When laying communications, installing lighting fixtures or installing household appliances, it is almost always necessary to drill round holes of large diameters in walls, ceilings or interior items. A comfortable ballerina drill will be a good helper in your work.

You can drill a small diameter hole (10-12 mm) in the surface using a simple electric drill. But even when trying to cut large diameter holes in the working surface, even a metal drill begins to vibrate and deviate from the vertical axis.

Specifications

To obtain a high-quality hole of the required size in such cases, you will need a special tool - a ballerina (round drill).

| Tool Options | Parameter values |

| Tool weight | 0.1-0.110 kg |

| Length | 90-120 mm |

| Shank type | Cylindrical |

| Shank length | 8-9 mm |

| Maximum outer circle diameter | 140-160 mm |

| Minimum outer circle diameter | 20-30 mm |

| Diameter of support bar | 7 mm |

| Working surface processing depth | 30 mm |

| Number of working cycles (for ballerina on tiles) | 30-40 |

Characteristics of metal for drill

The ballerina is made of high-quality carbon (tool) steel, which does not contain alloying additives or impurities. Carbon steel is used for the manufacture of high-strength static cutting tools that experience significant mechanical and physical stress.

The properties of carbon steel provide the ballerina with the following characteristics:

| Characteristic | Content |

| Hardness | Ensures that the drill remains in a vertical position when working with it |

| Strength | Ensures uninterrupted operation of the ballerina when drilling deep layers of the working surface |

| Cyclic strength | Maintains performance characteristics after repeated use |

| Plastic | Possibility of adjusting cutters |

| Heat resistance | Possibility of maintaining the working qualities of the tool when drilling at high speeds and heating |

| Wear resistance | Long tool life and resistance to corrosion processes |

Characteristics of a metal drill

The ballerina allows craftsmen to work with metal surfaces (steel, cast iron, brass, aluminum, bronze) up to 14 mm thick. Using this type of drill, mounted in a drill or in a tabletop drilling machine, you can cut a hole with a radius of 22-105 mm in a metal surface.

What is a ballerina

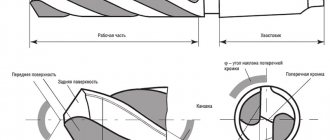

The cutting tool, commonly called a ballerina, also has a more professional name - “circular adjustable drill with cutters.” The drill is located in the central part of the tool and is used to center the hole. The radius of the circle that the cutters will describe is measured from the center line of this drill.

To equip ballerinas, drills of the first or auger type are used, since a conical tool does not cope well with ceramic materials and can slide off their surface. The result of such slipping can be damage to both the tool itself and the surface of the tile.

Ballerina on tiles differs from a nozzle designed for drilling holes in wood materials

Adjustable tool overview

Ballerina – adjustable drill. One of its structural elements is a bracket with a scale printed on it. With its help, you can independently set the required diameter. And in a three-cut drill, the cutting elements move synchronously along special grooves.

Before starting work (drilling), it is necessary to set both cutters at the same distance from the central hole.

Technical capabilities

The main use of ballerinas remains cutting sheet material. The ability to adjust the diameter allows you to use one tool for several purposes. Two or more cutting elements allow you to obtain a high-quality processed surface.

Almost any sheet material used in construction, repair and decoration can be processed with a circular drill. Carbon steel gives the structure strength. Special coatings are used to protect against corrosion.

The price range depends on the material of construction and cutting part, manufacturer, size and number of cutting elements.

Ballerina design

- Centering drill.

- Working incisors (from one to three)

The main drill can be firmly fixed on the work surface (drilled) and prevent the tool from slipping when working with tiles or laminated surfaces. The cutters move in a circle and cut a groove in the working surface. The drill is driven using power tools (drill, machine, hammer drill) or manually (using a brace).

A tool with replaceable cutters is used to work with surfaces of varying strengths - from soft plastic to porcelain stoneware. The master can independently set the working cutters to obtain a hole of a given diameter. This operation can be performed using an adjustable wood ballerina.

Recommendations for the use of ballerinas

There are many ways to make tile carving a simple and straightforward process. And at the same time, so that the hole made is even.

- You need to work with the ballerina at certain intervals so that the attachment cools down.

- Quite often the cutters and drill break. Moreover, no one is protected from the fact that this will happen during the cutting process. If this happens, there is a chance that the tool will hit the surface and damage it. Installing a limiter will help avoid an undesirable situation. It can be done using improvised means. The best option is electrical tape. It should be wound around that part of the instrument that can touch the surface if the ballerina breaks.

