Cutting metal with a grinder (angle grinder, angle grinder) is the easiest way to process various hard materials, including metal workpieces. This tool is used to clean and cut reinforcement, round timber, pipes and profiles of various types.

Photo No. 1: cutting metal with a grinder

Many people are interested in what is more profitable to cut metal: with a grinder or with gas. The answer depends on the scale of processing. In general, the cost of consumables when cutting metal products with an angle grinder is higher. However, in domestic conditions, when processing medium and small-sized rolled metal, the purchase of special machines is unprofitable. Gas cutting is more often used in large industries. In addition, edges treated with an angle grinder are more accurate, without the formation of scale and oxide.

Photo No. 2: gas cutting of metal

Further in the material we will tell you how to choose a tool and consumables, how to use an angle grinder correctly and what safety measures need to be followed.

Device Features

The simple design of an angle grinder does not prevent it from being one of the most popular and necessary tools in the household.

The principle of operation is an electric motor that drives the shaft through an angular gearbox, onto which a special disk is attached. The main advantage of this technique is its versatility, because when using various discs, cutting, polishing or grinding off excess material is performed. There are discs designed for working with wood, but they cannot be used for metal. Discs with an abrasive base of different grain sizes are used as polishing consumables.

Bulgarians are classified into several types:

- Professional;

- Low, medium and high power;

- Without handles;

- Household;

- With one or two handles.

Low-power equipment is powered from a simple household socket of 220 V, but powerful angle grinders are connected to a network with a voltage of 380 V. Regardless of the power, all machines perform manipulations such as cutting, grinding and polishing wooden, concrete, metal and plastic materials.

The only difference is the operating time. Powerful equipment can work longer without overheating, but household equipment must be given a rest. If necessary, an angle grinder serves as the basis for creating a small machine. To do this, the grinder is fixed permanently and parts, drills, cutters are turned and knives are sharpened.

The grinder is an indispensable equipment for construction and rescue work in auto repair shops and economic activities.

There are several reasons why an angle grinder is classified as a dangerous tool:

- Working with an angle grinder often takes place on an unstable surface, where it is impossible to find support for a stable position.

- Although protected, most of the rotating disk is not protected.

- Abrasive polishing discs often break during operation into medium and small pieces, which fly off in different directions at great speed.

Operations that can be performed using an angle grinder

The grinder is a multifunctional tool. The drive mechanism in it is an electric motor, which through a gearbox transmits movement to a shaft with a replaceable attachment attached to it. The general view of the device is shown in the photo below.

There are models on the market that differ in power and design:

- household;

Angle grinder (grinder) FT-1318

- professional;

Professional large angle grinder 230mm Stern AG230B

- with or without handles.

Powerful devices are powered by a three-phase voltage of 380 V, and household devices are powered by a single-phase 220 V network. Low-power battery models are also available.

An angle grinder (angle grinder) can do the following main types of work with various materials:

- cutting;

- grinding;

- polishing.

If you fix the grinder motionless, you can sharpen various tools on the wheel: cutters, drills, knives, etc.

The angle grinder is designed to work with the following materials:

- concrete;

- metal;

- tree;

- glass;

- ceramic tiles;

- stone;

- brick;

- plastic.

Grinders have become widespread both in everyday life and in industrial settings. This is due to their wide functionality, due to the following factors:

- a large selection of different attachments from different materials to perform various operations;

- Possibility of fixed fixation using special fastening devices;

- the presence in some models of additional handles and several speed modes of operation.

At the same time, you must always remember that only special discs are used to process each material.

Grinding with a grinder

First of all, let's figure out how to grind with a grinder, and what attachments are used.

For grinding and stripping, grinding discs, cups, wire meshes of various shapes and other devices are used. Both made entirely of abrasive material, and those having a steel or plastic base, onto which various abrasive pads and even sandpaper are attached.

