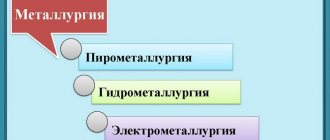

The metallurgical industry consists of ferrous and non-ferrous metallurgy.

Iron ore for the development of ferrous metallurgy is mined in 50 countries of the world, the leaders in production are China, Brazil, Australia, Russia, and India.

The location of ferrous metallurgy is influenced by the following factors:

| 1) | natural resource (focus on territorial combinations of coal and iron ore deposits); |

| 2) | transport (focus on cargo flows of coking coal and iron ore); |

| 3) | consumer (related to the development of mini-plants and pigment metallurgy). |

The largest steel producers are China, Japan, USA, Russia, and Germany. The main exporters of steel are: EU countries, Japan, CIS countries. The main importers of steel are the USA and China.

The location of non-ferrous metallurgy industries is influenced by the following factors:

| 1) | raw materials (in the production of heavy non-ferrous metals: copper, tin, zinc, lead); |

| 2) | energy (smelting light metals is an energy-intensive process, so the location of production of aluminum, titanium and magnesium depends on this factor); |

| 3) | transport (delivery of raw materials); |

| 4) | consumer (use of recycled materials). |

The leaders in copper smelting are Chile, the USA, Indonesia, Russia, and Canada. One of the largest areas of the copper industry, the so-called “Copper Belt,” developed in Central Africa. The main aluminum producers: China, Russia, Canada, USA, Australia, Brazil, Norway. The leaders in tin production are China, Indonesia, Peru, Brazil, Bolivia, and Malaysia. The largest producers of lead and zinc are the USA, Japan, Canada, Australia, and Brazil.

The metallurgical complex of Russia is the main synonym for the well-being and prosperity of our entire state, its confidence in the future.

First of all, it serves as the basis for all existing mechanical engineering. Understanding this, let’s find out which enterprises are included in the mining and metallurgical complex.

These are mainly those industries that mine, enrich, smelt, roll and process raw materials. The company has its own clear structure:

- Ferrous metallurgy - ore and non-metallic raw materials.

- Non-ferrous metallurgy: light metals (magnesium, titanium, aluminum) and heavy metals (nickel, lead, copper, tin).

Ferrous metallurgy centers in Russia

First of all, it should be remembered that Russia has always been and today is the absolute leader in terms of ferrous metal production density. And this primacy is without the right to transfer to other states. Our country confidently holds its position here.

The leading factories are, in fact, metallurgical and energy chemical plants. Let's name the most important centers of ferrous metallurgy in Russia:

- Urals with iron and ore mining;

- Kuzbass with coal mining;

- Novokuznetsk;

- Location of KMA;

- Cherepovets.

The metallurgical map of the country is structurally divided into three main groups. They are studied at school and are the basic knowledge of a modern cultured person. This:

general characteristics

The metallurgical complex belongs to the basic branches of the industry. This industry is engaged in the production of cast iron, steel and rolled products. In addition, it includes :

- mining, ore dressing;

- obtaining auxiliary and nonmetallic raw materials;

- secondary redistribution;

- production of refractories;

- coking of coal.

Ferrous metallurgy products are widely distributed in various sectors of the economy. However, it is of greatest importance for the metalworking and engineering industries, railway transport, and construction. This industry is also closely related to the chemical and light industries.

Rice. 1. Mechanical engineering.

Iron, as a pure chemical metal, does not have high structural parameters. To provide it with increased strength and at the same time ductility, other elements are added to it. Cast iron is an alloy of iron and carbon produced in a blast furnace. Steel is also an alloy of iron and carbon, but with a different concentration, as well as with other elements. Steel is smelted in open hearth furnaces.

The Russian ferrous metallurgy has a rich history. At first, iron ores were smelted in cheese furnaces and furnaces. Factory production of iron became possible in the 17th century, when the first plant with a blast furnace was built in Tula.

By the beginning of the twentieth century, iron and steel industry was well developed in several countries: Germany, USA, Great Britain, Luxembourg and Belgium. However, over time, the share of these countries has decreased significantly. Currently, the overwhelming majority of metallurgical products are produced by developed countries, which specialize in the production of high-quality steel and complex types of rolled products, while developing countries produce low-grade steel and cast iron.

TOP 2 articles

who are reading along with this

Topic Non-ferrous metallurgy (9th grade)

Mechanical engineering complex of Russia

Rice. 2. Metallurgical plant in Luxembourg.

Ural metallurgical base

It is this that is the main and, perhaps, the most powerful in terms of European and world indicators. It is characterized by a high concentration of production.

The city of Magnitogorsk is of paramount importance in its history. There is a famous metallurgical plant there. This is the oldest and hottest “heart” of ferrous metallurgy.

It produces:

- 53% of all cast iron;

- 57% of all steel;

- 53% of ferrous metals of all indicators that were produced in the former USSR.

Such production facilities are located near raw materials (Ural, Norilsk) and energy (Kuzbass, Eastern Siberia). Now the Ural metallurgy is in the process of modernization and further development.

Production Features

Metallurgical production involves a cycle of technological processes that can be carried out either entirely at one enterprise or at different ones. Stages:

- iron smelting;

- steel production;

- rolling production.

Thus, at full-cycle enterprises, all of the above stages are carried out. If the plant produces only rolled products, then such production is called marginal.

