Home / Electrodes

Back

Reading time: 2 min

0

1094

Welding electrodes are used to supply current to the metal being welded.

Coated electrodes are rods from 250 to 450 mm long, consisting of welding wire with a coating layer applied to it (stabilizing, protective, magnetic).

There is no generally accepted classification of electrodes, but there are brands of electrodes that differ in type, technical conditions, etc. Information about the characteristics of a particular brand is indicated in the electrode passport.

The ANO-21 brand is one of the most frequently purchased. Most often it is used by home welders, beginners, and experienced craftsmen. You can gain the necessary knowledge about this brand from this article.

- General information

- Usage

- conclusions

Purpose and GOST

Products are produced for connecting steel parts:

- installation of pipes and gas pipelines in the absence of pressure;

- assembling structures using fillet welds.

ANO-21 is used in shipbuilding, housing and communal services, repair shops, dachas and private homes. Rods with a diameter of 2.5 and 3 mm are often used.

Products are manufactured in compliance with GOST 9467-75 and coated on the outside with a rutile coating. It stabilizes the arc, reduces the rate of spattering of hot metal, prevents the occurrence of oxidation processes, and protects the seam from oxygen penetration.

At the junction of the parts, a smooth roller is formed that does not contain pores. Approximately 1.5 kg of rods are consumed per hour. This is a high figure.

ANO-21 welding electrodes are used when connecting steel products and parts made of other metals. The rods are easily excited and maintain an arc, are powered by a 220 V electrical network, and form an easily removable slag coating. This corresponds to GOST 380-2005 or 1050-88.

Welding is carried out with direct and reverse current. ANO-21 guarantee the quality of work.

Explanation of markings

The symbols that are part of the full name of the product - E46-ANO-21-d-UD E 430/3/- R 11, have the following meanings:

- E46 – product type;

- ANO – brand;

- D – diameter;

- U – intended for carbon steels;

- D – thick protective coating;

- 43 – level of seam rupture;

- 0 – elongation 18%;

- 3 – viscosity;

- R – rutile coating;

- 1 – welding position – any;

- 1 – alternating current.

The rods were developed by scientists from the Electric Welding Institute.

Letter designations:

- A – Academy;

- N – Sciences;

- O – coated;

- 21 – model.

The data will help beginners choose electrode products.

An example of decoding electrode symbols.

Protective covering

Electrodes differ in the type of coating used. There are four types of coatings:

- main or SSSI;

- cellulose;

- rutile;

- sour.

Rods with cellulose and base coating create elastic, reliable, impact-resistant seams when carrying out welding work with direct current. Rutile with acid coating are universal. Coatings are used for welding with both direct and alternating current.

Electrodes coated with acidic coating are toxic. Work with them is carried out in closed spaces only when the rooms are equipped with good forced exhaust. Rods coated with rutile, which has a bluish or greenish tint, are easy to ignite. This parameter remains unchanged when operating the inverter at low open circuit voltage.

Welding characteristics

Features of electrodes:

- product diameter – 1-5 mm;

- coating – rutile;

- metal spattering – does not exceed 4%;

- hourly consumption – 1.65 kg.

The arc remains smooth throughout the welding process.

The seam material can withstand:

- tensile strength – not less than 460 MPa;

- elongation – 18%;

- viscosity – 80 J/cm²;

- connection bend angle – 150°.

We recommend reading Description of rutile-coated electrodes

Other parameters are also important.

Chemical composition of the seam

Even for a person without work experience, the connection point between the parts is strong. Molten and solidified metal contains the elements presented in the table.

| Name | Quantity in % |

| Carbon (C) | 0,1 |

| Silicon (Si) | 0,3 |

| Magnesium (Mn) | 0,5-0,8 |

| Sulfur (S) | 0,04 |

| Phosphorus (P) | 0,045 |

The above list complies with state standards and must be observed in the production of electrodes at all factories. In practice, the composition of the seam is slightly different when welding with rods from different manufacturers.

Smooth weld seam.

Physical properties

Rutile coating consists of titanium dioxide and other substances: silica, calcium carbonate, ferromanganese. The mixture allows you to cook wet and corroded parts. You can make connections at non-rotating joints, which are often found on pipelines.

Products with a diameter of 2, 3, 4 and 2.5 mm are easy to ignite and burn evenly, the molten material hardly splashes.

