A metal stove is good for everyone; it quickly heats the room, and there are fewer problems with installing a steel or cast iron firebox than with a brick one. The only thing you need to pay attention to is the protective coating of the metal. Correctly painting an iron stove in a bathhouse is not difficult, but you need to choose the right paint and not engage in amateur activities in the process of applying the paintwork.

For heat-resistant paint, the viscosity does not change with increasing temperature, but there is an odor, so it is better to paint metal parts outside the bathhouse

Factors that have a negative effect on paint

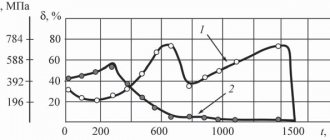

According to experts, it can reach +600°C in the furnace due to fuel combustion. The steel becomes red hot. Periodic heating and cooling has a detrimental effect on strength indicators. A metal stove in a Russian bath is simultaneously exposed to high humidity and heat; the walls begin to rust inside and out. In a sauna the air is drier, but the air temperature is also higher.

Carbon monoxide can leak into the bathhouse through burnt walls; using an unprotected stove is dangerous to life.

Periodic heating and cooling has a detrimental effect on strength indicators.

Painting procedure

Now you can start painting the potbelly stove. Before applying heat-resistant silicon-organic enamel, make sure that the prepared solution is not too thick. If you coat the surface with a viscous compound, it will not absorb well into the surface. In addition, such paint is quite difficult to work with. Therefore, first dilute it using a solvent specially created for organic materials. If you do not have such a solvent, you can dilute the paint using ordinary turpentine.

When the required thickness has been achieved, begin painting the potbelly stove. The paint should be applied in a fairly thin layer and wait until it dries completely. Then you need to apply a second layer. If the enamel lays down in an even layer through which the brick cannot be seen, you can complete painting at this stage. If the bricks are still visible, then you will need to apply an additional layer, and only after that paint the cast iron structural elements.

What tasks does paint perform?

A layer of paint for a metal sauna stove performs two functions at once: it increases the practicality of the sauna and improves the appearance of the dressing room and steam room. Heat-resistant coatings are resistant to thermal shock and have water-repellent properties.

By the way, welded structures with a tank for water and a firebox are sold in painted or unpainted form. The second option is painted before installation so that the steel does not have time to burn.

A layer of paint for a metal sauna stove performs two functions at once: it increases the practicality of the sauna and improves the appearance of the dressing room and steam room.

Color selection

It is traditionally believed that heat-resistant coating depends on the color and even shade of the paint. For example, if you want to get the maximum level of heat resistance, then it is better to choose dark colors, brown or black. Usually black bathhouses are made of metal stoves based on cast iron or silicon steel.

On the other hand, red, brown, cream and even white colors are widely used for alloy and stainless steel stoves. Usually the decision on what color to paint the stove is made in accordance with the design of the steam room and the entire bathhouse.

Do I need to paint or is there an alternative?

It is recommended to paint the metal before laying the heat-resistant brick screen and cover the inside of the tank. Instead of painting, bluing is used (details below) or other methods are used:

- Eco-friendly surface treatment with silver is quite effective;

- A budget option is red lead, used in metallurgy;

- A heat-resistant mixture of lime and cement provides good protection against oxidation.

It is recommended to paint the metal before laying the heat-resistant brick screen and cover the inside of the tank.

What to paint with?

A large number of requirements are placed on the paint and varnish material, but the modern chemical industry successfully creates dozens of paints that are ideal for such tasks. Construction stores offer products from dozens of manufacturers, but they are all divided into several large categories.

- The optimal heat-resistant paint for metal stoves is water-based acrylic. It is actively used for painting steel, brass, copper and some other alloys. The price is quite affordable, and the performance characteristics are suitable for many customers. An important advantage is the possibility of use in rooms where the air is not humid enough.

- Polyurethane varnish or enamel is also an excellent paint for a heavily used iron stove. The material can easily withstand high temperatures, and the metal surface acquires a beautiful silver tint.