Grinding with a grinder

The cleaning disc is noticeably thicker than the cutting disc. Its shape can be flat or dish-shaped. If such a “plate” is deepened and the edges are made narrow, we get a cup-shaped grinding attachment, or simply a “cup”.

We grind the entire plane of the nozzle or part of it. In this case, the axis of rotation is located almost perpendicular to the surface being processed.

Advice

. When grinding, it is better to rotate the front rotary handle of the angle grinder (if equipped) so that the axis of the handle coincides with the direction of the axis of rotation of the attachment. It is usually more convenient to work with a grinder when your hand is not on the side, but above the attachment, especially on surfaces of complex shape.

Cutting brick, concrete, metal with a grinder

Now about how to cut brick, concrete, metal, etc. with a grinder. For this purpose, special wheels are used, which are called cutting wheels.

A grinder can cut both metal and brick

They come in two types: for metal and for stone. If absolutely necessary, you can cut metal with a disc on stone and vice versa, but the productivity of the process will be lower.

In addition, if there are no problems with abrasive disks, then a steel disk with coating or inserts, designed for cutting stone, will quickly fail if it is used to cut metal.

Important!

It is strictly forbidden to cut thick wooden boards and logs with a grinder. It is even more dangerous to do this by installing a circular saw blade on the grinder. Unfortunately, such a violation is quite common and the consequences are sometimes quite tragic.

Cutting is performed using the edge of the disk, and the pressing force should not be significant; the tool must be held practically “in weight” and without distortions.

It is allowed to cut wood using an angle grinder using a special disk for wood. They are fairly new and commercially available.

Wood disc for grinder

Grinding with a grinder

Builders call a groove a channel cut into a wall, ceiling or floor to accommodate communications.

Let's look at how to groove with a grinder, since this type of work, although it is performed with cutting wheels, has its own characteristics.

To create a groove along its width, use a grinder to cut two parallel lines of the required depth, after which the material between them is selected using a hammer drill or a chisel with a hammer.

To work on concrete or ceramic bricks, it is better to use a steel disc with diamond coating or cutting inserts. Plaster, especially lime or gypsum, can be easily cut with a regular stone abrasive disc.

Gritting using an angle grinder

The work is noticeably simplified if you cut the grooves with a grinder with a special attachment - a wall chaser. This nozzle has two discs, the distance between which can be adjusted and cuts neat parallel lines in one pass. You can find out more about the methods of cutting channels for wiring in the wall → by following the link.

Cutting a round hole in metal using an angle grinder

In practice, it is often necessary to cut a circle in metal, and the only tool available is an angle grinder. But it is quite enough for this purpose. The algorithm of actions is as follows.

- Draw a circle with a compass on the surface of the metal or on a pre-made paper (cardboard) template with chalk or a marker.

- Holding the grinder at an angle to the surface of the sheet, make a preliminary marking cut of the metal along the marked contour, making short movements with the disk (sawing in small sections).

- Then, moving the nozzle in the same way, deepen the slot until it is completely cut out.

You need to cut along the outer contour of the circle so as not to reduce the size of the circle. If its diameter is small, then they cut by touching the metal with a disk point by point (without longitudinal movement of the nozzle). The round hole will have an oblique cut, as well as some minor flaws (they depend on the skill of the worker). Afterwards it is processed, if necessary.

The entire process of cutting a round hole in sheet metal using a special tool is shown in the video:

What are the dangers of an angle grinder?

An angle grinder is a dangerous tool. This is caused by the following reasons:

- high rotation speed of the working nozzle - it exceeds 10,000 rpm;

- openness (unprotected by the casing) of most of the disk;

- the ability to break the abrasive disk into fragments of different sizes, which fly to the sides at considerable speed;

- frequent inability to properly organize the workplace;

- the formation of small particles when cutting metal (or other material) or grinding.

When the disk jams, which occurs even due to its slight misalignment, it is almost impossible to hold the grinder in your hands, especially a powerful tool. This is caused by the high speed of rotation of the nozzle. Therefore, beginners are recommended to work with low-power models equipped with discs with a diameter of 115-125 mm. The latter must be free from the slightest defects that could lead to their sudden destruction and tearing of the angle grinder out of your hands with uncertain consequences.

