The welding consumables market is replete with many brands of coated electrodes . On the one hand, this makes it possible for experienced welders to choose the best option for welding work, on the other hand, it is difficult for beginners to understand this large number of different items. To help a novice welder, there is advice to immediately decide on the coating of the consumable. Essentially, retail outlets offer consumables with basic and rutile coatings.

If you have to weld a critical structure, where increased demands are placed on the ductility and strength of the seam, then the UONI brand with a base coating will be the best option to choose. Here we will not talk about the technical characteristics of brands. For more information about the characteristics, see the reference book on the pages of these brands, links to which are presented in the text.

UONI or rutile (MP3, ANO-21, OK 46 ESAB, OZS) - what is the difference

All brands of the listed electrodes are the same in application - they are used for welding carbon and low-alloy steels, widely used in industry and everyday life. The difference between SSSI and their rutile counterparts is the manufacturability of the welding process and the technical parameters of the connection .

If there is a need to repair or install by welding the frames of homemade equipment (circular saw, pipe bender and other similar devices), the horizontal bar on which you are going to spin the “sun,” then it is better to use electrodes with a basic coating. Welding seams made with these consumables guarantee more reliable and safe operation of these devices than using technology with rutile consumables.

If you do not have the skill to work with consumables with a basic coating, there are many welding jobs using rutile electrodes. The ease of initial and re-ignition of the arc, the absence of the need to control its length, gives beginners the opportunity to experience belonging to a contingent of people who know welding. At the same time, unlike consumables with a basic coating, there is no need to clean the welded edges from rust, coating residues and other contaminants. In a private house, it is sometimes necessary to repair leaking pipelines - the presence of moisture is not an obstacle to repair welding work using rutile consumables. It is better for beginners to weld thin-walled workpieces such as, for example, profile pipes with rutile electrodes.

General recommendations for choosing electrodes

You need to purchase rods only in specialized stores that guarantee the quality of the products offered. This is due not only to the characteristics of the proposed electrodes, but also to compliance with the rules for their transportation and storage, and the availability of all necessary documents and certificates. Damp elements can be dried, damaged ones cannot be used.

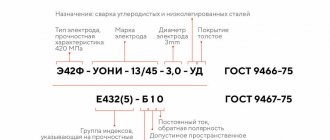

All necessary information about the electrodes is indicated on the packaging. It is recommended to choose welding rods with the lowest slag rate. Electrode consumption is no less important. The parameter indicator is also written in the labeling. Please note that the value may change upward. It depends on the purpose and quality of the surfaces being welded.

Welding rods are purchased according to their purpose. If the electrodes used are intended for another type of welding, the result of the work done will be of poor quality, and its safety indicators will sharply decrease. It is also necessary to take into account the area of application of the welding machine.

If the inverter is used for domestic needs, electrodes for them are selected with a diameter of 2 to 4 mm. To “grab” metal structures, electrodes of the MR and ANO brands are suitable. The quality will not cause any complaints. To weld utility forks, for example, water supply or heating pipes, it is necessary to use SSNI rods that ensure the reliability of the resulting seam.

Advantages of UONI 13/55 over rutile

Main advantages of SSSI.

The amount of slag produced is small , it is as fragile as glass and is easy to knock down. With rutile electrodes, the slag is plastic, making it more difficult to remove.

The weld seam made by UONI 13/55, due to its good fluidity, is clearly visible to the welder , which facilitates its high-quality formation - the seam is smooth and beautiful. Rutile electrodes form a fairly large amount of slag, which makes it difficult to control the quality of the weld, which creates conditions for the formation of welding defects (lack of penetration and others).

The strength characteristics of a weld made by UONI 13/55 exceed the corresponding parameters of a joint made with rutile electrodes.

UONI 13/55 is recommended for use when welding long-length seams without separation. (There is an opinion with which we do not entirely agree.) Such welding joints using this technology can be difficult to make with rutile electrodes, and frequent interruptions for re-ignition affect work productivity.