- The most modern product is heat-resistant silicone paint for metal furnaces, which is marked KO-8101, 822 or 8111. According to ongoing research, the material can withstand temperatures above 650 degrees, and the absence of toxic substances will preserve your health. An unpleasant feature is the rather high price, which is compensated by the high quality of the products.

Characteristics

Before painting a stove in a bathhouse, you should take into account a number of criteria by which paint and varnish materials are selected. There are several of them, each is important in its own way and affects the strength of coatings under the influence of “bath hazards”.

Before painting a stove in a bathhouse, you should take into account a number of criteria by which paint and varnish materials are selected.

Heat resistance

This indicator is indicated on the label in degrees. Manufacturers inform about the maximum heating at which the properties of the film formed after the coloring composition has dried are preserved.

Manufacturers inform about the maximum heating at which the properties of the film are preserved.

Corrosion protection

To prevent the metal from rusting, it is necessary to isolate the alloy from oxygen. Hydrogen increases the brittleness of metals, and nitrogen at high temperatures also has a negative effect on steel.

To prevent the metal from rusting, it is necessary to isolate the alloy from oxygen.

Water repellent properties

Choose paint coatings that repel moisture. This is necessary to prevent oxidation and cracking during the winter.

Choose paint coatings that repel moisture.

Safety

When heated, organic compounds release volatile hydrocarbons; such paints and varnishes can cause poisoning. The bath requires harmless, non-toxic paints and varnishes.

When purchasing paints and varnishes, the choice is made in favor of branded, time-tested products.

The bath requires harmless, non-toxic paints and varnishes.

Household protection options

Barbecues and barbecues have become very popular; they are produced both by employees of specialized organizations and by home craftsmen. The main material in such structures is often a thick sheet of steel. A good fireproof paint can greatly increase the longevity of your barbecue and give it a more attractive appearance.

Compared to intumescent coatings, this type of fire retardant should not lose the integrity of the layer. A barbecue or other metal grilling structure is typically exposed to high temperatures for long periods of time. After cooking, the metal alloy cools down. If such a load is constantly placed on the material, then pockets of corrosion may appear on its surface.

You can apply paint to the surface of the product using the following procedure:

- The metal surface is protected with sandpaper, hard brushes and special corrosion-converting agents.

- You can speed up the process using a drill and a special attachment.

- The paint composition can be applied to a metal surface with a sprayer, roller or ordinary brush.

The thickness of the applied layer can vary between 0.8−1 millimeters. Subsequent layers can be applied only after the previous one has dried. You can verify the completion of the polymerization process by touching the surface. If it is no longer sticky, you can move on to the next stage.

Kinds

Heat-resistant paint for sauna stoves is produced in a large assortment. Paint and varnish mixtures are classified according to their basic components:

- Organosilicon coatings form a glass film that retains strength at +800°C, have good adhesion to metal, and are not afraid of water;

- Polyurethane is wear-resistant, can withstand heating up to +600°C, and is often used for boiler equipment. Minus - some compositions change color due to thermal exposure;

- Water-based ones with acrylic filler are more suitable for saunas or painting the stove on the side of the dressing room, where there is no high humidity.

According to user reviews, several heat-resistant coatings deserve attention:

- “Hammerite”, “ELCON” - enamels with corrosion inhibitors;

- “Kudo” enamels with silicon;

- “Hansa” in aerosol cans or cans is produced in about 16 shades;

- Gray or black “Tikkurila” with alkyd resin;

- "Bosni" is a universal composition for many types of surfaces.

For reference. For thin-walled fireboxes, it is recommended to choose coatings with a heat resistance rating of +800...850°C.

Water-based ones with acrylic filler are more suitable for saunas or painting the stove on the side of the dressing room, where there is no high humidity.

Volumes and price

The choice of the size of a can of heat-resistant paint depends entirely on the volume of surfaces, as well as on the consistency of the paints.

Be sure to consult with sellers on this matter. The smallest jar is 0.2 liters, the largest is 12 liters. As for the price, the cheapest ones are decorative heat-resistant paint. However, keep in mind that the permissible temperature limit is only 200 degrees, which is not suitable for work carried out on parts that are close to the heat source. The most expensive are paints with aluminum shavings. If you are painting a flat and small surface, you can take paint in a spray can. Date: September 25, 2022

Is it possible to coat equipment with enamel?

