Do-it-yourself vibrating machine for cinder blocks

Making cinder blocks at home is a very profitable investment. Especially if you make a vibrating machine for cinder blocks for this work with your own hands. In this case, you will be able to save on the purchase of a factory vibrating table, without any loss in the quality of the resulting product.

Everyone knows that cinder block is a building material for any time. Houses made from it are strong and reliable, and the material itself is harmless and has excellent performance properties.

Creating a Form

First of all, you need to decide what kind of machine you need.

If you want to build a garage or temporary shed, then a machine with two or even one mold is enough. If you are going to organize a small business, then you will need a more productive machine, at least for 3-4 matrices. Cinder block dimensions

The most important part of the machine is the shape. The remaining parts and assemblies are additions that allow you to perform various manipulations with this form.

For example - filling, lifting, compacting the solution, moving, etc.

When producing cinder blocks, the plant uses standard iron molds, as well as professional equipment that presses concrete into a mold under a weight of several tons. Do-it-yourself cinder block molds are most often made from wood. There are many types and designs.

In essence, the form is a container into which concrete is poured and where it remains until it hardens completely. It should be noted that the forms must be collapsible so that the finished cinder block can be easily removed. In most cases, they are even made without a bottom, and a plate of material to which concrete does not stick is placed under the bottom.

The easiest way to create voids in a block is to immerse plastic water bottles or glass champagne bottles, which is preferable, into soft concrete at the desired location. But, if you want to set up a small production of cinder blocks with your own hands, then the void formers must be fixed in the mold.

Sketch of a wooden mold

Made of wood

First of all, you will need planed boards, the width of which will correspond to the height of the cinder block. Then it is necessary to make the outer cross members, which will be connected to the longitudinal boards with “sliding grooves”.

Then cuts are made from the inside of the longitudinal boards at a distance equal to the length of the cinder block. The transverse grooves should have a depth of 7 - 8 mm. The width of the cut corresponds to the thickness of the separating plates, which can be made of iron, getinax, textolite.

Sketch of a form filled with solution

The plates can be made from other sheet material, the main thing is that it is smooth. The drawing above shows how to make wooden molds for cinder blocks with your own hands. It is advisable to open the mold details with any oil paint. This will make it easier to remove the cinder blocks from the mold.

Please note that the sketch shows smaller dimensions than a standard cinder block requires. Before creating the mold, you can make your own cinder block drawings

This procedure will not be superfluous and will not require much work.

The above forms are used without a vibrator. The solution in them should be poured into a softer solution with a higher water content. However, with a little effort, you can create a more advanced vibrating machine.

Form-stretcher

The molds for the vibrating table look a little different. Handles must be attached to the sides so that two people can lift them and place them on the vibrating table. There should be two cones at the bottom of each cell.

You should not make a mold with a large number of cells, as such a stretcher will be very difficult to lift. Such forms cannot be disassembled, and the cinder blocks from them are shaken out by tipping them over. The internal surfaces of the mold must be smooth so that the products can be easily removed.

The photo shows a metal form

Made of metal

When creating a machine for making cinder blocks with your own hands, you will need a steel sheet 3-5 mm thick. Shape elements should be cut out of it based on the size of the cinder block. The standard is 190x190x390 mm; in accordance with these dimensions, do-it-yourself cinder block drawings are made. The height of the form should be 5 mm above the block so that you can pour the concrete mixture and press it on top with a plate

Since the cinder block must be hollow, it is important to make the void formers correctly. The easiest way to use pipes for these purposes is

Please note that they need to be given a conical shape. Thanks to this, the product will be easily shaken out

Blanks can be ordered from a turner so that he can remove a few mm from one side of the pipe. Sometimes rectangular void formers are made. Their shape doesn't matter, the main thing is that they are conical. Keep in mind that the cinder block should be no more than 30% hollow.

A wooden or rubber seal should be made at the bottom of the mold along the perimeter to avoid deformation of the edges of the matrix. You can also weld metal plates 20 mm wide along the edges.

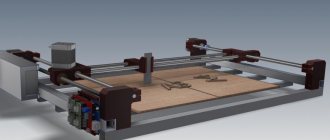

Vibrating table of the simplest design

Classification of vibration machines

This subtype of construction equipment is practically unfamiliar to the mass consumer, but brick making machines are manufactured by many domestic companies. There is no single standard regarding the principles of structural calculations, but a classification of such units exists, even if only conditionally. Vibrating machines are divided according to the following characteristics:

- by control method (from manual to fully automated);

- by the number of blocks produced per one working cycle;

- by type of product produced (hollow/monolithic);

- according to the degree of convenience and practicality in operation.

From the point of view of the last factor, industrial brick making machines are divided into three subclasses. The simplest and most structurally primitive equipment involves mainly manual labor; with its help, one cinder block can be produced per working cycle. This productivity is relatively low, because you can only make 50 building blocks per work shift.

