14Nov

- By: Semantics

- Uncategorized

- Comments: 0

When constructing objects, it is imperative to use calculations that include detailed characteristics of building materials. Otherwise, too much, unbearable load may be placed on the support, which will cause destruction. Today we’ll talk about the tensile strength of a material at break and tension, we’ll tell you what it is and how to work with this indication.

Tensile strength

PP - we will use this abbreviation, and we can also talk about the official combination “temporary resistance” - this is the maximum mechanical force that can be applied to an object before its destruction begins. In this case, we are not talking about chemical effects, but we mean that heating, unfavorable climatic conditions, and a certain environment can either improve the properties of the metal (as well as wood, plastic) or worsen it.

No engineer uses extreme values when designing, because it is necessary to leave a permissible error - for environmental factors, for the duration of operation. We told you what is called tensile strength, now let’s move on to the specifics of the definition.

Metal crystal lattice

The type of bond of a metal crystal lattice is more flexible and ductile than the ionic one, although in appearance they are very similar. Its distinctive feature is the presence of positively charged cations (metal ions) at lattice sites. Between the nodes live electrons that participate in the creation of the electric field; these electrons are also called electric gas. The presence of such a structure of a metal crystal lattice explains its properties: mechanical strength, heat and electrical conductivity, fusibility.

How is the strength test performed?

Initially there were no special events. People took an item, used it, and as soon as it broke, they analyzed the breakdown and reduced the load on a similar product. Now the procedure is much more complicated, however, until now the most objective way to find out PP is the empirical way, that is, experiments and experiments.

All tests are carried out under special conditions with a large amount of precise equipment that records the condition and characteristics of the experimental material. Usually it is fixed and experiences various influences - tension, compression. They are performed by instruments with high precision - every thousandth of a newton of the applied force is noted. At the same time, each deformation is recorded as it occurs. Another method is not laboratory, but computational. But usually mathematical analysis is used in conjunction with testing.

Definition of the term

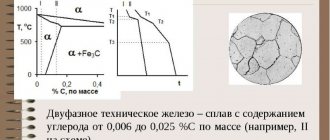

The sample is stretched on a testing machine. In this case, first it lengthens in size, and the cross-section becomes narrower, and then a neck is formed - the place where the thinnest diameter is, this is where the workpiece will rupture. This is true for ductile alloys, while brittle alloys, such as cast iron and hard steel, stretch very slightly without necking. Let's take a closer look at the video:

The beginning of the history of iron

In the third millennium BC. e. people began to mine and learned to process bronze and copper. They were not widely used due to their high cost. The search for new metal continued. The history of iron began in the first century BC. e. In nature, it can only be found in the form of compounds with oxygen. To obtain pure metal, it is necessary to separate the last element. It took a long time to melt the iron, since it had to be heated to 1539 degrees. And only with the advent of cheese-making furnaces in the first millennium BC did they begin to obtain this metal. At first it was fragile and contained a lot of waste.

With the advent of forges, the quality of iron improved significantly. It was further processed in a blacksmith, where the slag was separated by hammer blows. Forging has become one of the main types of metal processing, and blacksmithing has become an indispensable branch of production. Iron in its pure form is a very soft metal. It is mainly used in an alloy with carbon. This additive enhances the physical property of iron, such as hardness. The cheap material soon penetrated widely into all spheres of human activity and revolutionized the development of society. After all, even in ancient times, iron products were covered with a thick layer of gold. It had a high price compared to the noble metal.

Tensile strength of steel

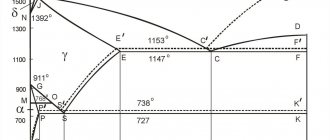

Steel structures have long replaced other materials, as they have excellent performance characteristics - durability, reliability and safety. Depending on the technology used, it is divided into brands. From the most common with a PP of 300 MPa, to the hardest with a high carbon content - 900 MPa. This depends on two indicators:

- What heat treatment methods were used - annealing, hardening, cryotreatment.

- What impurities are contained in the composition. Some are considered harmful, they are discarded for the purity of the alloy, and others are added to strengthen them.

Importance for the body

One of the most common chemical elements in the earth's crust is iron. We have already examined the properties of the substance, now let’s approach it from a biological point of view. Ferrum performs very important functions both at the cellular level and at the level of the whole organism. First of all, iron is the basis of such a protein as hemoglobin. It is necessary for the transport of oxygen through the blood from the lungs to all tissues, organs, to every cell of the body, primarily to the neurons of the brain. Therefore, the beneficial properties of iron cannot be overestimated.

In addition to affecting blood formation, ferrum is also important for the full functioning of the thyroid gland (this requires not only iodine, as some believe). Iron also takes part in intracellular metabolism and regulates immunity. Ferrum is also found in particularly large quantities in liver cells, as it helps neutralize harmful substances. It is also one of the main components of many types of enzymes in our body. A person’s daily diet should contain from ten to twenty milligrams of this microelement.

