Price list for diamond pencils GOST 607-80:

(new prices are being formed)

Those who have to deal with metalworking in production using grinding machines know very well that the grinding wheel must be adjusted from time to time in order to restore its geometric shape. In most cases, the grinding wheel is ground unevenly on different sides. Quite often you can find a grinding wheel whose edges are ground off or have a track in the center. In order to properly process a part, in most cases a perfectly flat surface is required. Changing the grinding wheel to a new one every time is not economically profitable, so it is much easier to buy a diamond pencil, with which you can restore the original shape of the wheel.

Features of editing with a diamond pencil

The technology for straightening with this tool is quite simple and does not require special skills or much effort. Diamond pencils can be used to process both the external and internal surfaces of circles. To ensure maximum contact of the working surface with the workpiece, the tool is placed in a clamp, on a tool rest or other device so that it is inclined at an angle of 10-15 degrees.

The decrease in the quality of abrasive wheels is associated not only with wear of the surface, but also with its contamination with particles of materials that are subjected to grinding. By filling the gaps between abrasive chips, chips and dust make the surface viscous. A diamond pencil removes these contaminants well and restores the processing ability of the grinding chips.

The tool is also used for finishing new circles. Very often their geometry is far from perfect, which is why runout occurs during processing of parts. To check the geometry of the surface, a marker is gradually brought closer to the rotating circle. In curved areas, it begins to leave marks that need to be traced with a diamond pencil. Thus, this tool allows you to improve the quality of processing and avoid mechanical damage to parts and the equipment itself.

Diamond pencils come in several types:

- Diamond pencil with a chain arrangement of natural diamonds;

- Diamond pencil with a layered arrangement of natural diamonds;

- Diamond pencil with layered arrangement of synthetic diamonds;

- Diamond pencil with non-oriented arrangement of diamonds.

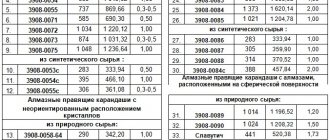

| Chain arrangement of natural diamonds | |||

| GOST 607-80 | GOST 607-63 | Diamond weight, carat | Weight group, carat |

| 3908-0051 | C 1 | 0,5 | 0,03-0,05 |

| 3908-0052 | c3 | 0,5 | 0,05-0,10 |

| 3908-0053 | C 4 | 0,5 | 0,11-0,20 |

| 3908-0054 | ts5 | 1 | 0,21-0,50 |

| 3908-0055 | — | 0,30-0,50 | 0,31-0,50 |

Note: for dressing wheels of moderate hardness, synthetic diamond analogues are supplied.

| Layered arrangement of natural diamonds | |||

| GOST 607-80 | GOST 607-63 | Diamond weight, carat | Weight group, carat |

| 3908-0081 | C1 | 1.0 | 0,017-0,025 |

| 3908-0082 | C2 | 1.0 | 0,05-0,10 |

| 3908-0083 | C3 | 1.0 | 0,11-0,20 |

| 3908-0084 | C4 | 2.0 | 0,11-0,20 |

| 3908-0085 | C5 | 1.0 | 0,11-0.20 |

Note: for editing of higher hardness, pencils 3908-0085, which have a more durable diamond, are used.

| Layered arrangement of synthetic diamonds | |||

| GOST 607-80 | GOST 607-63 | Diamond weight, carat | Diamond size, microns |

| 3908-0086 | — | 1 | 1250/1000 |

| 3908-0087 | — | 1 | 1600/1250 |

| 3908-0088 | — | 1 | 2000/1600 |

Note: synthetic diamond pencils are used for editing wheels of moderate hardness and diameters up to 600 m.

| Non-oriented diamond arrangement | |||

| GOST 607-80 | GOST 607-63 | Diamond weight, carat | Diamond size, microns |

| 3908-0059 | H1 | 1.0 | 63/50 |

| 3908-0060 | H2 | 1.0 | 100/80 |

| 3908-0061 | H3 | 1.0 | 125/100 |

| 3908-0062 | H4 | 1.0 | 200/160 |

| 3908-0063 | H5 | 1.0 | 315/250 |

| 3908-0064 | H6 | 1.0 | 400/315 |

| 3908-0065 | — | 1.0 | 500/400 |

| 3908-0066 | — | 1.0 | 630/500 |

| 3908-0067 | — | 1.0 | 800/630 |

| 3908-0069 | — | 2.0 | 1000/800 |

Note: These pencils are designed for dressing wheels, providing a high level of grinding finish.

Marking of diamond pencils and technical requirements for them

The crystals must rise above the surface of the steel bar so that they are the ones that come into first contact with the workpiece being processed. The stones should be free of cracks, shells and other visually noticeable defects. If such defects are present, the diamond pencil will quickly wear out and become unusable. In non-oriented products, the stones must be distributed evenly over the surface so that the load on them is also distributed equally.

The markings on diamond pencils contain the following information:

- trademark;

- type of installed crystals;

- cutting part size.

The letter A in the marking means that the instrument uses stones of natural origin. The letter C means the use of synthetic analogues.

In our catalog you can easily select a diamond pencil for processing both soft and hard grinding wheels of any diameter. The presented products vary in size and arrangement of stones, and the weight of the crystals also varies. We have a large stock of all types of products in our warehouse, so we are ready to ship batches of any size in a short time.

