Metalworking does not cause difficulties only for those who know how and what to work with. Beginners in this business have to start with the basics, for example, finding out which metal drills are better or what shape of tip is needed for round holes.

There are not many special tools that can be used to work without the help of a machine. Therefore, it is important to understand what drills are, how they are classified and what they are intended for.

Drill steel grades - which ones are better?

Nowadays, buying a high-quality metal drill is a real problem; most drills are Chinese, their quality leaves much to be desired.

The quality of a drill depends, first of all, on the grade of steel from which the drill is made. Most modern metal drills are made from R6M5 steel, although the difference between modern drills and drills from the USSR (with a quality mark) is simply huge, Chinese drills instantly roll up and it is impossible to drill even an ordinary corner made of 3mm iron with them. One drill is enough for several holes. However, there are also high-quality drills that last a long time.

Let's look at the steel grades, because the quality and durability of the drill depends on this.

P18 is now a legendary steel. Containing 18 percent tungsten, this steel supports metal processing even at high speeds. Drills made of P18 steel do not overheat, endure for a long time and drill well. True, finding the real ones is a whole problem. In Soviet times, r18 steel was used very widely for the manufacture of metal-cutting tools, but after the 70s, tungsten reserves were depleted and it was replaced by steel with a lower tungsten content - r6m5.

R6M5 - 6 percent tungsten, 5 percent molybdenum. Standard steel for metal-cutting tools. If the drill for metal is a Soviet one made from R6M5, then it is perfect for everyday use at home; such drills last for a long time, although they cannot drill through more hardened iron. The following drills with the addition of cobalt are suitable for this.

R6M5K5 is the same as R6M5, only 5 percent cobalt is added, which makes these drills even stronger and more durable. Cobalt drills are suitable for drilling where high temperatures are generated during drilling. Photo:

Excellent for drilling stainless steel and other hardened steels. In general, if ordinary drills do not take iron, then buy one with cobalt, you will feel the difference.

HSS is a foreign analogue of high-speed steel, translated as High Speed Steel, that is, steel for working at high speeds. HSS drills are similar in composition to the standard P6M5 high-speed cutter.

By the way, hss also comes with the addition of cobalt; drills are marked HSS-Co. Drills with this marking will be identical to our R6M5K5. Drills with cobalt - for drilling stainless steel and other durable steels.

It is also worth mentioning specialized drills for porcelain tiles, they are soldered and also come with crowns, if you are looking for information, follow the link, I prepared an article at the request of workers.

In general, if you decide to buy high-quality drills for your home, then I would recommend first asking around for drills from the USSR era; if they have a quality mark on them, then this is generally better than that. Soviet ones are inexpensive, you can even look at flea markets, you can probably find something there too.

Sovdepov drills are an excellent tool. If you take imported ones, then they cost a lot, for example, 6 mm HSS-Co drills cost around 70-80 rubles, while a similar Soviet one can be bought for 20-30 rubles.

Characteristics of HSS steels

HSS steels are divided into three groups:

- Tungsten (T);

- Molybdenum (M);

- High-alloy high-speed steels.

Tungsten steels are practically not used today due to the high cost of tungsten and its shortage. The most common are T1 general purpose steel and T15 vanadium cobalt steel. T15 is used for tools operating under conditions of high temperatures and wear.

Molybdenum group steels have molybdenum as their main alloying element, although some contain equal or greater amounts of tungsten and cobalt. Steels with a high content of vanadium and carbon are resistant to abrasive wear. A series of steels starting from M41 is characterized by high hardness when operating at high temperatures (red resistance). Molybdenum steels are also used in the manufacture of tools operating in “cold” conditions - rolling dies, cutting dies. In such cases, HSS steels are hardened to lower temperatures to improve toughness.