- Often when cutting tiles, the material can break. In this case, you need to put drywall or wooden beams under it. But what to do if the tiles need to be cut after the finishing work is done? You need to check the tiles by tapping. If there is a void behind the tile, you cannot drill.

As you can see, applying ballerina to tiles is not an easy job. If you listen to all the recommendations, you can perform even cutting. And for a better understanding of the principle of working with the tool, we recommend studying the video material.

Types of ballerinas

To work with materials of different densities and structures - soft and hard wood, plastic, plasterboard, concrete, stone, brick, porcelain stoneware - drills made from various grades of steel and having special designs are used.

For woodworking

You can drill a large diameter hole in a wooden surface using a 200 mm wood ballerina.

Before you start drilling in a wooden surface (especially laminated or veneered), you need to make a shallow hole with an awl. This will allow you to accurately comply with the specified dimensions. Drill at low or medium speeds (1000-1200 rpm) to avoid chipping at the exit (if necessary, drill a through hole).

To work with hard wood, use wood ballerina 40 (300). In some cases (hardwoods) a wood ballerina with a diameter of 30 200 mm mk is used (category Strong -stk, 057)

Drilling drywall

The design of the ballerina on plasterboard includes a centering tip and a rod attached above. The rod mount can rotate around its own axis.

At one end of the rod there is a disk cutter. It easily withstands several drilling cycles, holds tightly to the rod during operation and does not require sharpening for a long time.

For tiles

To drill hard tiles, a tile ballerina is used. The main difficulty in performing this operation is the need to cut through the glazed coating.

Immediately after this, experienced craftsmen advise drilling a groove on the back side of the tile. And then complete the drilling from the front side. For ballerinas on tiles 300 (057), a pobedit tip is often used, with which you can cut neat holes.

It is recommended to start working with a ballerina drill on tiles at low speeds (about 1000 rpm). And lubricate the drawn contour of the future hole with machine oil.

For porcelain stoneware

Porcelain stoneware is a very hard material. Working with him is always a difficult task. If it is necessary to cut a hole in porcelain stoneware, a ballerina with special cutting edges and a diamond tip is used. Its use extends the service life of the tool and significantly increases the speed of the operation.

On ceramics

When using a ballerina when working with ceramics, you should apply minimal physical effort. Ceramics is a fragile material. And even slight vibration can lead to cracks and chips. To avoid this, drilling should be carried out at low speeds (about 1000 rpm). Typically, diamond-coated tips are used for work.

For metal

A metal-cutting tool that makes it possible to obtain a hole with a diameter of 40-150 mm in sheet iron is a metal drill. Before starting the operation, a depression (up to 9 mm) is made in the center of the required cutout. It will be possible to install and securely fix the central axis of the ballerina.

For cutting gaskets

Car enthusiasts often encounter wear on the oil pump and overdrive gaskets. Of course, you can order and buy a new one in auto supply stores and online stores. But even in a home workshop, with the help of a ballerina, you can cut out a gasket from paronite. You need to have a sheet of paronite 0.5 mm thick, a measuring tool (ruler, tape), glue, several blades for stationery knives and a marker for marking. Place the worn gasket on the paronite sheet, glue it (without drying the glue) and trace along the contour.

To cut out the gasket along the outer and inner contours, a wood ballerina is used. Internal holes and grooves are cut with blades and finished with a round file or sandpaper.

For plastic

Plastic is a soft material and can be easily processed. But there is always a danger of cracking of the working surface. Therefore, when drilling plastic, you should not use much physical effort.

This material is quickly exposed to high temperatures and melts. It is necessary to work with it at low drill speeds (about 1000 rpm).

Compass ballerina

This type of drill is used for working with tiled surfaces. The design of the instrument includes:

- The pen tip acts as the main axis.

- Movable part (fastening mechanism, extension lever, cutting edge).

The cutting edge should be 5-8 mm shorter than the pen tip. This is due to the difficulty of processing tiles (there is a danger of the drill slipping).

You can use masking tape (adhesive tape) to firmly hold the markings. It also improves the adhesion of the drill to the surface, allowing it to be fixed on the drilling axis and make a central recess.

Due to the difficulties with sharpening a cutter made of hard alloys at home, a compass is considered a disposable tool. However, you can find sales of drills with replaceable bits.

Types by number of incisors

On sale you can find three types of drills, differing in the number of working cutters. A special bracket with a perpendicular tightening screw has a single-cut drill. Before starting the operation, the working cutter is simply set to a given length and tightened with a screw.