Among the large number of paints for a hot water tank in a bathhouse, it is better to choose special enamels marked “KO 8” from leading manufacturers. This means that silicone enamel can withstand high temperatures. Conventional enamels for metal quickly become painted due to temperature changes.

Silicone enamel can withstand high temperatures.

Principle of operation

The operating principle of stoves operating on wood and electricity is based on the possibility of automatically turning on electric heating elements when the temperature drops (after solid fuel burns out). This happens as follows:

- Kindling and heating of the stove is carried out using firewood. Since the firebox is located at the bottom of the device, it transfers heat from the burning wood to the upper part of the device - to the heat exchanger. An increase in coolant temperature is detected by a sensor installed in the system line;

- when the temperature begins to drop due to fuel burning, the electrical circuit is automatically closed and electric heaters are connected to operation;

- from this moment on, the specified coolant temperature parameters are maintained by the heating elements, based on the readings of the air or water sensor;

- when loading the next batch of solid fuel, the electrical part is automatically switched off, as the coolant is heated

- already from the side of the combustion chamber.

This transition from wood heating to electric heating and vice versa ensures continuous heating of water in the heat exchanger, which allows you to maintain the optimal temperature in the house around the clock.

Wood and electric stoves come in two types:

- single-circuit - connected to the heating system and used only for heating;

- double-circuit - designed to heat the coolant in the heating system and hot water for domestic needs.

Coating instructions

When painting stoves yourself, it is important to follow the sequence of operations and adhere to the technology, then the bathhouse will be protected.

When painting stoves yourself, it is important to follow the sequence of operations and adhere to the technology.

Tools and materials

In addition to paintwork materials and brushes, you will need sandpaper or a metal brush to remove rust, and a solvent to degrease steel. It is necessary to cover the floor and wall so that there are no smudges.

In addition to paintwork materials and brushes, you will need sandpaper or a metal brush to remove rust, and a solvent to degrease steel.

Surface preparation

The metal is pre-cleaned to a metallic shine. After removing dust, wipe the surface with a solvent.

Stainless steel fittings and adapters are coated with grease to protect them from staining.

The metal is pre-cleaned to a metallic shine.

Work algorithm

Mix the paint before use, start painting from hard-to-reach places, then cover the remaining areas. Coatings are applied in one layer, unless otherwise specified by the manufacturer.

The paint is mixed before use.

How long does it take for the coating to dry and after what time can it be heated?

It is better to wait 5 days after painting, only then start lighting the stove. Paint for a metal stove in a bathhouse dries on average from 72 to 96 hours, depending on the plasticizer.

Some coatings dry only when heated; the stove is lit, but not allowed to become very hot. For safety, open the window and door.

It is better to wait 5 days after painting, only then start lighting the stove.

Manufacturing

- The base is made of red brick. To do this, you need to lay out two rows so that the seams do not coincide with each other. The base should be 20–30 cm larger than the stove itself.

- The firebox is assembled from individual sheets of cast iron. It should be rectangular. Inside it needs to be divided into two parts by a parallel sheet. At the bottom there will be an ash drawer. The separating sheet must have many holes through which waste will flow after combustion.

- After assembling the metal box, you need to make holes on the top to which the chimney from the pipes will be attached.

Burnishing an iron stove

Blueing is the etching of metal with phosphoric acid, which creates a protective layer of phosphates on the steel. A similar technology is applicable in baths. The cleaned, degreased metal surface is treated with a solution of phosphoric acid. Add 150 ml of acid and 4 g of butyl alcohol per liter of water. After the solution has dried, the metal is washed with laundry soap. Then the surface is heated to 150 C, and a 10% solution of caustic soda is applied to them using a spray gun.

Blueing is the etching of metal with phosphoric acid, which creates a protective layer of phosphates on the steel.

If desired, the metal stove and tank can be made into decorative parts of the bathhouse interior. For painting, it is better to choose heat-resistant enamels, which are durable and decorative. There will be no rust with this coating.

