During construction or renovation, it is often necessary to drill holes in concrete and stone with a hammer drill. In order for the drilling process to proceed quickly, it is necessary to select the correct concrete drill for the hammer drill. Many people mistakenly think that they can make holes in such material with simple drills. But in fact, during the drilling process, ordinary consumables quickly bend and become dull. This article will discuss the criteria for choosing a drill for a hammer drill. To make it easier to understand, the most popular blastholes from well-known world brands will be listed today.

Types of boreholes

Drill and drill: what is the difference

A drill differs from a drill in that it drills holes through impact-rotational movements. Thanks to this, it is possible to make deep holes (up to 1000 mm) in high-strength structures, which are extremely problematic and often impossible to drill with conventional drills.

True, in the process of such drilling it is often necessary to make reciprocating movements to extract dust from the hole being made. The hole tip is generally equipped with a crown (most often consisting of several cutting segments), which significantly increases its service life.

Important! The most important thing is that the drill does not bite while drilling concrete, otherwise it will break or jam. To extract a hole, some types of hammer drills provide reverse operation. It is also necessary to regularly lubricate the shank so that it wears less.

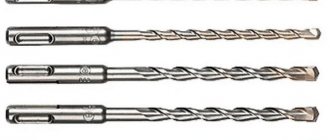

The drill differs from the drill and has a shank (the part fixed in the chuck). The drill is mainly fixed by movable cams. A special cartridge with locking balls is provided for drill holes. Today, drills with a chiselling function are sold on the market, but they are ineffective in working with hard materials.

SDS Plus Size Chart

Design features of a drill bit, what they look like

Before starting the work, the master determines which drill to use to drill the concrete. If used with a drill, the base will be round or hexagonal. No side grooves are made here due to the fact that this is not necessary. They are required when the master will work with a hammer drill, and are designed for stronger fastening of the part.

For drilling in monolithic slabs, a pobedit tip is used. It retains its sharpness for a long time even with intensive use. Pobedit is an alloy of tungsten and cobalt, with very high strength.

Note! Drilling with diamond bits is used to create recesses. They are cylindrical in shape and made of hardened steel, mounted on a rod to be secured in a chuck. The working edge can be smooth or serrated. To increase its strength, diamond coating is applied to it.

Using diamond drills is more expensive than conventional tools, but provides better results. When using such a tool, even the most durable types of concrete will be drilled quickly. The resulting holes will have smooth edges. When the master works in this way, the formation of dust and debris is almost completely absent.

Types of concrete drills for rotary hammers

They differ in some important parameters, which are discussed in detail below.

Shank size

There are 5 types:

- SDS - shank with a diameter of up to 10 mm with two grooves.

- SDS plus is the most common size used in household hammer drills. It is characterized by a diameter of no more than 25 mm. There are four grooves for fixing it.

- SDS-max - shank with a diameter of up to 80 mm, used in industrial units. For fixation, it uses three open and two closed grooves.

- SDS-top is an intermediate shank size with a diameter of 16-25 mm, used in some BOSCH power tools. It has 4 grooves for good fixation.

- SDS-quick is a hex shank with a diameter of 4-10 mm, designed for Bosch Uneo/Uneo Maxx rotary hammers. It uses dowels for fixation.

Diameter and length

These are the most important dimensions of the drill, so you should definitely pay attention to them during selection and purchase.

- Diameter. Depends on the length and type of shank - for example, the maximum permissible hole Ø SDS max is no more than 50 mm. It is expressed as an even number.

- Length. The maximum drill length for a rotary hammer is 1000 mm, and the minimum is 100 mm. In production, the most popular drills are Ø 18, 20, 22, 24, 28 and 32. The drilling procedure does not allow the use of longer holes - it is impossible to drill holes with them.

The length of the drill depends on its diameter. These characteristics must be balanced so that deep holes can be drilled efficiently and safely.

The article contains tables showing the length and diameter of drills produced today.

Size Chart SDS Max

It should be noted that the longest drill for rotary hammers in accordance with the latest table is 1320 mm.

Resource (durability)

Experienced installers drill a large number of holes in various structures every day, so the working surface of the hole quickly wears out and its productivity is lost. The durability of a concrete drill for a hammer drill mainly depends on the metal used in its production.

In particular, much depends on the quality of the soldered crown, which is responsible for the main function of the drill (destruction of solid material). If necessary, you can use a drill to drill holes in wood products.

Attention! When choosing a drill hole, you need to take into account its main performance characteristics so that you do not have to subsequently purchase a new one and spend additional money.

Correct selection of drills

The main criterion will be the choice of drill according to the chuck. Depending on the hammer drill chuck, the drill is also selected, because another type simply will not work.