But in a double-cut ballerina, the bolts for fastening are located on the holders of the working cutters. The master sets them at the same distance from the central axis before starting work. The most complex design is a circular tile drill with three cutters. They are fixed on a circular platform and are aligned when moving along the grooves provided for this purpose.

What drills to use

The central stabilizer can be replaced, this is due to the different characteristics of the materials for which it can be used. It is worth noting that conical drills are not allowed for use on tiles.

This is due to the fact that, due to the peculiarities of their design, they can slide off the intended, pre-deepened point and scratch the front surface of the tile.

For this reason, it is recommended to use auger or type 1 drills for these purposes. They are ideal for these tasks. It is worth noting that it is not always necessary to drill with a ballerina until the inner circle is completely separated from the tile, thus forming a hole.

- Some tiles have an extra layer at the back that is not tile, a hard material designed to improve the tile's adhesion to the stucco wall surface.

- In such cases, it is enough to drill with a ballerina to a depth of no more than 2/3 of the total thickness. After this, you can carefully knock out the resulting circle. The disadvantage of this method is that on the reverse side, when knocking out, chips form on the material.

However, you shouldn’t worry about this, because the back side of the tile will be attached to the wall using a primer, so the chips will be hidden from view. In addition, they will not affect the quality of adhesion between the surface of the slab and the wall, because the vast majority of the area's materials remain intact.

Making a ballerina cutter

A ballerina drill significantly saves time when processing (milling) the contours of a cut hole. Processing is carried out automatically using power tools (drill, hammer drill).

Therefore, the physical effort expended when working with a ballerina is also insignificant. Given these advantages, home craftsmen want to have such a tool in their workshop. Moreover, making a ballerina with your own hands is not at all difficult for a competent craftsman.

For this you will need materials:

- Working (metal) plate with dimensions 200x25x4-6 mm.

- Bolts: M8 grade - 2 pieces (in addition to them you need to take 2 nuts and 4 washers) and M10 grade - 1 piece (in addition to them you need to take 2 nuts and 1 washer).

To work you will need tools:

- To mark the work surface: a marker and a ruler with centimeter divisions.

- Painting tape.

- Stationary machine or power tools (hammer, drill).

- Vise.

- File.

- Kern.

- Grinder equipped with grinding and cutting discs.

- Drills for metal with a diameter from 9 mm to 10.5 mm.

- Keys: open-end and adjustable.

- Screw clamps.

Step-by-step instructions on how to make it yourself

- Marking and processing of the work plate.

- Creation and processing of working grooves.

- Manufacturing of cutters.

- Connection of cutters to the working plate.

- Marking (gradation) of the finished drill.

- At the first stage, we cut a 20 cm long strip from the metal sheet. This will be the basis of the tool being created.

- Using a drill with a diameter of 10.5 mm, we drill a through hole on the machine in the pre-punched center of the work plate.

- Stepping back 1 cm from the drilled hole to the edges of the working plate (at the same level as the central hole), we make marks (punch) on the plate for future drilling.

- The distance between the marks must exceed the diameter of the holes that will subsequently be drilled. This precaution will help preserve the drill.

- Using a grinder cutting disc, you need to create two oblong grooves by combining the existing holes. The working plate is in a vice during this operation.

- Using a file (square or flat), we process the resulting holes. The free movement of the incisors will depend on the thoroughness of this operation (we remove irregularities, hangnails, and tubercles).

- Pressing the work plate tightly against the table (we use clamps or a vice), we smooth out all the irregularities and sharp corners with a grinding disc. We insert an M10 bolt into the central hole and screw one of the nuts onto it from the reverse side.

- We put the second nut (lock nut) on it and press it tightly using an open-end (or adjustable) wrench. To make the cutters, we wrap the upper parts of the M8 bolts with masking tape. We fix the bolt heads in a vice.

- Using a grinder's grinding disc, we cut off the thread, processing the bolt on both sides until a metal handle 4-5 mm thick is formed.

- The pointed ends of the bolt, shaped like a one-sided hook, will serve as the working cutters of the drill. The resulting cutters must be inserted into the grooves, having previously been laid with washers on both sides.

- This will increase the area of their contact with the working plate.

- The rod of the future tool and the cutters should be located in opposite directions. The thread sections remaining on the side surfaces of the bolts will allow you to screw on the nuts and secure the cutters tightly.

- Using a ruler and a marker, we mark the entire plane of the working plate, making marks every 0.5 cm. Later on these marks it is necessary to make notches that will be clearly visible during operation.