Fatigue of steel

The second name is endurance limit. It is denoted by the letter R. This is a similar indicator, that is, it determines what force can act on an element, but not in a single case, but in a cycle. That is, certain pressures are applied to the experimental standard cyclically, over and over again. The average number of repetitions is 10 to the seventh power. This is exactly how many times the metal must withstand the impact without deformation or loss of its characteristics.

If you carry out empirical tests, it will take a lot of time - you need to check all the force values, applying it over many cycles. Therefore, the coefficient is usually calculated mathematically.

Flaws

In addition to a large number of positive qualities, there are also a number of negative properties of the metal:

- Products are susceptible to corrosion. To eliminate this undesirable effect, stainless steels are produced by alloying, and in other cases, special anti-corrosion treatment is carried out on structures and parts.

- Iron accumulates static electricity, so products containing it are subject to electrochemical corrosion and also require additional processing.

- The specific gravity of the metal is 7.13 g/cm³. This physical property of iron gives structures and parts increased weight.

Proportionality limit

This is an indicator that determines the duration of the loads applied to the deformation of the body. In this case, both values should change to different degrees according to Hooke’s law. In simple words: the greater the compression (tension), the more the sample is deformed.

The value of each material lies between absolute and classical elasticity. That is, if the changes are reversible after the force ceases to act (the shape becomes the same - for example, compression of a spring), then such parameters cannot be called proportional.

Crystal structure

MATERIALS SCIENCE

Substances can be in three states of aggregation: solid, liquid and gaseous. The transition from a solid to a gaseous state is called sublimation.

All metals are crystalline solids.

Each metal is characterized by its own spatial crystal lattice with long-range order in the arrangement of atoms (a certain arrangement of atoms at any distance).

In solids, the order of arrangement of atoms is natural. The arrangement of atoms can be represented in the form of elementary crystalline cells. There are 14 types of gratings in total: 3 types are typical for metals:

How are the properties of metals determined?

They check not only what is called tensile strength, but also other characteristics of steel, for example, hardness. The tests are carried out as follows: a ball or cone made of diamond, the most durable rock, is pressed into the sample. The stronger the material, the smaller the mark left. Deeper, wider-diameter prints are left on soft alloys. Another experience - for a blow. The impact occurs only after a pre-made cut on the workpiece. That is, the destruction is checked for the most vulnerable area.

Atomic crystal lattice

Substances with an atomic crystal lattice, as a rule, have strong covalent bonds in their nodes consisting of atoms themselves. A covalent bond occurs when two identical atoms share fraternal electrons with each other, thus forming a common pair of electrons for neighboring atoms. Because of this, covalent bonds bind atoms tightly and evenly in a strict order - perhaps this is the most characteristic feature of the structure of the atomic crystal lattice. Chemical elements with similar bonds can boast of their hardness and high melting point. Chemical elements such as diamond, silicon, germanium, and boron have an atomic crystal lattice.

Mechanical properties

There are 5 characteristics:

- The tensile and tensile strength of steel is temporary resistance to external forces, stress arising internally.

- Plasticity is the ability to deform, change shape, but maintain the internal structure.

- Hardness – willingness to meet harder material without causing significant damage.

- Impact strength is the ability to resist impacts.

- Fatigue is the duration of preservation of qualities under the influence of cyclic loads.

Strength classes and their designations

All categories are written down in regulatory documents - GOSTs, according to which all Russian entrepreneurs produce any rolled metal and other metal products. Here is the correspondence between the designation and parameter in the table:

| Class | Tensile strength, N/mm2 |

| 265 | 430 |

| 295 | 430 |

| 315 | 450 |

| 325 | 450 |

| 345 | 490 |

| 355 | 490 |

| 375 | 510 |

| 390 | 510 |

| 440 | 590 |

We see that for some classes the PP indicators remain the same, this is explained by the fact that, with equal values, their fluidity or relative elongation may differ. Depending on this, different maximum thickness of rolled metal is possible.

Metal crystal lattice

Due to the presence of ions at the nodes, the metal lattice may appear to be similar to an ionic lattice. In fact, these are two completely different models, with different properties.

Metal is much more flexible and ductile than ionic, it is characterized by strength, high electrical and thermal conductivity, these substances melt well and conduct electric current well. This is explained by the fact that the nodes contain positively charged metal ions (cations), which can move throughout the structure, thereby ensuring the flow of electrons. The particles move chaotically around their node (they do not have enough energy to go beyond), but as soon as an electric field appears, electrons form a stream and rush from the positive to the negative region.

The metal crystal lattice is characteristic of metals, for example: lead, sodium, potassium, calcium, silver, iron, zinc, platinum and so on. Among other things, it is divided into several types of packaging: hexagonal, body-centered (least dense) and face-centered. The first package is typical for zinc, cobalt, magnesium, the second for barium, iron, sodium, the third for copper, aluminum and calcium.

Thus, on the type of lattice . Knowing the type, you can predict, for example, what the refractoriness or strength of an object will be.

