Modern summer residents often have to solve a problem that our ancestors have faced since ancient times. Also, some other people have to solve this problem in some other conditions, even in the modern world. We are talking about chopping wood with your own hands.

This rather important activity in the conditions of the cold territory of residence and the cold climate was an integral way for survival before. Today the situation has changed somewhat, civilization has stepped forward and will definitely move forward. But the question of how to chop wood in places where there are no cities and firewood is really needed remains. But technical devices have greatly simplified this process and what seemed difficult to our ancestors is today a matter of technology and already a reality.

It is also a matter of money, and in some cases, simply free time to work and create the necessary wonderful equipment with your own hands. So, let me introduce you – a wood splitter. You can see it in the photo.

DIY manufacturing technology

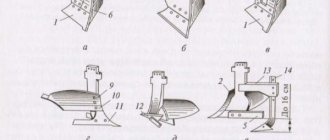

Drawing of a wood splitter (click to enlarge)

As can be seen from the description of the design and principle of operation, a wood splitter of this type can be assembled with your own hands.

But in order to perform high-quality work, the result of which will be an effective unit, first of all, you must adhere to the following series of recommendations:

1. Select a drawing. Today, there are many design schemes for a rack and pinion unit. Thanks to a source such as the Internet, you can choose a drawing that will best suit you.

2. Preparation of materials. After a detailed study of the wood splitter diagram, you need to prepare all the necessary materials. To do this, you need to inspect everything that is available in the household, and the missing materials need to be purchased.

3. Assembling the rack-and-pinion wood splitter frame. An important structural element of a rack-and-pinion unit is the supporting frame, so its installation must be treated with sufficient care and responsibility.

The most optimal materials for the frame are the following types of metal products:

- I-beam;

- channel;

- corner of the required thickness;

- profile pipe.

Advice: if you expect that the wood splitter should be mobile, then you need to make sure that the design includes wheels, as well as their reliable fixation.

Rack and pinion

4. Installation of structural elements of the wood splitter. The next stage of installation is the installation of the log pushing mechanism

It is important to understand that its installation must occur strictly in accordance with the selected drawing

For ease of use of the rack log splitter, you can install the following additional elements:

- thermal relay for units driven by an electric motor;

- protective coupling for increased safety;

- It is better to choose a four-cut cleaver, so the log can be immediately divided into four logs.

Advice: it is advisable to equip a rack-and-pinion wood splitter with a horizontal stacking mechanism, which is presented in the form of a chute. Thanks to this, it is possible to achieve optimal movement of the log to the splitter, or vice versa, depending on the chosen design.

And in conclusion, I would like to note one more important point: when working with a rack-and-pinion wood splitter, you must always follow safety precautions, otherwise you can harm yourself and seriously damage the newly created unit. In this article, we tried to outline the maximum number of recommendations and tips so that the firewood chopping unit you create will greatly facilitate your work. We hope that the information presented in the article will be quite useful for you.

Below, we invite you to watch a video on how to make a rack wood splitter with your own hands:

How to make a wood splitter

To make a rack-type wood splitter with your own hands, it is extremely important to draw up a high-quality drawing and layout of the tool parts. It is necessary to decide in advance on the material and calculate the quantity required for the work.

To make the frame, an I-beam, corrugated pipe, as well as a channel or steel angles are used. All these parts are assembled into a single structure so that the device stands quite firmly and does not swing.

An important part of the wood splitter is the piston, which ensures high-quality pushing of the wooden block during operation of the installation. For this purpose, you should calculate the required pushing force so that you do not have to catch the halves of the chocks at the exit, and also not cause harm to yourself. You can look for such a part on the market in a ready-made form, or you can borrow it from a car jack, tractor or other medium-sized agricultural machine.

For installations that use an electric motor as a drive, it is better to install a protective coupling, which increases the level of safety. It is advisable to choose a four-cutting cleaver; in this case, the log immediately splits into 4 equal parts.

It is better to equip the wood splitter not with a vertical, but with a horizontal method of laying it in the form of a gutter, due to which optimal movement of the log to the splitter is achieved. As for the nozzle, alloy steel is traditionally considered the best cutting material, so it is better to choose a well-polished metal surface as a cutter.

Peculiarities

Rack splitters are very reliable and efficient; they are characterized by high speed of operation and simplicity of the mechanism. The principle of operation is generally elementary - the lumps are placed on the work surface, after which the pusher is activated using a lever. It moves along the slats and with force pushes the workpiece onto a rather sharp knife, which is located at the very end of the unit.

All manipulations take a matter of seconds, and as a result the log splits into several parts.

The operating principle of such a wood splitter is based on the use of a rack and pinion gear:

- the gear rack is mobile, it is driven by a gear pressed onto the reduction gear shaft or belt drive pulley;

- the lath is fixed on the frame where the block is laid;

- the gear meshes with the rack using a special control handle;

- all these parts are mounted on a strong stationary frame, with a cleaver attached to one of its ends;

- there are guides on the frame along which the rack moves;

- With the help of a return spring, the rack returns to its original position.

The design can be driven by any type of engine - gasoline, diesel or electric; in addition, it is often driven by the power shaft of an agricultural tractor or a car wheel, that is, by any motor that produces torque. At home, some craftsmen even install a washing machine motor or a chainsaw motor.

Operating principle

Hydraulic wood splitter

The engine rotates the gear using a belt drive. When the control handle is turned, the gear sets the rack in motion. The rack, moving along the guides fixed to the frame, moves the pusher forward. The workpiece is located on the frame between the cleaver and the pusher; as the pusher moves, it splits the workpiece against the cleaver.

