A home craftsman should know about fastening elements such as an anchor bolt with a ring and a half-ring (hook), and also be able to use them. This fastener is intended for concrete, brick, and some types of natural stone. It is difficult or even impossible to hammer or screw standard nails and self-tapping screws without dowels into such materials, since they are very dense.

This system is not effective in porous and soft materials. The fasteners differ from each other in their ending: one has a ring, the other has a half-ring that looks like a hook.

On the left - an anchor bolt with a ring, on the right - with a half ring

Description, design and characteristics of the product

Anchor bolts equipped with a ring are a kind of fastening that has a high pull-out strength. Sleeve fasteners are not used to hold two objects together at the same time. It acts as a structure for hanging or stretching.

As a rule, this type of fastener is used for use on a concrete or brick base. You can attach the eye anchor to a natural stone surface. There are several structurally important elements of the product:

1. A rod with an end bent into a ring. On the back of the rod there is a thread for screwing in. 2. There is a nut under the ring. Sometimes manufacturers complete the fasteners with a steel washer. 3. Housing (acts as a bushing). At one end of the part there is a part of the sleeve with slots that act as a release mechanism. On the other side of the body there is a cap. 4. Spacer nut. Its ends have different shapes. The element has a longitudinal section.

It is easy to install a bolt anchor with a ring without specialized knowledge. You need to make a hole in the work surface using a hammer drill. Please note that the drill parameters must match the length and diameter of the fastener. It is imperative to get rid of construction dust and debris inside. A brush is used for this. If it is not possible to completely clean the hole, then it is better to make it about 0.2 centimeters longer than the actual length of the anchor.

An anchor bolt with a ring is inserted into the prepared place and driven in with a hammer or mallet. Then you need to screw the ring all the way. Typically, 3 to 5 turns will be needed. The final position of the ring is selected based on further operating conditions.

Chemical - innovative option

Chemical anchors are a metal fastening sleeve or reinforcing rod made of galvanized or stainless steel. The fastener is fixed by injecting a special adhesive composition into the hole, which, after hardening, ensures reliable adhesion of the concrete and the stud.

Chemical anchors are used almost everywhere. They can be used for mounting suspended structures, fences, equipment and any additional elements.

Thanks to the use of an adhesive composition, the anchor easily withstands dynamic loads and vibration, and is not subject to corrosion in an aggressive environment.

| Advantages | Flaws |

|

|

The price of such anchors is noticeably higher than that of other analogues.

| Manufacturer | Type | Dimensions | Peculiarities |

| Fischer (Germany) | R.M. | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M14, M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Reactionsanker An ampoule with resin, inside an ampoule with a hardener. Used with FCR-A anchors or RG studs. |

| FHP | Capsules: 10 (13x90), 12(15x110), 16(18x125), 20(24x180) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. Used when installing fittings. | |

| FIS V 360S | 360 ml composition + 2 mixers | Injections-Mörtel Double cartridge. A special mixing gun is required. | |

| FIS VS 150 C | 150 ml of composition + 2 mixers + adapter | Injections-Mörtel Special cartridge. A standard sealant gun is used. | |

| Hilti (Liechtenstein) | HVU | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(24x170), M24(28x210), M27(30x240), M30(35x270), M33(37x300) , M36(40×330), M39(42×360) | Adhesive Capsule Anchor Ampoule with polyurethane meta-acrylic resin, hardener, quartz sand. |

| HIT- HY150 | 330 ml + 2 mixers | Fast Curing Injection System Two special double tubes (Acrylic resin with additives and hardener). For extrusion, a special Hylti dispensing gun is required. | |

| HIT-HY50 | 330 ml + 2 mixers | ||

| HIT-HY20 | 330 ml + 1 mixer | ||

| Mungo (Switzerland) | MSP | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M16(18x95), M20(25x125), M20(25x175), M24(28x240) | Schlagpatron The ampoules have two cavities: with resin and with hardener. |

| MVA | Capsules: M8 (10x80), M10 (12x90), M12(15x95), M14(16x95), M16(18x95), M20(24x135), M20(25x175), M24(28x210), M30(35x 280) | Verbunanker An ampoule with resin, inside an ampoule with a hardener. | |