At the moment, the world gives preference to the development of small-scale metallurgy, where the production of steel and rolled products takes place at machine-building plants, and this significantly reduces the costs of the final product. However, large full-cycle plants remain in operation.

Neutral

Neutral are materials containing large amounts of Al2O3 and Cr2O3. For example, chromium-magnesite, fireclay bricks.

At high temperatures, the furnace lining interacts with fluxes and slags. If acidic fluxes are used in a furnace that has a lining lined with the main refractory material, then during the melting process acidic slags are formed, which, interacting with the main lining, will destroy it. The same thing will happen if basic fluxes are used in a furnace lined with refractory materials made from acidic oxides. Therefore, in furnaces with an acid lining, acidic slags are used, and in furnaces with a base, basic slags are used.

Carbon materials containing up to 92% carbon in the form of graphite have high fire resistance. The materials are used in the form of bricks, blocks for laying the bottom of blast furnaces, electrolysis baths for producing aluminum, crucibles for surfacing copper alloys.

Problems and prospects

There are problems in every industry. The metallurgical complex is no exception. Among the main problems of ferrous and non-ferrous metallurgy, the following can be identified:

- high energy consumption;

- low capacity of the domestic market;

- high level of depreciation of fixed production assets;

- shortage of certain types of raw materials;

- destruction of the process of reproduction of raw materials and ore reserves;

- technological backwardness and insufficient introduction of new technologies;

- shortage of professional personnel.

But all these issues can be resolved. Russia continues to be a major player in the global metallurgical products market. The share of Russian metallurgy in world production accounts for more than 5% of steel, 11% of aluminum, 21% of nickel, and more than 27% of titanium. The main indicator of the competitiveness of Russian metallurgy on the foreign market is that the country maintains and even expands its export capabilities.

Test on the topic

- /10

Question 1 of 10What products are not produced by ferrous metallurgy?

Start test

Hall of Fame

To get here, take the test.

- Elena Ermakova

10/10

- Lyudmila Akanaeva

10/10

- Elena Tyaglivaya

7/10

- Zhenya Shalabanov

7/10

- Natalia Kirik

9/10

Application area

Non-ferrous metal is used to create parts for cars, ships and aircraft. They are used to make metal structures, jewelry, and art objects. Alloys of non-ferrous metals are used in industry and medicine. With their help, equipment, hypodermic needles, and instruments for performing operations are created. Iridium is taken during radiation therapy, and gold and platinum are used in dentistry.

Ferrous metals are actively used in the food industry, in the creation of electrical engineering and energy generation. In the construction of houses, industrial buildings and cars, they are used more often than non-ferrous metal. Some alloys are specially created for harsh operating conditions, adding impurities that will make the material more stable, more reliable, etc.

Areas of application of ferrous metals

The availability and properties of the material have become the main reason for its demand in the market. Today, ferrous metal is widely used in the following industries:

- automotive industry;

- food industry;

- electrical engineering and thermal power engineering;

- industrial and civil construction;

- production of various types of products and others.

At the same time, a number of alloys with unique properties can be used in strict operating conditions. This applies to production under sudden temperature changes, in aggressive environments, and so on.

Notes

Mining Mining of ore raw materials | Extraction of non-metallic raw materials | Iron ore industry | Mining and chemical industry Fuel Gas | Oil | Peat | Coal Ferrous metallurgy Ferrous metal production | Pipe production | Production of electroferoalloys | Coke-chemical | Recycling of ferrous metals | Production of hardware Non-ferrous metallurgy Production: aluminum | alumina | fluoride salts | nickel | copper | lead | zinc | tin | cobalt | surma | tungsten | molybdenum | mercury | titanium | magnesium | secondary non-ferrous metals | rare metals | Industry of hard alloys, refractory and heat-resistant metals | Mining and beneficiation of rare metal ores Mechanical engineering and metalworking Heavy | Transport | Railway | Shipbuilding | Ship repair | Aviation | Aircraft repair | Rocket | Tractor | Automotive | Machine tool industry | Chemical | Agricultural | Electrical | Instrumentation | Exact | Metalworking Chemical Mining and chemical | Basic Chemistry | Paintwork | Household chemicals industry | Soda production | Fertilizer production | Manufacture of chemical fibers and threads | Production of synthetic resins Chemical-pharmaceutical Petrochemical Tire | Rubber-asbestos Lesnaya Woodworking (Sawmill, Wood and board, Furniture) | Pulp and paper | Timber Chemical Construction materials Cement | Reinforced concrete and concrete structures | Wall materials | Non-metallic building materials Glass Porcelain-faience Lightweight Textile | Sewing | Tanning | Fur | Shoe Textile Cotton | Wool | Linen | Silk | Synthetic and artificial fabrics | Hemp-jute Printing Food Sugar | Bakery | Oil and fat | Butter and cheese making | Fish | Dairy | Meat | Confectionery | Alcohol | Pasta | Brewing and soft drinks | Winemaking | Flour mill | Canning | Tobacco | Solyanaya | Fruit and vegetable

Principles of business location

Enterprises of the mining and metallurgical complex are not located randomly. They depend on the following factors of metallurgy location:

- Raw materials (physical and chemical characteristics of ores);

- Fuel (what type of energy must be used to produce metal);

- Consumer (geography of placement of raw materials, main energy sources and availability of transport routes).

Rice. 2 Fuel factor of metallurgy location