After the pusher reaches the end, the rack and pinion are disengaged, and the entire mechanism is restored to its original state. In some wood splitters, the rack is returned to its place manually - by moving the control handle back. After discarding the resulting firewood and replacing the workpiece, the entire process is repeated again.

Classification of homemade wood splitters

Before you make a wood splitter with your own hands to provide a bathhouse with firewood, you need to choose the best option for specific conditions. Equipment of this type is classified according to the following criteria:

- presence of an engine - non-volatile spring splitters, hydraulic, electric, gasoline wood splitters

- design – vertical, horizontal, combined, rack, cone

- operating principle – “screw”, screw pair, hydraulics/pneumatics

A budget version of the cleaver is a mechanical model, consisting of a support table, a stand, and a console.

The simplest option is a mechanical wood splitter.

A do-it-yourself cone log splitter will require, at a minimum, an engine, equipment, and a chain or belt drive from the drive shaft to the working element.

This is what a conical screw log splitter looks like, it literally drills a log into firewood

A do-it-yourself rack-and-pinion wood splitter is a complex design that requires the conversion of torque in the engine shaft into translational motion of the working body. Therefore, for assembly you will need a rack and gear.

A rack-and-pinion wood splitter cuts a log using the forward movement of the rack

There are homemade products with a crank mechanism that solves the same problem.

For small volumes of firewood harvesting, the simplest mechanical devices discussed below are sufficient. They are easier to store, there is no need to look for an engine, build a massive frame, order or make complex equipment yourself. However, the scope of application of such cleavers is limited by the needs for firewood for a garden bathhouse and a country fireplace. For regular large volumes of firewood (greenhouse stoves, home heating), wood splitters with gasoline or electric drives or pneumatic models powered by a compressor are more suitable.

The wood splitter can be powered by a gasoline engine

Professional equipment is used for large volumes of wood splitting.

For convenience, the wood splitter can be vertical

Precautionary measures

Working on electric wood splitter models requires special attention and increased caution:

- The wood splitter may only be used for its intended purpose;

- Before use, you must carefully read the instructions;

- Do not operate the wood splitter if there are third parties, especially children or animals, in the operating area;

- When working, special gloves and personal hearing and vision protection are used;

- Do not leave a running machine unattended;

- hands must be kept at a sufficient distance from the cutting mechanism;

- before work, you need to make sure that all components are securely fixed;

- The wood splitter must be serviced, repaired or transported when it is turned off.

It is forbidden to split logs or logs that are too large or contain nails or other foreign objects that could cause damage to the device. Before operation, you need to check the hydraulic system and make sure there are no oil leaks.

Scope of application

A rack-and-pinion wood splitter can be considered as machine tool equipment. In everyday life, such a unit will simplify the preparation of firewood for the winter when heating with a stove or if there is a frequently used wood-burning bathhouse or sauna on the site.

If you use firewood primarily to light a fireplace or barbecue, a manual wood splitter will be a more convenient alternative. It is much simpler and safer to use, and in addition, it has an aesthetic appearance (especially if it is a wood splitter with artistic forging or patina). With its help, you can quickly and easily prepare firewood and chips, surprise your guests with an interesting device, and turn routine physical work into entertainment.

113

Purpose of wood splitters

If you are the proud owner of your own country house, then you probably know well how hard it is to chop wood while swinging a heavy, heavy axe. However, progress does not stand still, so these days the work of collecting firewood can be significantly simplified. For this purpose, special machines called “wood splitters” are used.

Of course, not everyone has a need for such technology. If you split firewood once a month, then a regular splitting splitter is quite enough for you, but there are categories of homeowners who cannot do without a mechanical device. First of all, these are people who permanently live in houses with stove heating, fireplaces or solid fuel boilers. Such equipment is necessary in wood-burning boiler houses, and, of course, we should not forget about lovers of Russian baths - after all, before they take a good steam, they will certainly need to stock up on firewood to kindle the fireplace.

Thus, the wood splitter is suitable for anyone who, for one reason or another, is forced to periodically prepare firewood. The device will be useful if the owners of a private house are women, elderly people or physically weak men. One of the most popular models of wood splitters is the rack-and-pinion one.

Step-by-step instructions: assembly features

At home, you can assemble any wood splitter with your own hands: drawings, photos, instructions will help you do it correctly. Each model requires a separate approach.

From the description it is clear that the rack structure can be mounted with your own hands. To do this, you should adhere to certain recommendations and sequence of work:

| Image | Stages of work |

| Selecting a drawing. | |

| Preparation of necessary materials. | |

| Assembly of the frame. An important element is the supporting frame; it is made of a channel, I-beam or profile pipe. | |

| Installation of structural parts. The pusher mechanism is being installed. You can install additional parts: thermal relay, protective coupling. | |

| A four-cut cleaver should be chosen. |

It is better to equip the rack unit with a horizontal laying device, which is made in the form of a gutter.

Assembly of the hydraulic model is difficult due to the mechanism. You will need to find an oil tank, a special cylinder, a control unit for fluid flows and pumping equipment.

First of all, the frame is made. It is better to mount it on wheels or a chassis to move the device to the desired location. The main hydraulic part is attached to the frame. Instead of a knife, a conical wedge is fitted, which is moved towards the log using a central screw.

Cleavers with motors are characterized by greater productivity. Their installation requires a hydraulic cylinder, an oil tank, a control unit and an electric motor. Such a device works faster than a mechanism with a jack. This requires less effort.

Using the control button, a command is transmitted to the distribution device to supply liquid into the cylinder cavity. As a result of this, the persistent heel moves in the desired direction.