Table of common chemical compositions of HSS steels. Domestic analogues.

| Type | Fatherland analogue | Chemical composition, % | ||||||||

| C | Mn | Si | Cr | V | W | Mo | Co | Ni | ||

| Tungsten HSS steels | ||||||||||

| T1 | P18 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | — | — |

| T2 | R18F2 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | — | — |

| T4 | R18K5F2 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | 5,00 | — |

| T5 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | 8,00 | — | |

| T6 | 0,80 | — | — | 4,50 | 1,50 | 20,00 | — | 12,00 | — | |

| T8 | 0,75 | — | — | 4,00 | 2,00 | 14,00 | — | 5,00 | — | |

| T15 | R12F5K5 | 1,50 | — | — | 4,00 | 5,00 | 12,00 | — | 5,00 | — |

| Molybdenum HSS steels | ||||||||||

| M1 | 0,80 | — | — | 4,00 | 1,00 | 1,50 | 8,00 | — | — | |

| M2 | R6M5 | 0,85 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — |

| M3 | R6M5F3 | 1,20 | — | — | 4,00 | 3,00 | 6,00 | 5,00 | — | — |

| M4 | 1,30 | — | — | 4,00 | 4,00 | 5,50 | 4,50 | — | — | |

| M6 | 0,80 | — | — | 4,00 | 2,00 | 4,00 | 5,00 | — | — | |

| M7 | 1,00 | — | — | 4,00 | 2,00 | 1,75 | 8,75 | — | — | |

| M10 | 0,85-1,00 | — | — | 4,00 | 2,00 | — | 8,00 | — | — | |

| M30 | 0,80 | — | — | 4,00 | 1,25 | 2,00 | 8,00 | — | — | |

| M33 | 0,90 | — | — | 4,00 | 1,15 | 1,50 | 9,50 | — | — | |

| M34 | 0,90 | — | — | 4,00 | 2,00 | 2,00 | 8,00 | — | — | |

| M35 | R6M5K5 | 0,82-0,88 | 0,15-0,40 | 0,20-0,45 | 3,75-4,50 | 1,75-2,20 | 5,5-6,75 | 5,00 | 4,5-5,5 | up to 0.30 |

| M36 | 0,80 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — | |

| High alloy HSS steels | ||||||||||

| M41 | R6M3K5F2 | 1,10 | — | — | 4,25 | 2,00 | 6,75 | 3,75 | 5,00 | — |

| M42 | 1,10 | — | — | 3,75 | 1,15 | 1,50 | 9,50 | 8,00 | — | |

| M43 | 1,20 | — | — | 3,75 | 1,60 | 2,75 | 8,00 | 8,25 | — | |

| M44 | 1,15 | — | — | 4,25 | 2,00 | 5,25 | 6,25 | 12,00 | — | |

| M46 | 1,25 | — | — | 4,00 | 3,20 | 2,00 | 8,25 | 8,25 | — | |

| M47 | R2AM9K5 | 1,10 | — | — | 3,75 | 1,25 | 1,50 | 9,50 | 5,00 | — |

| M48 | 1,42-1,52 | 0,15-0,40 | 0,15-0,40 | 3,50-4,00 | 2,75-3,25 | 9,50-10,5 | 0,15-0,40 | 8,00-10,0 | up to 0.30 | |

| M50 | 0,78-0,88 | 0,15-0,45 | 0,20-0,60 | 3,75-4,50 | 0,80-1,25 | up to 0.10 | 3,90-4,75 | — | up to 0.30 | |

| M52 | 0,85-0,95 | 0,15-0,45 | 0,20-0,60 | 3,50-4,30 | 1,65-2,25 | 0,75-1,50 | 4,00-4,90 | — | up to 0.30 | |

| M62 | 1,25-1,35 | 0,15-0,40 | 0,15-0,40 | 3,50-4,00 | 1,80-2,00 | 5,75-6,50 | 10,0-11,0 | — | up to 0.30 |

Not all analogues may be indicated in the table, since at present there may be a large number of borrowed, non-governed brands.

A cutting tool made with tungsten content (W) will have a very useful quality for the tool - red resistance. It allows tools to maintain a sharp cutting edge and hardness at red-hot temperatures (up to 530°C). Cobalt further increases the red hardness and wear resistance of HSS steels.

M1. Used for the production of drills for a wide range of applications. M1 steels have lower red resistance than M2 steels, but are less susceptible to impact and are more flexible, making them suitable for general work.