Devices that allow the production of several cinder blocks in one cycle are more productive, but require the use of physical labor and the involvement of several workers in the technological process.

The most important part of the machine is the shape

A professional block vibrating machine can produce more than three finished products per cycle. Being equipped with many additional devices and accessories, a high-performance vibrating machine significantly facilitates the work process, requiring the use of minimal amounts of manual labor.

The cost of such devices can vary greatly, because they are aimed at different categories of consumers. Budget category machines have such a simple design that some experts prefer to make such units themselves. At the same time, the technical characteristics of homemade vibrating machines are not inferior to factory ones in terms of important operational characteristics.

Making a vibratory pressing machine

Adding a slag concrete vibrator to the above-described production scheme provides the opportunity to significantly improve the quality of products and at the same time speed up the process.

It is not difficult to assemble such a machine; if you follow all the recommendations, this equipment will work no worse than its factory counterparts. The simplest version of a vibrocompression machine involves the use of a homemade matrix, a vibrator and a hand press. To reduce physical stress, the manual press can be improved by using a lever system.

Drawing of a homemade machine with a vibration motor for making cinder blocks and expanded clay blocks

A set of tools and materials necessary for the manufacture of a vibration machine with a metal mold:

- welding machine;

- Bulgarian,

- a set of keys;

- vice;

- sheet metal with a thickness of at least 3 mm;

- pipes for creating voids with a diameter of 8-10 mm;

- channels, strips of metal;

- low-power electric motor (up to 1 kW);

- connecting elements (bolts, nuts, cotter pins).

The sequence of actions when making a homemade vibrating machine:

- Using a grinder, we cut out the walls of the matrix from sheet material. If the mold is intended for the manufacture of several block products, we provide for the presence of the corresponding number of partitions in the matrix.

- We cut off the required number of blanks from the pipe (at the rate of 3 pieces per brick), the height of which should be 3-5 mm less than the height of the matrix. The taper of the pipes is achieved using the following technique: cut the pipe in half and crimp the workpiece in a vice (for thick-walled pipes you can use a lathe).

Drawing for the manufacture of a machine with lightweight extrusion of building blocks

- Each pipe section is welded tightly on both sides.

- We weld the plates to the pipes, connecting them together. For fastening to walls, it is better to provide a removable connection, which will allow, if necessary, to remove the limiters for the production of monolithic cinder blocks.

- Using welding, we attach bolts for attaching the electric motor to the long outer wall.

- We weld a metal apron on top of the form.

- We make a press in the form of a thick-walled plate, provide for the presence of holes with a diameter slightly larger than the smaller diameter of the limiter pipes (so that the press enters the matrix at a distance of no more than 50 mm).

- We weld the handles to the press.

- We install the motor. We weld an eccentric onto the electric motor shaft (ordinary bolts are suitable as material for the eccentric; they are welded parallel to the shaft and leave room for screwing on the nuts, which will allow you to adjust the amplitude of vibrations).

- We thoroughly clean the device, polish the surfaces, and paint the homemade unit for the blocks.

Homemade machines with a vibrating device

Homemade machine diagram

Vibrating machines for making cinder blocks are more advanced equipment. Making blocks using them is faster and more convenient, since you don’t have to wait for the solution to set. In this case, the concrete solution is prepared more rigid and thick, it should have a slight shrinkage.

Technically, this is implemented in two ways:

using a vibrating table;

Vibrating table

equipping the mold itself with a motor, on the shaft of which an eccentric with a displaced center of gravity is installed.

A machine with an eccentric is more convenient for producing large quantities of material, since it allows you to obtain a finished block in one go without turning over.

Homemade machine according to the “laying hen” scheme

Machine – “laying hen”

The given drawing of a machine for making cinder blocks is one of the simplest.

Its design includes the following basic elements:

- molding box - matrix (it has no bottom);

- vibrator on the side wall;

- drawer handles designed for easy removal without damaging the impression shape;

- replaceable sets of pressure plates;

- void formers for various void shapes.

The current standard provides for the established dimensions of one such block - 39 x 19 x 18.8 cm. In this case, the voidness should not exceed 30%.

Matrix manufacturing

- Sheet metal is taken (from 3 mm);

- A shape is cut out of the sheet to the size of one block (5 cm is added to the indicated dimensions for compaction);

- A through box is formed (no bottom);

- Special strips welded at the ends give the box greater stability. For this purpose, profile pipes with a small cross-section are used;

- The base of the matrix is upholstered with sheet rubber, which will serve to protect the lower edges of the matrix from deformation;

- An apron is formed for the edging, which will prevent the solution from spilling when filling the mold;

- Handles are attached.

Composition of sand blocks

What a sand block is was discussed earlier. Sand block is a universal building material for walls and partitions in the house, the main materials for which are sand and cement.

In the manufacture of sand blocks, cement acts as a binder. Some craftsmen replace it with clay, gypsum or lime. However, it is still not worth giving up adding cement completely.