Structure and capabilities of the grinder

An electric angle grinder is used for grinding, polishing and cleaning surfaces, welds and edges. The technique is effective in cutting various materials and making products from metals, stones, bricks and concrete. The development of artificial diamond technology has made it possible to turn the grinder into a universal cutting machine. Now the quality of their execution is regulated by GOST R IEC60745-2-3-2011 and is tested in laboratories.

Grinder grip

In general, the device in an angle grinder is as follows:

- The rotation of the motor rotor is ensured by an electric motor with a control unit and a current supply cable.

- A gear and a fan are installed on the shaft. The mechanism is engaged with a driven gear mounted on the drive spindle. The latter rotates the working tool - a disk or stone.

According to their design, there are one- and two-handed grinders:

- One-handed tools. There is no main handle, they weigh up to 2.5 kg, the diameter of the circle is 100, 115 and 125 mm.

- Two-handed instruments. There are main and additional handles, the diameter of the circle ranges from 125 to 230 mm, the weight of the machines is 2.5-6 kg.

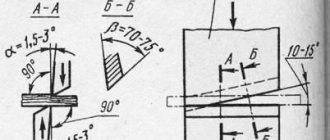

How to cut correctly

First of all, you need to pick up the instrument correctly. Right-handed people hold the grinder with their right hand by the body. In this case, the circle is located on the left, and the gearbox is on the right side of the machine. With your left hand you need to hold the tool by the handle, which is screwed into the body. The correct position of the handle is up. The guard should cover the blade and hands, dispersing sparks away from the worker. For left-handers, the handle is screwed into the other side of the body, the protective casing is rotated and secured in the desired position.

Tool manufacturers give three main tips for working with an angle grinder: hold firmly with your hands, do not be on the cutting line, stop and do not start the machine if the disk is jammed.

How and in which direction to cut, everyone decides for themselves, taking into account the fact that when biting, the grinder is thrown in different directions.

Rule #1: Adjustable Handle Position

The handle should be on top. Many craftsmen screw it in from the side, in a horizontal position, claiming that this way the cutting area is better visible, and therefore higher safety, but this is a dangerous misconception. Only with a vertical position of the handle on top is it possible to ensure a strong grip and protect yourself and others from the situation when the grinder flies out of your hands when you “bite” the disc.

The handle should be located on top - this will ensure a secure grip.

Many will ask why the lateral position of the handle is provided in this case. It is used during grinding work, when there is no danger of the disc being “bitten” by metal parts.

Rule #2: Direction of disk rotation

Inexperienced craftsmen often believe that the blade should rotate, making the cut "from itself" so that the sparks fly away from the operator. However, not a single specialist who has experience working with angle grinders would agree with this statement. The fact is that a special casing protects from flying sparks, so the master is not afraid of them. Here the question arises differently: how will the grinder behave if the disc is “bitten” by metal?

When rotating towards itself, the jammed disk that suddenly stops causes the angle grinder to be pulled out of the operator’s hands towards the ground, i.e. away from the master. If this happens during reverse rotation, “from itself,” the angle grinder may fly into the head of the person working with it, which at best will be very unpleasant, and at worst is fraught not only with a hospital bed, but also with more dire consequences.

The disk should rotate towards itself. The protective cover will prevent sparks from flying into the eyes, and use will be safer

Rule No. 3: positioning the metal when cutting it

Many novice craftsmen make a serious mistake by fixing the pipe or channel being cut on both sides and starting cutting between the fasteners. With this arrangement, there is a high probability of the disc jamming at the end of the cut. For example, we can recall an ordinary board that everyone sawed at least once in their life. In the end, the hacksaw gets jammed and you have to look for a position that will lead to the opposite effect. It's the same story with pipes. One end should be suspended. In this case, decompression will occur, not jamming.