This design does not have a high speed of operation, but is distinguished by a certain convenience.

How to build a model of a screw wood splitter with your own hands: drawings

The easiest way is to assemble the screw unit yourself. To do this, you need to buy a screw cone for a wood splitter. You will also need a powerful engine, a strong frame, a reduction gearbox and a shaft.

First of all, the motor and gearbox are mounted to the frame. A cone is attached to the shaft, and the mechanism itself is connected to the reduction gearbox using a motor. Important points to consider during assembly:

- the nozzle cannot be directly mounted to the motor;

- if you do not have the skills of an electrician, then electrical mechanisms should be made by a highly qualified specialist;

- Belt and chain drives are protected by a special casing;

- The minimum rotation speed of the cleaver is 250-300 rpm.

This type of wood splitter works using a rotating metal cone that splits logs using a special thread. When assembling a screw model with a cone-shaped splitter, it is necessary to select the correct cone depending on the logs used. The base for the device has the form of a working platform with a fixed splitting shaft. A keel is welded to the table to prevent particles from falling under the rotating mechanism. The power supports are mounted, and the cleaver is installed in the working position. Then the motor is connected.

A popular model of a wood splitter with a washing machine engine is popular. Three types of motors can be used: asynchronous, commutator or electronically controlled. The most common option is asynchronous motors. Older models have a separate winding for starting.

What is needed for making

Making an “iron lumberjack” does not require the use of scarce parts, so most components and blanks can be found at home or in the garages of friends and acquaintances. Here's what you'll need during the process:

- cone (you can grind the screw yourself or purchase it on the construction market);

- shaft (if you make your own threaded wedge, you can use a suitable hub from agricultural machinery);

- pulleys or sprockets;

- drive belt or chain from automobile or motorcycle equipment;

- bearings with housings (supports for car driveshafts are an excellent option);

- steel profile pipes or angles for the frame;

- metal sheet with a thickness of at least 4 mm for the desktop;

- electric motor;

- wiring;

- switch or magnetic starter;

- bolts and nuts M8 or M10.

Most parts can be used from old automobile or agricultural equipment

. The only thing that may be difficult is making a cone screw. However, you should not even try to cut this part using a grinder, as some “authoritative” sources advise. The time spent is not worth the resulting misunderstanding, which can only indirectly be called a screw. Moreover, in operation this “carrot” will not even come one iota close to the efficiency that a cone made by turning will give.

Main components of a cone log splitter

When making a machine, you will need tools that any “handy” owner will have:

- welding machine;

- electric drill with a set of drills;

- Bulgarian;

- hammer;

- set of wrenches;

- tape measure, marker.

Any enamel for exterior use is suitable for protection against corrosion.

It is only important to prepare the metal surface well for painting, so if necessary, prepare a metal brush (manual, as well as in the form of an attachment for a drill or grinder), a primer and a rust converter

Preparatory work: approximate dimensions and drawings

Before taking up the tool, it is important to draw up at least a simple sketch diagram with the location of the main components and parts of the machine and indicating its main dimensions. In addition, you will need an electrical connection diagram, which you can use a familiar electrician to work on.

The diagrams and drawings of finished structures presented to your attention will help you correctly configure the wood splitter and avoid mistakes in its manufacture.

Layout of a log splitting machine

The most important step in the process of creating a mechanical cleaver is making a wedge, so let’s look at this in more detail.

The best material for a cone is tool steel, but not every turner will undertake to make a part from it - the metal has increased hardness and requires special handling. Most likely, the screw will be made of the most popular grade of structural steel - St 45. In this case, it is better to strengthen its threaded part by any available method - hardening, nitriding or carburization.

Long-term and efficient operation of the cone is ensured only if it is manufactured correctly. When placing an order with a turner, be sure to specify that you need a screw with a 1:2 taper and a persistent double-start thread with a pitch of 5 - 6 mm. Regular metric threads will not work due to rapid wear. In addition, the standard screw thread fits into the wood much worse.

The size of the screw wedge and the value of its taper are directly related to the maximum size of the logs to be split, therefore, when determining the parameters of the drill, you can use the table.

Table for calculating cone sizes

The approximate dimensions of the bed depend on the operator’s build and can be:

- height - up to 80 cm;

- width - up to 60 cm (with folding table 100 cm);

- length - up to 85 cm.

The most commonly used scheme is with a bottom-mounted electric motor. This will protect its rotating parts from chips and chips. If an internal combustion engine is used as the power unit, then it is installed at the same level as the wedge. This arrangement is more convenient both during startup and during operation, when it is necessary to adjust the rotation speed of the wedge, fill the tank with fuel, etc.

In the process of designing a cone log splitter, they must provide a method for tensioning the chain or belt - using an additional sprocket or roller, slide, etc. A protective casing mounted on a chain or belt drive would also be useful. It can be bent from sheet metal and secured to the frame with screws.

Pay attention to how well the flexible transmission protection is designed.

Step-by-step instructions for making your own tool

Of course, the easiest and fastest to make yourself is a mechanical type of tool, which does not require the use of special components or any professional equipment. However, an electric wood splitter has a wider application; it is practical and very easy to use.

Mechanical option

The most popular and easiest to manufacture independently is the standard rack design.

The rack wood splitter is the easiest to manufacture

- Selecting a ready-made diagram or independently preparing the optimal version of the drawing for the wood splitter design being manufactured.

- Acquisition and preparation of all materials necessary for the manufacture of a wood splitter.

- Assembly of a bed and a stable supporting frame, made using a reliable channel, profile pipe or I-beam.

