When carrying out welding work, physical and chemical processes take place that have a negative impact on the human body. For example, ultraviolet radiation burns the retina of the eyes, the skin of the face and hands. Just a few minutes of such ultraviolet welding radiation level is equal to several tens of hours of exposure to the scorching tropical sun.

But that's not all. The fumes contain microparticles of molten metals, which can cause poisoning, affecting the welder’s respiratory system. There is always the possibility of getting burned from splashes of molten metal. Therefore, it is very important to follow safety rules that are specially developed and take into account all the nuances of welding work.

At manufacturing enterprises, welders are allowed to perform their duties only after instruction. All of them are informed about the impending danger and know perfectly well how to protect themselves from it. Hobbyists working at home should take exactly the same precautions.

Hazardous factors

Regardless of where welding equipment is operated - indoors or outdoors - there are always dangerous factors that affect both the welder and the people standing nearby. Protective equipment is needed not only by specialists, but also by assistants. It is worth considering, for example, that sparks from electrodes can scatter within a radius of up to five meters. You can catch the reflection of welding (the so-called “bunny”) from a distance of three meters.

There are many reasons that cause accidents and injuries:

- sparks easily burn through all types of fabric, except special ones, and can cause burns;

- the melt easily burns through modern shoes made from artificial materials;

- flammable materials may ignite in the area where sparks fly;

- hot fumes rise from the hot metal, which can injure the skin of the face or eyes;

- sparks can hit exposed skin and cause minor burns;

- Poor cable insulation may result in electric shock;

- if equipment or additional equipment explodes, fires may occur;

- poorly secured structural elements fall to the ground, injuring people;

- When performing welding work at height, the welder may fall.

Chemical and physical factors:

- operating welding equipment generates high levels of noise;

- infrared and ultraviolet radiation;

- when electric arc welding operates, blinding light is emitted;

- when working with metal alloys, lead, zinc, chromium, cadmium and other substances hazardous to the respiratory tract evaporate into the air;

- there is a high-temperature suspension with microinclusions above the bath;

- there is a high probability of thermal effects from a burner or electric arc.

Equipment safety requirements

Before performing work, the equipment is checked:

- Strength of connection of hoses to the burner and gearboxes.

- Tightness of connections.

- Hose integrity.

- Gearbox serviceability.

- Burner condition.

- Water level in the seal and connection density.

- Serviceability of pressure gauges.

Cylinders

The generator together with the cylinder is installed outdoors, and the gas is transferred to the place where welding work is performed through hoses. It is prohibited to place it near fans and air intakes.

A “Flammable” sign should be posted near the generator. The acetylene cylinder is marked with the inscription “Acetylene” in red; the oxygen cylinder and the reducer are painted blue.

After removing the metal cap from the cylinders, the fitting and valve are checked for serviceability and mechanical damage. If the cap cannot be removed, it is strictly unacceptable to unscrew it using impact tools (hammer and chisel).

Before connecting the gearbox, you need to inspect the fitting and nut for damage, make sure that the threads are in good condition and that there is no grease or oil. The fitting is purged by opening the valve ¼ turn for a short time.

When opening the valve, care must be taken to prevent the jet from reaching people.

It is unacceptable to use a gearbox that has damaged threads or whose pressure gauges are faulty (pressure gauges with expired service life and those that have not been tested are equated with this).

Repairing valves yourself is strictly prohibited. For this purpose, there are special stations and services that carry out repairs and replacements.

Cylinders must be installed vertically or on special racks to which they are attached with clamps and chains. The cylinder must not be brought closer than a meter to heating or an open flame source.

Hoses and cylinders must not come into contact with live wires. The cylinder and the generator must be separated by at least five meters.

Hoses

The standard length of hoses for gas welding work is within 20 m. But if installation work is carried out, then you can use hoses with a length of up to 40 m.

It is not permitted to attach tees, plugs and other devices to the hoses to power multiple burners. Hoses must not have connection defects, and hoses with a length of no more than 3 m are allowed for joining.

The hoses are tightly secured to the nipples of the reducer and burner using clamps and wire. It is forbidden to interchange oxygen hoses with those designed to supply acetylene.

Kinking of hoses during their installation and storage is not allowed . There should be no oil marks on them.

During welding work, hoses are suspended to prevent damage.

Generators

The welder must ensure that the generator water seal is filled with water. The fill indicator must be periodically checked to the desired level by opening the control valve of the valve.

The minimum distance of the generator from the gas welding site and the fire source is 10 m. If the hose catches fire, you must immediately bend it from the gearbox side and turn off the valves.