| MIT-P | 150 ml + 2 mixers | Injectionstechnik Special cartridge. A standard sealant gun is used. | |

| MIT-P | 235 ml + 2 mixers | Injectionstechnik Double cartridge with parallel arrangement of containers for resin and hardener. A special mixing gun is required. | |

| MIT-SF | 380 ml + 2 mixers | ||

| MIT-EA | 825 ml + 2 mixers | ||

| Sormat (Finland) | KEM | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Kemiallinen ankkuri An ampoule with polyester resin, inside an ampoule with a hardener. Used with KEVA studs. |

| KEMLA | Capsules: M10 (12x90), M12(14x110), M16(18x140), M20(22x180) | Kemiallinen ly ö ntiampulli Ampoule with polyster resin and hardener. For horizontal and floor mounting only. VSS studs. | |

| ITH | 150 ml, 380 ml | Injektointitekniika Injection mass based on polyester resin. Large cartridges (380 ml) require a special gun. | |

| KEW (Germany) | VAR | Capsules: M8 (10x80), M10 (12x90), M12 (14x110) | Verbundankerpatrone An ampoule with resin, inside an ampoule with a hardener. For use with AS studs. |

| V.M. | 150 ml, mixer SM | Verbundm örtelkartusche Special cartridge with adhesive mass and adapter. A standard pistol is used. | |

| Tox (Germany) | TVA | Capsules: M8 (10x80), M10 (12x90), M12(14x110), M16(18x125), M20(25x170), M24(28x210), M30(35x280) | Verbund-Anker An ampoule with resin, inside an ampoule with a hardener. Used with TVA-G studs. |

| THP | Capsules: M10 (12x85), M12(14x105), M16(18x135), M20(24x160) | Hammerpatrone The ampoules have two cavities: with resin and with hardener. | |

| TVM-K | 150 ml, 380 ml | Verbundm örtel Injection mass. Large cartridges require a special gun. | |

| NOBEX (Italy) | NCF NCS N.C.E. | Injection formulations NCF and NCE – 380 ml NCS – 150 ml | Fissaggi chimici estremamente efficaci |

| Technox (Poland) | SVA | Capsules: M8 (10x80), M10 (12x85), M12(14x95), M16(18x95), M20(24x175), M24 (28x210) | Ładunek chemicalzny |

| INKA (Türkiye) | IDKIN | Capsules: M12(14x95), M16(18x95), M20(24x170) | Normal Tip Kimyasal Dubel |

Scope of application

Due to the high technical and operational characteristics, the scope of application of double-expansion anchor bolts with a loop is very wide. They are used in construction for reliable and safe fastening of scaffolding near the walls of buildings.

In addition, the fastening element has proven its effectiveness when carrying out serious electrical work, as well as when it is necessary to firmly secure a cable or other communications. You can use ring bolt anchors for mounting lighting sources, installing ceiling fans, sports walls and other structures.

Please note that eye bolts can only be installed in solid and solid foundations, such as concrete, natural stone, brick, etc. Otherwise, the performance of the anchor will deteriorate significantly.

You can buy high-quality double-spacer fasteners in the MAGKREP store in a wide range. When choosing a product, you need to focus on the scope of further application, and select the correct length and diameter, as well as taking into account the load. All products on the site are made of high-quality metal and protected from aggressive environmental influences. This ensures the longevity of the ring sleeve anchor.

Marking of anchor bolts

When planning to use anchor bolts for concrete, you need to learn how to determine the dimensions by markings. Let's figure out how the abbreviation stands for the example of a fastener with the designation M8 10/35x90:

- The alphanumeric designation M8 indicates the thread diameter;

- the number 10 corresponds to the diameter of the drill for making a cavity in concrete;

- the number 35 indicates the maximum thickness of the attached material;

- the number 90 characterizes the minimum depth of the hole for installing the anchor.

Knowing how anchor bolts are marked, it is easy to select fasteners to perform a specific task.

