Home / Solid fuel boilers

Back

Published: 05/25/2019

Reading time: 2 min

0

6358

In the recent past, the rate of fuel combustion in solid fuel heating units could only be adjusted manually. For this purpose, there was a ash door, by opening or closing which the air flow to the firebox increased or decreased.

Today, an automatic device called a draft regulator for a solid fuel boiler is successfully used for this purpose. To set the required temperature. When using it, it is enough to determine the required coolant temperature. The presented characteristics will help demonstrate the capabilities of a useful invention for the home.

- 1 Why do we need draft regulators?

- 2 Operating principle

- 3 Types of regulators, and which ones are better

- 4 How to install and configure the regulator

Installing a draft regulator on a solid fuel boiler and its further adjustment

Before installing the regulator on the boiler, use pipeline fittings to cut it off from the pipeline and drain the coolant from the boiler. If it is not possible to shut off the boiler (the fittings were not installed during installation), all the coolant is drained from the system.

Having unscrewed the plug from the coupling (sleeve), we manually tighten the regulator to check the thread size. If everything is normal and it is clear which layer of FUM tape to wrap on the thread of the device, apply a sealant to the thread and tightly, but without fanaticism, screw it into the sleeve with a wrench. If the sleeve is on the side of the boiler, then the arrow on the regulator handle points upward when screwed in all the way. When mounted from above, the slot of the device scale must be tightened to the front of the boiler.

A lever is inserted into the regulator seat so that the chain inserted into its hole hangs vertically above the ash pan door and does not interfere with operation when tensioned. After broaching, all connections are secured with a heat-resistant compound. After installation, the coolant level in the heating system is restored and the pipeline fittings are opened, and the firebox is loaded with fuel.

The installed regulator must be configured; for this, the following sequence of actions is carried out:

- The ash door is raised completely and the fuel is ignited.

- The latch on the handle of the device is unscrewed.

- The coolant temperature of the lower level of the range is set to 60° C.

- The chain is attached to the lever.

- After reaching the set temperature, the blower door is lowered, leaving a gap of about 2 mm.

- The second end of the chain is fixed on the handle of the ash pan so that the slack is no more than 1 mm.

- The screw on the thermostat knob is tightened.

Life advice. Before actively operating a boiler with a mechanical thermostat, it is necessary to patiently train the heating system at different temperatures within the control range, and, if necessary, adjust the length of the chain to reduce the error to 5%.

Combustion of solid fuel and heating of the coolant to a given temperature is an inert process, not fast. Therefore, the reaction to changing the setting on the thermostat knob will be delayed and it would be right not to rush things.

It is advisable to calibrate the device more often, especially at the beginning of the heating system operation. A change in the type of solid fuel and supplier should also first lead to a regular check of the compliance of the set temperature on the regulator handle and the actual temperature on the boiler thermometer. If necessary, configure the device by adjusting the size of the chain.

Conclusion. This method of obtaining stable operation of a solid fuel boiler is not as accurate as those associated with fans, smoke exhausters and a computer, but for the money it is reliable, autonomous and, in many cases, a benefit for a long time.

First start and ignition

Attention ! Ignition of a solid fuel boiler using flammable liquids is prohibited!

1

Place dry small wood chips on the paper through the loading door and open the damper on the chimney. Close the loading door and light the paper and wood chips through the ash door. Close the ash door and open the air damper completely.

2

Place a small layer of larger wood through the loading door onto the ignited wood chips. Wait until large logs burn well and add the main fuel in an even layer throughout the entire depth of the firebox to the bottom edge of the loading door.

When the boiler heats up, vapors from the flue gases may condense in it and flow down the inner walls of the firebox, which may give the impression that the boiler is leaking. As soon as the water temperature at the boiler inlet exceeds 60°C, condensation will stop.

3

Set up the mechanical draft control, see below.

4

To prevent coal caking, it is recommended to first heat the water in the boiler with wood to a temperature of at least 60°C, and then begin loading coal. Gradually and evenly load coal in an amount sufficient to form a layer approximately 50-60 mm high, then stop loading for 15-20 minutes to ignite the fuel. After loading, close the loading door and open the air damper.

When the first layer of main fuel (approximately 2/3 loaded) ignites, new fuel is loaded onto the layer of unburnt fuel. For the boiler to operate in nominal mode, it is necessary to maintain a fuel layer on the pipes of about 150-250 mm.

As the fuel burns in the boiler, it should also be added in an even layer throughout the entire depth of the firebox.

5

If the flame of burning fuel turns dark red, you should increase the draft by opening the air supply damper or the damper in the smoke channel more strongly. After the flame turns yellow, close the air supply damper.

Vary the air supply until the flames become straw-colored with orange tongues. Always monitor the presence of a flame in the firebox; fires that produce smoke and smoldering fires result in inefficient combustion of fuel and the formation of tar in the chimney.

6

The boiler power can be changed within rough limits by using a damper on the smoke exhaust pipe. To increase the temperature, it is necessary to open the damper (gate) and set the draft regulator control knob to a higher temperature mark; to decrease, partially close the damper and set the regulator control knob to a lower temperature mark.

Also, the boiler power can be adjusted by loading fuel; large pieces and a small amount of fuel give low power, and small pieces with a large amount of fuel give high power.

7

During prolonged burning, the grates should be periodically drilled so that the layer of caked ash does not interfere with the supply of air for combustion.

8

To stop the boiler, wait until the fuel burns out completely or stop the air supply to the firebox of the solid fuel boiler by closing the air damper.

If it is necessary to emergency stop a solid fuel boiler, carefully open the loading door, remove the burning fuel from the firebox using additional devices and extinguish the removed fuel with water

What is a draft regulator for solid fuel boilers?