Sand is used as a filler in sand blocks

It is important that it is free of impurities in the form of earth or coal. An alternative to sand can be slag or granulation

The composition of sand blocks and its proportions are as follows:

- One part cement;

- Nine parts sand or slag;

- Water.

The calculation of materials for the manufacture of sand blocks is approximately as follows. From one bag of M500 cement, approximately 30 sand blocks are obtained. Moreover, to make one sand block, you will need approximately 15 kg of filler.

If we talk about large-scale production, then with 1000 kg of cement and 10,000 kg of sand, you will get approximately 600 sand blocks. This amount of material is enough to build a garage, the process of which has already been discussed on the website.

Sand block sizes

The weight of sand blocks, depending on their size, varies between 8-40 kg. In this case, the sizes of sand blocks can be different:

- Length 190-500 mm;

- Height 185-300 mm;

- Width 90-500 mm.

These dimensions are typical for wall sand blocks.

As for the fundamental blocks that are used when laying the base, their dimensions are much larger:

- Width 300-600 mm;

- Length 880-2380 mm;

- Height 280-580 mm.

To make sand blocks at home, you will first need to assemble molds that are installed on a vibrating table or other homemade device. To assemble forms for sand blocks, it is best to use wood, and the forms themselves should not have a bottom so that they can be easily disassembled into parts.

In addition, a distinctive feature of sand blocks is the presence of 2-3 voids inside. To organize them, you can use a bottle with which the finished mixture is pressed, or you can weld metal molds with two or three pieces of thick pipes inside.

Forming methods

Do-it-yourself bathhouse made of expanded clay concrete blocks: step-by-step instructions and the best projects with 52 photos and 2 videos

Factory molds for preparing cinder blocks are made of reinforced concrete or steel. Such parts can easily withstand the weight of a large volume of solution. As for do-it-yourself molds, they are most often made of wood or steel sheets. Such elements largely play the role of special formwork.

To save on raw materials and free time, molds are mainly assembled without a bottom. You can put a simple film under them. Thanks to this method, the entire process of block formation can be significantly simplified. It must be remembered that the forms themselves must be made of perfectly smooth wood parts. The working surface will be a concrete base, a table with a flat and smooth tabletop, or a sheet of iron, which also does not have any defects.

Let's take a closer look at how to make a mold for slag blocks:

- you need to choose sanded boards 14 cm long (the width should be a multiple of this parameter);

- then, using a hacksaw, you need to separate the segments, which will then play the role of transverse partitions;

- then you will need to connect the segments with longitudinal elements to form a rectangular frame;

- Next, you need to cut a sheet of steel or any other material with a smooth surface into separate plates measuring 14x30 cm;

- in the inner part of the resulting structure, cuts are made that will act as grooves, the width of which is equal to the dimensions of the dividing strips;

- then the sections responsible for the separation are fixed in cuts, creating a mold for the production of 3 or more slag blocks.

In order for the resulting container for hardening the solution to serve as long as possible, at the final stage it is recommended to coat both metal and wood structures with oil-based paint. This form is suitable for preparing cinder blocks, the dimensions of which are 14x14x30 cm.

Equipment for the production of foam blocks

A machine for producing foam blocks at home is a pressure unit.

Let's look at the 6 main reasons why you need to choose this particular unit:

- Unlike the classic foam concrete production scheme, in the installation the entire process is carried out under pressure. Therefore, when unloading the solution, the pores in it are much larger, which in turn will make the blocks lighter;

- Using a conventional pressure plant, you can easily produce foam blocks and foam concrete for various needs:

- Foam blocks of various sizes and configurations, which are suitable for the construction of low-rise buildings;

- Foam concrete mixture used to fill lightweight brickwork (for insulation and sound insulation);

- Small blocks and slabs that are used for internal and external wall insulation.

- You can produce foam blocks and foam concrete even in a small room or in the open air - the installation itself occupies an area of less than 1 m²;

- Using a pressure unit, you can significantly save on hired labor. You will not need people to supervise the operation of the foam generator;

- Even a child can be taught how to operate a pressure unit - with the help of this unit, producing foam blocks has become very simple;

- The production of foam blocks and concrete using a pressure setting is not only a cheaper way to build a house, but also an opportunity to earn good money.

Vibration pressing and vibration casting

Diagram of a vibrating table and sand sifter.

Vibrocompression is the compaction of a semi-dry concrete mixture when the latter, while in a mold, is subjected to pressure from above and, at the same time, vibration loads. Production using this method is easily automated. The production process itself is as follows:

- a semi-dry concrete mixture is placed into the mold (matrix);

- the punch, vibrating together with the frame, begins to put pressure on the mixture;

- after the mixture is completely compacted, the vibrations stop;

- the punch and then the die rise up, leaving the finished product.

This method was the impetus for the creation of a wide range of construction products. This is not a complete list of these products: building blocks, paving slabs, panels, columns, bricks, curbs, pillars, etc. All of these products have the following positive properties:

- strength;

- wear resistance;

- high structure density;

- frost resistance;

- resistance to external influences.