- Carrying out the installation of all structural parts with the installation of a pusher mechanism and, if necessary, various additional parts, represented by a thermal relay and a protective coupling.

- It is strongly recommended to use a four-cut element as a cleaver in this type of device.

Electric wood splitter

To independently manufacture a unit for chopping wood with an electric drive, you should prepare the materials presented:

- steel frame for fixing all elements of the installation;

- an engine whose power is selected according to individual needs;

- shaft mechanism;

- reduction gearbox;

- conical nozzle with thread.

Three types of motors can be used: commutator, electronically controlled or asynchronous, but the latter option is the most popular and widespread.

A simple but functional mechanism under the simple name “Carrot” is easily made independently and does not require the use of high-tech or too expensive parts. Self-production involves preparing a drive, a simple gearbox with a belt drive, a pair of bearings and a shaft, as well as a threaded cone and a frame table.

Before making a wood splitter, familiarize yourself with the diagram of its structure

A drive with a power rating of about 2 kW or more can be removed from any old washing machine, and the most complex part of such a system is represented by a cone, which is purchased ready-made or made to order. Quick and easy splitting of wooden blocks occurs due to the process of screwing the cone into the wood fibers.

The rack and pinion design is less popular, due to the increased level of danger when operating this device. In this case, the rack and pusher plate must be placed on a carriage moved along the frame

Maximum attention will need to be paid to the stability of the frame, as well as the quality characteristics of the installed rail

The operation of such a homemade design requires a very careful calculation of the rotation speed of the gear, which transmits force to the rack. Most often, splitting logs using such a wood splitter is done easily and quickly. The operator sets the device in motion by pressing the rack against the gear. As a result of releasing the handle, the contact with the operating gear decreases, which is due to the presence of a spring and the operation of the return mechanism.

Video

When you need a lot of wood

For mass preparation of firewood, push-type wood splitters with a hydraulic or mechanical rack pusher and a stationary working body - a splitter - are used. The pusher pushes the block onto the cleaver, which splits it into 2, 4 or 8 segments suitable for loading into the furnace firebox. In both cases, the speed of feeding the block onto the cleaver is determined most of all by the properties of the wood and is 4-5 cm/s. To prevent the engine from “losing speed” during the reverse stroke of the pusher and consuming too much fuel/electricity, the reverse stroke speed is set to 7-7.5 cm/s. In this case, you can prepare up to half a ton or more of firewood in the morning.

Note: do not chop raw, freshly chopped churaki into segments. For a year they should dry from the ends in a separate section of the woodpile or woodshed. If you chop logs that are still oozing juice onto firewood, the wood will lose up to 15-20% of its calorific value during further drying. And you, respectively. money for fuel.

More about safety

A homemade wood splitter can be made similarly to factory ones with horizontal or vertical supply of wood, see figure:

Wood splitters with horizontal and vertical feeding of wooden logs

Vertical type wood splitters are more compact and allow the use of a more durable U-shaped frame. However, the probability of ejection of cross-layered, knotty, twisted, crooked and/or non-parallel cuts or its fragments from a vertical wood splitter is much greater than from a horizontal one; the side paws are here, as they say, for peace of mind. In addition, the operator of a horizontal wood splitter is normally located outside the area of scattering of parts of the log in an emergency situation; he can only be hit by a ricochet. In a vertical wood splitter, the debris scattering zone is almost circular and people around it are directly affected by them with full force. Therefore, it is better to make a horizontal wood splitter with your own hands from random materials at hand, and a vertical one only when there is very little suitable space. A typical case is a stationary wood splitter with an electric drive. It cannot be left outdoors due to safety requirements, but a vertical one can be placed in a woodshed.

Hydraulic

The hydraulic wood splitter in this segment is the most economical and productive. This is determined by the external characteristics of the hydraulic drive, see below, and by the fact that the hydraulic pump drive motor operates in a stable mode. The device diagram, appearance and diagram of a hydraulic drive with one pump are shown in the figure: the drive motor rotates the hydraulic pump, which pumps oil from the tank into the system, and the distributor supplies it to the cavities of the forward and reverse hydraulic cylinder.

Diagram of a hydraulic wood splitter

A significant drawback is that the owner-operator must be skilled in operating and maintaining hydraulic systems. Less significant is the need to periodically change the oil, which costs money. Another drawback (in this case a small one) is that the motor power is taken away both in forward and reverse, therefore, if the components are available (see below), craftsmen sometimes make hydraulic systems with 2 pumps for forward and, low-power, for reverse, see . video clip:

Video: homemade hydraulic wood splitter

Note: it is quite possible to make a vertical hydraulic wood splitter with your own hands, see the video below:

Video: vertical hydraulic wood splitter

The safety of the hydraulic splitter is average: there is no return spring, and the switching time to reverse is quite long - about 0.5 s for the best branded designs. During this period, the “harmful” block may have time to burst and fly apart, even if the operator is experienced and his reaction is instantaneous.

Make or buy?

Hydraulic wood splitter with additional functions

The first thing you need to decide if you already like a hydraulic splitter is whether it’s better to buy a ready-made one with a guarantee? A good diesel fuel unit for double splitting straight-layered blocks up to 20 cm in diameter can be found for up to 20 thousand rubles. A device for splitting logs up to 30 cm with separate knots and strands into 4 segments (which is optimal for a stove) with adjustable splitting splitter height and automatic dumping of logs (see figure on the right) will cost up to 25-27 thousand rubles. For a high-performance wood splitter for splitting into 8 segments of knotted and twisted ridges up to 60 cm in diameter, you will have to pay more than 100-120 thousand rubles.

