting the process, you need to study the rules for performing welding work and the operating instructions from the manufacturer.

- Do not use the unit in metal containers. Iron walls may cause electrical shock.

- It is not allowed to connect a device to the network with a missing protective casing or damaged insulation on the welding cables.

- When carrying out the process, you need to use personal protective equipment: gloves, goggles, etc.

- A specialized mask is used to protect the operator’s eyes from the radiation of the welding arc.

- Contact of wire insulation and internal components with aggressive liquids is not allowed.

- It is prohibited to move the device and touch live parts if it is connected to the network. When replacing the electrode, the device must be turned off.

From the above it follows that this model is a machine for manual electric arc welding. They can weld metal parts made of medium-carbon and low-carbon steels. The product meets safety requirements and is equipped with a specialized clamp for grounding connection.

Safety precautions at the welding workplace

Areas of use

The significant weight makes the device an unacceptable option for home work, despite the simplicity and reliability of the design. Welding inverters will cope much better with simple tasks in a summer cottage or garage. In addition, the cost of the rectifier is quite high for the average user.

Therefore, these devices are successfully used at various industrial enterprises that require the connection of thick-sheet products with deep welding of the seam. As practice shows, subject to timely maintenance and compliance with safety requirements, the device can operate for 20 years or more.

Work safety

The safety requirements state:

- The place for welding must be equipped with a fire shield;

- you cannot turn on the equipment without grounding;

- if the cable is damaged, it should be replaced;

- all contacts must be tightened;

- the part is placed on a special rack or plate and secured.

The welder must work in a special suit made of non-flammable material, leather boots, gloves and a mask. To preserve the equipment, it is imperative to maintain the operating mode and allow the device to cool.