Metal structures welded from metal are in demand in various spheres of life. However, during welding work, various types of weld defects may occur. They shorten the possible service life of the connection and reduce the safety level of the finished product.

Types of weld defects

All tolerances on weld dimensions are regulated by GOST requirements for each type of welding. Any deviations of the readings from the approved standards are considered to be defects. They can be a consequence of errors in the process of both preparation and execution of welding work.

Most defects in a welded joint have a negative impact on its strength characteristics. All defects are divided into three groups:

- external _ The main indicators are irregular joint shape, cracks, sagging, craters, seam undercuts, burns and other visual signs that can be detected on the surface. They are visible upon careful visual inspection and only a few can be noticed at first glance;

- internal . Defects are incomplete or uneven fusion of metals, cracks or porosity in the structure, the presence of foreign inclusions - slag, oxide, non-metallic impurities; other flaws located inside the seam;

- end-to- end Cracks, undercuts, burns and other damage that are end-to-end and visible on both sides.

Any defects are grounds for rejection of the work and must be corrected. This rule is especially relevant for supporting metal structures - frames, frames, sheathing, etc. They must be welded flawlessly to withstand the expected loads. Otherwise, the structures may become a source of danger to others.

Types and causes of non-fusion

The defect manifests itself in different forms. There is a lack of penetration of the root of the weld (first type) and the edges (second type).

Lack of penetration in a welded joint of the first type is characterized by a lack of fusion of metals at the root of the weld. Loads, especially impact loads, reduce the resistance of the deformation area. Reasons for lack of penetration at the root of the seam:

- small gap;

- fine burner tip;

- soft flame;

- lack of welding eye;

- high welding speed;

- rusty, oxide, dirty edge surface.

There is such a thing as local lack of penetration of edges. This is the contact of a molten part on the surface of an unmelted one. A strong bond does not form between the metals, and the seam bead can even separate from the edge. The reasons are:

- poor melting;

- the burner is located on one side;

- fine tip;

- a large gap between the flame core and the metal surface.

In the case when liquid metal flows onto the edges of the main unheated material, sagging is formed. Most often they occur during welding of horizontal seams. They are easy to see and feel on a smooth surface.

Surges are formed due to the fact that:

- the metal of the object being fused is not sufficiently heated;

- the master guides the bar incorrectly;

- a mistake is allowed in calculating the angle of inclination for the mouthpiece from the burner.

Lack of penetration is usually hidden under the sagging. There are other defects that can ruin the design.

Classification of defects in welded joints

Not in every case is it possible to achieve ideal quality of the welded joint. If desired, you can find deviations from the established requirements. The full classification of welded joints is set out in paragraphs of GOST 30242-97. The document contains information about all possible flaws. Of these, we can highlight some that are most often encountered during control inspection of connecting joints.

Cracks

Cracks have the greatest negative impact on the quality of the weld. Potentially, they are the most dangerous, since they can cause rapid destruction of the entire structure, which in turn can lead to tragedy.

Cracks appear for various reasons:

- the joints are positioned incorrectly;

- the welding site was sharply cooled;

- incorrectly selected consumables;

- the metal crystallized due to excessively high temperature.

Based on the method of formation, cracks can be longitudinal, transverse or radial, and based on size, it is customary to distinguish between macro- and microcracks. Regardless of the type, causes and method of formation, a crack is an unacceptable defect.

Undercuts

Visually, the flaw is a longitudinal depression on the outer part of the seam. Due to the undercut, the cross-section of the seam is reduced and internal joint stress is generated. The strength of such a seam is highly questionable. The main reason for the formation of a defect is an overestimated welding current. Most often, undercuts are characteristic of horizontal seams.

Surges

Excess melt flows onto the surface of the workpiece, cools and forms a false bead. This is an influx that does not have strong fusion with the working surface. Most often, a defect is formed during horizontal welding of butt or fillet welds. The reason for their formation is insufficient heating of the base metal, due to excess filler material or scale on the edges of the mating surfaces.

Burns

A flaw is a through hole that is formed due to metal leaking out of the weld pool. As a rule, an influx forms from the reverse side. Burn-through is caused by too slow movement of the electrode along the joint line, too much current, insufficient thickness of the gasket or its loose fit, or a large gap between the parts.

Lack of penetration

If there are areas between the seams and the base metal where lack of fusion between them is visible, then this is a lack of fusion. That is, the base metal did not warm up properly to form a single whole with the melt. Such a defect greatly reduces the strength characteristics of the connection and the entire structure as a whole. The reason for lack of penetration may be too high a speed of movement of the electrode, poor preliminary preparation of the edges, the presence of scale, rust and other contaminants on the surface of the workpieces being joined.