The Sv-08 wire (the electrodes are made from) contains additives that can increase the surface tension in the weld pool. This allows vertical and ceiling seams to be made without leaking metal.

The maximum permissible moisture content in the coating is 0.9%. For larger values, the rods are calcined for 30-40 minutes. The temperature is 120°C. In the future, electrodes are used for welding non-ferrous and ferrous metals, incl. and aluminum.

When purchasing, you should choose dry products. You shouldn’t settle for cheap products; it’s better to buy more expensive products from popular manufacturers.

When welding with an ANO-21 electrode, there is almost no spatter.

Welding modes

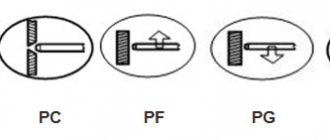

These indicators depend on the thickness of the electrode. The parameters are indicated in the table indicating the spatial location of the seam.

| Diameter (mm) | Length(cm) | Quantity (1 kg) | Current (A) | ||

| Lower | Vertical | Ceiling | |||

| 2 | 30 | 95 | 60-100 | 70-80 | 80-100 |

| 2,5 | 30 | 58 | 70-120 | 70-100 | 90-110 |

| 3 | 35 | 40 | 100-150 | 90-110 | 110-140 |

| 4 | – | – | 160-190 | 150-170 | 150-180 |

| 5 | – | – | 170-220 | 150-190 | 120-160 |

It is not recommended to weld workpieces thicker than 5 mm and pipe joints with subsequent injection of pressure.

Welding with an inverter machine

A characteristic feature of any type of inverter is the constant performance and stability of the welding current, which guarantee the quality of the resulting seam and the formation of alternating voltage that forms the welding arc. The connection of the surfaces to be welded is carried out by the melting method.

The qualitative indicators of the reliability of the unit are due to its design feature. Each device, regardless of type, consists of the following elements:

- frequency converter;

- control systems (center);

- transformer;

- power rectifier;

- network filter.

All of them form the general circuit of the inverter, and the main tool for welding is the electrode.

Dimensions and packaging

After release, the finished products are placed in moisture-proof film and a cardboard box. Packages of 1 or 5 kg are available for sale.

| Rod Diameter (mm) | Length(cm) | Weight 1 pc. (G) | Quantity per 1 kg |

| 1,6 | 25 | – | – |

| 2,0 | 25 | – | – |

| 2,5 | 30 | 17,0 | 58-59 |

| 3,0 | 30 or 35 | 26,5 | 38 |

| 4,0 | 45 | 53,0 | 18-19 |

| 5,0 | 45 | 84,5 | 12 |

| 6,0 | 45 | 135,0 | 7 |

We recommend reading Composition of electrode coating

Small packages are convenient for home use.

Consumption rate

When connecting parts in small volumes, a competent calculation of the required number of electrodes and the diameter of the rod will ensure the continuous activity of the master and eliminate unjustified monetary costs.

This requires parameters that are inserted into tables developed by scientists from the Montazhspetsstroy Research Institute and other organizations. Detailed information about the types of welding is presented in document VSN 452-84.

In practice, the consumption is 1.65 kg for every hour of operation.

Pros and cons of using

Positive aspects of the rods:

- accessibility for all users;

- fast ignition and stable arc burning;

- hot metal hardly splashes;

- formation of an easily removable slag layer;

- seam strength;

- lack of sensitivity to galvanic protection and traces of rust on the edges of the metal being welded;

- reduced toxicity.

Negative features:

- welds only metals up to 5 mm thick;

- the use of fluxes is required;

- impossibility of welding high pressure pipelines.

Prices cover all existing shortcomings. You can purchase materials of different diameters in specialized stores by paying 70-152 rubles per 1 kg.

A pack of electrodes weighing 5 kg.

Electrode diameter

With increasing wall thickness of the metal surface, the required time for welding work increases. The thicker the surface, the larger the diameter of the electrodes used. Rods with a thin diameter burn out very quickly and are most often used on tacks. Working with them requires a certain skill in welding.

“Troika” (rods with a diameter of 3 mm) is suitable for welding structures and elements with a thickness of 3-4 mm, “four” - for elements with a thickness of 4 to 9 mm, “five” - for elements with a thickness of 9-10 mm. For areas where major sealing is not required, rods with a diameter of 0.5-2 mm can be used. Profile structures for support and assembly can be welded using electrodes up to 2 mm.