The generator may only be operated by an authorized and qualified person. The following conditions must also be met:

- One-time loading of carbide cannot exceed 4 kg.

- A maximum of 2 burners is allowed if there is a water seal for each.

- Burner power should not exceed 2000 l/hour.

The acetylene generator must be installed in such a way as to avoid falls, shocks and shocks. The shutter must be in a vertical position and in good working order.

The use of generators without a water seal is strictly prohibited. When using generators outdoors or indoors at sub-zero temperatures, you must prevent the water from freezing.

If the equipment freezes during work, then they need to be warmed up in a warm room or with steam. Heating with open fire sources is not allowed.

The use of carbide with a finer granulation than specified in the technical data sheet is strictly prohibited, as this may lead to excessive gas emissions. Before loading, you need to sift out and remove fine fractions and carbide dust. Carbide may only be loaded into the basket.

Safety rules when performing welding work

The safety regulations developed in May 2015 are in effect today. Their requirements must be strictly observed by all employers and specialists performing welding work without exception. At a minimum, all amateurs who have welding machines at their disposal must know them.

Basic requirements of safety regulations:

- You must not be distracted when performing work. It is necessary to constantly monitor the process of seam formation;

- so that the electric arc cannot harm bystanders, it is necessary to protect the welding site with protection 1.8 meters high;

- The area where welding work is carried out must be kept clean. There should be no flammable objects or flammable substances at a distance of up to five meters;

- the welder must use a special mask to protect the eyes and face;

- An effective ventilation system must be equipped at the welder's workplace indoors. In exceptional cases, it is allowed to work in a respirator for a short time;

- When working at height, the specialist must use safety belts. It is important to securely fasten the elements to be welded to prevent them from falling from a height;

- carrying or moving welding equipment is allowed only after the power supply has been interrupted;

- During welding work, it is necessary to monitor the cables. It is very important that they do not curl;

- When performing body work on vehicles, it is imperative to disconnect the battery;

- The welder must wear special clothing made of thick fabric and impregnated with a fire-resistant compound.

Completion of work

Extinguishing the burner is carried out in the following sequence: close the acetylene valve then the oxygen valve. After completing the welding work, be sure to close the valve on the oxygen cylinder and remove the reducer. The retort on the generator must be unloaded. If the carbide has not cooled down, the retort cannot be opened until it cools completely.

Then you need to clean the generator and rinse the housing with water. For cleaning, you can use a brass, aluminum scraper or hair brush. After completing all work, it is necessary to thoroughly ventilate the room in which the generator was located.

electrical safety

The Safety Rules have a special section that regulates the work with electrical circuits. They are created taking into account the damaging factors that can be generated by power supply systems. According to accepted standards, electric current with a voltage of over 110 Volts is dangerous to life, and a current of more than 0.05A is dangerous.

In order not to harm your health, a specialist must adhere to simple safety rules:

- for lighting it is advisable to use sources with a voltage of 12V;

- the maximum permissible no-load voltage should not exceed 90V;

- Before turning on the equipment, its grounding must be checked;

- Always check the condition of the insulation of power and working cables. There should be no tears, cracks or other damage;

- the power supply must go through a distribution board with installed fuses;

- Do not use a cable longer than 10 meters;

- Twisting or other connections of the power cable are not allowed. As an exception - contact through a coupling connection.

Absolutely forbidden

Important restrictions are specifically highlighted in the Safety Regulations. These points are often ignored by novice welders:

- During rainfall, you cannot work in an open area. And the type of precipitation is not important: both rain and snow are equally dangerous;

- You cannot work with electric arc welding if the filter or screen of the protective mask is damaged;

- Do not work in enclosed spaces without adequate ventilation. It can be replaced with a special helmet with independent air supply;

- It is prohibited to hold the part suspended with your free hand. The workpieces must be mechanically secured;

- proximity to flammable or flammable substances is not allowed;

- It is forbidden to work in clothes that are oily or have traces of grease;

- Prolonged electrical contact with the workpieces to be welded should not be allowed. The likelihood of electric shock or equipment failure increases.

Gas welding and cutting

When working with gas welding equipment, the Safety Rules provide for:

- Be careful when transporting cylinders. They should only be in a vertical position. The valves must be closed with protective caps.

- In cases where the backfire pops are heard during operation, you need to quickly turn off the gas supply. First of all, acetylene closes and only then oxygen. For safety reasons, gas lines should be turned off strictly according to the instructions. Gas tanks must be located at least five meters from the work area. It is advisable to hang the hoses.