The draft regulator is an automatic device designed to control combustion and regulate temperature. The uniqueness of this device is that it is completely energy independent, and therefore, in the absence of electricity, the boiler will be able to continue operating and the functioning of the heating system will be stable. Draft regulators are installed on most simple-type solid fuel boilers. Modern boilers use more complex and multifunctional mechanisms. But these remain popular due to several advantages:

- Simplicity in design and operation;

- Reliability;

- Possibility of making it yourself;

- High accuracy;

- Low cost and easy to repair.

Quite banal, but very important advantages of a draft regulator for solid fuel boilers. They are bought for both old and modern, expensive boilers

Traction controls are important in operation, but how does a simple design take on so much?

Operating principle of a draft regulator for a solid fuel boiler

The regulator itself can be installed in different places on the boiler. As a rule, the manufacturer himself shows where it is necessary to connect the draft regulator for the boiler, or where the water jacket fits. The traction regulator needs to be in contact with the coolant so that the special gas (sometimes liquid) located in the sleeve expands during the heating process. After this, the actuator is assigned the task of lowering the lever, which already reduces the draft in the solid fuel boiler.

The principle of operation is very simple, which is why these levers can be made with your own hands. With the correct design of a homemade draft regulator, it is no different and can also serve usefully.

How to set up a draft regulator for a solid fuel boiler?

- Before setting up, you must disconnect the circuit from the air damper

- Loosen the handle lock as much as possible

- Adjust the scale according to the current situation and set the required temperature level

- Light the boiler and reach the set temperature (see point 4)

- When this temperature is reached, place the chain on the choke handle. When set correctly, the chain should be taut.

After this, you can enjoy the operation of the traction regulator and have peace of mind about heating when you are away from home. These designs are really useful and easy to use; they save the situation when there is a power outage, which often happens in our country. The operating principle, based on mechanics and the laws of physics, is the most reliable way to regulate the boiler.

Useful tips

The main recommendation from manufacturers is that the draft regulator must be tested at all possible temperature conditions before active use.

Don't worry if something goes wrong the first time. After closing or opening the damper, several minutes will pass until the coolant cools down/heats up.

Watch videos about the Kupper line on our company’s website, as well as a free course on installing and configuring the regulator. Teplodar specialists are always happy to answer any questions you may have.

The draft regulator for boilers of the “Kupper” line is an easy-to-use, convenient and effective tool for automating room heating, significantly increasing the ease of operation of the heating system.

Principle of operation

The draft is adjusted by changing the degree of rarefaction of the gases in the pipe. For this purpose, a stabilizer is built between the chimney pipe from the firebox and the entrance to the chimney. It can work in manual or automatic mode.

The chimney draft regulator is a damper (valve) built into a separate housing. When the draft increases, the valve opens slightly and releases a portion of air from the room. The gas flow cools, the lifting force from the thermal component decreases, and the ejection speed decreases. And, conversely, with the closing of the valve, the influx of cold air decreases, and the output force increases.

Note! That is, when the valve is closed, the maximum output of combustion products is ensured. Fully open damper – minimal gas flow.

It is advisable to install a draft stabilizer on solid fuel boilers operating:

- on coal;

- firewood;

- pellets;

- peat or coal briquettes, etc.

This is due to the presence of time at which the boiler reaches its planned capacity and, accordingly, a stable operating mode. That is, the oven should melt.

Delivery to regions

Dispatch of goods to the regions occurs with 100% prepayment.

Carried out by transport companies to the nearest TK terminal.

The price to the place of receipt of the goods is calculated according to the internal tariffs of the transport company and is paid separately upon receipt.

| For order amounts over 15,000 rubles | delivery to shopping center is free |

| If the order amount is less than 15,000 rubles | from 500 rub. |

Delivery terms

We deliver the goods to the entrance of a residential building or the entrance to a commercial building. Unloading is carried out by the customer. The manager will agree on the delivery date and time with you by phone. Do not forget to check the appearance and completeness of the goods in the presence of the forwarder.

ATTENTION: Most of the products we offer are heavy, so we ask you to take care of unloading in a timely manner. Don’t forget to check the appearance and completeness of the goods in the presence of the forwarder!

Don’t forget to check the appearance and completeness of the goods in the presence of the forwarder!

If you have any questions about the terms, please contact the manager by phone:

+7

or

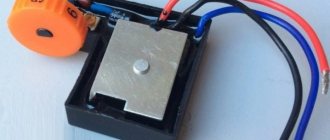

Do-it-yourself installation and calibration of the draft regulator

The simple design allows you to install the device yourself. If we consider the boiler from all sides, in projection, then the front or side surface of the unit is selected to install the regulator. For this purpose, the product has a special hole. The regulator is mounted using a threaded connection. The diagrams show how to install the regulator and how not to install the device.

Note: In this case there can be no middle solution. As indicated in the instructions, this is how the draft regulator is installed on a solid fuel boiler.

Correct installation is determined by aligning the device vertically and horizontally. After the regulator is installed, all rotating elements are tightened, the existing interfaces are subject to sealing with a special heat-resistant compound. The lever is placed in a position so that the hole through which the chain will pass is above the damper, in a vertical position.

If the first stage is quite clear and simple, then subsequent actions require special attention, accuracy and consistency of actions. Calibration of the regulator is the most important step in its functionality.

Stage one

Having installed the regulator on your heating unit, you can start kindling. Having brought the boiler water temperature to 60 C, record this same temperature on the flywheel (thermostat) of the draft regulator. The lever at this time must be connected by a chain to the damper.

Having fixed the damper in a certain position, with the regulator set at 60 degrees, we do the following.

Stage two

We turn the thermostat to 80 0C. If you have installed the draft regulator correctly and completed all previous steps according to the instructions, when the boiler heats up to the set temperature, the damper will automatically close. Air will stop flowing into the firebox, and the intensity of fuel combustion will decrease accordingly. The error in temperature measurement accuracy can reach +/- 5 C, which is not critical for ordinary, simple heating devices of heating systems.