Important! Monitor the condition of the disc edge. At higher RPMs, a small chip can cause the wheel to fly apart, causing serious injury.

The edge of the part should be suspended - this will prevent the disk from jamming

Rule No. 4: Using the side of the disc is prohibited.

Many “craftsmen” claim that sharpening drills with the side surface of a cutting wheel is completely safe. Sometimes such delusion can cost lives. After all, the circle itself consists of an abrasive, which is reinforced on both sides with a metal or fiberglass mesh. If the reinforcing layer is damaged, the abrasive may not withstand the rotation speed and break into pieces. That is why only the end surface is considered working.

Also, do not use a metal cutting wheel to cut wood. Despite the fact that this material is softer, when the circle rotates, its temperature rises sharply, which first leads to the appearance of smoke, and as work continues, to the melting of the adhesive base of the disc. The result may be its destruction, which, again, will lead to injury.

Working with the side plane of the disc is prohibited

Rule No. 5: nuances of working with an angle grinder

When installing a disc on an angle grinder, many people try to thoroughly tighten the nut using the wrench included in the kit. This is a big mistake. This key is intended for unscrewing only. The installed disk just needs to be tightened manually. The grinder is designed so that the nut is tightened during operation. Therefore, using a wrench during installation will lead to difficulties, and sometimes even to the impossibility of unscrewing the nut later.

It is worth paying attention to the launch of angle grinders. The button should only be pressed if there is nothing obstructing the disk. This means that under no circumstances should the wheel be immersed in a started cut before it unwinds and enters the rotation cycle.

The nut must be tightened by hand - no wrench is used.

Features of working with thick metal, copper, cast iron, aluminum

When it is necessary to cut thick metal into separate fragments, it is recommended to additionally perform the following steps:

- constantly cool the area of contact between the metal and the disk using cold water due to the strong heating of the slot;

- make all cuts only in a straight line;

- different curved contours should be cut out in separate straight sections of short length, removing unnecessary parts;

- You need to completely cut the workpiece in several approaches, deepening the slot with each subsequent one;

- if you need to cut corners, I-beams, channels, rails, then each of their structural parts is sawed separately.

Cutting cast iron, stainless steel, as well as non-ferrous metals, such as aluminum and copper, is carried out using special wheels designed for working with these materials. All necessary information about the discs is contained in the markings of these products, printed on their sides. In this case, the circles differ in the composition of the fillers:

- in some, the additive is a super-strong material that can cut alloy steel;

- others use mild binders.

Cutting stainless steel with conventional metal cutting discs is prohibited, because they contain substances that lead to accelerated corrosion of the cut site . Aluminum and copper are very viscous non-ferrous metals. They are sawed using a grinder, pouring kerosene over the slot formed by the disc. In this case, it is necessary to comply with fire safety rules.

The nuances of cutting some materials

When cutting concrete, follow these recommendations:

- before work, check for the presence of pipes, fittings, and electrical wiring embedded in concrete (with a metal detector or devices for searching for wiring);

- to reduce dust, the work surface is moistened with water (for example, from a spray bottle or a brush);

- periodically cool the cutting element with air or water.

In the absence of a tile cutter, a grinder can also be used to cut tiles. Experts even cut circles into the tiles. Stone and tiles are cut in two ways:

- wet (wet the work area with water);

- dry (without moisture).

Final part

You should not think that a grinder with a cutting disc is a tool used exclusively for dismantling metal structures and does not require careful operation. Quite the contrary. An angle grinder requires extreme concentration and accuracy in work. This is a rather traumatic tool, and therefore, when working with it, you should not forget not only about the correct markings, but also about safety requirements.