- Before starting work, you should carefully check the burner. The presence of oil is especially dangerous - it can lead to detonation of the combustible mixture.

- During operation, it is important to maintain an optimal gap between the workpiece and the nozzle. The gas pressure must be constant.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. If a gas leak is detected, stop work immediately, eliminate the leak, and ventilate the room.

4.2. Clean the tip mouthpiece with a brass needle, not steel wire.

4.3. If the flame backfires, immediately close the acetylene and oxygen valves on the burner (cutter), the water seal valve and the valve on the cylinder. After this, cool the burner (in cold water without traces of oil).

4.4. Before re-igniting the burner, check the water level in the water seal and the condition of the burst disc in the seal, as well as check the hoses and purge them with gases.

4.5. Stop gas welding work if a fire occurs near the gas welding station.

4.6. In the event of an accident, you must immediately report the incident to the administration, call an ambulance by calling 103 (if necessary), maintain the situation as it was at the time of the incident (if this does not threaten the life and health of workers and will not lead to a further accident), provide assistance to the victim.

4.7. If a fire occurs, call the fire brigade by calling 101 and begin extinguishing the fire using the available primary fire extinguishing equipment.

4.8. If you detect a smell of gas or a break in pipelines (water supply, sewerage, heating and others), call the appropriate specialized emergency team.

Means of protection

Strict requirements are placed on welder protective equipment. It must reliably protect against electric arcs and metal scale. Protective clothing is made of special non-flammable fabric:

- thick skin;

- tarpaulin;

- special cloth;

- split wood;

- canvas impregnated with a fire-resistant compound.

The protection kit includes a suit, safety shoes, helmet and mask, and leggings.

Before starting the working day, clothing should be checked for contamination with oil or other industrial lubricants. Shoes should have thick soles to prevent the passage of current. It must not have metal plates or nails on it. There should be a thick insert inside the sock to protect your toes from heavy objects.

Leggings come in different varieties and are selected depending on the type of welding work. There are two-, three- and five-fingered models; without cuffs or, conversely, with high sides that protect the arms up to the elbows. For some types of work (for example, gas welding), it is permissible to use oversleeves and aprons instead of special suits.

Defects in the mask are not allowed. It must not only be in full working order, but also selected in size and tightly attached to the head. There is a wide range of masks available on the consumer market, including those with artificial inflation, adjustable filters, etc. The filter must protect the eyes well and at the same time provide a good enough view to control the work process.

OCCUPATIONAL SAFETY INSTRUCTIONS FOR ELECTRIC GAS WELDERS

1. General labor protection requirements

1.1. Persons who have reached the age of 18, have passed a preliminary medical examination upon hiring (extraordinary medical examination upon transfer from another job) and do not have medical contraindications, have received the qualification of a welder, have at least group II in electrical safety, have passed training, instruction and testing of knowledge of labor protection requirements.

1.2. Before being allowed to work independently, an electric and gas welder must undergo training, which includes: internship, testing of knowledge of labor protection requirements, fire safety. Admission to independent work is formalized by an entry in the briefing log or a local administrative document of the unit. An electric and gas welder must undergo fire safety training at a specialized organization and receive a certificate of the established form. The certificate gives the right to carry out hot work.

1.3. Electrical and gas welder internship is carried out under the supervision of a responsible training person. Admission to an internship is issued by order of the unit. The duration of the internship is set individually depending on the employee’s preparedness.

1.4. After completing the internship, the electric and gas welder must undergo an initial test of knowledge on labor protection, electrical safety, and technical operation of the equipment used in the scope of production instructions. The results of the knowledge test are documented in a protocol.

1.5. An electric and gas welder who has not passed the knowledge test in the field of labor protection within the established time frame is not allowed to work independently.

1.6. During the work process, an electric gas welder must undergo:

— repeated instructions at least once every three months;

- targeted instruction - when performing high-risk work and one-time work not related to the direct performance of work in the specialty;

— periodic testing of knowledge on labor protection at least once a year from the moment of passing the exam;

— periodic confirmation of group II electrical safety approval at least once a year from the date of initial assignment;

- medical examination (examination) at least once every 2 years, and for those under 21 years of age - once a year.

elektrogazosvarshchik

Also, during the work process, the electric and gas welder undergoes instructions on labor protection :

— introductory — upon entry to work, according to the induction program ;

- primary at the workplace - when entering work directly in the department;

— repeated — at least once a quarter according to the program of initial training for mechanics in equipment maintenance and repair;

- unscheduled - when adopting new regulatory legal acts containing labor protection requirements, or making changes and additions to them, in case of violation of regulatory legal acts containing labor protection requirements, during breaks in work in the profession for more than two months, upon receipt of information about incidents and accidents that occurred in single-profile organizations, at the request of the employer or an official of the organization who is entrusted with the responsibility for organizing labor protection;

- targeted - when performing one-time work not related to direct responsibilities in the specialty (loading, unloading, cleaning the territory, etc.); liquidation of consequences of accidents, natural disasters and catastrophes.