It is necessary to adjust the draft regulator as often as possible. Mechanical damage to the chain or a tightly moving damper can cause a malfunction of the device.

Rules for installation and preparation for operation

Installing a draft regulator on a solid fuel boiler is done independently if the unit is not initially equipped with one. The device needs to be configured correctly.

Installing the regulator in most cases requires draining the coolant from the water jacket. To avoid draining the entire system, close the appropriate shut-off valves. Then remove the plug from the sleeve on the boiler body and screw in the control device without connecting the chain to it. Then refill the system with water.

The setup is carried out in several stages:

- Open the ash pan door (without attaching the chain to it).

- Loosen the locking screw located on the adjustment knob.

- Select the temperature mode and set the handle to the appropriate position (for example, 60°C).

- Connect the chain to the lever.

- Light the boiler with the ash pan door open, wait until the coolant heats up to 60 degrees (monitor the readings of the boiler thermometer).

- Close the door so that it is slightly open by 2 mm.

- Secure the free end of the chain by tensioning it (allowable free play - 1 mm).

- Tighten the fixing screw on the handle.

The installed thermostatic regulator must be tested at all temperature conditions, including maximum, to ensure that the device is working properly and is correctly configured. Solid fuel boilers are characterized by high inertia - changes in the intensity of combustion of coal or firewood occur smoothly and the heating of the coolant decreases or increases even more slowly. Therefore, after closing the damper, a certain time passes until the coolant in the system begins to cool. For this reason, when checking the settings of the control device, do not rush to make adjustments.

Sources

- https://fb.ru/article/278673/regulyator-tyagi-dlya-tverdotoplivnogo-kotla-ustanovka-i-regulirovka

- https://otivent.com/chto-takoe-regulyator-tyagi-i-kak-ego-ustanovit-na-tverdotoplivnyj-kotel

- https://obinstrumente.ru/dlya-doma/regulyator-tyagi-dlya-tverdotoplivnyx-kotlov.html

- https://cotlix.com/regulyator-tyagi-dlya-tverdotoplivnyx-kotlov

- https://termost.ru/otoplenie/kak-ustanovit-regulyator-tyagi.html

- https://ProfiTeplo.com/tverdotoplivnye/26-regulyator-tyagi-dlya-tverdotoplivnyx-kotlov.html

Setting up the draft regulator

In general, using the instructions that come with the device, you can easily understand the design settings. However, in case of its loss, a step-by-step list of moves is provided:

- First you need to light the boiler. Then open the door, but most importantly, do not attach the chain to it. This is necessary in order to create access for air masses.

- Then loosen the screw that secures the position on the adjusting mechanism.

- After which you can set a certain temperature by turning the handle.

- When the value is reached, it is advisable to attach the actuator to the damper. It should be a little open.

- Finally, secure the screw.

The main thing is to periodically monitor the thermometer and not rush to change settings

In addition, the distance of the chain is important - less than 1 millimeter. Some models of the device are characterized by a certain delay, since the coolant is unable to extinguish at lightning speed

Programmable room thermostat

A programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time; it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern on weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or shift work. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If the heating system is controlled by a boiler with a radiator, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall as the clocks move forward and backward or certain changes in climatic conditions occur. We also recommend changing the temperature settings when changing from day to night.

This climate controller has several options that expand its capabilities:

Operating principle and functions of draft regulators for solid fuel boilers

Control of the boiler damper or the furnace ash door by the operator (stoker) changed the amount of oxygen in the firebox and changed the temperature of the coolant in one direction or another (due to more or less intense combustion). The operating principle of a mechanical device capable of doing this work is also quite simple.

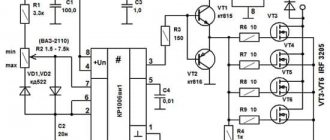

This thermostat consists of the following parts:

- sleeve with a heat-sensitive element;

- mechanical temperature change amplifier;

- calibrated knob that sets the temperature;

- a spring, the compression of which will determine the level of the task;

- lever with a chain that controls the door of the ash pan (blower).

The coolant temperature setting is set by the regulator handle, which compresses the spring with the required force. The difference between it and the force of the cold heat-sensitive element is large, so the lever mechanism opens the damper in a chain to a certain large angle. A lot of air enters the firebox, intense combustion occurs. As it heats up, the linear dimensions of the sensitive element increase, and the difference between the set and operating temperatures becomes zero. The ash pan door, smoothly lowering, takes a position corresponding to the specified one and subsequently reacts to temperature deviations.

The functions of the traction control include the following tasks:

- stable maintenance of the specified temperature of the coolant within the control range, preventing it from boiling;

- control of the power and efficiency of the boiler due to the supply of oxygen, achieving complete combustion of the fuel, which reduces its consumption.

Boiler operation using pellet fuel

Recently, pellet fuel has been widely used. The Don 16 boiler, just like any other, can be converted to pellets. Although this is not a very cheap measure, after installing a pellet burner with a hopper it helps to save on fuel, as well as on boiler maintenance time. In addition, there is practically no waste from this fuel; it is very easy to store in bags.

To transfer, you need to purchase and install the pellet burner itself and the fuel hopper. It is worth saying that when switching to this fuel, no permits are required, although the boiler will operate almost like a gas one.

Heating boiler Don 16 with pellet burner

Draft regulator - its importance for solid fuel boiler equipment

The operation of a heating device with an open and closed combustion chamber depends 90% on the state of draft in the heating system. The more stable the draft parameters, the better the heating unit works. Under the influence of draft, solid fuel burns better in the combustion chamber; combustion products easily evaporate through the chimney. With normal draft, the fuel burns more intensely, heat exchange processes improve, and the efficiency of boiler equipment increases accordingly.

Despite the fact that today most models of solid fuel heating devices are equipped with automation, the most effective and efficient are still mechanical control and adjustment devices. Energy dependence is the main drawback of solid fuel boiler automation. There is no electricity in the house, the battery powering the UPS is dead, the boiler becomes uncontrollable. A mechanically driven device installed on the boiler and adjusted in accordance with the specified temperature parameters of the boiler is capable of completely controlling the combustion intensity.