Craters

Small depressions in the weld bead are formed as a result of a break in the welding arc. Defects lead to a reduction in the cross-section of the joint, which reduces its strength. The secondary danger of the crater is that its bottom may have additional loose inclusions, leading to the appearance of cracks.

Fistulas

Flaws are surface defects in the form of cavities. They reduce the strength of the joint and are additionally dangerous because they can provoke the formation of cracks. Fistulas are characterized by an arbitrary shape and can form both on the outside and on the inside.

Pores in the weld

Gas-filled pores may form during the welding process. The reason for their occurrence is various contaminants on the surface of the workpiece, high speed of electrode movement, and too high carbon content in the filler material.

Foreign inclusions

The quality of the weld is significantly reduced due to foreign inclusions - slag, flux, oxide, tungsten and others. The main reason that causes them is an incorrectly selected welding mode.

Cracks: types, reasons for their formation

A crack is a discontinuity that is caused by sudden cooling or exposure to stress. A type of this defect, which can only be detected with optical instruments with a magnification of at least fifty times, is called a microcrack.

Longitudinal cracks are located along the welded joint and can be located:

- in the weld metal;

- in the main material;

- at the fusion boundary;

- in the area of temperature influence.

Longitudinal crack

Cracks in the base metal, caused by high stresses, are called hidden. Outwardly, they resemble steps. This defect is inherent in welded joints of considerable thickness. High voltages are caused by joints that are too rigid or by incorrect selection of welding technology. Reducing welding stresses reduces the likelihood of hidden longitudinal cracks.

The configuration of longitudinal cracks is determined by the fusion lines of the weld and the base metal.

These cracks are divided into:

- hot, their cause is the high-temperature brittleness of the alloys;

- cold - occur during the slow destruction of metal.

Transverse cracks are oriented perpendicular to the axis of the weld. They can occur both in the base material and metal of the welded joint, and in the temperature-affected zone.

Radial cracks diverge from one point and are otherwise called star-shaped. Their locations are similar to the locations of transverse cracks. The reasons for the formation of transverse and radial cracks are the same as for longitudinal ones.

At the point where the arc is torn off, a depression is formed on the surface of the seam. Defects that occur at this location are called crater cracks. They are divided into longitudinal, transverse, star-shaped. The configuration of this defect is determined by: the microstructure of the welded joint zone, phase, thermal and mechanical stresses.

If a group of cracks not connected to each other occurs, then they are called separate. The locations and causes of their occurrence are similar to these characteristics of transverse and radial cracks.

If a group of cracks is formed from one crack, then such a marriage is called branched cracks. Their locations are the base material, the weld metal, and the thermally affected area. The causes of occurrence are the same as for longitudinal cracks.

Causes of weld defects

Any defect is formed due to a certain factor. There are different reasons for the formation of weld defects:

- During the work, low-quality consumables were used;

- the technology for performing welding work was not followed;

- low quality metal used to create the welded structure;

- equipment malfunction or poor quality work;

- incorrectly selected welding mode;

- technological errors were made due to the low qualifications of the specialist.

To obtain a high-quality metal structure, strict adherence to technological parameters and welding standards is required, and specialists with a sufficient level of qualification are involved in the work.

How to fix a lack of fusion defect

When high strength requirements are not imposed on a welded joint, the product can be accepted for service if a minor defect is located along the direction of the load. The shape and depth of the flaw is also taken into account. If the lack of penetration of the weld is accessible for welding, it is cleaned and welded. When installing critical structures, the rejected area is cut down or cut out, and after preparation it is welded again.

Regulatory documents allow the formation of lack of penetration if they do not exceed the established limits. Therefore, novice welders should not be afraid of defects; the main thing is to eliminate them in a timely manner. Knowing the reasons for the formation of lack of penetration, you can quickly learn to identify the places where they appear.

Defect detection methods

Various methods are used to identify weld defects:

- joint measurements and visual inspection;

- checking connections for leaks;

- searching for defects using special instruments;

- laboratory tests of samples for strength.

Visual determination of the quality of the weld is carried out only after thoroughly cleaning its surface from slag, eliminating various contaminants and frozen metal spatters. The dimensions, shape, and presence of defects are checked - burns, fistulas, cracks, craters and other flaws.