1.7. If an electric and gas welder, during a knowledge test, has shown unsatisfactory knowledge of labor protection, then he is allowed to work independently only after undergoing additional training and re-testing his knowledge no later than one month.

1.8. If an unsatisfactory assessment is received again, the commission may raise the issue of dismissing the employee in accordance with the procedure established by law to the administration.

1.9. An electric and gas welder undergoes an extraordinary knowledge test:

— upon appointment, transfer to another job, when requiring additional knowledge on labor protection;

- when moving to another organization;

— in case of changes to production instructions and/or labor protection instructions for a given profession;

- as prescribed by officials of state supervision and control bodies in the field of labor protection.

1.10. Unscheduled safety briefings for electric and gas welders are carried out:

— when changing the technological process, replacing or upgrading equipment, devices, tools and other factors affecting labor safety;

— in case of violation of labor safety requirements, if these violations created a real threat of serious consequences (industrial accident, accident, etc.);

— during a break in work for more than 30 calendar days;

- as prescribed by officials of state supervision and control bodies in the field of labor protection.

1.11. If there is a break in work in the specialty for more than 12 months, the electric and gas welder, after testing his knowledge, before being allowed to work independently, undergoes an internship to restore practical skills.

1.12. Dangerous and harmful production factors at the workplace of an electric and gas welder:

Physical factors:

— increased (lowered) temperature, humidity, air speed, thermal radiation;

— non-ionizing electromagnetic fields and radiation: electrostatic fields, permanent magnetic fields (including geomagnetic fields), electric and magnetic fields of industrial frequency (50 Hz);

— production noise;

— vibration (local, general);

— aerosols (dusts) of predominantly fibrogenic action;

— lighting – natural (absence or insufficiency), artificial (insufficient illumination, direct and reflected glare, pulsation of illumination);

- electrically charged air particles - aeroions;

— welding aerosols;

- increased levels of ultraviolet and infrared radiation;

— increased temperature of surfaces and materials;

— sparks, splashes, emissions of molten metal and slag;

— sharp edges, burrs and roughness on the surface of workpieces;

— location of the workplace at a significant height from ground level (floor);

— height differences of 1.8 m or more;

— moving construction equipment and transport.

Chemical factors:

— toxic (odorant, hydrogen sulfide, sulfur dioxide, methanol);

— low-toxic (natural gas, propane, gas condensate, carbon monoxide).

1.13. According to the “Standard Industry Standards for the Free Issue of Workwear, Safety Footwear and Other Personal Protective Equipment,” an electric and gas welder must use:

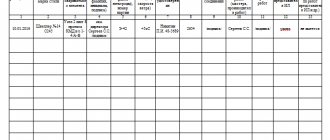

| Name of personal protective equipment | Wearing period |

| Canvas suit or welder suit | 1 year |

| Leather boots with a hard toe cap or rubber boots with a hard toe cap | 1 pair/year |

| Canvas mittens or welder's gloves | 12 pairs per year |

| Safety glasses or face shield | Before wear |

1.14. It is prohibited to wash workwear in flammable liquids (kerosene, acetone, methanol and others).

1.15. The electric gas welder is responsible for careful handling, proper use and application of PPE.

1.16. Maintenance of the territory, workplace, equipment and mechanisms.

1.16.1. The territory, workplace, operated equipment and mechanisms must be kept clean and in working order.

1.16.2. Contamination of the territory, workplace, equipment and mechanisms with flammable substances and flammable liquids, and debris is not allowed.

1.16.3. It is prohibited to obstruct or use driveways, entrances to fire extinguishing equipment, and fire breaks between objects on the territory for storing materials.

1.16.4. Workers should be in safe areas when working at heights, using lifting mechanisms, gas hazardous, fire and other high-risk work.

1.16.5. The dangerous area where work at height is carried out must be fenced along a safe perimeter and safety warning signs posted.

1.16.6. The employee must be careful with moving vehicles and moving loads. Do not cross pipelines in undesignated places, do not crawl under them, do not go beyond the fences of dangerous places without the permission of the head of the facility or work.