The main advantages of a mechanical draft thermostat are as follows:

- simplest design and reliable operation, unlike automatic devices equipped with electronics;

- non-volatile (automatic traction control requires uninterrupted power supply);

- convenient and understandable installation of the device;

- low cost.

The simple design and principle of operation allow you to make such a device yourself, install and configure it. The mechanism has a scientific and technical name - a thermostat for the boiler. To get the maximum possible effect from the existing heating unit, it is enough to correctly install the thermostat. Subsequent calibration of the device is carried out in accordance with the main functions of exhaust ventilation and the specified temperature parameters.

Instead of a preface

Today, high technologies make it possible to create various automation tools; thanks to them, boiler equipment works independently, and there is almost no need to pay attention to it. But most of them use electricity, which is not very convenient. Along with power outages, the house is filled with cold, this situation cannot be called rare

The reason is that the heating device is turned off automatically

Along with power outages, the house is filled with cold; this situation cannot be called rare. The reason is the automatic shutdown of the heating device.

However, on sale today you can find fairly simple automation equipment that does not require electricity to operate; this includes a draft regulator, which is used in conjunction with mechanically driven boilers.

Principle of operation

The main role in the design of the draft regulator is played by a thermostatic element located inside a cylindrical body. It has a mechanical connection with the lever, which, in turn, is attached by a chain to the vent flap.

The thermostatic element is presented in the form of a sealed flask, which is filled with a heat-sensitive liquid that has the ability to expand under the influence of temperature.

The element itself is located in the lower part of the housing, which, when installed, falls inside the jacket and has direct contact with the heated coolant. Control of fuel combustion, in this case, is carried out by adjusting the position of the ash valve.

- During the combustion of fuel, the coolant is heated, which acts on the thermostatic element. This, in turn, overcomes the resistance of the return spring and activates the actuator.

- Lowering, the lever loosens the chain, the detached damper lowers, reducing the cross-section of the air supply opening. When the air flow to the firebox is reduced, the combustion process slows down.

- When the temperature of the coolant decreases, all actions occur in the reverse order. As a result, the damper rises, resuming the flow of air to the firebox.

- The cyclical adjustment of the air flow to the firebox occurs continuously until the fuel is completely burned. In this case, the thermostatic element completely releases the return spring, which opens the air supply valve as much as possible.

At the end of the thermostat there is a setting handle that can limit the amplitude of movement of the lever, regulating the movement of the damper. This allows you to control the temperature of the coolant. The operating principle of a gas boiler does not allow the use of these devices.

Brief conclusions

We can conclude about the need for draft regulators for solid fuel boilers: such primitive automation is better than its complete absence. Yes, mechanical regulators cannot boast of high accuracy, but they will save you from manual control “by eye” and will allow you to save wood and coal. The devices have an undeniable advantage over controllers and fans - energy independence.

In the recent past, the rate of fuel combustion in solid fuel heating units could only be adjusted manually. For this purpose, there was a ash door, by opening or closing which the air flow to the firebox increased or decreased.

Today, an automatic device called a draft regulator for a solid fuel boiler is successfully used for this purpose. To set the required temperature. When using it, it is enough to determine the required coolant temperature. The presented characteristics will help demonstrate the capabilities of a useful invention for the home.

Types of regulators and features of choice

If the solid fuel heater is not equipped with a draft regulator as standard, you will have to install the device yourself.

A prerequisite for this is

:

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are available that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

On the left is a boiler with the ability to install a regulator, on the right is with manual control

When choosing a model, pay attention to the following parameters:

- the force that the drive develops (the value is indicated in the passport, it should be sufficient to lift the ash pan door);

- temperature range for heating the coolant (60-90°C);

- the operating stroke of the drive (it should be sufficient to fully open and close the damper);

- type of threaded connection on the body - it must match the thread in the boiler unit sleeve (usually 3/4″).

The design of the draft regulator may provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the water jacket of the boiler. For such models, the immersion sleeve is removable.

Tips for choosing a device

Specialized stores have a huge selection of solid fuel boilers. And, oddly enough, even today you can find models without automation. Most of these “ancient” devices are equipped only with a sleeve mounted inside the heat exchanger. Installation of a draft regulator on a solid fuel boiler of this type is mandatory. This will prevent the temperature from rising to critical levels and will make the structure safer.

In this regard, it is necessary to pay attention to the presence in the design of a sleeve and a flap that rises upward.

When choosing a mechanized draft regulator, you must adhere to the following recommendations:

- the thermostat power must correspond to the weight of the sash in order to successfully lift it;

- it is better to choose the ability to regulate the temperature in the range from +60 to +90°C;

- the angle of rotation of the lever should be enough to fully open and close the sash;

- The threads in the boiler must match the threads of the draft regulator in order to freely fasten the two parts together.

The heating process using modern mechanized and automatic draft regulators has become easy and convenient today

When choosing a regulator, you should also pay attention to the position in which it can operate, since the sleeve can be located on the side or on top. There are models that can work in any position.

Review of manufacturers

On sale you can find thermostats for heating boilers to suit every taste. There are budget and more expensive models. And in order to choose it correctly, you need to consider the following.

- The temperature adjustment interval should be 60-90°C.

- The force specified in the design passport, which is developed by the drive, must be sufficient to lift the door.

- It is necessary to ensure that the operating stroke of the drive is sufficient to fully open and close the flap.

- The thread connection on the body must match the corresponding part in the boiler and be ¾.

The location of the draft regulator sleeve on the body of the heating boiler can be at the top, side or front. For the vertical option, you need a device that can function in a vertical position, and for the rest - in a horizontal position. Of course, there are also regulators that do not care about position and operate on two adjustment scales.

