Abrasive and cutting tools in metalworking machines play a major role in the process of processing workpieces. The quality depends on the characteristics of the device and how firmly it is attached.

As this device, a collet chuck is chosen, which is distinguished by a variety of variations and standard sizes depending on the type of shank and type of machine.

Operating principle of collet chucks

The collet chuck secures cutters and axial workpieces on milling equipment and CNC machines where fastening with high precision and minimal axle runout is required. Regardless of size or type, all types of collet chucks function according to the following principle:

- a self-clamping twisting mechanism presses on the end of the collet chuck;

- yielding to pressure, the collet moves into the cone-shaped opening, which leads to the closure of the petals, which are the working part of the part;

- the closed blades of the collet firmly hold the workpiece or tool shank.

Thanks to this type of fastening, the element is securely held and is perfectly cited. To remove the collet, the self-clamping nut is unscrewed enough to reduce the pressure on the tool, after which the workpiece is removed from the mount. For tightening and unscrewing, use a regular spanner.

Design features

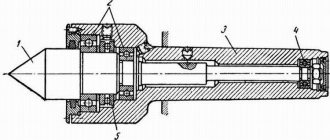

The structure of any collet chuck includes the following elements:

- a housing with which clamps are installed on milling cutters. Made of special hard alloys that are not subject to mechanical damage or deformation;

- a clamping nut that securely fixes the workpiece with the chuck, preventing it from moving or vibrating;

- a collet made in the form of a sleeve into which the end of the cutter fits. In the process of screwing the nut, the workpiece is evenly and firmly compressed, due to which it is securely fixed.

Advantages and disadvantages

There are several advantages that distinguish the collet chuck from other types of clamping mechanisms:

- fixation of the cutting tool over the entire area. When the scurvy nut is tightened, it evenly and equally firmly fixes a large area of the shank, thereby reducing vibration when working with the workpiece. Lateral load does not affect the position of the tool axis, which ensures excellent centering. With the help of collet chucks, metal workpieces are processed with high quality; when working with small parts, the product parameters are strictly observed;

- compatibility with many types of cutters. The multifunctionality of the housing design allows you to replace only the cutting part when working with all kinds of mechanisms. To do this, simply unscrew the nut and manually install a collet of the required diameter. This feature greatly simplifies the production process;

- minimal vibrations of the fixed part during the working process. The vibration of the inner cone in relation to the outer end part is 0.005-0.010 mm.

Among the disadvantages, the need to select collets for different diameters of the shank of the installed part or tool was noted.

Range of machine tool chucks

You can purchase the following types of chucks for milling machines that are in demand in metalworking:

- collet;

- thread-cutting;

- drilling;

- power milling.

For each category of clamping tool, there is a special section where you can find detailed information about this or that equipment, as well as buy suitable chucks for metal milling machines.

Collet chucks

Universal chucks used for fixing axial cutting tools Collet chucks can be used to work with cutters and drills of the corresponding diameter. This type of clamp provides high precision work due to the uniform fixation of the tool with a spring collet, which is a mandatory structural part of chucks of this category. Due to this, a minimum level of runout of the cutting part is achieved, which increases processing accuracy and extends the service life of the drill or cutter.

Threading chucks

This type of milling chuck is designed to withstand the high instantaneous loads that can be achieved during the tapping process. The chucks have a mechanism for compensating axial and torque forces. Such critical loads can arise, for example, when a threading tool passes to the bottom of a blind hole, as well as during reverse movement.

In addition, thread-cutting chucks provide a quick-change mechanism for adapters, which allow you to expand the range of cutting tools of various diameters used.

Drill chucks

This type of equipment has a narrow scope of application and can be used exclusively for fixing drilling cutting tools of different diameters. The range includes chucks that allow you to work with drills with a diameter from 1 to 16 mm. It should be noted that this category of equipment is not intended for working with taps or cutters, since the chuck mechanism is not designed for significant radial loads.

Power milling chucks

This category includes chucks for metal milling machines that are designed for high loads. The equipment is used in conjunction with cylindrical collets. In addition, the design of the power milling chuck allows you to quickly change the working tool without applying significant effort. The equipment is universal, since milling chucks can be used in conjunction with adapters for different diameters of cutter shanks.

Types and features

Depending on the area of application and the design features of the mechanism, collet chucks are divided into several types:

- ER collets. With two clamping points and a through hole, the most commonly used type;

- for taps. With a square groove compensating the axis;

- through and blind. The former process parts of unlimited length, the latter are suitable for workpieces of limited size, for example, workpieces in which one end is sealed;

- with one and two clamping sections. The second type, compared to the first, fixes the part more reliably by holding it at two points on the axis.