1.17. The electric and gas welder's workplace is provided with primary fire extinguishing means and fire equipment. There must be easy access to primary fire extinguishing means and fire equipment.

1.18. Oily and flammable cleaning materials are collected in special metal boxes with tight-fitting lids, and at the end of working hours (before starting a shift, finishing work), the contents of the boxes must be taken to a specially designated place for subsequent destruction in the prescribed manner.

1.19. Smoking on the territory of the enterprise is allowed only in specially designated areas that are approved by the head of the organization and marked with fire safety signs.

1.20. Safety requirements for hand tools, devices and devices.

1.20.1. When working with hand tools, devices and devices, comply with the requirements of labor protection instructions for the types of work for their safe use.

1.20.2. Tools, fixtures and devices may only be used after external inspection, have no external damage and have timely passed, if necessary, appropriate tests, confirmed by stamps, tags, plates or other means.

1.20.3. When choosing tools, devices and devices, it is necessary to take into account the conditions of their use (presence of explosive and fire hazardous environments, sources of electricity, precipitation, air humidity, etc.).

1.20.4. When using and moving tools, devices and devices from one workplace to another, it is necessary to take into account the places of their use, routes and methods of movement (work at height, steeplejack work, use of scaffolding, ladders, stepladders, tower lifts and others).

1.21. When performing his duties, an electric gas welder must know and perform:

— requirements of labor protection instructions for electric and gas welders and other instructions for ore protection by type of work;

— instructions on fire safety measures of the enterprise;

— requirements for instructions on the content and use of protective equipment ;

— requirements of instructions on fire safety measures in premises ;

— requirements for instructions on providing first aid in case of accidents at work;

— the scope of qualification requirements according to the assigned category;

— characteristics of dangerous and harmful production factors in the workplace;

— the procedure for maintenance and preventive maintenance;

— the procedure for notifying your immediate or superior manager about any emergency situation (accident, fire, incident) that threatens the life and health of people;

— procedure for action according to the plan for localization and elimination of emergency situations;

— rules of personal hygiene;

— requirements for safety signs and posters;

- location of the first aid kit.

1.22. An electric gas welder is prohibited from:

- smoke in the workplace, be in a state of alcoholic and drug intoxication at the workplace (use alcoholic beverages and narcotic substances);

— store food and eat food at the workplace (except for specially equipped places);

- do not visit other facilities or workplaces without production necessity or without the permission of the manager.

1.23. The employee is obliged to notify his immediate or superior manager about every accident at work, about all violations of labor safety instructions, malfunctions of equipment, tools, devices and personal and collective protective equipment noticed by him.

1.24. It is prohibited to work with faulty equipment, tools and devices, as well as personal and collective protective equipment.

1.25. The employee bears responsibility for violating the requirements of the labor protection instructions in accordance with the current legislation of the Russian Federation.

2. Labor protection requirements before starting work

2.1. Before starting work, the electric gas welder:

— puts on special clothing, shoes and protective equipment;

— tidies up the work clothes used: buttons up the sleeves, tucks in the clothes so that there are no hanging ends. It is prohibited to roll up the sleeves of workwear. Overalls and gloves must be free of oil;

— receives a production task from the responsible work manager;

— checks compliance with labor safety requirements before operating cylinders and equipment used during hot work, for compliance with labor safety instructions for their operation;

— checks the serviceability and presence of grounding of electrical machines and transformers;

— checks the workplace and approaches to it for compliance with safety requirements;

— makes sure that the workplace is safe based on the results of an express analysis of the air environment for the content of harmful substances, with a note in the permit;

— checks the performance of supply and exhaust ventilation;

— checks the serviceability of the electrical holder and the reliability of the insulation of its handle.

2.2. Before performing high-risk work under a work permit, the electric and gas welder must undergo targeted instruction on labor protection and sign for the instructions in the work permit for hot work and the logbook for registering the instructions at the workplace.

2.3. When performing work at height, the electric and gas welder must be instructed by the work supervisor on how to secure it with a safety belt and be provided with a bag for carrying tools, electrodes and cinders. Throwing electrodes down is prohibited.

2.4. Before working at height from scaffolding, check that it is in good condition. The scaffolding flooring must be dense and secured; Scaffolding must have handrails and side boards secured from the inside. Wood flooring must be protected from ignition by sheet metal or asbestos.

2.5. It is prohibited to perform work with mechanical tools (electric, pneumatic) from ladders. For this purpose, step ladders are used with a working platform fenced with railings along the entire perimeter.