Their varieties

The screw ring closes tightly enough. Varieties of hardware are associated with this element. The ring screw can be:

- With an unwelded ring.

- With a welded ring. Ring screws serve as a reliable fastening for scaffolding. The design feature in the form of a welded end ensures reliable fixation of suspended materials. Due to the fact that the welded screw cannot unbend, it is able to withstand quite large loads. The diameter of such products can reach 16 mm.

Screws with a welded ring are used for fastening scaffolding to the facades or walls of buildings. This type of screws is also used for fixing supporting structures on brick walls, concrete bases and natural stone. As with an unwelded screw, a plastic dowel is used during installation.

After the scaffolding is dismantled, the drilled hole is plugged with a special plug. This plug helps protect the hole and the inserted dowel from moisture.

For very heavy loads, a screw with a round plate under the ring is provided. It is thanks to this that a fairly reliable fixation occurs.

Depending on the type of coating, a ring screw can be:

- Plated with white zinc.

- Plated with yellow zinc.

Some manufacturers produce these screws in different colors. The ring screw can be blue, brown, yellow, purple, gray, orange and red.

Read below about the sizes of ring screws according to GOST.

The video below will tell you what a ring screw for scaffolding is:

How to unscrew a screw with stripped edges

In a situation where, when screwing or unscrewing a screw, the edges have turned and it is no longer possible to turn it with a standard tool, if the head is not completely immersed and protrudes even slightly above the surface, then you can try to unscrew it using good pliers. To do this, you need to strongly compress the protruding part of the screw head with the jaws of a metalworking tool and slowly begin to unscrew the rod.

If the screw is screwed flush and “tight” into the surface, then it is not possible to remove it in a simple way without damaging it. Then you need to resort to a proven method and use a special device such as an extractor for unscrewing screws.

You can see the various ways to unscrew a screw with torn edges in the video:

Wedge anchors

This type is also called an anchor bolt or a stud anchor. It is most widespread due to its ease of installation and high load-bearing capacity. Installed in stretched and compressed areas of concrete, natural stone.

Withstands high loads subject to a number of conditions:

- sufficient tightening force of the nut to create frictional clamping of the sleeve with the walls of the hole;

- exact correspondence of the hole diameter to the anchor diameter;

- sufficient strength of concrete and absence of sinks;

- meeting the requirements for distances from the edge and between attachment points.

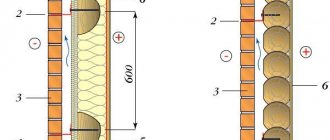

Wedge anchor elements

Company Sormat

(Finland) has developed highly effective wedge anchors for concrete with adjustable tightening torque for through installation of heavy and medium-heavy structures. They are made of high quality cold-formed steel. The consumer is offered a wide selection of sizes and levels of corrosion protection:

- S-KA – electrogalvanized;

- S-KAK – hot-dip galvanized;

- S-KAH – made of stainless acid-resistant steel A4;

- S-KAD – with “Delta” coating.

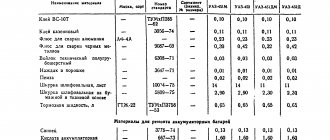

Table 1. Dimensions, installation parameters and loads of anchors S-KA and S-KAK

| Marking | Anchor and drill diameter, mm | Anchor length, mm | Thickness of the mounted part, mm | Hole depth, mm | Min. anchorage depth, mm | Tightening torque, Nm | Loads (compressed zone of concrete C20/25) | |

| Breakout, kN | Shear, kN | |||||||

| 6x40 | 6 | 40 | 2 | 35 | 25 | 4 | 1,0 | 2,0 |

| 6/15x65 | 6 | 65 | 15 | 45 | 35 | 7 | 1,7 | 2,5 |

| 6/50x100 | 6 | 100 | 50 | 45 | 35 | 7 | 1,7 | 2,5 |

| 8x50 | 8 | 52 | 2 | 45 | 30 | 15 | 3,3 | 3,4 |

| 8/10x72 | 8 | 72 | 10 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/30x92 | 8 | 92 | 30 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/50x112 | 8 | 112 | 50 | 60 | 45 | 15 | 3,6 | 5,7 |