Vibrator table diagram.

Vibration casting is the production of construction products by vibrating the concrete mixture on a special device, a vibrating table. The concrete mixture is poured into a rubber or plastic mold and placed on a continuously vibrating surface of a vibrating table. To prevent knocking from the walls of the mold, the vibration amplitude must be constant. It is necessary to strictly monitor the filling of the molds with the mixture, otherwise marriage is inevitable.

After vibration treatment, the molds are removed and sent to a warm place to stand (dry) for 46-47 hours. Then the process of stripping begins: the products in the molds are placed in a water bath, and then the products are knocked out of the molds using special devices. The process is very difficult to automate. To increase frost resistance, it is necessary to add plasticizers and modifiers, and increase the amount of cement.

Vibratory casting is more often used in the production of paving slabs, especially colored ones, and paving stones. It is used for paving squares and sidewalks, and laid on pedestrian paths. Such products have a presentable appearance, but do not have very high performance qualities. In winter, they are covered with a thin layer of ice and can crack under the influence of frozen water. In contrast, the same qualities of tiles made by vibration pressing are much higher.

Cinder blocks: composition and proportions

The cheapness of cinder blocks is due to the use of a wide range of materials as filler, many of which are waste from various industries. Accordingly, there are several recipes for mixing mortar, but cement remains the main component. Builders prefer to use Portland cement M400. If there are cement of other brands, the proportions will be slightly different: brands with a smaller number will require an increase in cement content by 15-20%, the use of higher quality cements allows you to reduce its content. In addition to cement, the solution for cinder blocks includes a filler and a plasticizer. Available materials can be used as filler:

- sawdust;

- dropout;

- ash;

- construction waste, including broken bricks;

- sand;

- small stones, gravel.

Plasticizer is an optional additive, but it improves certain properties of the solution. There are plasticizers that increase the moisture and frost resistance of the mixture, which is important for areas with harsh climates. You can find additives that improve the strength characteristics of the solution, prevent the formation of cracks, and accelerate the hardening process of the working solution. The percentage of plasticizers in the mixture is insignificant: 3-5 grams of the additive is enough to produce a unit of product.

The production technology itself and the composition of cinder blocks provide for the fact that the blocks use special devices and machines that can be made with your own hands

The name “slag blocks” was assigned to this building material, since in Soviet times it was mainly produced from coal slag, a waste product from metallurgical production. Today, other material can act as a filler, but as an example, we will give the proportions of the slag mixture:

- three parts slag;

- one part plaster;

- water.

The slag mixture is moistened before use. Preparing such a solution takes 5-10 minutes, while one cubic meter of the finished mixture will require approximately 340-360 liters of water. The addition of plasticizers improves certain characteristics of the mixture, increasing the cost of the cinder block. When using dyes, it is possible to obtain products with different colors, which improve the aesthetic perception of the building.

Basic requirements for cinder block production

Standard product dimensions are 180*90*390 mm, each block usually has 3 holes

The standard dimensions of the product are 180*90*390 mm, each block usually has 3 holes. The production technology involves the use of M400 type cement mortar, as well as the addition of the required proportion of blast furnace slag and sand. Cinder block production involves hand-making and the use of a cinder block machine. It is worth noting that one bag of cement mixture allows you to make about 36 blocks. The product must be in perfect shape, otherwise small irregularities or deviations can lead to poor wall laying. To obtain the correct geometry, the cinder block mold is filled to the end with a small slide; during vibration, the solution will shrink and lie flat. The solution is prepared in the following proportion:

- 7 parts slag;

- 2 parts sand;

- 1, cement parts;

- no more than 3 parts water.

Additional components you can add are ash, broken brick, sawdust or gypsum. But to increase the moisture resistance and strength of the product, you can add a plasticizer (see example in the photo), only 5 grams is enough.

If you are planning to make building material yourself, it is important to know that it is better to carry out the production process in a room where the resulting material can be properly dried. It is advisable to choose a location for the production of cinder blocks close to sand quarries or cement plants.

It is advisable to choose a location for the production of cinder blocks close to sand quarries or cement plants.

Description of manufacturing technology

Many private developers often wonder: is it possible to create high-quality cinder blocks on their own and how to do it? In fact, the procedure does not require special skills or complex algorithms. If you follow the basic recommendations and follow the instructions, the action can be completed in a short time.

Conventionally, the production procedure is divided into three stages:

- Preparation of concrete mortar, which consists of water, cement and any screenings. If necessary, it is supplemented with plasticizing additives, which have a positive effect on the quality indicators of the finished product, increase water resistance and resistance to low temperatures.

- Pouring the prepared composition into special molds. The concrete mixture is compacted through a vibration process. To do this, you need to purchase professional equipment or make a machine for the production of cinder blocks on your own.