2.6. Ladders and stepladders must be equipped with a device that prevents them from moving or tipping over during operation, and must also be no more than 5 m long. It is prohibited to work from the top two steps of stepladders and ladders that do not have railings or stops.

2.7. Before welding barrels and other containers containing hydrocarbons (gasoline, condensate, petroleum products, etc.), it is necessary to thoroughly rinse them with hot water, steam them or blow them with an inert gas, and analyze them for hydrocarbon content.

2.8. To perform welding work at height (at pipeline air passages), electric and gas welders are checked to have a medical certificate confirming their suitability for steeplejack work, to have at least one year of experience in steeplejack work, and to have a welder category of at least III.

2.9. Before working in a pit, you should make sure that its slopes are stable and the walls are secured, and remove pipe scraps and other objects that could fall and cause injury from the edge of the pit. The place where welding work is carried out must be provided with fire extinguishing means.

2.10. An electric gas welder should not start work if it is discovered that the workplace does not comply with the requirements of labor protection instructions.

2.11. If violations are detected, the electric and gas welder is obliged to report this to the work manager and act on his instructions.

2.12. An electric gas welder should not start work if the housing of the welding transformer or converter does not indicate the inventory number, the date of the next insulation resistance measurement and the workshop (site, etc.).

3. Labor protection requirements during work

3.1. During work, the electric gas welder must:

— keep your workplace, assigned equipment and territory clean, use protective equipment and devices that ensure labor safety;

— use safe labor practices during work, follow the sequence of operations provided for by the work permit and equipment operating instructions;

- do not allow persons unrelated to the work performed to enter the workplace;

- perform only the work that is assigned to him (by the administration, the work manager) and provided that the safe methods of performing it are well known;

— protect electric gas welding areas with mobile shields if the work is carried out near other workers, technological installations or equipment;

— make sure that the wires are not in the water, do not cross roads or railway tracks;

- use only a special welding wire to supply voltage to the structures being welded. It is prohibited to use metal rods, strips, rails or any other objects for this purpose;

— when working, to protect your eyes and face, be sure to use a shield or helmet with special protective dark glasses.

3.2. Welding is allowed to be carried out at a distance of at least 10 m from flammable or explosive materials (fuel barrels, cylinders, acetylene gas generators).

3.3. When carrying out hot work in the rain, it is necessary to use a portable tent.

3.4. When carrying out welding work on barrels and other containers containing hydrocarbons (gasoline, condensate, petroleum products, etc.), all openings in them must be open. Welding on pressure vessels is prohibited. Welding (cutting) of freshly painted structures and parts should be done only after the paint has completely dried.

3.5. Hot work in a closed space without a hose gas mask can be carried out provided that the volume fraction of oxygen in the atmosphere of the tank or other containers is at least 20%, and the content of harmful vapors and gases does not exceed their maximum permissible concentrations. In this case, the possibility of harmful, explosive vapors and gases entering the work area from the outside must be excluded. Everyone working in a confined space and observing must have hose gas masks in the “ready” position.

3.6. When performing hot work inside closed tanks and other containers, it is necessary to use a safety belt, the free end of which must be in the hands of a worker outside the container.

3.7. When performing electric gas welding inside steel tanks, the electric gas welder must work in dielectric galoshes on a rubber mat.

3.8. It is prohibited to lay the welding cable together with oxygen, propane hoses and pipelines under pressure or at high temperatures, as well as near oxygen cylinders and acetylene units.

3.9. It is prohibited to touch uninsulated or unshielded live parts of electrical devices, open the doors of electrical distribution cabinets, put mittens, gloves, food, dishes, etc. in them, remove fences and protective covers from live parts and equipment.

3.10. When working in explosion- and fire-hazardous rooms, as well as in wells and tanks, it is necessary to work with electric welding installations that have an electrical interlock, which ensures automatic switching on of the welding circuit when the electrode comes into contact with the workpiece being welded and automatic shutdown of the welding circuit when idle, or use a voltage reduced to 12 V in welding chain.

3.11. As a return wire, it is allowed to use steel busbars of any profile, but of sufficient cross-section (at least 25 mm2), as well as welding racks and welded pipes.

3.12. Clean welding seams from slag and scale with a wire brush while wearing safety glasses. The parts to be welded must be securely fastened before welding begins. When cutting structural elements, the electric and gas welder is obliged to take measures against accidental falling of the cut elements.