Read also: How to soften a rubber gasket

© 2007—2019 “SovInstrumentService” Site map

What is a diamond pencil

A diamond pencil is a tool steel tool 40-80 mm long, with pressed diamond crystals. Diamonds are pressed onto the underside of the diamond pencil. Depending on what model of diamond pencil is used, its shape and location of the diamonds may vary. All standards for the manufacture of such equipment are regulated by GOST 607-80, but there are pencils for wheels of varying abrasiveness and degree of softness. Diamonds deserve special attention - they can be natural or synthetic.

Diamond Pencil Marking

Each such pencil has its own special marking; it is necessary to make it easier to determine what each of them is intended for. Usually the main types of pencils are most often used, as noted earlier, they differ depending on various indicators. Marking: • type C. In this case, the diamonds are arranged in the form of a chain. This type of diamond pencil is used when it is necessary to process a circle of medium hardness; • type C. In this case, the diamonds are arranged in layers; they can overlap or, on the contrary, not overlap. They are used when it is necessary to edit sanding wheels of increased or moderate hardness; • type N. In this case, the diamonds are not oriented. They are used for processing wheels that are used for high-class grinding. Depending on their weight and the number of stones used, diamond pencils can also be of different brands. An important difference is the size of the frame and insert.

How is a diamond pencil marked?

In order to select the best option for a diamond pencil, the price of which directly depends on the specific application, a unified marking system is used, which can significantly reduce the selection time. These mandatory labeling items include:

- Trademark of the enterprise that produces diamond pencils for straightening wheels;

- Diamond pencil designation excluding the first six characters;

- Subgroups of diamonds used – A-1, A-2, A-3 with corresponding numbers when using natural diamonds and “C” for diamonds based on polycrystals;

- Number according to the manufacturer's internal marking system.

The first five digits of the marking are a standardized designation of the location of diamonds and their weight, which, depending on the model, can be 0.5-2 carats.

Types of diamond tools

The type of diamond pencil depends on the location of the diamonds in the working part, as well as on their characteristics. Main types of devices:

- Type C. In this type of pencil, diamond crystals are placed in a chain. To make the device, high-quality stones are selected, the weight of each of them is 0.03-0.5 carats. These tools are used for dressing wheels intended for centerless shaped, internal and cylindrical grinding.

- Type C. In this case, the stones are arranged in layers, and the layers may or may not overlap. To make a pencil, two grades of diamonds are used: the first grade includes stones with small grains, the number in one layer is 10 pieces; the second brand includes small-grained diamonds, weighing 0.1-0.2 carats each, 2-5 stones fit in one layer. The device is characterized by increased wear resistance and is intended for straightening abrasive discs during fine grinding.

- Type N. Such pencils are distinguished by a chaotic (not oriented) arrangement of stones, as well as the use of diamonds with different weights and sizes, up to the inclusion of chipped and crushed crystals. In addition, devices are characterized by belonging to different brands and various dimensions of the frame and insertion of stones. Diamond pencils type H are used for dressing grinding discs with a fine grain structure during centerless and cylindrical grinding, as well as as a device for dressing spline and gear grinding wheels of disc, flat and single-filament types.

Depending on the design, there are cylindrical, conical and stepped pencils.

In addition, diamond pencils may differ in purpose: there are types for hard or soft circles. To make it easier to make a choice, each device has its own marking:

- pencils No. 0051 - 0055 belong to type C, the mass of diamonds is:

0051 – 05 carat,

0052 – 05 carat,

0053 – 0,5,

0054 – 1;

- pencils No. 0081 – 0085 are type C, the weight of the stones is 1 carat, with the exception of No. 0084, where the stone weighs 2 carats;:

- pencils No. 0086 – 0088 belong to type C, the weight of all diamonds is 1 carat.

- pencils No. 0059-0068 belong to type H and are distinguished by the weight of diamonds of 1 carat.

Specifics of using a diamond pencil

To restore the cutting characteristics and shape of a grinding tool, using a diamond pencil is a simple process and does not require much effort. The high abrasion resistance of the diamond pencil allows for a constant wheel profile even with regular adjustments. Using a diamond pencil, you can polish the outside or inside of the grinding wheel. The price of a diamond pencil deserves special attention - it depends only on the type of diamond used (natural or synthetic) and its weight, but the cost of such a diamond tool is much lower than regularly replacing grinding wheels.

Types of Diamond Pencils

- With a chain arrangement of crystals. The weight of stones in this instrument ranges from 0.03 to 0.5 carats. This diamond pencil is suitable for shaped centerless grinding and is used for processing internal and curved surfaces.

- With a layered arrangement of crystals. The diamonds in this tool can be either small or large. Small ones are arranged in a layer of up to 10 pieces, the number of large ones in one layer does not exceed 5 pieces. Due to the increased working surface, such diamond pencils are characterized by increased resistance to wear and are used for finishing abrasive wheels.

- With a non-oriented arrangement of stones. Crystals of different qualities are suitable for the production of this instrument. With its help you can create a perfectly flat plane. It is especially effective when processing fine-grained abrasives and is used in circular and centerless grinding.

The main advantages of diamond pencils are:

- durability, resistance to corrosion and wear, due to the uniform distribution of load between the crystals;

- ease of operation (no special preparation required before use) and storage.

It is also worth noting the wide price range of the tool. The price depends on what kind of stones are used for its production. Pencils with diamond inserts of natural origin are more expensive and are more often used for industrial purposes to perform large volumes of work. Models with synthetic stones are cheaper and are designed for everyday use. In any case, purchasing a diamond pencil is more economically feasible than regularly purchasing new grinding materials.