At the same time, a set of scattered units for a homemade hydraulic splitter will cost at least 60 thousand rubles. Even if you have parts of an old hydraulic system lying around in your shed, this is not an option. Firstly, worn-out hydraulic system components are difficult to repair. Secondly, the hydraulic cylinders of special equipment are designed for a higher feed speed than is optimal for chopping wood. Accordingly, the pump will have to be over-efficient, and the motor to drive it is obviously more powerful. As a result, either fuel consumption will be significantly higher, or the thrust will be weaker than that of the factory prototype.

If you do anyway

Let's say you have hydraulic system components from a mini-excavator or other mini-special equipment in your trash or you can buy them cheaply (these will do just fine). In this case, the hydraulic cylinder is selected (or the performance of the wood splitter is determined) based on the splitting force:

- Churak 20 cm in half - 2 tf straight layer; 2.7 tf is a bit knotty/wilted.

- Churak 25 cm – 2.3/2.7 tf, respectively.

- The same, for 4 segments - 3/4 tf.

- Churak 30 cm into 4 segments – 3.5/4.5 tf.

- The same for 8 segments - 4/5.5 tf.

- Churak 40 cm into 8 segments – 5.5 tf / 7 tf.

Next, based on the feed speed of 4 cm/s and the volume of the hydraulic cylinder, the performance of the hydraulic pump is determined and, according to the specification for the hydraulic cylinder, the appropriate pressure is selected. After this, a distributor is selected. Then the efficiency of the hydraulic system is set to 75% and the drive motor is selected for the required power with a margin of 5-10%. Additionally, based on the external characteristics of the drive motor, they look at its most economical speed and check whether they correspond to those of the pump. Hoses, valves and other fittings are selected according to operating pressure with a margin (for amateur design) of at least 50%.

Cleaver

The most important part of a homemade wood splitter is its cleaver. Hobbyists make it from old truck springs. In terms of the quality of the material, it cannot be better, but the spring leaves are slightly curved, which reduces performance and increases the risk of injury to the product. The best option is the top 1.5-2.5 cm of the heads of old rails. Convicts also really value railroad wheel tires and car buffers for their knives (they also went through a long cold hardening process), but they are less suitable for the configuration of a wood splitter.

Incorrect and correct designs of wood splitter splitter

The relative position of the cleaver knives is also very important. A horizontal knife protruding forward (on the left in the figure) immediately makes the wood splitter dangerous and, most likely, a thin straight-layered pine block will get stuck in it. The chock should be met with a vertical knife sharpened to a straight (symmetrical) wedge, pos. 1 in the center. The horizontal knife is positioned 15-20 mm posteriorly and is sharpened on the upper oblique wedge, pos. 2. It is very useful to equip the vertical knife with a piercing pin at the bottom (item 3 on the left) with a height of approx. 30 mm protruding approx. 20 mm forward. Such a cleaver will be better able to split clumsy logs if they are placed on the support with the flattest side down. The sharpening angles are:

- Vertical knife for soft and/or straight-grained wood (except birch) – 18 degrees (3 knife thicknesses).

- The same for hard fine-grained wood and birch - 15 degrees (3.7 knife thickness).

- Horizontal knives – 15 degrees.

- The needle is 22-25 degrees (2.5-2.7 knife thickness).

Rack and pinion

A rack-and-pinion wood splitter is cheaper than a hydraulic one: a branded one can be bought for 8-17 thousand rubles. Its device is shown in Fig. – the pusher on the rack is fed by a small gear-tribe (or tribe). The gear ratio from the motor to the tribe shaft is calculated using a feed speed of 4 cm/s.

Wood splitter device with rack drive

It is also easier to make a wood splitter with a rack drive with your own hands - the parts of a rack jack (you can use old ones) are quite suitable for the base. A rack-and-pinion splitter is also simpler to operate: maintenance of the hydraulic system is completely eliminated. Its safety is greatest: it is enough to release the pressure roller lever (or reflexively throw it out of fear), and the return spring will lift the rack above the bushing and throw it back.

The main disadvantage of the rack-and-pinion splitter is the poor external characteristics in this case (pos. P in the figure below): as the feed speed approaches zero, the stop increases sharply, and then also sharply drops to zero. That is, if there is a defect in the block in which the cleaver gets stuck, the drive will jerk strongly (which can cause its breakdown), and then the force of the tribe will be spent on pushing the rack away from itself, and not pushing it forward. It looks like this: the feed lever (if not released) beats painfully in the hand, the mechanism cracks, trembles, and may break. The initial section of the external characteristic of the hydraulic drive is soft: the greatest emphasis is created at zero feed speed. If a hydraulic splitter comes across a very stubborn chump, he will just as stubbornly push and shove him onto the splitting ax; maybe it will split.

External characteristics of the rack and hydraulic drive of the wood splitter

The first consequence of the rigidity of the initial branch of the external characteristics of the rack-and-pinion splitter is that more motor power is needed. Shift the splitting force values for the hydraulic drive in the list above by one position, and throw out the 40 cm block and 2/2.7 tf for the 20 cm one - get the initial data for calculating the rack drive; however, its efficiency can be taken as 0.85. Secondly, the internal defect of the block, which can slow down the cleaver, may also be the bark that has fallen into the split. As a result, the rack and pinion drive is more suitable for low-performance manual mechanical wood splitters (see below) with the adaptive external characteristic of the “motor” - our muscles.

Note: The poor external performance of the rack and pinion drive can be improved to some extent by a chain drive from the motor to the drive shaft, see below.