- The last stage is to harden the blocks. At natural temperature conditions, this action takes from 36 to 96 hours. During this time, the mixture takes on a suitable shape and becomes ready for further processing. To speed up the process, special substances can be added to the composition.

If you intend to start producing high-quality building materials at home, be prepared to stock up on:

- Vibrating machine.

- Suitable materials.

- Relatively flat area.

- Access to an electrical network with a voltage of 220 V.

First you need to find a high-quality machine for making cinder blocks. Fortunately, these days such a purchase is not something difficult to obtain, since these devices are sold in many hypermarkets and construction equipment stores. And the device is easy to create with your own hands. However, if we are talking about mass production of the material mentioned, then it is better to give preference to a professional machine with high productivity.

Drying

Drying is another important step in the production of slag blocks. The production process itself usually takes about 2-4 days. Sufficient strength characteristics that allow you to proceed to the use of blocks are usually achieved after 28 days. This is exactly the amount of time needed to obtain high-quality building material suitable for carrying out certain works. Cinder blocks can also dry naturally. Typically, this process takes place using a simple method of producing materials (in conventional forms).

To dry cinder blocks, special chambers are often used to prevent cracking during the hardening process. To prevent the blocks from becoming cracked, they must be moistened from time to time. This process is especially relevant if the production process is carried out in hot weather.

How to make a matrix with your own hands

The mold for making a cinder block is the most important thing in the process and the most important thing in the configuration of the machine. Without the correct shape, the whole point of making a cinder block yourself becomes a useless circle of Skillful Hands. The more irregularities and voids there are in the cinder block, the longer the wall will take to build, and the poorer the quality of the masonry will be. During the manufacturing process on a vibrating table, slag concrete tends to shrink, and this is quite natural, since the whole point of the vibrating table is to compact the solution as much as possible, driving all the air out of it.

If the matrix does not take this into account, the cinder blocks will be of different sizes, and it will be very difficult to make normal masonry from them. Therefore, professional machines also use a press to quickly stabilize the mixture. The matrix drawings and the step-by-step process of its manufacture require no explanation. Everything is clearly visible in the photo, and by observing these dimensions, you will get the perfect cinder block.

Advantages of cinder blocks

The advantages of such building materials are as follows:

- such blocks are excellent heat insulators. Walls built from them are warmer than their counterparts made from traditional materials;

- due to their large size, the construction process is much faster than when using conventional bricks;

Cinder blocks are large in size

- the next advantage follows from the previous one - large dimensions allow you to use less cement mortar;

- is lightweight and does not cause excessive weight to the building;

- its price is low;

- You can make such blocks at home and this will require a minimum of equipment.

Features of the material

Cinder block is a building material that has proven itself to be one of the most durable and unpretentious. It has considerable dimensions, especially if you place an ordinary brick next to it. You can make slag blocks not only in a factory setting. Some craftsmen undertake this work at home. If you strictly adhere to the technology, you get high-quality and strong blocks from which you can build a house or any outbuilding.

If a decision has been made to independently produce such products, then a number of its features should be taken into account.

- Cinder block is a fireproof material. It does not ignite itself, and does not intensify an existing flame.

- Really good quality blocks make long-lasting and sustainable homes/outbuildings. Such buildings will not be harmed by harsh climatic conditions, hurricanes, or constant gusty winds.

- Repairing cinder block buildings does not require extra effort and free time - all work can be completed in a short time.

- Cinder blocks are also distinguished by their large sizes, thanks to which buildings made from them can be erected very quickly, which pleases many builders.

- This material is durable. Buildings built from it can stand for more than 100 years without losing their previous characteristics.

- Another feature of cinder block is its soundproofing component. Thus, in dwellings made from this material there are no annoying street noises.

- The production of cinder blocks is carried out using various raw materials, so it is possible to select the optimal products for any conditions.

- What distinguishes cinder block is that it is not subject to attacks by various kinds of parasites or rodents. In addition, it does not rot, so it does not have to be coated with antiseptic solutions and other similar compounds designed to protect the base.

- Despite their decent dimensions, such blocks are light in weight. This feature is noted by many masters. Due to their lightness, these materials can be easily moved from one place to another without calling a crane. However, it must be taken into account that some types of such products are still quite heavy.

- Cinder block is not afraid of low temperatures.

- These blocks are distinguished by their high heat capacity, thanks to which they make cozy and warm homes.

- Temperature fluctuations do not harm the cinder block.

Cinder block buildings are usually decorated with decorative materials to give a more aesthetic appearance.

However, it is very important to remember that the cinder block cannot be covered with ordinary plaster (any “wet” work with this material should not be carried out). You can also use a special decorative block, which is often used instead of expensive cladding. When working with cinder block, it is important to take into account one important feature - this material is characterized by high water absorption, so it must be protected from contact with moisture and dampness

Otherwise, the blocks may collapse over time. Unfortunately, the geometry of the slag blocks leaves much to be desired. That is why, when laying floors from such material, you will have to constantly adjust individual elements - trim them and saw them. Cinder blocks have a relatively low cost.