Currently, automatic draft regulators for solid fuel boilers are produced by several domestic and foreign companies. In Russia, devices most often purchased are from the Italian and Ukrainian brands “Air Auto”, the American “Watts”, and the Polish “Tech”.

It’s worth saying right away that prices for draft regulators for solid fuel boilers vary. And this is mostly influenced by the location of the manufacturer and the type of action (electronic thermostats are always several times more expensive).

For example, the Ukrainian brand “Air Auto” costs an average of 7,000 rubles, and the similar Polish brand “Tech” costs 10,000 rubles.

We suggest looking at some brands of popular regulator manufacturers in the table.

ManufacturerCountryCharacteristics

| Atos | Italy | Specializes in the production of exclusively automatic systems. Assumes manual or automatic fuel loading. Electrohydraulics involves installing a system from 15 kW. |

| Air Auto | Ukraine | Assumes manual loading of fuel. The product is provided with a control unit with several operating modes. The set includes circulation equipment, smoke exhausters, fans. A special feature of the brand is the ability to smoothly control the fan speed. During operation, an integral-differential algorithm is used, which increases the duration of fuel combustion by 20%. |

| Watts RT | America | Wide range of operating temperatures, from 30 to 100°C. The brand has a standard threaded connection and is also perfect for installation in modern boilers. |

| Tech | Poland | It mainly produces automation, which is controlled by a microprocessor. The brand has a simple design, with a basic set of functions necessary for the operation of the boiler. The modules have four operating modes and built-in protection against overheating of the coolant. |

| ICMA | Italy | This model is characterized by chain tension with a load of up to 850 g, a wide range of power settings (from 30 to 100°C) and the possibility of both horizontal and vertical installation. |

| Euroster | Poland | Offers electronic automatic thermostats that connect to room thermostats and automatically ensure the combustion process. Accurately monitors room temperature and is ideal for controlling underfloor heating systems. If desired, the heating temperature can be 30-90°C. The maximum load on the chain is 800 g. |

| ESBE | Sweden | The brand produces mechanical and electronic temperature controllers for heating boilers. The latter are intended for boilers with automatic fuel supply. The thermostat is connected to circulation equipment and blower fans. |

| Regulus RT3 | Slovakia | The “regulus” draft regulator implies an adjustment range of 30 – 90°C. 120°C is the highest temperature for heating water, 60°C for the medium. Working position horizontal and vertical. Its improved model is the regulus rt4 traction control. It is distinguished by its smaller dimensions, and, unlike rt3, its load on the chain is not 800 grams, but up to 1 kg. |

| Lemax | Italy | It has an adjustable handle made of thermosetting resin - and this is the main feature of the manufacturer. There is a heat-sensitive element, so you don’t have to worry about safety. The brand boasts of precision settings and reliability. The control equipment produced is of standard sizes, therefore suitable for many solid fuel boilers. |

| Honeywell FR 124 | Germany | Compatible with most solid fuel boilers (BURNiT, Wirbel, Viadrus Buderus, KChM, ZOTA, DON, etc.) Maximum operating temperature is 115 °C. The adjustment range of the draft regulator is 30-90 °C. The temperature-sensitive element is filled with wax. It has two scales, suggesting both horizontal and vertical installation. |

We recommend: Heating equipment for the home

Thus, the draft regulator allows you to increase the ease of operation of the solid fuel boiler.

Traction regulator

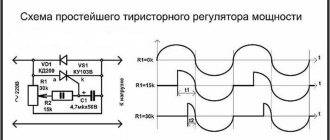

The combustion process directly depends on the presence of air. If we transfer this statement to the operation of a heating device, then the more air enters the combustion chamber, the faster and at a higher temperature the fuel burns. In other words: by supplying air to the fuel combustion chamber, you can regulate the degree of heating of the coolant. In the design of solid fuel heating systems, an air damper is provided for this function. By changing the position of the damper, conditions are created under which fuel combustion occurs according to the pattern specified by the user.

The only problem: the owner of the boiler unit must adjust the position of the air damper manually, relying on the thermometer readings and his own experience. To automate this process, an automatic draft regulator was invented.

The principle of operation of the regulator: when temperature affects the thermoelement, it changes its shape and, through the rod, acts on a lever, which is connected to the air damper of the boiler unit using a chain. When the coolant temperature changes, the position of the air damper automatically changes. The regulator sets the upper temperature limit.

To set up a draft regulator for solid fuel boilers with your own hands, you need to follow these steps:

- Install the regulator into the heating system. Depending on the boiler model, both horizontal and vertical installation of the device can be provided. Each installation option corresponds to a specific scale color on the regulator. At this stage the chain is not connected to the choke and hangs freely.

- Set (by selecting the color of the scale corresponding to the orientation) the desired temperature indicator of the coolant and start the boiler installation.

- When the coolant temperature reaches the value you set on the thermostat, close the air damper, leaving a gap of 2-3 mm.

- Attach the chain to the damper rod.

Let's digress a little, because we want to inform you that we have compiled a rating of solid fuel boilers by model. You can learn more from the following materials:

- Long-burning solid fuel boilers with a water circuit - domestic manufacturers

- Long-burning solid fuel boilers with a water circuit - foreign manufacturers

Design and principle of operation

The device diagram is quite simple. The main structural elements are:

- temperature control handle;

- rod and guide;

- actuating mechanism;

- immersion sleeve;

- temperature sensitive element;

- spring;

- drive lever;

- handle and lever mounting screws;

- chain.

The main component is a sensor that responds to temperature fluctuations. It interacts with a spring, which, when heated or cooled, activates the working part (sleeve and rod).

That, in turn, is connected through a mechanical drive to the fuel compartment flap. The draft regulator for solid fuel boilers, under certain conditions, opens and closes the door, maintaining the set temperature.