M2. Standard material for making tools from HSS steels. M2 has good red hardness and retains its cutting edge longer than other HSS steels with lower tungsten content. Typically used for the manufacture of tools for high-performance machine work.

M7. Used for heavy-duty drills for drilling hard sheet metal. Typically used where flexibility and extended service life are equally important.

M50. Used to make drill bits that are used for drilling on portable equipment where breakage due to bending is a problem. Does not have the same red resistance as other HSS tungsten steels.

M35. M35 steels have increased red resistance compared to M2. At the same time, cobalt slightly reduces impact resistance.

M42. M42 “Super Cobalt” steels have excellent abrasion resistance and good red-hardness. Used for work on viscous and complex materials.

Selecting drills for metal

Metal drills are intended for drilling holes in alloyed and non-alloyed steel, its various alloys, cast iron, and other types of various metals, as well as in particularly hard plastics. In addition, drills are used for drilling ready-made holes and drilling or, in other words, for creating blind recesses in metal. To understand how to choose a drill for metal, it would be nice to have at least a basic understanding of their classification, materials of manufacture and design features of different types of this cutting tool.

Types of drills for metal

Metal drills differ from each other in several ways: manufacturing method, shank shape, scope of application, and, of course, diameter. First, let's look at what types of metal drills there are based on their design features. Here are their main types:

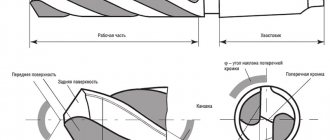

- Spiral or screw. Such metal drills are distinguished by the fact that they have the same diameter along their entire length and are used to produce both through and blind holes. The drill consists of a cylindrical working part with a pair of helical cutting edges and grooves along which the chips flow away.

- Stepped. Unlike the first type on our list, these drills are not cylindrical, but conical, so they can be used to drill holes of different diameters without changing the cutting tool. The main advantage of step drills is their versatility, however, they are designed to work mainly only with sheets of metal, since they cannot drill a hole in a metal workpiece thicker than 2 mm.

- Crowned. Designed for making large-diameter holes or when drilling several sheets of metal at the same time, the so-called multi-layer hole making. Such drills differ in the frequency of cutting edges and are made of high-speed steel.

- Countersink. Also made in the shape of a cone. These are metal drills that are intended for countersinking, that is, this type of mechanical cutting in which both cylindrical and conical holes are machined to increase their diameter.

Features of heat treatment

The result of high-temperature processing of high-speed steels is a change in the structure of the material to obtain certain physical and mechanical properties required when working with this tool.

Annealing

HSS steel after the rolling and forging process acquires increased hardness and internal stress. In this regard, the workpieces are preliminarily annealed. Annealing relieves the internal stress of the material, improves machinability and prepares it for hardening.

The annealing process occurs at a temperature of about 850-900°C. However, one should be wary of excessively increasing the temperature and duration of exposure, because this may cause the steel to become more hard. Due to the reduced thermal conductivity of the alloy, heating is carried out slowly and evenly.

The products are loaded into the oven at a temperature of 200-300oC, while subsequent heating is increased at a rate of 150-200o/hour. The process ends with slow cooling: first in an oven to 650 ° C, and then to room temperature in the open air.

Machine-building plants subject a small number of workpieces to isothermal annealing. They are heated to 880-900oC for a short time, and then transferred to an oven with a temperature not higher than 720-730oC for 2-3 hours. To protect against the appearance of excessive internal stresses, the workpieces are cooled in an oven to 400-450°C and then left in the open air.

Conventional annealing takes longer than the isothermal process. Subsequently, the workpieces undergo mechanical processing, and then the tool undergoes the final heat treatment process - hardening and tempering.

Hardening

Tools made of high-speed steel are hardened at temperatures above 1300°C. After the hardening process, repeated tempering occurs at 550-560°C. This temperature is necessary to dissolve a large number of carbides in the austenite to obtain highly alloyed austenite.

With further cooling, highly alloyed martensite is obtained, which contains large amounts of tungsten, vanadium and chromium. Martensite does not disintegrate when heated to 600°C, which gives high-speed steel red-hardness.