Equipment overview

In order to produce foam concrete, it is not necessary to buy new equipment - used or mini installations can cope with the required volume. Now, in order to understand the equipment in more detail, we will consider each element of the system separately.

Pressure setting

Pressure installation - unique equipment

This unit is a machine for producing foam blocks with your own hands. Foam production and mixing are carried out using an activator built into the mixer.

Main advantages of the device:

- Using a mobile unit, you can deliver concrete directly to the work site;

- Reliability in operation;

- The resulting concrete is more cellular, and blocks prepared from this solution are lighter;

- No special qualifications are required to operate the unit;

- Ideal option for private developers or small construction firms.

Vibrating sieve

Vibrating sieve is a guarantee of high quality

Another unit without which you are unlikely to be able to prepare a high-quality foam block. It is designed for sifting and sorting sand and cement. The device consists of a mesh, a frame and a vibration motor powered by electricity.

When turned on, the vibration motor causes vibrations in the block with the sieve and the sand poured into it is sifted. Then it is poured along the tray into a general collection.

The main advantage is that the resulting homogeneous fraction of cement and sand can significantly improve the quality of the foam blocks you produce.

Compressor

The new compressor will last a long time

Another unit useful in many areas of construction. The single-stage, direct-drive piston tool is used with a fairly diverse selection of accessories and other air tools. In the production of foam concrete it is a mandatory element of the system.

Main advantages of the compressor:

- The oversized and lightweight compressor can be easily transported to the work site with your own hands;

- Aluminum heads and cylinder block (cast iron) with large cooling fins help to increase the service life of the unit;

- The electric motor is equipped with special protection against overheating;

- It is possible to adjust the outlet pressure.

Foaming agent

Without a foaming agent, you will not be able to prepare foam concrete. This mixture is highly stable (holds foam), which allows the finished mass to be transported over long distances without harm to the solution.

Depending on the desired density of the foam blocks, the foam concentrate consumption can range from 0.25 l to 1.2 l per 1 m³ of solution.

The foaming agent itself is sold in plastic barrels with a volume of 220 liters.

Specifications

Do not forget that in addition to the equipment and foam concentrate, you will need to carefully read the technical specifications of the production.

Fully assembled system

You have two good reasons for purchasing TU:

- With the help of technical specifications, you can familiarize yourself with the recipe for producing high-quality foam concrete;

- You simply cannot do without them if you decide, in addition to your own construction, to sell blocks to private developers. After all, to sell foam blocks you will need a special quality certificate for the products being manufactured. In order to receive this document, you will be required to provide the certification authorities with a sample of your product and a copy of the specifications according to which it was prepared.

Which is the best block machine to use?

Developers who decide to independently produce cinder blocks for the construction of walls are faced with the question of choosing equipment. It is not always possible to rent a machine for the production of building blocks, especially in small towns. Many people decide to make the equipment themselves. Depending on your financial capabilities, you can choose the following options:

- the simplest design that allows you to produce wall blocks at home at minimal cost;

- a modernized version of the unit, equipped with a compaction device and additional mechanisms.

It is difficult to give a definite answer as to which block production machine is preferable to use. It all depends on the number of blocks that need to be produced and financing possibilities. Let us dwell on the features of each unit.

Simplified block machine

To make cinder blocks on your own in a reduced quantity, it is not necessary to make a mechanized unit, use a vibrator, or additional mechanisms. The manufacturing process using simplified technology can be carried out in special forms.

Simplified block machine

Procedure:

- Assemble the molds and coat their inner surfaces with waste oil.

- Pour cinder block mixture into collapsible molds.

- Leave for 3-4 hours until the solution hardens.

- Disassemble the containers and carefully remove the blocks.

- Allow to dry indoors.

If it is necessary to produce hollow products, it is advisable to use ordinary drink bottles to form cavities. A simplified machine for the production of blocks, which is a container of the required size made of wood or steel, can be manufactured at a minimum amount of cost.

Modernized machine for the production of building blocks

With an increased need for cinder blocks for the construction of a large building, you can make a more complex machine for producing blocks, equipped with special devices:

- vibration mechanism. An electric motor is used as a vibration motor, with an eccentric located on the drive shaft. The drive power depends on the size of the mold, the mass of the slag concrete solution and is 0.5–1.5 kW. Under the influence of vibration, the slag concrete mass is compacted, the material is evenly distributed throughout the entire space of the mold, and air inclusions are removed. As a result of compaction, the specific gravity and strength of cinder block products increases;

- lifting device. It is designed for accelerated extraction of finished products from molding containers. There are many design solutions to speed up and facilitate the removal of blocks. In the simplest version, it is enough to weld handles of any shape to the molding container, by pulling which you can remove the hardened block. Using ready-made drawings, you can independently assemble a lever mechanism from scrap materials.