Specific strength formula

R with the index “y” is the designation of this parameter in physics. It is calculated as PP (in writing – R) divided by density – d. That is, this calculation has practical value and takes into account theoretical knowledge about the properties of steel for use in life. Engineers can tell how the temporary resistance changes depending on the mass and volume of the product. It is logical that the thinner the sheet, the easier it is to deform.

The formula looks like this:

Ry = R/d

Here it would be logical to explain how the specific tensile strength is measured. In N/mm2 - this follows from the proposed calculation algorithm.

GCC, BCC, GPU lattices

Studying the crystal structure of metals, we will characterize in more detail each type of crystal lattice. Let's start with the HCC. It is shown in the figure below.

As you can see, this lattice is a cube in which atoms are located at its vertices and at the centers of all six faces. Using crystallographic methods, it is easy to show that to obtain such a lattice in space, only four atoms and translation vectors coinciding with the edges of the cube are sufficient.

Examples of metals that crystallize in fcc are aluminum, copper, gold and silver. Iron forms an fcc lattice only at high temperatures.

The bcc lattice is shown below.

We see that it corresponds to a cube, at the vertices and in the center of which there is an atom. Only two atoms are needed to construct a bcc lattice in rectangular Cartesian coordinates. Metals such as vanadium, tantalum, niobium, and tungsten have exactly this crystalline structure.

Finally, the GPU grid. It is shown below in the figure.

This crystal lattice of metals differs from the previous two in that in space it forms not a cube, but a regular hexagonal prism, which consists of six atoms. Elements such as titanium, zirconium, magnesium and cobalt crystallize in this structure.

Using the properties of metals

Two important indicators - plasticity and PP - are interrelated. Materials with a large first parameter degrade much more slowly. They change their shape well and are subjected to various types of metal processing, including die stamping - that’s why car body elements are made from sheets. With low ductility, alloys are called brittle. They can be very hard, but at the same time have poor stretching, bending and deformation, for example, titanium.

Resistance

There are two types:

- Regulatory - prescribed for each type of steel in GOSTs.

- Calculated – obtained after calculations in a specific project.

The first option is rather theoretical; the second is used for practical tasks.

Types of crystal lattices

The distance between neighboring atoms is called the lattice parameter; for different metals it is 2 - 6 angstroms. There are three main types of crystal lattices:

- Cubic: body-centered - contains nine atoms. Characteristic of iron, chromium, molybdenum, and vanadium.

- Cubic face-centered: already includes 14 atoms. Inherent in copper, gold, lead, aluminum.

- Hexagonal: there are already 17 atoms and they are placed most densely. This is how magnesium, zinc, cadmium and others crystallize.

Ways to increase strength characteristics

There are several ways to do this, two main ones:

- addition of impurities;

- heat treatment, for example, hardening.

Sometimes they are used together.

General information about steels

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

Also watch a more detailed video:

All of them have chemical and mechanical properties. Below we’ll talk in more detail about ways to increase strength, but first, let’s present a diagram showing all the varieties:

Carbon

The higher the carbon content of a substance, the higher the hardness and the lower the ductility. But the composition should not contain more than 1% of the chemical component, since a larger amount leads to the opposite effect.

Manganese

A very useful additive, but with a mass fraction of no more than two percent. Mn is usually added to improve machinability. The material becomes more susceptible to forging and welding. This is due to the displacement of oxygen and sulfur.

Silicon

Effectively increases strength characteristics without affecting ductility. The maximum content is 0.6%, sometimes 0.1% is enough. Combines well with other impurities; together, they can increase corrosion resistance.

Nitrogen and oxygen

If they get into the alloy, but worsen its characteristics, they try to get rid of them during manufacturing.

Alloying Additives

You can also find the following impurities:

- Chrome – increases hardness.

- Molybdenum – protects against rust.

- Vanadium – for elasticity.

- Nickel – has a good effect on hardenability, but can lead to brittleness.

These and other chemicals must be used in strict proportions according to the formulas. In the article we talked about tensile strength (short-term resistance) - what it is and how to work with it. They also gave several tables that you can use while working. To finish, let's watch the video:

To clarify the information you are interested in, please contact our managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Atomic crystal lattice

The nodes contain atoms, as the name suggests. These substances are very strong and durable , since a covalent bond is formed between the particles. Neighboring atoms share a pair of electrons with each other (or rather, their electron clouds are layered on top of each other), and therefore they are very well connected to each other. The most obvious example is diamond, which has the greatest hardness on the Mohs scale. Interestingly, diamond, like graphite, consists of carbohydrates. Graphite is a very brittle substance (Mohs hardness 1), which is a clear example of how much depends on the type.

Atomic region lattice is poorly distributed in nature, it includes: quartz, boron, sand, silicon, silicon (IV) oxide, germanium, rock crystal. These substances are characterized by a high melting point, strength, and these compounds are very hard and insoluble in water. Due to the very strong bonds between atoms, these chemical compounds hardly interact with others and conduct current very poorly.