3.13. To avoid splashing of molten metal, first clean the welding area on the product.

3.14. It is not allowed to disconnect the welding wire by jerking without approaching the rheostat.

3.15. It is prohibited to work near unfenced or unclosed hatches and openings.

3.16. The serviceability of electric welding units and the absence of voltage on the housing are regularly checked by an electrician of at least III electrical safety approval group using a megohmmeter.

3.17. Labor protection requirements when operating acetylene generators:

3.17.1. Portable acetylene generators must be installed outdoors or under a canopy; for temporary work, installation of acetylene generators in production and service rooms is allowed, provided that these rooms are well ventilated.

3.17.2. When loading calcium carbide into the generator, it is necessary to exclude the possibility of pieces of carbide hitting the metal surface of the retort in order to avoid sparks. Load carbide while wearing rubber gloves and safety glasses.

3.17.3. It is prohibited to leave a portable acetylene generator unattended while it is running.

3.17.4. When operating reducers, it is prohibited to attach a reducer and a hose intended for flammable gas to an oxygen cylinder, install reducers and open the valves of oxygen cylinders with oily hands, and lubricate the reducer of oxygen cylinders to avoid an explosion.

3.17.5. It is prohibited to consume acetylene from the generator until the pressure is completely reduced and the flame of the burner (cutter) goes out, in order to avoid air leaks and the occurrence of a backfire. Select acetylene (depending on the outside air temperature) to a residual pressure of at least 0.05 - 0.3 MPa. The gearbox must be connected to the cylinder using a key that is always in the possession of the welder (gas cutter). Tightening the union nut of the gearbox with the cylinder valve open is prohibited. In cases where gas is detected passing through the acetylene valve seal after connecting the reducer, tightening the seals must be done with the cylinder valve closed. The use of a cylinder with a valve that allows gas to pass through is prohibited. Such a cylinder with a chalk inscription indicating a valve malfunction should be sent to the filling plant (workshop).

3.17.6. If the flame backfires, immediately close the valves on the burner (cutter), cylinders and water seal.

3.17.7. Before the flame is re-ignited after a blowback, the condition of the valve must be checked by disassembling it and inspecting the check valve, and in a diaphragmless valve the reflector must be inspected.

3.17.8. After each return blow, the hoses should be purged with inert gas and checked for strength or replaced with others.

3.17.9. It is prohibited to heat metal with a torch using only flammable gas without connecting oxygen.

3.18. Labor protection requirements when using hoses:

3.18.1. Sleeves must be inspected before work to identify cracks, cuts, abrasions, etc. The outer surface should be free of peeling, bubbles, exposed areas of braid, dents and other defects.

3.18.2. The use of defective hoses, as well as wrapping them with insulating tape or other material, is prohibited. If it is necessary to repair a hose, damaged areas must be cut out and individual pieces connected with special nipples. It is prohibited to connect hoses using sections of smooth tubes. The minimum length of the section of joined hoses must be at least 3 m; the number of joints on the sleeves should not be more than two. The length of hoses for gas welding and cutting should not exceed 30 m, and for installation work - 40 m.

3.18.3. Fastening the hoses to the connecting nipples of equipment (burners, cutters, gearboxes, etc.) must be reliable; For this purpose, special clamps must be used. It is allowed to tie the sleeves with soft annealed steel (knitting) wire in at least two places along the length of the nipple. The hose connection points must be carefully checked for tightness before and during work. The sleeves should be placed tightly on the nipples of the water valves, but not fastened.

3.19. Labor protection requirements for gas-flame work:

3.19.1. The gearbox valves should be opened slowly and smoothly, and the opening valve should be located in the direction opposite to the direction of the gas stream. There should be no people or loose (loose) objects directly in front of the valve when it opens. Oxygen must be removed from the cylinders until the residual gas pressure in the cylinder is at least 0.05 MPa (0.5 kgf/cm2).

3.19.2. It is forbidden to leave the unit with the valve closed on the burner (cutter) and open on the cylinder, as gas condensation in the hose is possible.

3.19.3. Tightening the threaded connections while the cylinder valve is open is prohibited.

3.19.4. Moving propane and oxygen cylinders is permitted only on special carts and stretchers. Carrying them on the arms and shoulders is prohibited.

3.19.5. Gas-flame work (welding, cutting, heating products) must be carried out at a distance:

- at least 10 m from groups of cylinders (more than two) intended for gas-flame work;

— 5 m – from individual cylinders with oxygen and flammable gases;

- 3 m - from gas pipelines of flammable gases, as well as from gas dispensing stations located in metal cabinets, when performing work manually, and 1.5 m - when producing it mechanized. The indicated distances apply to gas-flame work, when the flame and sparks are directed in the direction opposite to the gas power sources. If flames and sparks are directed towards gas sources, measures must be taken to protect them from sparks and the effects of flame heat by installing metal screens.