Only accurate calculation and cutting will allow the pipes to be perfectly aligned at an angle Sources

- https://instanko.ru/osnastka/kak-pravilno-rezat-bolgarkoj.html

- https://instrument-blog.ru/elektroinstrumenty/kak-rezat-bolgarkoj.html

- https://trubaspec.com/montazh-i-remont/kak-rovno-otrezat-trubu-instrumenty-i-sposoby-otrezaniya.html

- https://rezhemmetall.ru/sposoby-razmetki-i-rezki-metallicheskix-trub.html

- https://WikiMetall.ru/metalloobrabotka/kak-rovno-otrezat-trubu.html

- https://alsver.ru/rezka/metalla-bolgarkoy

- https://HouseChief.ru/kak-rovno-otrezat-trubu-bolgarkoj.html

[collapse]

Similar posts:

- How to work with an angle grinder correctly: step-by-step instructions

- Why is an angle grinder called an angle grinder, and what else is it called?

- FBS GOST blocks: foundation blocks 13579 78

- How to cut a plastic window sill evenly

- Do-it-yourself semi-automatic inverter: reworking algorithm

- How to become a good leader - where to start

How not to work with an angle grinder

Safety precautions when using angle grinders should come first. According to it, it is prohibited:

- perform work manipulations without PPE;

- works in light clothing that does not completely cover the body (arms, legs);

- use a machine that is not equipped with a casing to protect against sparks;

- without checking the functionality of the tool at idle, start using it;

- work with a disc that is defective or unsuitable for the material;

- be located in the cutting plane;

- press hard on the tool;

- work so that the direction of rotation of the circle is towards the operator;

- perform work without taking breaks, because your hands get tired and it’s difficult to hold the grinder tightly;

- so that the workpiece being processed is not fixed (for example, in a vice or clamps);

- use the side of the disc to sharpen metal parts;

- cut workpieces whose thickness exceeds half the radius of the circle used;

- presence of unauthorized persons in the work area;

- touch the attachments until they have cooled down, because they become very hot during cutting and grinding due to friction;

- when deepening the circle into the workpiece, turn on the tool;

- grind with thin discs;

- use nozzles with a larger diameter than the angle grinder is designed for;

- position the workpiece so that when cutting, the circle is clamped (the cut should be for breaking, not for squeezing).

Safe use of the saw in an angle grinder is ensured by the fact that it is replaced only when the device is disconnected from the network.

Safety precautions when operating an angle grinder

Note! It is no secret that when interacting with a dangerous tool, there is always an instruction consisting of rules that allow you to avoid unpleasant consequences when working with an angle grinder.

The following points should be emphasized:

- Compliance with requirements and instructions.

- Do not work with a damaged disk.

- Use the wheel according to its intended purpose: cutting wheel for cutting, grinding wheel for processing.

- A good master is careful, attentive and calm.

- Monitor the situation both before and after the operation.

- When using an angle grinder, do not stretch

Basic rules for safe work when cutting metal with an angle grinder

Layout of the most dangerous sectors when working with an angle grinder, taking into account rebound and destruction of the disc.

The most necessary condition when cutting is strict adherence to safe work rules.

Manufacturers of angle grinders are constantly trying to minimize the risk of injury and injury by inventing and improving various protection systems. But no one will take care of the employee like he himself.

The main dangers that arise when cutting metal are the flying out of fragments of a broken disk, a flow of sparks and tiny abrasive particles, and the inability to hold the tool in your hands.

If the disk breaks or gets jammed, the angle grinder can break out of your hands at the most inopportune moment and with great force, so even before starting work, you should foresee the direction of its possible movement.

Safety rules cannot be neglected even when performing minor work.

Before starting work you should:

- Protect your face, eyes, hands and, if possible, all parts of your body.

- Remove all flammable materials and objects that are in the direction of the sparks.

- If possible, secure the part being processed with a grinder in a vice. It is prohibited to hold the workpiece with your free hand or press it with your feet.

- If you are installing a new disk, you need to “scroll” it with a grinder at maximum speed, placing it further away: the disk may turn out to be defective and fly into pieces.

- Install, adjust and secure the protective cover.

It is best to protect your face with a special shield when working with an angle grinder.