Drill - ballerina. For large holes.

Instructions on the back. Pay attention to the correct placement of the incisors. Equipment:

The key, the device itself, the drill and the nozzle (if the hole is already drilled) Photo with a ruler:

The design did not fit into a regular drill. We use a hammer drill:

We test on 4 mm plywood. Smallest diameter first:

Cutters after drilling. Apparently after each hole it is better to correct them with a file.

I'm trying to drill a 9 cm hole. I set the speed to almost minimum. It's scary to drill at high speeds:

The cutters come out of the plywood unevenly. Here you need to act carefully.

I was afraid to drill anything other than wood. After the very first hole, the cutters already required correction with a file. The holes are not quite accurate as they are set. The movement of the incisors and vibration affect. With these notes in mind, the drill can be used.

Addition. Shank diameter 1 cm

Planning to buy +23 Add to favorites Liked review +26 +46

Advantages and disadvantages

Working with a ballerina is not particularly difficult for a home craftsman. However, even when using a three-cut drill, special skills are required.

| Advantages | Flaws |

| Saves time when you need to make a large diameter hole Exact compliance with specified dimensions Carefully processing the contour of the drilled hole Saving physical strength | Possibility of vibration when working with a single-tip drill Wear and destruction of cutters Clamp screw breakage The need to take breaks during work, which prevents overheating of the nozzle |

What can a “ballerina” do?

We continue to get acquainted with various tools, today we will analyze a circular adjustable drill, in common people it is called a “ballerina”, apparently by analogy with the appearance of the drill during its work with a spinning ballerina. The main purpose of this tool is to drill large diameter holes in tiles.

I’ll immediately give you a link to my other article about diamond bits - here it is, with the help of which you can also make large-diameter holes.

As you can see, there are many things you can use to drill into tiles; some people prefer to work with a ballerina, while others prefer to use crowns. Let's continue.

With its help you can drill “holes” in tiles with a diameter of 30-90 mm. As you can see, the maximum size is very large, it will be difficult to find such a crown (and I won’t say anything about how much it will cost), so when you need to make a hole larger than 60 mm (as a rule, crowns are sold individually up to this diameter), you have to use a “ballerina”.

It consists of a centering drill and a second cutting element fixed parallel to it and moving along a guide. The cutting part and centering are equipped with hard alloy tips, which actually cut the tiles. The main cutting plate moves along a guide, the minimum diameter is 30 mm, the maximum is 90 mm. The moving cutting part is secured using a bolt.

From this we can conclude that, if desired, you can drill a hole of any diameter in the range of 30-90 mm. Agree, you are unlikely to be able to find a diamond crown with a diameter of, for example, 53 mm. But such a circular drill will cope with the task without any problems. That is why they are in demand among finishers involved in cladding. It can be safely called universal - any diameter within the tolerance without any problems.

According to customer reviews, these drills have proven themselves well when working with tiles. Of course, the cut is not as smooth and even as when working with a crown, however, if a clean cut is not required (for a socket in a tile, for example), then purchasing this drill will be optimal.

How to work correctly?

The work is done using a drill; if it is an impact drill, then the impact mode must be turned off.

We drill at low speeds, it is very important that the carbide plates do not overheat, then your drill will serve you for a very long time. I remember once the neighbors called a plumber, so he got a ballerina that looked as if it had been worked on for many years. I already thought that the master would not be able to do anything for them, but to my surprise, the hole in the tile was made quickly and very efficiently. This is what it means to use a tool correctly. The master drilled carefully, at slow speeds, without pressing hard on the drill. The tile was drilled like clockwork.

The price for it is around 230 rubles, if you look at how much diamond crowns cost, then it’s better to buy it, it will be cheaper. If used correctly, it will pay for itself many times over. Of course, if the holes must be neat and even, then priority is still given to crowns.

— If you need holes, the edges of which will still be hidden later, then take a ballerina. - If the “holes” are clean (you won’t hide the edges) - then there will be crowns.

And of course, a video about how to use this very “ballerina”.

As you can see, everything is simple and clear. Hold on, tiles now))

Another note: How can you unscrew a broken bolt?

Precautionary measures

- All parts of clothing (work apron, robe, shirt cuffs) must be secured (tied, buttoned).

- To prevent metal shavings and dust from getting into your eyes, you must wear work glasses.

- It is advisable to tuck long hair under a cap (beret, bandana).

- Rotating parts of drills and power tools (machine) must be securely fastened.