Collet chuck clamps come in two types:

- clamping The bushing is made in the form of several springy petals corresponding to the size of the fastener. The three-lobe bushing is designed for processing workpieces with a diameter of up to 0.3 cm, four-lobe bushings - from 0.3 to 8 cm, six-lobe bushings - for parts more than 8 cm in diameter;

- servers. The steel collet is equipped with three longitudinal grooves, forming petals with converging ends. The well-springing design feature allows for easy installation and reliable holding of a workpiece of the required diameter in the chuck. During operation, the feed mechanism with the screwed collet begins to move, which contributes to an even closer approach of the petals.

The feeding type of cartridge is more reliable, but requires a special key for fixation. Clamping types are used in cases where frequent replacement of cutters during operation is necessary.

How to choose the right collets?

In order to choose the right tool and avoid certain difficulties in the future, when choosing, take into account some characteristics of the collet:

- method of attachment to the spindle - direct installation or screwing onto the thread using an adapter;

- quantity, material, shape of cams;

- flange sizes;

- the type of alloy from which the element is made, depending on the type of work to be done.

It is not recommended to purchase tools from an unknown manufacturer, since such tools are not of high quality or have a long service life.

Collet chuck device

The design of the collet chuck is quite simple. The main part of the equipment is a collet, a special device in the form of a sleeve with longitudinal cuts. These cuts form springy petals that securely hold the workpiece. There can be three, four, six or more petals, depending on the diameter of the sleeve.

Mechanical engineering companies usually use ER type clamps. These parts have two clamping zones along the axis. Therefore, the tool placed inside is rigidly fixed, and there are no radial runouts, so they are not even taken into account in the calculations.

Image No. 1: Collet chuck design

Serial collet chucks are made of hardened tool steel and have high strength and wear resistance. Homemade clamps are made from bronze, brass, aluminum and steel.

How is a collet chuck different from a jaw chuck?

Collet chucks, like jaw chucks, are holders for tools and workpieces, so they are often confused. However, these equipments have fundamental differences. Jaw chucks are considered more universal and can therefore be used to hold tools with shanks of different diameters. On the contrary, collets are designed to work with certain diameters and are not suitable for tools with other shanks.

Areas of application

A fixing tool with replaceable collets is used on various types of machines where reliable fastening of cutters, axial workpieces, drills, etc. is required:

- CNC milling machines with a machining center;

- vertical and horizontal milling equipment;

- equipment for drilling, boring, milling groups.

The use of auxiliary adapters for fixing workpieces reduces the reliability of the production process, as well as the level of safety. Universal chucks with spring petals optimize the operator’s work, since to replace cutters and taps, simply open the collet and insert the part into the chuck.

Types of collet clamps

Chucks of this type are made according to the same principle: when the tightening nut is rotated, the collet sleeve compresses and fixes the cutting tool. But there are big differences in the sizes and shapes of such nodes. Slotted bushings can be long, short, with two or multiple slots, thin or thick petals, with different clamping diameter amplitudes.

What matters is the way such a chuck is mounted on the spindle of a milling machine or hand router. It can be fixed on a thread, mounted on a Morse taper or a straight bushing with a key.

On some manual routers, the main part is not removable, but is made as a single part of the spindle. In such cases, only the clamping nut and the conical collet clamp itself are removed.

Clamping pair nut/collet for hand router

The clamp is designed for one cutter shank diameter - 6,8,10 or 12 mm. There are options in the inch system of metrics, translated into mm - 6.35 mm, etc.

You can use a cutter with a shank of a different diameter if you install a replacement collet for the desired diameter. As a rule, replacement elements are supplied with the router.

Spindles and clamps on CNC machines are made according to the same principle. The only differences are in the size and method of fitting the entire assembly onto the spindle. There are monolithic options, when the end of the spindle itself is made as a base for the clamp, and only the nut/cone clamp pair is removed. There are options when the entire cartridge is removed, seated on the spindle through a Morse taper, thread or bushing with a key.

There are differences in the types of such clamps. A distinction is made between the retracting and pushing arrangement of the clamping sleeve:

- in the first case, when the nut is tightened, the sleeve is pressed inward and compressed there;

- in the second case, the petals extend out and compress, like cams on a drill chuck.

The principle itself remains unchanged - when the nut is tightened, the clamp blades are compressed.

Collet clamps with a nut are very widespread today. They are used in hand tools, pencils, for pipe connections in metal-plastic pipelines, garden hoses, sewers, etc.