Requirements for a cone splitter

The design of the screw splitter should ensure not only high reliability and performance, but also safety during operation

Therefore, when choosing a unit layout and its manufacture, it is important to adhere to the requirements for equipment of this type and the recommendations of the craftsmen who have tested the machine in action.

Flexible transmission is a simple and affordable way to change the speed of rotation of the propeller when using high-speed electric motors

- the electric motor power should be in the range from 2 to 4 kW;

- to reduce the number of revolutions, it is recommended to use a gearbox or flexible transmission;

- cone screw rotation speed - no more than 500 rpm;

- the machine must be equipped with an on/off button (magnetic starter) and a residual current device (RCD);

- the cone shaft is mounted on bearing supports;

- the cone must have a persistent thread;

- when driving with a belt, it is better to use double-ribbed pulleys and a pair of V-belts;

- During operation, the supply of logs must be carried out with their vertical orientation, otherwise the screw may jam and damage the installation.

You should not follow the lead of the “craftsmen” who offer the simplest design of a wood splitter, in which a shaft with a wedge-shaped screw is clamped into the chuck of a powerful electric drill or hammer drill. Such a device not only has low efficiency, but is also very dangerous, since it will not be easy to hold it in your hands with the increased resistance of the wood. If you still decide to use this scheme, then try to secure the tool on a solid base in order to use it in the traditional way.

To obtain a mobile design, an internal combustion engine is used to drive the machine

A type of wood splitter

To date, several variations of devices have been created for chopping wood. Depending on the type of their drive, there are several types:

- A variant of autonomous wood splitters equipped with a gasoline or diesel engine.

- Models that work when connected to the mains.

- Mechanical wood splitters, suitable for small volumes of work.

Experts also identify other classification characteristics of wood splitters. Depending on how exactly they will chop wood, they are divided into:

- rack wood splitters;

- hydraulic wood splitters;

- electric models, where the log is positioned vertically;

- the most powerful screw units.

Each of them has its own characteristics and areas of practical use. For domestic use, screw ones remain the most preferred. You can also consider the option of hydraulic wood splitters.

Design with a cone-shaped cleaver

Many diesel units and electric units are equipped with a special cone-shaped cleaver. They may or may not have threads. The peculiarity of this machine is that it breaks apart the block of wood using mechanical pressure combined with rotation of the working tip. As a result, the unit makes minimal effort to obtain the result, which explains its efficiency in operation.

There are several basic components of the machine.

Cone drawing

The bed is a kind of table mounted on legs. Firewood is placed on it. This is the supporting element to which the engine and gearbox are attached.

The engine can be of various types. For full operation per minute, it must perform more than 400 revolutions at a voltage of 380 W and a power of 1.5 kW.

A gearbox is a device through which the required number of engine revolutions is set.

When assembling the unit yourself, you should pay attention to what type of structure is needed. Parts for it are inexpensive

It is suitable for home use, as it does not provide high productivity at work. This is due to the manual supply of firewood.

Hydraulic wood splitter

If you plan to work with significant volumes of firewood, the best option would be a hydraulic wood splitter. Its operation is ensured by an engine in conjunction with a hydraulic pump. The cleaver itself in these units is installed on the rod or at the stop itself. Moreover, in the first case it is more powerful, and in the second it is reliable.

There are a number of main characteristics for this wood splitter, namely:

- Maximum log dimensions.

- Engine power.

- Horizontal or vertical position of the log in the machine.

- The force of splitting logs, which is determined by the power of the motor and its cylinders.

Drawing for assembling a hydraulic log splitter with your own hands

Assembling a wood splitter of this type involves a number of difficulties. But the time and effort spent is worth the high productivity. This option is relevant for both home and commercial use.

The principle of its operation is similar to a jack. This can be seen when examining the drawings of the machine in detail.

When assembling it yourself, it is especially important to correctly calculate the dimensions of the future installation, depending on what logs you intend to work with further

Rack splitter

The device of a rack wood splitter

The third popular option for equipment in this category is rack-and-pinion splitters. The logs for splitting are placed between the protective stop and the splitter itself, which is located in the area of the gearbox housing. The name of rack wood splitters is explained by the option of attaching the working element to the rack. And its movement is determined by a gear transmission.

When examining the drawings of this type of wood splitter in detail, it is noticeable that the working elements begin to move after pressing a certain handle on the unit. The movement of the rack with the cleaver attached to it begins against the background of the clutch of the gears, as a result, the firewood is divided into small parts. After this, during the reverse movement, the working body returns to its original position.

Rack splitters are good units for home use. Their advantage is the lack of special maintenance. In most cases, they are powered by an electric motor.

The main parameters of these machines are as follows:

- the shape of the cleaver, which determines how many parts the log is divided into;

- maximum log dimensions;

- the force used to split the log being processed.

If you wish, you can assemble a rack-and-pinion wood splitter with your own hands - purchasing a ready-made version is much more expensive.

Drawing of a rack cleaver

Using other methods

The question may arise: “why not just cut the wood with a chainsaw.” Although this is an option, the chainsaw is designed for something else. Its design does not imply precise and high-quality processing of wooden boulders. The essence of the question is that with the help of a chainsaw they perform transverse cutting of wood , and hard and heavy logs are from a different area.

The question of whether it is good to use heavy hammers and thick wedges falls under the same category of answer. The productivity of such an action is, in principle, much higher than that of working with a chainsaw, but nevertheless, the effectiveness of this method is not so great and your tasks that you want to do besides chopping wood will have to be postponed until later. Because doing splitting work using a hammer and wedges will take too much of your time.