- It is advisable to use a ballerina equipped with a protective grille.

The working surface should be less hard than the steel from which the drill is made. Bring the already rotating drill to the surface. These tips will help extend the life of your tool.

How to choose the right one

When purchasing a drill, be sure to evaluate the configuration of the ballerina. Three-cut drills are considered the most reliable and in demand.

They have good mounting screws that firmly secure the working cutters. The length of the working cutters should be 4-5 mm less than the length of the centering cutter.

Some models use standard clamps to secure the incisors. They require a Phillips screwdriver and are much less reliable than models with hex screws.

- For drilling tiles, it is better to choose a ballerina with two incisors. With its help, you can make a hole with a diameter of up to 160 mm, whereas when working with a single-cut tool, the maximum diameter will be only 120 mm.

- A double-sided wood ballerina will allow you to make a hole with a diameter of up to 300 mm. And for working with thin (less than 5 mm) sheets of wood, a special drill is included in the kit.

- To work with hard surfaces (metal, porcelain stoneware, stone), use a one-sided ballerina. Before drilling begins, its central axis is securely clamped in the drill chuck.

On the brackets of branded ballerina models there is a ruler with clearly visible divisions. As a rule, the movement of the cutters is carried out synchronously. You should also pay attention to the width of the incisor run (it can be up to 150 mm). This parameter determines the radius of the future hole. Usually, the quality of the working surface (wood, metal, tile) is taken into account when choosing the permissible width of the cutters.

Some models are equipped with a protective plastic grid that holds large sawdust.

Characteristics of a metal drill

A special purpose tool is used to drill a hole in metal. The most popular device is considered to be a one-sided ballerina drill for metal, with a cylindrical axis and cutters with a cutting edge made of pobedite. Before drilling, a hole with a diameter of 0.9 cm is created in the metal for the hook of the tip of the central axis of the circular drill. The device allows you to make a through or blind cavity with a diameter of 40 mm to 150 mm.

For large hole diameters on MDF, plastic, multi-layer plywood, special tools with cutting knives are used to create cavities with a radius of 300 mm. Similar in design, but with excellent characteristics, devices cut ceramic and tiles. Each device model is provided with accompanying documents, which indicate the design features of the equipment and the maximum thickness of the material being processed.

A ballerina for cutting gaskets can most often look like a shank with a flattened cutting part and a screw tip. The feather drill has a high working potential and is produced from alloy steel in different dimensional parameters, allowing you to drill plastic of any thickness.

Other tools used for the same purposes

Craftsmen can use several more tools to produce large-diameter holes. When drilling wooden surfaces (the diameter of the required hole exceeds 25 mm), you can use a Faustner drill.

Unlike a ballerina, it has a number of disadvantages:

- A large contact area with the working surface is accompanied by strong heating of the drill.

- It is difficult to align the central tip with the applied markings, because only the outer circle with the working incisors is visible.

- The Fostner drill bit is primarily intended for drilling blind holes (to hide the head of a nail if necessary).

- High price (due to the high heat resistance of the drill).

A hole saw is useful for drilling large diameter holes in hardwood, drywall, brick, and laminated surfaces. Some models of this tool are adjustable; you can set the required diameter yourself. When drilling hard surfaces (stone, porcelain tiles, concrete, tiles), you can use crowns. However, they are already produced with a given diameter. And the master has to buy several pieces of crowns or even a whole set. Such financial costs are not always justified. In addition, when working with crowns, a lot of fragments and construction dust are formed. Therefore, drilling using crowns in an already finished and furnished room is impossible.

Circular drill device

A ballerina drill for wood is made from carbon, tool, and alloy steels, which are not suitable for processing hard materials: metal, tile, porcelain stoneware. But they cut drywall and plastic easily.

The two-incisor ballerina looks like an ordinary compass . But the design is much more complex. The bracket and cylindrical shank are manufactured in one piece. There are two holes in the bracket. A centering drill is installed in one. A rod is installed in the second. Both are secured with screws.

To set the required diameter, the cutters move along the rod. It has a vernier scale on it. The tool holders are also secured with screws. The incisors are shaped like a knife. The oblique edge of the cutter should be directed in the direction of rotation, clockwise.

If the drill becomes dull during operation, it can be easily replaced. If the cutters are dull, then, having the skills to work on a sharpening machine, you can refill them. The shank of the structure is fixed in the chuck of an electric drill. It is worth remembering that the small power of a power tool may not be enough to work with a ballerina, unlike metal drills.