Characteristics and Application

UONI-13/55

Rods with a basic coating are recommended when working with low-alloy and carbon steel, designed for DC welding machines and inverters. The advantage of electrodes of this brand is the production of plastic seams that can easily withstand shock loads and low temperatures.

These electrodes also have disadvantages. The required minimum voltage to ignite the rod at idle speed should be 65-70 V. If there is rust, oil and other contaminants on the edges of the structures and parts being welded, the seams will be porous and of poor quality.

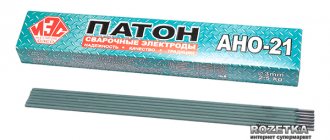

ANO-21

Electrodes coated with rutile coating are used for welding carbon steel of small thickness. They are easy to light both during the first and repeated use. They form a fine-scaled seam of small waves. Work with alternating and direct current of any polarity. Need to warm up before use. The rods are calcined for about 40 minutes at a temperature of 120 degrees. Their use is permissible for welding water and gas supply pipes.

MR-3

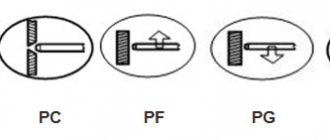

They ignite when working even with devices that do not have a very high current-voltage characteristic (volt-ampere characteristic). Provide good protection and allow you to control the position of the weld pool. There may be some difficulty starting the fire. If this happens, the electrode is calcined at a temperature of 150-180 degrees for 40 minutes. Used for all types of seams, with the exception of vertical top-to-bottom seams. Lights up quickly and easily. For this quality they are also called “sparklers”. Professional welders do not use them in cases where small movements are necessary for good warm-up. Soft welding and the complete absence of the need to clean the surfaces being joined made them an ideal choice for beginners learning the basics of welding. OK 63.34

Used for welding vertical seams, making overlap and butt joints, and multi-pass welding. The minimum open circuit voltage for working with rods of this brand should be 60 V. The formation of slag during welding is minimal and can be easily removed. Requirements for electrodes for inverter welding

The best ones for working with inverter welding machines are melting-type metal rods, which have the following characteristics:

- 1. Provide ease of welding work

If the electrode is selected incorrectly, that is, does not match the composition of the metal, the welding process becomes significantly more difficult.

- 2. Shows a high-quality seam result

An important factor when performing sealed and outdoor work. High-quality electrodes should allow you to obtain both concave and flat seams.

- 3. Form detachable slag

The quality of the electrode used can be easily checked by slag. Bad seams fly off along with the slag being beaten off. If this happens, the reason lies precisely in the electrodes, and not in the skills of the welder.

- 4. Meet sanitary standards

The electrodes used must be made in full compliance with existing government regulations and standards.

- 5. Allows welding on corrosive metals

The permissibility of such work is an exception and not a universal practice. If such a need arises, the UONI, ANO and MP-3 brands will ensure quality of work in this case as well.

Advantages of rutile over SSSI 13/55

The main advantages of rutile electrodes (MP3, ANO-21, OK 46 ESAB, OZS) .

Rutile electrodes are easy to ignite both at the beginning of work and if re-ignition is necessary to continue work. Easy ignition makes it possible to work at low current , which allows you to cook thin-walled workpieces without burning (this method is in the arsenal of beginners). The use of tack welding technology with rutile electrodes is based on problem-free re-ignition.

Changing the arc length when working with rutile electrodes is not critical for the stability of the technological process . UONI 13/55 operate only on a short arc, which can only be maintained by experienced welders.

Rutile electrodes do not require careful adjustment of the welded edges to each other; there is no need to clean them from rust, remnants of previous coatings and other contaminants. UONI 13/55 on a dirty and poorly mated surface to be welded will fade and stick to it.

Rutile electrodes are less demanding on the power source than consumables with a basic coating. Welding is performed by them both on direct current and alternating current. UONI 13/55 produces a high-quality weld only with direct current of reverse polarity.