To obtain high red-hardness values, the temperature during hardening must be very high. However, there is a limit, when exceeded, rapid grain growth begins in high-speed steel and melting occurs.

Vacation

Hardened high-speed steel must undergo a tempering process. At a temperature of 550-560°C, a multiple process is carried out at intervals of 1 hour. The purpose of tempering is to transform austenite into martensite. High speed steel goes through two internal processes:

- When heated and subsequently tempered, ground carbide is released from the retained austenite. As a result, the alloying of austenite is reduced, which facilitates easy transformation into martensite.

- During cooling at 100-200°C, martensite is obtained. This also relieves the internal stress that arose during hardening.

Nowadays, factories most often use the process of accelerated tempering of steel, which takes place at elevated temperatures.

What steel are metal drills made from?

The vast majority of metal cutting tools are made of high-speed steel, which may have various impurities, such as tungsten, cobalt, chromium, vanadium or molybdenum. The presence of one or another additional metal in the composition of high-speed steel can be understood from the markings of the drill. So, the letter M indicates the presence of molybdenum in the alloy, the letter F indicates that the alloy contains at least 3% vanadium, and if the letter P is present in the marking, then this is a sign that the alloy contains tungsten. It should be noted that chromium and carbon are not marked.

What is high speed steel? This is a type of steel that has ultra-high hardness, resistance to fracture and outstanding red-hardness. Thus, conventional carbon tool steels are not capable of providing high drilling or cutting speeds, but high-speed steels, thanks to alloying with the above-mentioned impurities, successfully cope with such extreme conditions.

In addition, not only the markings, but also their color can tell something about the materials from which drills are made. So, bright golden indicates that the drill is coated with titanium nitrite. Such drills have a long service life due to their increased wear resistance. And the black color of a drill, for example, indicates that it has been treated with steam, which also improves the quality of the cutting tool.

Tips for choosing

To choose the right drill, you need to pay attention to important points

- Study the characteristics of the material and the capabilities of the drill so that the tool meets the requirements of the work being performed.

- Look at the color of the product. It can talk about how the metal was processed.

- steel color indicates that no heat treatment was performed;

- yellow – the metal has been processed, internal stress in the material has been eliminated;

- a bright golden hue indicates the presence of titanium nitride, which increases wear resistance;

- black – the metal is processed with hot steam.

- Study the markings to find out the type of steel, diameter, hardness.

- Find out about the manufacturer, consult with specialists.

- Study the issue of tool sharpening.

Often drills are sold in sets, for example, with different diameters. The question of purchasing such a tool requires an understanding of what purposes the drill is required for and how many options can be used.

To learn how to make a device for sharpening a drill on a grinder, see the video below.

Sharpening a drill for metal

Not everyone can afford to buy new drills every time they become dull. Moreover, a high-quality metal drill, and not a cheap Chinese knockoff, is quite expensive. The good news is that with basic skills and a sharpening machine, you can sharpen a drill at home, thus avoiding unwanted financial expenses. Even if you don't have a sharpening machine at home, a regular drill and sharpening wheel will do the job. When sharpening a drill, you need to keep in mind that not only the drill head should be processed, but also the entire side cutting edge.

Which metal drills are best?

Metal drills are made from tool high-speed steel HSS (High Speed Steel

). These are alloy steels containing elements such as tungsten, molybdenum, as well as vanadium and cobalt. These additives have a positive effect on steel characteristics such as hot hardness (the heating temperature that steel can withstand), red-hardness (the time that steel can withstand high temperatures), and fracture resistance.

During the operation of the cutting tool, intense heat is released, which is used to warm up the tool. For tools made of ordinary carbon steel, operating mode when heated above 200°C is unacceptable, because The hardness of the steel begins to drop rapidly. Modern high-speed steels retain their properties at 500-600°C, which makes it possible to significantly increase drilling speed.

The process of manufacturing and heat treatment of drills plays a very important role. Large enterprises - industry leaders - have expensive control and measuring equipment at their disposal, which allows them to maintain consistently high quality of their products. NoName drills are often made of poor steel, the geometry is not maintained, and it is almost impossible to resharpen them - after the factory sharpening is completed, the drill becomes unsuitable for further use.