| 8/85x147 | 8 | 147 | 85 | 60 | 45 | 15 | 3,6 | 5,7 |

| 10x60 | 10 | 62 | 3 | 50 | 30 | 30 | 3,5 | 3,8 |

| 10/10x92 | 10 | 92 | 10 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/20x102 | 10 | 102 | 20 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/30x112 | 10 | 112 | 30 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/50x132 | 10 | 132 | 50 | 75 | 60 | 35 | 6,3 | 10,3 |

| 10/80x162 | 10 | 162 | 80 | 75 | 60 | 35 | 6,3 | 10,3 |

| 12x85 | 12 | 85 | 3 | 75 | 55 | 50 | 6,5 | 9,6 |

| 12/5x103 | 12 | 103 | 5 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/20x118 | 12 | 118 | 20 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/30x128 | 12 | 128 | 30 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/50x148 | 12 | 148 | 50 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/65x163 | 12 | 163 | 65 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/80x178 | 12 | 178 | 80 | 90 | 70 | 50 | 7,9 | 13,1 |

| 12/155x253 | 12 | 253 | 155 | 90 | 70 | 50 | 6,4 | 6,4 |

| 16x90 | 16 | 90 | 3 | 80 | 60 | 100 | 9,9 | 21,8 |

| 16/5x123 | 16 | 123 | 5 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/20x138 | 16 | 138 | 20 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/50/168 | 16 | 168 | 50 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/60x178 | 16 | 178 | 60 | 110 | 85 | 120 | 16,7 | 25,1 |

| 16/95x213 | 16 | 213 | 95 | 110 | 85 | 120 | 10,0 | 10,0 |

| 20/20x170 | 20 | 170 | 20 | 135 | 110 | 240 | 19,8 | 27,7 |

| 20/70x220 | 20 | 220 | 70 | 135 | 110 | 240 | 19,8 | 27,7 |

| 20/130x280 | 20 | 280 | 130 | 135 | 110 | 240 | 19,8 | 27,7 |

Mungo Company

(Switzerland) proposed its own version of wedge anchors, approved for use in crack-free concrete with a strength of at least 25 N/mm2 (C 20/25). The anchoring depth is marked on the stud for correct installation. The fastener is available in four versions:

Wedge anchor Mungo m2

- – with GreenTec coating and flat washer DIN 125A;

- m2f – hot-dip galvanized, coating thickness 40 microns;

- m2-C – with 5 micron zinc coating and wide washer DIN 9021;

- m2r – made of stainless steel A4 / 316.

| code | Thread | Loads in concrete C20/25 | Bending moment, Nm | Distance between fasteners, mm | Distance from edge, mm | Min. thickness of base material, mm | Tightening torque, Nm | |

| pullout, kN | shear, kN | |||||||

| m2, m2f | M6 | 3,6 | 2,1 | 5,8 | 120 | 60 | 100 | 5 |

| M8 | 5,7 | 3,9 | 14,3 | 150 | 75 | 100 | 15 | |

| M10 | 7,6 | 6,2 | 28,5 | 174 | 87 | 120 | 30 | |

| M12 | 8,3 | 8,4 | 46,8 | 204 | 102 | 140 | 50 | |

| M16 | 9,9 | 15,7 | 118,6 | 240 | 120 | 160 | 100 | |

| M20 | 16,5 | 24,5 | 231,5 | 300 | 150 | 200 | 200 | |

| m2-C | M8 | 5,7 | 3,9 | 14,3 | 150 | 75 | 100 | 15 |

| M10 | 7,6 | 6,2 | 28,5 | 174 | 87 | 120 | 30 | |

| M12 | 8,3 | 8,4 | 46,8 | 204 | 102 | 140 | 50 | |

| M16 | 9,9 | 15,7 | 118,6 | 240 | 120 | 160 | 100 | |

| m2r | M6 | 3,6 | 3,9 | 6,4 | 120 | 60 | 100 | 6,5 |

| M8 | 5,7 | 7,1 | 16,1 | 150 | 75 | 100 | 25 | |

| M10 | 7,6 | 11,2 | 32,2 | 174 | 87 | 120 | 35 | |

| M12 | 11,9 | 16,3 | 56,4 | 204 | 102 | 140 | 125 | |

| M16 | 14,3 | 30,3 | 142,8 | 240 | 120 | 160 | 140 | |

Table 2. Dimensions, installation parameters and loads of anchors m2, m2f, m2-C, m2r.