3.19.6. When welding and cutting, the following basic safety rules must be observed:

— while working, it is prohibited to hold gas welding sleeves and metal cutters under the armpit, on the shoulders, or pinching them with the legs;

— it is not allowed to move a worker with a lit burner (cutter) outside the workplace, as well as climb ladders, scaffolding, etc.;

— during breaks in work, the flame of the burner (cutter) must be extinguished, and the valves on it must be tightly closed;

— during long breaks in work (lunch, etc.), the valves on oxygen and acetylene cylinders or on gas dispensing stations must be closed, and the pressure screws of the gearboxes must be turned out until the spring is released;

— if the burner (cutter) overheats, work must be stopped, and the burner (cutter) must be extinguished and cooled to ambient temperature. To cool it, the electric gas welder must have a vessel with clean cold water.

3.19.7. An electric gas welder is prohibited from:

— leave energized electrical holders unattended;

- allow auxiliary workers to work if they do not have glasses with special protective lenses;

— touch the hot electrode and heated areas of the pipes being welded with your hands;

— work when there is gas contamination in the air or leakage of flammable gases or liquids from an existing pipeline laid nearby;

— carry out welding work from ladders and stepladders;

— carrying out simultaneous welding and paint work on equipment located in the same room.

3.19.8. During work, the electric and gas welder must observe personal safety measures, use safe work practices, and comply with labor protection, occupational hygiene, and fire safety requirements.

4. Occupational safety requirements in emergency situations

4.1. If an emergency occurs, the electric and gas welder must stop work, leave the danger zone and report the incident to the work manager.

4.2. In case of an accident at work:

- inform the head of the department;

— help organize first aid for the victim and, if necessary, transport him to a medical organization;

— take urgent measures to prevent the development of an emergency or other emergency situation and the impact of traumatic factors on other persons;

- before the investigation of the accident begins, preserve the situation as it was at the time of the incident, if this does not threaten the life and health of other persons and does not lead to a catastrophe, accident or other emergency circumstances, and if it is impossible to preserve it, record the current situation (compile schemes, carry out other activities).

4.3. If an accident occurs with the electric and gas welder himself, you should stop working, report the incident to the work manager, or ask someone around you to do this, and if possible, go to a medical facility.

4.4. Attention: When freeing a victim from the effects of electric current, be careful not to come into contact with a live part or under voltage.

4.5. In order to prevent occupational etching, the electric gas welder must observe the rules of personal hygiene:

- do not enter the dining room in dirty overalls;

- wash your hands thoroughly before eating and take a shower after finishing work;

- when working with lead or its inorganic compounds, before the lunch break and after work, wash your hands with a 1% solution of acetic acid, and then with warm water and soap, and before eating, rinse your mouth with a weak solution of potassium permanganate (pink);

— when working with lead or its inorganic compounds, it is necessary to consume food products, drinks or natural fruit juices with pulp enriched with pectin before starting work, and fermented milk products during the working day;

- if you feel very unwell, consult a doctor and strictly follow his advice and prescriptions;

- when performing work where the dispensing of milk is established due to harmful working conditions, it is mandatory to drink milk;

- Do not wash your hands with leaded gasoline, benzene, antifreeze, or methanol.

5. Labor protection requirements upon completion of work

5.1. Upon completion of work, the electric and gas welder is obliged to:

— turn off the switch of the welding machine;

— collect used cleaning material, waste liquids (if any), and other waste in special containers and hand them over for disposal in the prescribed manner;

— turn off local ventilation;

— examine all places where hot metal particles and sparks can fly and cause a fire;

— hand over the workplace clean to the manager and report all comments and malfunctions identified during work;

— remove and clean the personal protective equipment, collect the wires and place them in a specially designated place;

— hand over additional PPE and safety devices to the work manager;

— take the necessary personal hygiene measures (wash your hands thoroughly, take a shower, etc.).

Download: Instrukciya-po-ohrane-truda-dlya-elektrogazosvarshchika

Similar articles:

- Instructions for labor protection when performing electric welding and gas welding work. Instructions for labor protection when performing electric welding and gas welding work. Requirements for safe work performance. Download. Sample…

- Occupational safety instructions for tractor drivers Occupational safety instructions for tractor drivers. Requirements for safe work performance. Download…

- Instructions on labor protection for a cook. Instructions on labor protection for a cook. Requirements for safe work performance. Download. Sample instructions...