Modernized machine for the production of building blocks

The shape used in this unit must correspond to the size of the cinder block that is planned to be made. In most cases, products are manufactured of standard dimensions - 0.4x0.2x0.2 m. The molding container must have a height increased by 4m5 cm so that the molded block after compaction has the required dimensions. To simulate cavities, pipe scraps of the required diameter can be welded to the bottom of the container.

Homemade vibrating table and its application

A vibrating table is a movable table with a vibrator attached to it - the already familiar electric motor with an eccentric.

Its purpose is the production of paving slabs, figures, statues, etc. by vibration casting method, as well as from composite blocks. To make building blocks, molds filled with mortar are placed on the table surface. The process of forming blocks is approximately the same as on a vibrating machine. Champagne bottles are sometimes used to form voids.

When producing paving slabs and other building and architectural elements using the vibration casting method, appropriate forms are installed on the table. The concrete recipe for making colored paving slabs is as follows:

- sand – 1 part;

- cement M500 – 1 part;

- crushed stone with a granule size of 10-20 mm – 2 parts;

- dye – 5%;

- plasticizer – 2%.

The technology of its production was described above.

We hope that the descriptions given will help not only to make a homemade vibrating machine or vibrating table, but also to organize the production of the necessary concrete products with their help.

Table

Taking into account the total weight of the matrix and concrete solution, as well as vibration during the manufacturing process of the blocks, only metal is used as a material. The photo shows several possible table options.

Its task is to use vibration to ensure compaction of the solution, which achieves the required strength of the artificial stone. The method of “controlling” the vibrating table is manual or electric.

Engine power does not have much effect on vibrations. It is enough to take a product from a household appliance, for example, a used washing machine. The main thing is to ensure an optimal shift in the center of gravity, which causes the tabletop to oscillate. How to do this depends on capabilities and skills.

The first is using bolts that are located perpendicular to the shaft axis. The amplitude and speed of vibration are regulated by screwing the nuts on them.

The second is to install a washer whose center of gravity is shifted.

If difficulties arise related to the process of constructing a specific model, it would be useful to read articles on the relevant topic (for example, what is an eccentric and the principle of its operation), and remember the lessons of physics.

The tabletop is attached to the frame using springs. They are easy to pick up, for example, from decommissioned equipment. Sofas are clearly not suitable, since they must be quite hard and durable.

Since it is much more convenient to work with a mobile machine, the frame should be equipped with wheels.

Types of building blocks

Brick is still the main material in the construction of high-rise buildings, but for low-rise construction it is cheaper to use other building materials. If you exclude wood, which is now expensive, the choice will still be varied. Modern wall materials are made from:

- foam concrete;

- slag concrete;

- aerated concrete;

- expanded clay concrete.

Block characteristics comparison table

As a filler for cinder blocks, a variety of and sometimes exotic materials are used, which are industrial waste: screenings, broken glass and bricks, sawdust, wood chips.

Let's first consider how expanded clay blocks and cinder blocks are made independently, as the most budget-friendly among all the above building materials.

Block production process

Vibrating machine for block production.

Composition of concrete mortar for such blocks (in parts):

- slag (preferably blast furnace, without ash and coal) – 14 parts;

- coarse sand (expanded clay) – 4 parts;

- gravel with granule size 5-15 mm – 4 parts;

- cement (M400-M500) – 3 parts;

- water – 3-6 parts.

Slag, coal combustion waste, brick waste, expanded clay, perlite, crushed stone, sawdust, etc. can be used as filler.

It is important to monitor the water content in the mixture. The solution should crumble when falling to the ground, but when squeezed in a fist, it should come back together

First, the dry ingredients are mixed, and only then water is added to them.

The sequence of operations when making blocks on a vibrating machine:

- a solution with a slide is placed in the mold;

- the vibrator is turned on for 3-5 seconds, the solution settles;

- if there is not enough solution, add it, insert the punch (clamp) and turn on the vibrator again;

- molding is completed when the clamp sits on the stops;

- turn on the vibrator for another 5-10 seconds and remove the form while the vibrator is still running.

The blocks should dry within 5-7 days, but it takes about a month to completely harden.

How to prepare a solution for a machine for making cinder blocks

It is important to prepare the solution correctly so that the cinder block made at home has the required properties. Necessary materials:

- coal ash or metallurgical slag;

- sifted sand;

- fine-grained crushed stone or screenings;

- cement M400 or M500.

The name itself speaks for itself of what this block is made of, and it is made from coal slag, which remains after heating boilers in a coal boiler house.

Use the following recipes:

- mix ash with cement in a ratio of 7:2, add water until it reaches a plastic consistency;

- mix the ash and screenings in equal proportions, add 10–12% of the total volume of cement, dilute with water.

When mixing, follow proven recipes.

Cinder concrete blocks - characteristics and purpose of the material

One of the reasons for the increased popularity of slag-filled concrete blocks is the low cost of the material. It is associated with the use of waste from metallurgical enterprises - slag - in the production process.