Note:

The table shows the recommended loads taking into account the safety factor of resistances, as well as the safety factor of the actual load yF = 1.4. Let us recall that 1 kN = 101.9 kg.

Technical data valid for single fastening installed in concrete C20/25

(minimum compressive strength 25 N/mm2), without taking into account the influence of edge (

C

) and interaxial (

S

) distances.

When reducing parameters S, C or the thickness of the concrete base, it is necessary to take into account reduction factors to clarify the pull-out and shear load.

Price list

| Name | Unit change | Retail price (RUB) | Wholesale price (RUB) | YOUR SPECIAL Price, rub) |

| Screw-hook ring | ||||

| Screw - hook ring 3.0*16 | PC. | 1,60 | 1,12 | * |

| Screw - hook ring 3.0*30 | PC. | 2,20 | 1,54 | * |

| Screw - hook ring 3.5*16 | PC. | 1,80 | 1,26 | * |

| Screw - hook ring 3.5*30 | PC. | 2,40 | 1,68 | * |

| Screw - hook ring 3.5*40 | PC. | 2,50 | 1,75 | * |

| Screw - hook ring 3.5*45 | PC. | 2,80 | 1,96 | * |

| Screw - hook ring 4.0*20 | PC. | 3,60 | 2,52 | * |

| Screw - hook ring 4.0*40 | PC. | 3,80 | 2,66 | * |

| Screw - hook ring 4.0*50 | PC. | 4,00 | 2,80 | * |

| Screw - hook ring 4.0*60 | PC. | 4,20 | 2,94 | * |

| Screw - hook ring 4.0*70 | PC. | 4,50 | 3,15 | * |

| Screw - hook ring 5.0*30 | PC. | 5,60 | 3,92 | * |

| Screw - hook ring 5.0*50 | PC. | 6,00 | 4,20 | * |

| Screw - hook ring 5.0*60 | PC. | 6,40 | 4,48 | * |

| Screw - hook ring 5.0*75 | PC. | 7,20 | 5,04 | * |

| Screw - hook ring 5.0*80 | PC. | 8,40 | 5,88 | * |

| Screw - hook ring 6.0*50 | PC. | 9,40 | 6,58 | * |

| Screw - hook ring 6.0*60 | PC. | 10,00 | 7,00 | * |

| Screw - hook ring 6.0*65 | PC. | 10,60 | 7,42 | * |

| Screw - hook ring 6.0*70 | PC. | 10,80 | 7,56 | * |

| Screw - hook ring 6.0*80 | PC. | 11,00 | 7,70 | * |

| Screw - hook ring 6.0*100 | PC. | 14,40 | 10,08 | * |

| Screw - hook ring 8.0*50 | PC. | 14,80 | 10,36 | * |

| Screw - hook ring 8.0*70 | PC. | 18,00 | 12,60 | * |

| Screw - hook ring 8.0*80 | PC. | 22,00 | 15,40 | * |

| Screw - hook ring 8.0*100 | PC. | 24,00 | 16,80 | * |

| Half-ring hook screw | ||||

| Screw - half ring hook 3.0*16 | PC. | 1,30 | 0,91 | * |

| Screw - half ring hook 3.0*30 | PC. | 1,50 | 1,05 | * |

| Screw - half ring hook 3.5*30 | PC. | 2,50 | 1,75 | * |

| Screw - half ring hook 3.5*45 | PC. | 2,80 | 1,96 | * |

| Screw - half ring hook 4.0*20 | PC. | 3,00 | 2,10 | * |

| Screw - half ring hook 4.0*30 | PC. | 3,50 | 2,45 | * |

| Screw - half ring hook 4.0*40 | PC. | 4,00 | 2,80 | * |

| Screw - half ring hook 4.0*50 | PC. | 4,30 | 3,01 | * |

| Screw - half ring hook 4.0*65 | PC. | 4,50 | 3,15 | * |

| Screw - half ring hook 4.0*70 | PC. | 4,60 | 3,22 | * |