How to make painting materials for a brick stove yourself

The price of lime and chalk is the lowest. Such materials are available in abundance at any hardware store. To breed them you only need water.

The difference between the solutions and each other is as follows:

- After painting the first layer with chalk solution, you need to wait for it to dry completely.

- When painting with a lime solution, all subsequent layers are applied immediately.

To paint the stove, you need to prepare the correct solution with your own hands:

- One kilogram of chalk or lime.

- Water – 1.5 liters.

Instead of salt, you can use wood glue; 0.1 liters of glue per 10 liters of paint is enough. Such compositions may have a yellowish tint. To achieve a classic white color, you need to add 20 milliliters of regular blue to the solution. A color additive should be used to obtain the desired color.

How to make natural varnish for the stove

Our ancestors used an ordinary chicken egg to prepare varnish when painting stoves.

For this you will need:

- Egg whites.

- Milk.

- Brick dust remaining after adjusting and trimming bricks when laying a stove.

After conducting experiments, it was determined that the best composition is obtained with a 1:1 proportion of egg whites and milk. To finish a square meter of oven surface, you will need approximately 0.25 liters of milk and 8 proteins. The amount of brick dust is determined independently; it only affects the color characteristics of varnish made from natural materials.

When preparing the composition:

- Flour is rubbed from red brick.

- Add beaten egg whites and milk until a thick consistency is formed.

- The mixture is stirred.

- The oven is painted with a new brush onto a preheated surface.

- The coating turns out to be an even red color. It has heat resistance and increased abrasion resistance.

- The oven is covered with drying oil, after which the dark red surface becomes matte.

- To obtain shine, a special synthetic varnish is used.

After applying such varnish to the surface of the stove and drying it, the brickwork will not be very dirty, but it will get dirty. To eliminate this drawback, you can apply one layer of a solution made from pure egg white to the stove. The disadvantage of this coating is that it emits the aroma of baked milk in the room when the stove is in use.

How to paint a stove correctly

Tools for performing the work:

- Metal spatula for surface preparation and puttying.

- Brush to remove any remaining finish.

- Small special container.

- Soft brush.

After choosing how to paint the red brick stove, you can do the preparatory work.

For this:

- The surface of the stove is carefully leveled with plaster (see How to plaster a brick stove with your own hands).

- In a rough way, protruding fragments of clay mortar located between the bricks are scraped off with a special scraper.

- The surface is prepared with sanding paper to improve the adhesion of paint and brick.

- The paint is applied in two or three thin layers using a new brush or roller. The brush adds texture to the surface, and the roller distributes the paint more evenly, which makes the surface smooth.

- If desired, patterns are applied mechanically to the dried coating layer, as in the photo.

Today, interiors decorated in the following styles are extremely popular among homeowners:

- Country.

- Chalet.

- Shabby chic.

Their distinctive feature is the naturalization of various elements and decorative details. In such interiors, the best bright and stylish addition is a Russian brick stove or fireplace. To do this, you can simply paint them with transparent paint. The video in this article will show you how to properly prepare surfaces and then paint them.

Since ancient times, people have built working fireplaces in their dachas or country houses, which filled the rooms with warmth and made it possible to cook food. If such a structure is old enough and needs to be restored, then a logical question arises: how to paint the brick stove in the house.

Here we should start from two ideas: either the owners are pursuing an aesthetic goal, or safety is of primary importance to them. In most cases, you can do this work yourself; the main thing is to choose the right tools and paint materials.

Brickwork processing

Packaging

You can purchase heat-resistant paints in various packaging - these can be spray cans or jars. From cans, paint is simply sprayed over the surface, and from a can, paint is used with brushes, rollers or special sprayers.

The volume of the cylinder is usually 500 ml. Cans are produced in 400 g, 800 g, 2.5 kg and 5 kg. There are also large buckets of 5-15 kg and barrels.

Exactly how to apply thermal paint is everyone’s personal choice. For some, it will be more convenient to use a brush or roller, while others will opt for a spray can. In the latter case, the material consumption will be significantly lower, and the paint will apply more evenly and evenly.