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

Instructions for making a rack wood splitter

For obvious reasons, no one can give any exact dimensions. We only show dimensions in the drawings of devices that have been tested and built for the conditions in which they are used. Nevertheless, there are general principles for assembling a wood splitter:

A competent drawing is half the work. It is necessary to provide not only the type of wood with which the wood splitter will primarily work, but also the installation location and the desired performance

The choice of engine will depend on this. A stationary or mobile frame is welded from a metal profile, an angle, and if the device is stationary, then a heavier and more massive channel or I-beam will do. When welding a frame, it is necessary to clearly check the dimensions, horizontal and vertical; all this affects not only productivity, but also the safety of the worker. Particular attention is paid to the stability of the structure; it should not sway during operation, and in the case of building a mobile device, the wheels should support the weight of the device with a small margin. The speed at which the log is fed to the knife can only be calculated experimentally. If the speed is high, chips from the log can injure the worker, and if it is too low, you can fall asleep near the wood splitter.

Actually, this is all that can guide you when building a rack-and-pinion wood splitter. Good luck to everyone and keep your homes warm during the coldest winter!

Wood splitters are considered a rather convenient device, which greatly facilitates the work of collecting firewood in private homes and summer cottages. Wood splitters come in a variety of designs, with rack and pinion splitters being the simplest. Let's give a brief overview of the main characteristics of this device.

When firewood is sometimes needed

That is, for heating a decorative fireplace or temporary heating with improvised waste fuel; eg in the country. Abroad, logs of low-value soft wood are sold specifically for fuel for fireplaces: poplar, aspen, willow, etc. And they are accompanied by wood splitters like the one in pos. 1 pic. below. The core of marketing promotion is that the ridges on the knife immediately provide a kindling light. But in general the idea is strange: a block of wood that can be split with a light blow of an ax is placed in a clip and hit it hard several times with a sledgehammer. True, chopping wood, on the contrary, is safer. Maybe this is relevant there. There is a saying in America (translated into Russian): “If the average American, rushing to get to work, doesn’t slip and break his neck in the shower, he will cut his own throat while shaving.”

Simple wood splitters for preparing small amounts of firewood

A reciprocating wood splitter (item 2) is much more convenient and not at all more dangerous. He acts according to a well-known saying: a lazy man was asked why he chops wood while sitting? “I tried lying down - it’s uncomfortable.” The reciprocating wood splitter can be attached to both the wall and the floor. Cutting lever arm from 0.8 m for soft straight-grained wood; for birch and pine from 1.2 m.

Split oak, etc. with a reciprocating wood splitter. or wood from fruit trees is already difficult and does not always work out. Therefore, at a dacha visited in the cold season, a foot-operated lever wood splitter (item 3) will not hurt: it copes with the wood of any tree with a diameter of up to 25-30 cm; however, productivity is low. In this log splitter, a sliding stop pulls the shackle (shown by the arrow) when you press the pedal. The swinging cradle is raised until the block fits in it, then released and pressed on the pedal until the wood splits.

Safety precautions at work

When working with a screw cleaver, you must be especially careful - high torque on the cone shaft can be unsafe. Therefore, you should only place the chocks on the screw with your bare hands. When working with gloves or mittens, there is a risk that they will get wrapped around the screw, which can seriously injure your hands or fingers.

The logs should be placed on the wedge in a vertical position. Otherwise, the screw may jam or break.

You should be careful when splitting logs with large knots, as well as logs from the butt part of the round timber. The process in this case can go unpredictably - with jamming of the shaft, sharp turning of the log, throwing large chips to the side, etc. An increased speed of rotation of the cone is also fraught with danger - too high speeds will not make it possible to control the work, so it is better if the number driven shaft revolutions will be within the recommended limits.

To make a cone log splitter with your own hands, you will need minimal skills in working with plumbing tools. One day spent on its manufacture will pay off in the future by saving time and effort.

It is only important to follow safety rules when chopping wood, and then this simple activity will not bring surprises

Advantages and disadvantages

There are quite a few advantages of a wood splitter, regardless of whether a factory-made model is used or the device is made in a home-made environment. Advantages include:

- ease of operation;

- long service life;

- ability to work with 220 and 380 V drives;

- the tool works in any weather conditions, except, of course, in open areas when it rains (the electric motor can burn out);

- the efficiency of the wood splitter is unchanged regardless of the type of wood;

- high splitting power;

- the tool is equipped with double protection, as well as a safety clutch and a special thermal relay;

- low energy consumption - no more than 1.5 kW per hour (gasoline consumption is only 500 grams);

- high speed of work - a log about 70 cm long splits in 1-1.5 minutes;

- performance comparable to that of hydraulic equipment.

Among the shortcomings, one can note only non-compliance with European safety standards, but with proper use and compliance with all operating standards, the risk of injury is no higher than when purchasing more expensive imported units. And certainly working with an inertial rack and pinion wood splitter is fraught with much less danger than chopping wood with an ax by hand

Advantages of a wood splitter

Buying this expensive unit will hit your pocket hard, because you will have to shell out at least 100 thousand rubles. A homemade wood splitter is much more affordable. In terms of functionality, it is no different from an industrial device. A wood splitter, no matter which one - purchased or made by yourself - has certain advantages:

- ease of use;

- durability;

- double degree of protection;

- consumes a small amount of energy;

- low gasoline consumption;

- works in any conditions.

The wood splitter is not difficult to use and is easy to maintain. If you decide to make it yourself, you can get a design that is ideal for you.