Along with traditional components, Portland cement and river sand, various aggregates are used:

- brick break;

- crushed stone screening;

- granite chips;

- various slags and ash;

- expanded clay particles.

The use of cinder blocks in construction allows you to reduce the cost of constructing walls several times

The manufacturing process is carried out in various ways:

- industrial method at specialized enterprises with processing of products in drying chambers;

- at home from available raw materials, using a self-assembled machine for making blocks.

Using homemade equipment you can produce various types of slag concrete products:

- full-bodied, with an increased margin of safety. They are used quite rarely, as they retain heat less well;

- hollow, characterized by high thermal insulation properties. To ensure strength, the volume of cavities should not exceed 1/3 of the total volume of the product.

The dimensions of the products are determined by the dimensions of the mold. When making products yourself, the size of the molding box can be any. However, many people prefer the standard dimensions of 19x18.8x39 cm.

The increased volume of the slag concrete block can significantly reduce the duration of various types of construction work:

- construction of capital walls;

- construction of internal partitions.

It is perfect for the construction of utility buildings, sheds, and storage buildings.

If you need to make a cinder block yourself, the machine allows you to quickly solve the problem. The resulting material has many advantages:

- high thermal insulation characteristics. Due to reduced thermal conductivity, the material prevents heat loss;

- increased dimensions and low weight. This makes it easy to transport products and quickly build walls from them;

- resistance to the development of microorganisms. This is achieved due to the properties of the slag included in the structure of the block;

- low price. A cinder block machine with your own hands allows you to make products that are cheaper than purchased blocks.

The material also has weaknesses:

- low durability. The period of operation of buildings made of slag concrete is up to three decades;

- reduced safety margin. The characteristics of the material allow the construction of buildings no more than two floors high;

- the appearance of cracks under the influence of shear forces. During shrinkage, cracking occurs along the cinder block mass.

To ensure an attractive appearance of buildings, the cinder block surface needs external cladding. These disadvantages do not stop developers who want to build a utility building or a small building in a limited time at low costs.

You can use homemade cinder blocks a month after they are made.

Stages of making molds for blocks with your own hands

To make metal matrices, you will need a 3 mm steel sheet and a 8 mm D metal pipe to form voids, as well as a grinder, a welding machine, and other working tools.

- Blanks for the walls are being prepared. They can be cut at home with a grinder 450x210 and 220x210 in 2 zigs. The bottom of the mold should have a side 3-3.5 cm high and a handle. Notches are made on the walls (f.3).

- To make voids you will need cylinders (photo 4). To do this, the required number of blanks is cut from the pipe at the rate of 3 units. for 1 block. The height should be a few mm less than the height of the walls. To give the pipe blank a conical shape, on one side you need to cut the pipe halfway and clamp it in a vice. Each pipe blank must be welded on both sides, resulting in hollow plugged cylinders (fillers). They are welded to the bar, then inserted into the mold and the bar is welded to the walls of the mold (f. 5).

- All seams must be welded from the outside.

- From a thick-walled plate we make a press with holes with a diameter exceeding the diameter of the hollow cylinders. The press should enter the matrix approximately 50 mm. Handles are welded to the press (photo 6).

Do-it-yourself ready-made forms for blocks do not require large expenses. People who do not have special qualifications can work with them. The main thing is to do the correct kneading and compact the contents.

Manufacturing method of a vibrating machine

Making a vibrating machine with your own hands is not a difficult task for an enterprising performer. Using a drawing, use a grinder to cut a steel sheet and, using welding, form a shape consisting only of side walls (if you plan to produce two, three or four blocks per cycle, take care of constructing partitions, which can be made from thin-walled material, 1.5-2 mm). If you adhere to current industrial standards, the size of a cinder block will be 190x188x390 mm, but no one forbids making blocks according to your own dimensions. From below, strips are welded to the shape of the vibrating machine, making the device stable (in case of strong vibrations, this is a mandatory requirement).

Manufacturing hollow products allows you to significantly save on cement and other components of the solution.

For this purpose, the matrix design provides for the presence of removable or rigidly fixed conical void formers. Since it is highly desirable to produce cinder blocks with exactly repeatable geometric dimensions, to ensure a standard height of the finished product, make a limiter below which the press will not fall.

Vibrocompression - compaction of a semi-dry concrete mixture when the latter, while in a mold, is subjected to pressure from above

The press is a plate with cutouts for void formers, to which handles are welded. It is with the help of a mold (and a vibrator, of course) that the mortar is compacted.

The motor is installed on the side face of the concrete block mold; the motor is turned into a vibration unit by an eccentric - this is an additional weight rigidly mounted on the motor shaft.

Minor design improvements will make it easier to form building blocks with your own hands. By providing the device with a simple lever system, you will reduce the physical effort expended when lowering the press. Equipping the brick making press with small wheels will make it possible to produce cinder blocks directly on the construction site, without the need for stacking.