The principle of operation of the device is banal, but still effective. When the damper opens slightly, more air enters the firebox. Due to this, fuel combustion occurs more intensely, more heat is released, and the room is heated more efficiently. When the valve closes, the fuel is less supplied with oxygen and barely smolders.

If we briefly describe the operation of the draft regulator, based on design features, we get the following diagram:

- when the heat load decreases, the thermostatic sensor reacts to fluctuations;

- the sensor increases the spring tension;

- the spring lifts the lever;

- the damper opens;

- the combustion intensifies.

To reduce the intensity of the process, the steps are performed in reverse order.

The regulator body has a handle with a temperature scale. This sets the required minimum value. The temperature will rise as necessary, but will never fall below the set level.

On the regulator body there is a handle with a temperature scale, so the required minimum value is set.

How to configure the regulator after installation

In order to properly configure the device after installation, you must strictly follow the step-by-step instructions:

- Open the boiler door and do not close it with a chain. This is done in order to let air in.

- The locking screw on the adjustment handle is loosened.

- The handle is inserted at the required temperature, for example, 65C.

- The thermometer on the solid fuel boiler is monitored; after the mark reaches 65C, it is necessary to connect the chain wire to the damper. The main thing is not to close the damper completely. It should always be slightly open a couple of millimeters.

- The fixing screw is tightened.

Important! The chain has free play, but it should not exceed 1 mm. After this, the device is checked in all modes, even at the maximum

The main thing to remember is that time must pass between checks, since the solid fuel boiler heats up and does not always have time to cool down. To get the most effective result, you need to wait a while so that the temperature conditions do not go astray

After this, the device is checked in all modes, even at the maximum. The main thing to remember is that time must pass between checks, since the solid fuel boiler heats up and does not always have time to cool down. To obtain the most effective result, you need to wait for some time so that the temperature conditions do not go astray.

Coal or firewood fades gradually, so solid fuel thermogenerators need a little more time to cool down than other similar equipment.

Setup instructions

Thermostatic draft regulators have 2 types of markings for operation in different positions. On the RT 10 device, the red scale is intended for operation in a horizontal position, and the yellow markings are for vertical operation. The product is configured in the following order:

- Before starting the adjustment, the lower end of the chain must be disconnected from the air damper so that it hangs down freely, and the screw that locks the handle must be loosened.

- Having chosen the color of the scale in accordance with the orientation of the thermostat in space, set the value of the desired temperature on it.

- Light the heat generator and warm it up, monitoring the temperature of the coolant using a boiler thermometer.

- When the temperature of the water in the jacket reaches the value at which the draft regulator is set, put the end of the chain on the ash pan door. Make sure that the chain is tensioned; the free play should not exceed 1 mm. After this, you can fix the handle with a screw.

After setting, it would be useful to check the operation of the thermostatic regulator by changing the temperature with the handle and comparing it with the readings of the thermometer. It should be taken into account that in solid fuel boilers there is a phenomenon of inertia. This means that after closing the ash pan door, the increase in the temperature of the coolant will not stop immediately, since the firewood or coal in the firebox cannot go out at once. You need to wait some time during which the thermometer readings stabilize.

Possible installation problems and ways to eliminate them

Compliance with technical rules, taking into account basic norms and standards cannot always guarantee achievement of the desired result. Even the slightest mistake that was made at any stage of the installation work can lead to improper functioning of the entire system. The most common problems that builders face are:

- Non-vertical arrangement of the tube lumen. The permissible deviation is no more than 10 cm per meter of product. A deviation of only 1 cm is considered ideal, however, it is almost impossible to achieve such results without special practical skills and outside help.

- The presence of gaps that create obstacles for the free passage of the pipe into the chimney channel. The existing gaps must be sealed with a clay-sand mortar or a sealed substance that is resistant to high temperatures. The chimney draft control can be sealed using sealant, soaked asbestos or asbestos cord.

Ferrum devices meet all the presented requirements. Assembling the chimney will not take much time, a tight connection guarantees tightness, and the rigidity of the structure ensures no deviations.

Afterword

The safe operation and efficiency of stoves and boilers is highly dependent on the presence or adequate draft in the chimney. In case of even minor problems with the smoke removal system, it is necessary to inspect the chimney for permeability and begin to normalize the draft. The presence of carbon monoxide indoors is very dangerous to human life. Carrying out repair work and installing a stabilizer on your own is quite possible.

Sources

- https://zen.yandex.ru/media/id/5b02bffd8c8be3dd3cd115f1/5e39392e5b4a3e23cf825f88

- https://pechiexpert.ru/stabilizator-tyagi-dymohoda-01/

- https://livelyday.ru/teplodom1.ru/kotly/2229-reguljator-tjagi-dlja-kotla-zachem-nuzhen-kak-primenjaetsja.html

- https://www.teplodar.ru/help/articles/detail/regulyator-tyagi-dlya-tverdotoplivnykh-kotlov/

- https://www.tproekt.com/nuzen-li-siber-ogranicitel-tagi-na-dymohode-kotla/

- https://kaminguru.com/kotel/kak-ustanovit-reguljator-tjagi.html

- https://ZnatokTepla.ru/kotly/tverdotoplivnie/regulyator-tyagi-dlya-tverdotoplivnyh-kotlov-ustrojstvo-i-montazh.html

- https://feflues.ru/blog/problemy-dymokhoda/kak-ustranit-obratnuyu-tyagu-v-dymokhode-prichiny-vozniknoveniya-v-pechi-i-chto-delat-chtoby-izbezha/

- https://domsdelat.ru/otoplenie/obratnaya-tyaga-v-dymohode-i-chto-takoe-stabilizator-tyagi-dymoxoda-prichiny-i-ustranenie.html

- https://vseotrube.ru/ventilyatsiya-i-dymohod/stabilizator-tyagi

- https://otoplenie-guide.ru/oborudovanie/pech/stabilizator-tyagi-dlya-dimohoda

Traction force

The traction force depends on various factors:

- Flue gas temperatures.