Mechanical spring cleaver

Recommendations on how to make a mechanical wood splitter with your own hands come down to the assembly technology of the following design:

- concreting a vertical post

- hanging a horizontal beam on it (hinged upper unit in combination with a lower shock absorber)

- fastening at the free end of the beam of a short post with equipment for splitting at the bottom, weighting material at the top

- installation of a working log on which a log is placed for splitting

Diagram of a mechanical wood splitter with a spring mechanism

Another option for a mechanical cleaver is the design in the bottom photo.

Homemade mechanical splitter based on the principle of a pile driver

It uses the principle of a pile driving machine and uses a minimum number of parts:

- rod for moving equipment - installed in the working deck on which logs will be split

- equipment - a wedge welded to a sleeve sliding along the rod, an upper weighting material put on an additional rod extending from the top of the wedge

To work, it is enough to install the working rod into the hole in the log, place a log on it, lift the weighting agent, and give it acceleration. To increase the efficiency of chopping wood, the lower surface of the bridge connecting the sleeve to the wedge also has a cutting edge, helping to split the wood. The main advantage of the device is its low weight/size and mobility. Large volumes of firewood collection will require significant physical exertion. However, a wood splitter is quite suitable for a bathhouse in the garden or country house.

When you need a little wood

In southern regions and/or for heating utility rooms, little firewood is required. A normal guy could pin them by hand effortlessly, and then let the missus just try not to serve the stopar for dinner. But there is a problem: the correct swing. Without it, swinging a cleaver is exhausting and dangerous, and developing a swing for chopping wood is no easier than skills in using edged weapons; see, for example, how a fighter chops firewood in Kurosawa’s “Seven Samurai.”

A manual mechanical wood splitter, again contrary to popular belief, saves little or no muscle effort when chopping wood, but allows you to do it quite safely without having to master the woodcutter's swing. Its additional advantage is that it can work both in gravitational-inertial and pressure modes. The latter allows you to little by little, but manage the most stubborn chumps of almost any diameter. The main thing is that their cuts are parallel and approximately perpendicular to the longitudinal axis of the log, otherwise the work will be much more dangerous.

Wood splitter device with a sliding ax

The structure of a manual mechanical wood splitter is shown in Fig. The lever arm is taken from 1.5 m; the bigger, the better. Load - depending on its strength, 10-50 kg. If the splitter is fixed motionless, this wood splitter works only as an inertial one: the lever is lifted by the handle and forcefully lowered onto the block. If the splitter can be moved along the lever, then the wood splitter can also be push-type; The lever arm is extended by a pipe placed on the handle.

There are a number of significant nuances in the design of a lever manual wood splitter (shown by arrows on the right in the figure). The first is the cleaver. A simple wedge made from a piece of rail is ineffective and gets stuck in the wood. Such a wood splitter works much better with the Strela cleaver (see above), especially since it can be inexpensively purchased ready-made. The second is the spring; it is the most traumatic element in this design. The spring force is needed such that the free lever with the cleaver in the farthest position is held approximately horizontally. The spring must be secured to the heels so that it does not come off them with the full swing of the lever; It’s better to pass a swinging guide into the spring.

Device of a manual mechanical wood splitter

And lastly, if the lever wood splitter is not rigidly attached to the supporting area, then its front legs must be made no less than the maximum length of the lever arm + double the diameter of the largest block. How to make your own lever wood splitter with improved kinematics, see next. video:

Video: firewood cleaver on a spring

Note: you should not make a mechanical wood splitter with a cleaver sliding along a support, see fig. higher right. You have to hit the butt of the cleaver with a sledgehammer, but it still jams every now and then.

Review of the best models of wood splitters

Over the past few years, many companies have launched the production of various models of household wood splitters of various types and modifications. Most often on sale you can find wood splitters produced by two companies: Artmash and SPRINT. Below is an overview of several models for solving various problems.

If you need to chop small workpieces and require a wood splitter with an electric drive, powered by a 220V network, then a wood splitter produced by the Artmash company with a 2.2 liter electric motor is perfect for this. With. and a generated force of 12 tons.

With a supply voltage of 380V and the need to chop larger workpieces, you should pay attention to SPRINT wood splitters with a 3 liter engine. pp., if engine power does not play a fundamental role, then it is better to consider the model of the Artmash company

Rack wood splitter Artmash 220 V

The same principle applies to gasoline and mixed drives. Almost all manufacturers use 6.5 liter gasoline engines. s., while SPRINT wood splitters are focused on splitting larger workpieces, and Artmash rack wood splitters are more suitable for simple household needs.

What it is

Equipment designed to split wood into logs is called a wood splitter.

For professional harvesting, wood splitting machines are produced in industrial quantities. These complexes are capable of trimming logs into pieces of the required length and splitting them into logs. Finished products are removed from the working area by a conveyor.

Log splitters are used in sawmills to split logs into logs of the required size.

A household wood splitter is intended only for splitting logs into logs, but the log must first be sawed into blanks. The performance and operating time of this equipment is limited. With the help of household wood splitters in the private sector, firewood is prepared for the bathhouse, fireplace and for the winter.

Logs after splitting can be used as fuel for a boiler, fireplace or stove

Design and features of the wood splitter

A wood splitter is a special device for chopping wood, replacing the usual principle of preparing “wooden fuel” (an ax plus brute male strength).

Despite the large number of varieties of wood splitters, they share common characteristics:

- dimensions of the device (can be both industrial and household models);

- splitting power (a value that determines the amount of force that needs to be applied to split a log);

- working length and diameter (To determine the dimensions of a wooden workpiece).

All these parameters must be taken into account when purchasing a new one or when assembling a homemade wood splitter.

Particular attention should be paid to the wedge/cone (the part of the device responsible for splitting the workpiece into two or more parts). It must be made of durable metal and sharpened with high quality.