| Screw - half ring hook 5.0*30 | PC. | 5,00 | 3,50 | * |

| Screw - half ring hook 5.0*45 | PC. | 4,30 | 3,01 | * |

| Screw - half ring hook 5.0*50 | PC. | 5,60 | 3,92 | * |

| Screw - half ring hook 5.0*60 | PC. | 6,60 | 4,62 | * |

| Screw - half ring hook 5.0*70 | PC. | 7,00 | 4,90 | * |

| Screw - half ring hook 5.0*80 | PC. | 7,20 | 5,04 | * |

| Screw - half ring hook 6.0*30 | PC. | 7,10 | 4,97 | * |

| Screw - half ring hook 6.0*40 | PC. | 7,40 | 5,18 | * |

| Screw - half ring hook 6.0*50 | PC. | 7,80 | 5,46 | * |

| Screw - half ring hook 6.0*60 | PC. | 8,60 | 6,02 | * |

| Screw - half ring hook 6.0*75 | PC. | 11,60 | 8,12 | * |

| Screw - half ring hook 6.0*80 | PC. | 12,00 | 8,40 | * |

| Screw - half ring hook 6.0*100 | PC. | 14,40 | 10,08 | * |

| Screw - half ring hook 8.0*50 | PC. | 12,00 | 8,40 | * |

| Screw - half ring hook 8.0*70 | PC. | 14,40 | 10,08 | * |

| Screw - half ring hook 8.0*80 | PC. | 20,40 | 14,28 | * |

| Screw - half ring hook 8.0*90 | PC. | 25,60 | 17,92 | * |

| Screw - half ring hook 8.0*100 | PC. | 28,20 | 19,74 | * |

| Straight hook screw | ||||

| Screw - straight hook 10*100 | PC. | 16,80 | 11,76 | * |

| Screw - straight hook 10*120 | PC. | 19,80 | 13,86 | * |

| Screw - straight hook 3.0*30 | PC. | 1,90 | 1,33 | * |

| Screw - straight hook 3.0*35 | PC. | 2,00 | 1,40 | * |

| Screw - straight hook 3.0*40 | PC. | 2,10 | 1,47 | * |

| Screw - straight hook 3.5*45 | PC. | 2,30 | 1,61 | * |

| Screw - straight hook 4.0*40 | PC. | 2,80 | 1,96 | * |

| Screw - straight hook 4.0*44 | PC. | 3,30 | 2,31 | * |

| Screw - straight hook 4.0*50 | PC. | 4,00 | 2,80 | * |

| Screw - straight hook 4.0*60 | PC. | 4,50 | 3,15 | * |

| Screw - straight hook 4.0*70 | PC. | 5,00 | 3,50 | * |

| Screw - straight hook 5.0*40 | PC. | 3,80 | 2,66 | * |

| Screw - straight hook 5.0*50 | PC. | 4,80 | 3,36 | * |

| Screw - straight hook 5.0*52 | PC. | 5,20 | 3,64 | * |

| Screw - straight hook 5.0*70 | PC. | 6,40 | 4,48 | * |

| Screw - straight hook 5.0*80 | PC. | 6,80 | 4,76 | * |

| Screw - straight hook 6.0*40 | PC. | 5,00 | 3,50 | * |

| Screw - straight hook 6.0*60 | PC. | 5,80 | 4,06 | * |

| Screw - straight hook 6.0*65 | PC. | 6,20 | 4,34 | * |

| Screw - straight hook 6.0*68 | PC. | 6,40 | 4,48 | * |

| Screw - straight hook 6.0*75 | PC. | 6,60 | 4,62 | * |

| Screw - straight hook 6.0*80 | PC. | 7,20 | 5,04 | * |

| Screw - straight hook 6.0*100 | PC. | 10,00 | 7,00 | * |

| Screw - straight hook 8.0*100 | PC. | 18,80 | 13,16 | * |

| Screw - straight hook 8.0*120 | PC. | 16,40 | 11,48 | * |

| Screw - straight hook 8.0*80 | PC. | 15,80 | 11,06 | * |

Material hardness

Brinell hardness is a characteristic that allows you to determine the hardness of a material.