Thanks to leakage tests, it is possible to determine the presence or absence of pipeline defects - pores, cracks, lack of fusion. The tightness of the structure is checked in the following ways:

- air blowing;

- filling with water under pressure;

- kerosene treatment.

If a defect is detected, additional processing is required to eliminate it.

What is lack of penetration

In reference books, lack of fusion refers to defects in places where the base and deposited metal have not fused or the weld cross-section is not completely filled. Defects of this type are formed on the edges, between layers when welding wide joints in several passes, and at the root of the seam. On fractures and areas cut out for inspection, lack of penetration looks like a dark stripe between the base and deposited metal. Visually, a flaw can be detected by external cracks and pores that form on the outer surface of the weld. Internal cracks and other defects are detected by scanning the welded joint with X-rays, gamma rays, and ultrasound.

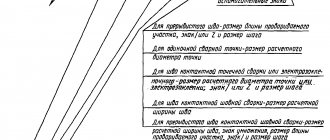

Types of lack of weld penetration

Methods for eliminating defects in welded joints

Regardless of the equipment involved - inverter, classic device, transformer, etc. - the formation of defects is not excluded. It is customary to distinguish between so-called acceptable and unacceptable welding defects. Depending on the type and complexity of the defects, the suitability of the finished product for use is determined.

Designs that are not approved for use are sent for revision. How the defect will be eliminated depends on the type of defect:

- the burn is welded after thoroughly cleaning the welded joint;

- undercuts are eliminated by applying a thin overlay along the entire length of their formation;

- the area with the crack is drilled out, the body of the seam is cut out, the surface is cleaned and degreased. After this, the recess is welded;

- incomplete brews are cut out and re-brewed;

- fistulas and craters are eliminated using the same scheme. First of all, everything is cut down to the base metal. After this, the joint is welded in a new way;

- the sagging should be carefully cut off, checking for any lack of penetration;

- deformed areas are leveled by heating or mechanically;

- any of the defects, implying the presence of foreign inclusions, is eliminated by cutting out the seam (section) and applying a new one.

If during the inspection process defects in the technological nature of pipe connections are discovered, correction is carried out using one of the following methods:

- mechanically without welding;

- mechanically in combination with welding of the defective area;

- cutting out a section of the pipeline containing a technological defect;

- the seam is completely removed and the joint is welded in a new way.

The strength and tightness of gas supply networks is restored by arc welding. The use of gas welding installations is not permitted.

Detection and control methods

A high-quality seam has appropriate markings. At large enterprises, each specialist places a certain mark on the joined area. The following methods are used to detect defects:

- visual inspection;

- color flaw detection;

- ultrasonic method for identifying defective areas;

- radiation;

- magnetic method.

After a defect is discovered, an employee of the quality department determines the further fate of the part; in most cases, they are sent for revision. Sagging is removed using an abrasive tool through mechanical action. Welding is used for flaw detection of large cracks, with the residual welding area previously cleaned.

Group 2. Pores

200 A Gas cavityen gas cavity

fr soufflure

A cavity of arbitrary shape formed by gases trapped in molten metal, which has no corners 2011 Aa Gas poreen gas pore

fr soufflure spheroidale

Gas cavity is usually spherical 2012 Uniformly distributed porosityen uniformly distributed porosity

fr souflures spheroidales

A group of gas pores distributed evenly in the weld metal. Should be distinguished from chain of pores (2014) 2013 Cluster of poresen localized (clustered)

fr nid de soufflures

A group of gas cavities (three or more), arranged in a cluster with a distance between them of less than three maximum sizes of the largest of the cavities 2014 Chain of poresen linear porosity

fr soufflures allignees

(ou en chapelet)

A series of gas pores arranged in a line, usually parallel to the axis of the weld, with a distance between them of less than three maximum dimensions of the largest of the pores 2015 A b Oblong cavityen elongated cavity

fr soufflure allongee

A discontinuity extended along the axis of the weld. The length of the discontinuity is at least twice the height 2016 Ab Fistulaen worm-hole

fr soufflure vermiculaire

A tubular cavity in the weld metal caused by the release of gas. The shape and position of the fistula are determined by the hardening mode and the gas source. Typically, fistulas are grouped into clusters and distributed in a herringbone pattern 2017 Superficial poreen surface pore

fr picure

Gas pore that breaks the continuity of the surface of the weld 202 R Shrinkage cavityen shrinkage

fr retassure

Cavity formed due to shrinkage during solidification 2024 K Crateren crater pipe

fr retassure de cratere

Shrinkage cavity at the end of the weld bead, not welded before or during subsequent passes