- Chimney sections.

- Weather conditions (humidity, outside temperature, etc.).

The influence of these parameters on the operation of heating devices can be different, so you should always consider the specific operating conditions of communications. It is necessary to note one more parameter, which often escapes the attention of consumers, but has a significant impact on the traction force - the type of boiler equipment. As practice has shown, the dependence of the operation of gas and solid fuel boilers on their type is as follows:

When operating gas equipment, the traction force fluctuates slightly; the indicator can be considered stable. This is explained by the fact that the flue gases generated during boiler operation have almost the same temperature. Unevenness can only occur when the chimney warms up and is short-term. Solid fuel boilers show different data. It is impossible to unambiguously judge the influence of absolutely all models on traction performance. This is explained by the use of different types of fuel (firewood, peat, coal, pellets, sawdust). Also, the heterogeneity of indicators may depend on the type of solid fuel boiler. Despite the type of boiler and type of solid fuel, there are a number of similarities

The following are of greatest importance: the long time required for the fuel to ignite, a significant difference in the temperature of the exhaust flue gases at the beginning of operation of the equipment and after the boiler returns to normal operation. When operating solid fuel boilers, there is a possibility of not only a decrease in draft and a deterioration in the combustion process, but also the appearance of hyperdraft. A sign of this phenomenon is loud noise during equipment operation, and the most “pleasant” consequences are smoke and increased fuel consumption.

Electric boilers

A fairly common alternative to gas and solid fuel boilers. Lots of advantages, high efficiency, but long payback period. The connection is simple, like with gas boilers, but without a cold water supply. Temperature regulation and overheat protection are provided.

Mechanical boiler timer

Using a simple mechanical timer for an electric boiler, there are three options for starting the central heating system:

Mechanical timers usually have a large round dial with a 24-hour scale in the center. By turning the dial, you can set the desired time, and then leave it in that position. The boiler will turn on at the right time. The outer part consists of a set of tabs for a 15-minute period, which are inserted for easy adjustment of operation and mode settings. Emergency reconfiguration is possible, which is performed with the boiler connected to the network.

Mechanical timers are easy to set up, but the boiler always turns on and off at the same time every day, and this may not satisfy the owners if the family is large and bathing procedures are carried out several times a day at different times.

How to choose the right draft regulator

The modern market offers a large number of models of solid fuel boilers. But not all of them are equipped with automation. In such models, the sleeve is mounted directly into the heat exchanger. Such boilers must be equipped with a draft regulator.

In order to choose the right mechanical traction device, you must adhere to the following instructions:

- To successfully lift the sash, it is necessary that its weight and the power of the thermostat match.

- The temperature range should be between 60-80C.

- The lever must have a rotation angle such that it is enough to completely close and open the sash.

- The threads in the boiler and the draft regulator must match each other in order to be connected.

Attention! The sleeve on the equipment may be located on the top or side, so it is very important to select a regulator with the correct operating mode. Models have been developed in which work can be done in any position

Connection diagrams

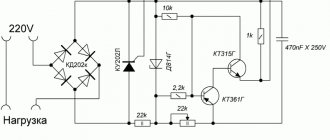

All methods of connecting a thermostat to a heating system are divided into three connection options:

- Directly to the boiler.

- To the circulation pump.

- On the pipe supplying coolant to the radiator.

The first two schemes eliminate the deterioration in the throughput of the heating pipeline. No additional locks are placed in it, and the hydraulic resistance of the entire system does not change. The thermostat here only controls the operation of the pump or boiler; it “does not come into contact” with water.

When installing a thermostat on a battery or a common pipe with several radiators, the hydraulic resistance, on the contrary, increases. Even when fully open, the thermostat valve slightly slows down the flow of coolant.

Ideally, the boiler piping project should be carried out immediately, taking into account all thermostatic and other devices.

If the water heating system in the house is made according to a single-pipe scheme, then it is better to immediately abandon the third option. When the temperature sensor is triggered, the valve will immediately shut off the entire radiator line in several rooms, and then you can immediately forget about comfort in rooms far from the boiler.

The thermostat should be connected to the radiator input via a bypass. So, when triggered, it will redirect the coolant flow bypassing the battery. In this case, the water will return uncooled back to the boiler. The latter will stop heating it, thereby reducing the consumption of gas fuel or electricity.

The temperature sensor must be mounted:

- in a place where there is no direct sunlight;

- away from cold bridges, drafts and rising heat flows from radiators;

- so that it is not covered by decorative screens or curtains;

- at a height from the floor within 1.2–1.5 meters.

If the sensor is installed incorrectly, the thermostat will produce false signals. This can lead to overheating not only of the air in the room, but also of the coolant in the system. And in the second case, it won’t be long before there are problems with the boiler.

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of increasingly complex systems for automatically controlling the processes of heat production and hot water supply. They are more accurate and do not require user participation in most operations. However, such systems are becoming increasingly dependent on electricity and increasingly expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. Operates reliably in the range of 35˚-95˚С, operating temperatures from –20°C to +150°C. Can be used with various antifreezes, allows replacement of the thermostatic element. When used in low temperature environments, it requires heating. Can be installed in any position and does not require service. Inserts into a sleeve with 3/4" pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuel, due to its extreme unpretentiousness, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device can be mounted in a vertical or horizontal position; the temperature level scale allows this. Coolant temperature control range 30–90°C, maximum operating temperature +120°C. Coupling for connection with internal thread G3/4”. Device weight 0.42 kg, manufacturer – Czech Republic.

Cost: from 1500 rubles.

Specifications

Main parts are made of brass for protection against high temperatures

The planned operating temperature of the heating unit is included in the setting range with a margin of two sides. The connecting thread on the mechanical regulator must correspond to the parameter of the threads at the junction with the boiler. The weight of the damper should not exceed the lifting force of the lever, otherwise the door will not budge; in this case, a support part with greater force is selected.