Stainless steel fasteners are also equipped with special markings on the top of the fastener.

Type of steel A2 or A4 and tensile strength - 50, 70, 80, examples: A2-70, A4-80. Fasteners that have a clearly defined thread are color-coded for A2 in green and for A4 in red. The value for the yield strength is not specified.

For example, a value of 70 is the most standard and demonstrates the maximum strength of stainless steel fasteners.

Maximum fluidity for stainless steel hardware, often only a reference value.

The fluidity in this case will be 250 N/mm2 for A2-70 and about 300 N/mm2 for A4-80.

The approximate increase will be no more than 40%. In other words, this type of steel perfectly changes shape before irreparable deformation occurs.

Old domestic measurement methods according to GOST did not allow paying due attention to the maximum permissible loads on bolts, so the produced hardware was significantly lower in quality compared to modern ones.

An example to calculate the load on a material as accurately as possible using strength classification:

M12 fastening with strength 8.8, size d2 = 10.7 mm and maximum section length 89.87 mm2. In this case, the maximum permissible degree of load will be: (8*8*10)*89.87;0) = 57520 Newton.

Load chart for carbon steel and stainless steel bolts.

| ST-4.6 | ST-8.8 | A2-70 | A4-80 | |||||||

| THREAD | d2, mm | Area 62, tt2 | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg | Max. load, Newton | Working load, kg |

| M1 | 0,8 | 0,5 | 121 | 322 | 10 | 126 | 151 | |||

| M2 | 1,7 | 2,27 | 544 | 20 | 1 452 | 70 | 567 | 20 | 681 | 30 |

| M3 | 2,6 | 5,31 | 1 274 | 60 | 3 396 | 160 | 1 327 | 60 | 1 592 | 70 |

| M4 | 3,5 | 9,62 | 2 308 | 110 | 6 154 | 300 | 2 404 | 120 | 2 885 | 140 |

| M5 | 4,4 | 15,2 | 3 647 | 180 | 9 726 | 480 | 3 799 | 180 | 4 559 | 220 |

| M6 | 5,3 | 22,05 | 5 292 | 260 | 14 112 | 700 | 5 513 | 270 | 6 615 | 330 |

| M8 | 7,1 | 39,57 | 9 497 | 470 | 25 326 | 1 260 | 9 893 | 490 | 11 872 | 590 |

| M10 | 8,9 | 62,18 | 14 923 | 740 | 39 795 | 1 980 | 15 545 | 770 | 18 654 | 930 |

| M12 | 10,7 | 89,87 | 21 570 | 1 070 | 57 520 | 2 870 | 22 469 | 1 120 | 26 962 | 1 340 |

| M14 | 12,6 | 124,63 | 29 910 | 1 490 | 79 761 | 3 980 | 31 157 | 1 550 | 37 388 | 1 860 |

| M16 | 14,6 | 167,33 | 40159 | 2 000 | 107 092 | 5 350 | 41 833 | 2 090 | 50199 | 2 500 |

| M20 | 18,3 | 262,89 | 63 093 | 3 150 | 168 249 | 8 410 | 65 722 | 3 280 | 78 867 | 3 940 |

| M24 | 21,9 | 376,49 | 90 359 | 4 510 | 240 956 | 12 040 | 94 123 | 4 700 | 112 948 | 5 640 |

| M27 | 24,9 | 486,71 | 116 810 | 5 840 | 311 493 | 15 570 | 121 677 | 6 080 | 146 012 | 7 300 |

| M30 | 27,6 | 597,98 | 143 516 | 7170 | 382 708 | 19130 | 149 495 | 7 470 | 179 394 | 8 960 |