During work you should:

- When replacing disks during rest, you must disconnect the angle grinder from the network.

- Use goggles or a face shield to protect your eyes and face—professionals use both during long periods of work.

- Hold the grinder firmly during all work.

- To replace the disk, you need to wait until it stops completely.

- Work in protective gloves. It is not advisable to use cotton mittens; they do not provide sufficient protection, they can catch fire, and the threads can wrap around the grinder spindle or disc.

- During work, you need to position yourself so that your face, and, if possible, all parts of your body, are not in the plane of rotation of the disc.

Upon completion of work you should:

- wait until the rotation of the disk has completely stopped and only after that put the tool on the floor with the disk facing up so as not to damage it;

- disconnect the grinder from the network;

- make sure there is no smoke or other signs of fire.

A typical mistake made when cutting metal: if the diameter of the new circle is larger than the size of the protective casing, it is removed. The casing is a protection in case the disk breaks and falls into pieces during metal cutting.

Instead of a disk, many people use cutters, saws or other available materials. Doing this is strictly prohibited.

Individual protection means

The name PPE, or personal protective equipment, refers to means for personal use that are used to protect against pollution, prevent or reduce the effects of harmful and dangerous factors. For most workers, this is workwear appropriate to their profession. It usually includes trousers, a jacket, a hat, and closed shoes. Since the grinder is a tool of increased danger, clothing is supplemented with other means of protection:

- glasses or shield;

- anti-noise headphones or earplugs (ear plugs);

- vibration-isolating gloves;

- a respirator, especially when cutting stone, tile, concrete or slate.

Methods for cutting metal pipes at an angle

There are several ways to saw off a pipe or cut it into pieces. Of the available tools, a grinder is the best for this task. But the biggest problem remains the need to correctly mark the cutting lines. They can be different, most often you have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. The techniques vary somewhat depending on what products need to be cut:

pipes for laying water supply, gas and for heating distribution;

profile products for assembling gates, canopies, and other metal structures;

large-diameter pipes - as a rule, this is rarely needed at home, where the widest clearance is only in the sewer system;

pipes made of steel, cast iron, thin-walled of non-ferrous metals and soft alloys.

Both problems can be solved quite simply even without the use of a special pipe angle pattern.

45 degree cutting

One particular example of such a situation is the need to cut a metal pipe at an angle of 45 degrees. Such cutting of material is often required when laying water pipes or heating systems. In this case, you have to deal with steel pipes. For these purposes, conventional cylindrical pipes are usually used. If we are talking about the installation of some kind of metal structures, then profile pipes of rectangular or square cross-section are more often used. The main problem here is that in order for the elements to be connected to coincide, the cut must be as smooth as possible, which means that especially close attention should be paid to marking the material.

In cases where cutting at an angle is required, a simple square sheet of paper can be used as a marking template. It must be folded strictly diagonally, and then wrapped around the pipe with the template. In this case, it is necessary to carefully ensure that the side of the sheet, which is located closer to the end of the pipe, is perpendicular to its central axis. Next, using marking material, a series of dotted lines is applied and after the marking is completed along the entire circumference, the template can be removed.

Photo of the template for cutting pipes - side view

Larger pipe blank

Marking a 45 cut using a template

If you have to cut a profile pipe, then it is advisable to make a special template from the same pipe, but with a larger cross-section. In this case, you will only have to use the measuring devices once. To apply markings you will need to use a protractor or a construction square. After sawing off the template, the pipes to be cut can simply be inserted into it and marked. This approach will significantly save work time and cutting a profile pipe at 45 degrees will be convenient.

As for what to use when carrying out work, you should choose the most suitable and familiar one. This can be a simple hacksaw for metal, or a grinder with an installed cutting disc.

90 degree cutting

When the need arises to cut at 90 degrees, the situation is even simpler. In the case of cylindrical elements, you can use the same sheet of paper that is used to wrap the pipe as a template. It is important to ensure that the edge of the sheet is smooth and matches the entire circumference. After marking is applied, the element to be cut is fixed and the cut is made.