Mechanism characteristics:

- the body is made of all-metal chrome-plated brass;

- the handle is made of resin with high heat resistance;

- the chain is made of galvanized metal;

- a highly sensitive wax thermocouple is used;

- the temperature is set in the range +30 – +100°С;

- connecting chain up to 1.2 m long;

- useful chain force is 0.85 - 1.2 kg;

- the lever has a length of 0.12 - 0.14 m;

- lever rotation angle 100 – 150°;

- connects to the unit with a ¾-inch conical thread;

- maximum water temperature +120 – +130°С.

What is it and what is it for?

There are several standard options for placing the gate. The valve is placed in the firebox of a stove or fireplace. This arrangement is often used because it is convenient for adjusting the position of the plate in the pipe. The device is inserted into the pipe at a height of no more than 1 m from the top of the heating compartment in an area that is not insulated.

The damper is installed according to the principle of one pipe in another. This is what they do when making a chimney from metal. As a standard in factory systems, the gate valve comes complete with pipes; its installation does not require additional fasteners. The product is installed in accordance with the manufacturer's instructions.

To simplify the heating operation, obstacles to the warm flow are installed, which requires a damper in the chimney. It performs the functions:

- Partially or completely obscures the passage in the pipe, which makes it possible to open the exit for smoke from the firebox or stop its movement outward. When the oven is not burning, the scraper is in the closed position.

- The valve regulates the draft in the pipe. The open plate increases traction, and the closed position reduces the intensity of air output, which saves firewood and coal. The impact on the air flow occurs as a result of a decrease or increase in the cross-section of the chimney.

- Using the part, the intensity of combustion in the firebox changes - the degree of heating of the room is regulated.

You can answer the question of what a gate is by considering its positive aspects. The damper retains heat in the fireplace or stove; when the correct position is selected, the fuel energy is used to heat the interior of the room and does not escape outside. Fuel economy is an important factor for home owners. The valve regulates the draft and prevents the fire in the hearth from going out.

The use of a damper in the design of a smoke duct has several disadvantages:

- After installing the device, it becomes difficult to clean the internal space of the pipe from carbon deposits and soot, since the damper prevents the passage of the brush.

- The gate quickly becomes dirty and requires periodic maintenance. Its upper surface is cooled by the supplied outside air, and the lower plane is heated by hot flows from the furnace mouth. Contact of 2 different temperatures leads to the appearance of condensation drops, which contributes to the rapid destruction of the damper.

- An incorrectly mounted damper causes a lot of trouble during use: it jams, and unaccounted heat flows escape through the gaps left behind.

- To install the damper yourself, a minimal understanding of how the gate operates is required.

The valve serves for different periods of time under changing operating conditions. The period of use without failure is affected by the type of material used for the body and plate. Stainless steel up to 3 mm thick will last 7-9 years without replacement, cast iron will last 12-14 years.

The smooth stainless steel valve, polished during manufacture, collects little soot, but a layer will build up over time. Periodic cleaning of the device is required to prevent the moving part from jamming. Anti-corrosion lubricants are used to treat the rubbing parts of the gate.

Stainless steel gate (Photo: Instagram / ventilyciy.dumoxod.kondicioner)

Ways to increase chimney draft

There are several ways to increase draft in a pipe:

- The first thing to do is clean the pipe. To do this, you can resort to the services of a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- Everyone knows about the dependence of thrust on the height and diameter of the pipe. In this regard, the power of the chimney can be increased by increasing the height of the chimney above the roof surface, adding several additional segments to it. In the same way, the chimney is removed from the area of wind support from the ridge and a higher building.

- Exhaust pipe attachment to improve draft. This is a special device designed for automatic traction control. It is made in the form of an umbrella with a temperature sensor, which is mounted on the chimney pipe. The temperature sensor monitors the temperature of the exhaust gases and operates independently. The nozzle on the pipe to increase draft is responsible for maintaining the pressure in the chimney within 10-35 Pa, thereby optimizing the functioning of the heating device and the amount of fuel consumed.

- Use of a special deflector. Models of deflectors are produced that are made in a special aerodynamic shape. Due to the ability of air to reduce pressure, during the fall effect while passing an obstacle, a rarefaction area is formed in the deflector, which stimulates smoke to exit the pipe. However, such devices are effective only in windy weather.

Preventing the condition of the chimney

To avoid the need to use means of forced exhaust of a chimney made of heat-resistant material, it is necessary to use preventive means to maintain it in working condition.

Since the main reason for reducing the intensity of flue gas extraction is the reduction in the passage of the pipe by soot accumulated on the walls, we will consider means of combating this phenomenon.

These methods could be:

- Burning about half a tablespoon of naphthalene in the furnace firebox. Naphthalene vapor decomposes soot into loose components, large ones fall inside the firebox and are subsequently removed with the ash, and small ones fly out through the pipe along with the furnace gases. This product cannot be used for smoke removal from a fireplace and for pipes of open hearths - it leaves a characteristic suffocating smell in the rooms.

- From time to time, burn potato peelings in the firebox. They are pre-dried. Starch vapors loosen the soot deposit and it will fall into the firebox. Pure starch acts similarly, which is fed into a well-lit firebox in the amount of one tablespoon.

- A good way to remove soot from pipes is walnut shells. It burns at a high temperature, burning off soot deposits on the inner walls. A single dose of shells should be no more than three liters. Frequency of application - as accumulation occurs.

- Aspen firewood has a similar effect on soot. One or two logs are burned at the end of the last stack of firewood. They burn at high temperatures.

The frequency of use of high-temperature products should be regular, at least twice a week, so that soot does not have time to accumulate. Otherwise, you can cause a serious fire, since the soot burns and releases a very large amount of heat.

In addition to those listed, there are many anti-soot agents on the market for both chemical and thermal decomposition of soot. The use of preventive measures can eliminate the need for forced measures to improve the exhaust hood on the chimney.