After this, you need to choose the required size. When choosing a drill, choose a size that is slightly smaller than the required hole. This is due to the fact that when the hammer drill operates, an error is created, which crushes the concrete (and other elements) around the circumference as the drill moves. The assortment on the market is very large, so it will not be difficult to choose a smaller one.

The third thing you need to pay attention to is the length. It's a matter of the depth of the required hole, and the assortment allows you to find what you need.

But long drills with half a meter and a diameter the size of a match simply do not exist - as the length increases, small diameters are discarded and vice versa.

The best drill bits for a concrete hammer drill: rating

Listed below are the most popular drill bits for household and industrial hammer drills today. Thanks to this rating, you can choose effective and durable blast holes for them.

DeWALT EXTREME 2 DT7935B-QZ

Set of 10 drills (USA) in a convenient case with a latch. The drills have an SDS-plus shank, a diameter of 5-12 mm and a length of 110-160 mm. They are designed to work with stone, concrete and brick. Capable of working flawlessly for a long time with proper care.

Intended for household use. It is worth noting that this set is inexpensive.

Set DeWALT EXTREME 2 DT7935B-QZ

BOSCH 3.5×50/110 mm

The drills are distinguished by high quality workmanship and durability. This drill with an SDS+ shank allows you to quickly carry out construction and repair work in a house or apartment.

The cutting segments of the drill bit are made of high quality, so it allows you to make holes in stone, brick and concrete without any problems.

BOSCH 3.5×50 – 110 mm

Granite 425100 25/1000 mm

Has an SDS-plus shank. It uses four cutting segments and a double spiral for high-quality dust removal. It is made of high-alloy steel, and is subjected to hardening. Thanks to this, the service life of the product is significantly increased.

For reference! Due to high demand, it is difficult to find on the domestic market.

Granite 425100 25/1000 mm

Makita D-00050 /100 mm

This drill is designed for household power tools with SDS-plus chucks. It uses two carbide cutting edges, so the process of drilling the material is more uniform and faster.

The drill tip is well centered, due to this, drilling takes place exactly in the given direction. Thanks to the use of this tool, vibration is practically not felt during drilling.

Makita D-00050 −100 mm

Granite Quadro-X 845570 45/570 mm

Designed for industrial hammer drills with SDS-max chucks. Its cutting bit consists of four cutting parts made of high-alloy metal. Thanks to this, the drill has increased wear resistance.

It has a double spiral, due to which the destroyed material is quickly discharged out.

Granite Quadro-X0 mm

Thanks to this rating, the reader will no longer have the question of which drill bits are best for rotary hammers today.

With the help of this article, you can quickly select the optimal drill for a household and industrial hammer drill, and then at any time make the required number of holes in walls, floor slabs and other structural elements of buildings and structures. The most important thing in the drilling process is to adhere to drilling technology and safety precautions so as not to get injured or break the tool used in the work.

Drilling recommendations

Drilling concrete has its own characteristics and is very different from working with metal, wood or plastic. The reason for this is the heterogeneous composition of concrete. Thus, its structure contains mineral inclusions of various fractions, metal reinforcement and technical cavities.

When drilling concrete, you need to follow a few simple recommendations:

- Use drills or drill bits that are appropriate for the tool (drill or hammer drill). In order not to make mistakes, you need to use the instructions supplied with the tool or find its specification on the manufacturer’s website.

- To drill pure concrete, you need to use either drill bits with Pobedit cutters or drill bits for a rotary hammer (with the same Pobedit inserts).

- If you plan to drill ceramics or stone such as marble, then you need to use diamond-coated drills or core bits. You need to work at low speeds, take breaks to cool the working part (naturally - with air, without any liquids). In addition, you need to regularly remove crushed material from the hole using a construction vacuum cleaner.

- If you encounter a large stone in the thickness of concrete, you need to crush it using some kind of hammer and only then continue drilling.

- When drilling a hole in concrete, you need to take into account that its diameter 2-3 mm greater than the diameter of the drill. The reason for this is the inevitable beating and, accordingly, chipping of the hole walls.

- When using conventional drill bits in a drill, they should not make impact movements - this will damage their cutting part. This recommendation also applies to diamond-coated drills.

- Drill bits for concrete hammer drills and diamond-coated bits are distinguished by high hardness and at the same time brittleness. Therefore, they need to be drilled at medium speeds without overheating and under no circumstances should shock loads be allowed.

- In no case should you make holes or recesses using a hammer drill on the edge of walls or ceilings - this can lead to chipping of the surface (concrete, for all its hardness, is very fragile and in such places, impact loads can damage it uncontrollably)