Features of operation and storage

The main property of rods coated with rutile coating is that they work in conditions of high humidity of the parts being welded and with metals with traces of rust on the edges being joined.

The electrode must remain dry. Therefore, it is better to store it in a hermetically sealed box in a warm room, away from the ground, away from sunlight. If it gets wet, it is dried for 40-60 minutes at a temperature of +90 ... +120 ° C.

Vertical fillet welds are made by holding the electrode at an angle of 40-70°. Do not exceed the recommended currents, this will lead to metal burns. The seam always turns out strong even by welders without experience. Waste is easily removed from metal.

Rods should be purchased from specialized stores that comply with the rules for storing welding consumables. The temperature in the warehouse must be at least +15°C.

Electrodes for inverter

They are electrically conductive metal rods (cores) with a special protective coating - coating. The arc temperature during welding causes the core to melt. This process is accompanied by burning and melting of the coating. The combustible coating turns into a gas cloud, blocking the access of oxygen. The melting part of the coating becomes liquid, covers the molten metal with a thin layer, and protects it from interaction with oxygen.

The presence of chips on the protective coating is unacceptable. Violation of the coating does not allow achieving uniform heating and high-quality execution of the seam. In order for the arc to be in the center, you need to choose electrodes whose tips have a coating thickness that is uniform on all sides. The coating must be dry. Electrodes with wet coating do not ignite easily. You can dry them, but this will reduce their performance characteristics.

Comparison table

Electrode products, including ANO-21, are produced by several enterprises. The manufacturing technology is not followed at all, for this reason the properties of products from different manufacturers differ in ignition, maintaining arc stability and the appearance of pores.

We recommend reading Characteristics of OZS-12 electrodes

Masters conducted comparison tests with the participation of ANO-21, MR-3 and SSSI. The test results depending on the welding direction are shown in the table.

| Index | ANO-21 | MR-3 | SSSI |

| Metal consumption (1 kg) | 1,7 | 1,7 | 1,6 |

| Viscosity (J/cm²) | 80 | 80 | 200 |

| Elongation (%) | 18 | 18 | 26 |

| Capacity (kg/h) | 1,4 | 1,7 | 1,3 |

| Yield Strength (MPa) | 460 | 400 | 350 |

| Maximum current (A) | 220 | 260 | 200 |

| Minimum current (A) | 40 | 30 | 40 |

| Calcination (min.) | 60 | 60 | 60 |

The table will help in selecting the electrodes needed for the job.

What types of electrodes are there?

Conventionally, rods for working with an inverter-type welding machine are divided into two categories. The former are intended for complex and critical work, while the latter can be used when welding in less demanding and simple areas. The first group consists of UONI melting-type electrodes, and the second group consists of ANO, MP-3.

ANO brand electrodes are chosen for performing simple welding for domestic needs. They are suitable for working with almost all types of inverter welding machines. They are most widespread among home and novice craftsmen. Electrodes of the MP-3 brand are considered unpretentious and universal. They can weld wet, rusty, poorly cleaned metal surfaces.

The SSSI brand is more “capricious”, it requires certain skills, but it allows you to weld surfaces of any complexity together and obtain the most dense seams. Electrodes in this category are often chosen by professionals. A novice welder with no actual experience will find it difficult to work with them.

The best manufacturers

The rods are manufactured at various enterprises in Russia and abroad.

Popular companies producing rods:

- Lincoln Electric (USA);

- ZELZ (Zelenograd);

- LEZ (Moscow);

- "Paton" (Kyiv);

- "PlasmaTek" (Ukraine);

- "Strength" (Kyiv);

- "SpetsElectrod" (Volgodonsk);

- "TANTAL LTD" (Syzran);

- "Sumy-Electrode" (Ukraine);

- YaEMP (Yaroslavl).

Analogues of products are considered to be:

- ESAB OK 46.00;

- BÖHLER FOX SPE;

- ANO-4;

- OZS-6;

- MP-3;

- RC standard;

- OZS-12.

Top businesses:

- "Paton";

- "Granite";

- LEZ;

- KOMZ;

- MaxWeld;

- "Tigarbo";

- "Monolith".