Core

Consumable type metal rods used when working with an inverter are selected in accordance with the type of metal of the parts and structures being welded. The welding wire from which the electrode core is made must comply with state standards.

There are three types of electrodes for inverter devices: alloyed, highly alloyed and carbon. Each of them is made from a corresponding type of welding wire. When working with high-alloy and stainless steel, experts recommend using rods TsL-11, carbon steel - ANO-21, UONI-13/45, MR-3S, cast iron - OZCH-2, low-carbon steel - ANO-4 and ANO-6.

UONI 13/55 and LB – 52U

Consumables UONI 13/55 and LB-52U are essentially, in the context of our article, not absolutely complete, but analogues, since in addition to their general applicability for welding carbon and low-alloy steels, they have similar welding characteristics due to the similarity of the coating material related to the main coating. Some differences occur due to differences in production technology between Russian and Japanese manufacturers.

Which electrodes to choose for an inverter

It was said above that electrodes for MMA welding (manual arc welding) differ in the composition of the coating and the materials of manufacture. Electrodes for arc welding can be of consumable and non-consumable types. Electrodes of the second type are used specifically for argon welding.

The materials used to manufacture the electrodes also play an important role in the selection. For example, different electrode materials are used for welding cast iron and steel.

Below we will consider the electrodes that are used for welding cast iron and steel with an inverter:

- Carbon electrodes for inverter - used when it is necessary to weld products made of low-carbon and low-alloy steel;

- Electrodes ANO-21, OZS-4 and MR-3 - used for welding products made of alloy steel;

- OZCH-2 electrodes are a special type of electrodes for welding cast iron.

The diameter of the electrodes for the inverter is selected according to the thickness of the metal being welded. To weld thin metal, you need electrodes of the smallest diameter. To weld metal with a thickness of more than 6 mm, electrodes of a much larger diameter will be required.

Advantages of LB – 52U over SSSI 13/55

Japanese consumables LB-52U perform welding on both direct and alternating current, unlike UONI 13/55, which operates only on direct current.

Deeper penetration of the seam with the LB-52U electrode makes it possible to increase the strength of the reverse side of the seam.

The ability to perform high-quality hermetic one-sided welding is a distinctive feature of the LB-52U brand in comparison with analogues, including UONI 13/55. Important: there are many fakes on the market under the LB-52U brand that do not match the quality of the original. Here you should find a reliable seller and use his products.

General information

First, let's look at the technical characteristics of the ANO-21 brand. Produced according to GOST 9467-, type E46. The coating is rutile, which stabilizes the arc and reduces the pulverization of the metal.

So, when working with ANO-21, we have a stable arc and low spatter. The rutile coating prevents oxidation processes from starting by protecting the weld from interaction with oxygen.

It is possible even for a non-professional to obtain a quick and even seam with minimal likelihood of pores forming in it. About 1.5 kilograms of electrodes are needed per hour, which indicates the high productivity of the process.

Analogues of this type can be ANO 4, MR-3, OZS-6 or OZS-12. Usually they stop at the ANO 21 3mm and 4mm types. Reasonable prices for rods from manufacturers LEZ, ChZSM, which will cope with welding at home and for those trying their hand at this business.

conclusions

The brand of welding electrodes ANO-21 will be of help to both novice welders and professionals. Some will not have to worry about igniting the arc, while others will not have to worry about the stability of the main process. The result will be high-quality welded joints.

Not the last advantage will be the price criterion. When choosing, you need to carefully inspect the rods for deformation and dampness.

Giving preference to brands of a low price category is a dubious decision. It is better to pay attention to brands of well-known manufacturers.

When purchasing welding rods in basement stores, you may encounter failure to comply with favorable storage conditions. Do you have experience working with ANO-21 brand electrodes? Share it in the comments below. We wish you success in your work!