Let us briefly list the main types of metal drills

made of high-speed steel:

- HSS-E

drill steel contains cobalt and has superior cutting properties to other steels, so it is used for working on tough and complex materials. They are mainly used for drilling stainless steel, as well as alloy and non-alloy steel with a tensile strength of up to 1200 N/mm2.

| Testing of Diager HSS-E Co 5% drills | Diager HSS-TiN drill in use |

- The three-layer coating of HSS-TiAlN

(titanium-aluminum-nitrite) has a lower coefficient of friction and also forms a thermal barrier (the drill does not lose its properties when the outer shell is heated to 700°C), increases strength and increases the life of the drill by approximately 5 once. A drill coated with TiAlN should not be re-sharpened; damage to the coating will negate all the advantages of this drill. HSS-TiAlN drills are used for productive drilling of alloyed and non-alloyed steel with a tensile strength of up to 1100 N/mm2, aluminum, and cast iron. - HSS-TiN

drills made of steel coated with titanium nitride also heat up significantly less during operation, which increases drill characteristics such as strength and life by at least 3 times. TiN coated drills should not be re-sharpened. HSS-TiN drills are used for drilling alloyed and non-alloyed steel with a tensile strength of up to 1100 N/mm2, cast iron. - HSS-G

drills are ground drills made of high-speed tool steel with increased durability and low radial runout. HSS-G drills are the most common cutting tools for standard tasks. HSS-G drills are used for drilling alloyed and non-alloyed steel with a tensile strength of up to 900 N/mm2, cast iron. - HSS-R

drills are roller rolled and heat treated. Drills have the lowest durability. Mainly used for drilling mild steels and cast iron.

Special mention should be made of carbide drills

or drills with a soldered carbide tip, they have maximum strength and can withstand heavy loads. Used for drilling heat-resistant steels, stainless steel, titanium alloys.

To the question “Which metal drills are better?” We will answer this way - drills that will allow you to perform a specific task as efficiently as possible.

Full catalog

Legend

Deciphering the chemical composition of steels classified as HSS is difficult, since their designation does not contain any detailed data. As a rule, catalogs for tools made from steels of this category contain information about the materials for which they can be used. In order to relatively accurately determine the chemical composition of HSS steels, it is necessary to use special equipment or solve this issue experimentally.

Most likely, this is a German analogue of high-speed steel HSS M2

H.S.S.

The letter R is often added to this abbreviation. These are drills that are characterized by the least durability. They undergo roller rolling and heat treatment.

HSS G

This designation is applied to drills whose cutting part is ground using Borazon (CBN). HSS G tools are the most common and are distinguished by their increased durability. In addition, a metal drill on which such a designation is applied creates the least runout when processing with it.

HSS with letter E

This designation indicates that the material used to manufacture the product contains cobalt. Tools with the HSSE designation are ideal for machining difficult materials and materials with high viscosity. As mentioned above, an analogue of the HSSE designation is the M35 marking. There are also international analogues of the HSSE designation (HSS-Co5 and HSS-Co8), which can be used to accurately determine how much cobalt is contained in the steel alloy.

Steel of this grade is extremely difficult to cut with a grinder

HSS G TiN

This designation indicates that the surface of the tool is coated with titanium nitride. Due to this, both the hardness of the surface layer of the product increases (by approximately 2300 HV) and its heat resistance (up to 600°).

HSS G TiAIN

The surface of the tool with this designation is coated with titanium nitride alloyed with aluminum. Thanks to this coating, the hardness of the surface layer of such a drill increases by approximately 3000 HV, and the thermal resistance by 900°.

HSS E VAP

Products with this designation can be used for. There is less chip sticking to their surface, so they break less often and provide high quality processing.

You can often find tools with the designation HSS 4241, which are used primarily for processing wood, plastic and aluminum products. As for the Super HSS designation, each manufacturer puts into it their own ideas about the quality of the tool.

The video shows a test of a knife made of HSS W18 steel.