The video shows the process of cutting a pipe at 90 degrees.

How to cut a profile pipe evenly

You can cut a profile pipe in much the same way, but here it will be easier to use a square. The device is applied to each side in turn, for which the element to be cut will need to be rotated, and markings are applied. Next, the pipe must be secured firmly and work can begin.

Any suitable tool can be used for sawing. If you have to cut a lot of pipes, then it is advisable to make full-fledged templates from scraps. In this case, measuring and marking work will have to be done only once.

Large diameter pipe cutting

When it is necessary to cut a large diameter pipe, a number of special devices and tools can be used. This may be necessary if, for example, a pipeline needs to be repaired.

- Bulgarian. The use of an angle grinder is justified from the point of view of the availability of tools and the comparative cheapness of the work. However, you should not count on greater productivity in this case; in addition, carrying out work in this way is associated with considerable risk.

- Roller machine. Such devices are also often called pipe cutters. In essence, such a device is the same grinder, but more suitable for this type of work. The machine includes a special frame where the element to be cut is fixed, as well as a holder with installed cutting rollers, which do the actual work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is carried out due to the action of a high-intensity flame, and the waste produced is blown away by gas pressure. The method can be considered the most practical and effective.

Gas cutting is the fastest option in this case.

There are other options for carrying out the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it smoothly you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting such a pipe, you need to determine an algorithm of actions.

- We mark in the same way as steel pipes.

- At the cutting site, you need to place a wooden beam as a support.

- Next you need to make a cut of a few millimeters around the entire circumference.

- After this, a chisel is inserted into the groove and a sharp and strong blow must be applied with a hammer.

As a result, it will split along the line, forming a fairly even cut area, which can be further processed if necessary.

Precautionary measures

An angle grinder is a dangerous tool. When working with it, a number of conditions must be observed:

- Do not use the tool without safety glasses;

- Before starting cutting or polishing, check the suitability of the disc at idle speed;

- Clothing should cover your hands and protect from hot sparks;

- Do not remove the protective cover from the angle grinder;

- When cutting on a plane, the master and assistant should be on the side of the tool;

- The unit cuts material under its own weight, and excess load will lead to deformation or jerking;

- Working without a break leads to overheating of the equipment and fatigue of the master, who must hold the grinder firmly in his hands, observing the cutting angle;

- The workpiece to be processed must be firmly secured;

- You cannot grind parts with the side of a cutting disc, because there are specialized wheels for such work;

- Within the work area there is a master and his assistant. All other people move to a safe distance;

- The radius of the cutting wheel should correspond to 1/6 of the thickness of the workpiece.

Straight cut

An even cut at an angle of 90º can be made only after marking has been applied. Use a piece of paper or masking tape. The latter is preferable, because it is attached directly to the surface and does not move.

The sequence of actions looks like this:

- Using a tape measure, measure a piece of the required length, mark this place with a line with a marker.

- Next, stick tape along the resulting mark around the circumference of the pipe. The smoother you apply the adhesive tape, the better - it is optimal that the wide edges meet as accurately as possible. This will allow you to accurately cut the pipe according to the mark.

- The next step is to secure the pipe in a vice or press it to a flat plane so that it does not move during operation and an even seam is obtained. Note that one end of the pipe must be left in a free position so that during the cutting process the disk is not pinched by the walls. Cutting starts from top to bottom.

- The last thing you need to watch out for is how to cut the pipe smoothly with a grinder. To do this, you need to guide the disc as accurately as possible along the edge of the adhesive tape.

In cases where tubular products with large sections are being cut, the work must be done in small sectors. To do this, the pipe will have to be constantly rotated around its axis upon completion of the next cut.

When working with cast iron pipes, the procedure will be slightly different. First, a continuous cut is made along the entire diameter of the product, then, using a chisel and a hammer, the resulting groove is gradually tapped, as a result of which the pipe should split strictly along the cut line.