Home / Devices

Back

Reading time: 3 min

0

2105

What should you pay attention to when choosing welding equipment? As a rule, when buying a welding unit for the home, they take into account the power, size, additional settings, and also the price tag.

Speaking about industrial units, the voltage of the electrical network they request plays a big role here.

Residential buildings are supplied with 220V voltage as standard. But providing constant 380V power in factories is a completely solvable task. Therefore, three-phase devices can be easily installed and used in workshops.

This article will discuss the industrial welding machines themselves, their varieties and parts that you should know about when choosing.

- General information

- Variations Transformer

- Rectifier

- Inverter and semi-automatic

general information

Industrial welding machines differ from household ones in that they are three-phase and require a power supply of at least 380 Volts. They are very common even in modern industries, because they are unpretentious and repairable. Thanks to the use of an industrial welding machine, it is possible to weld parts of any thickness and use electrodes of any diameter.

Unlike single-phase machines, three-phase machines produce welding much softer and of better quality. Because it is possible to obtain more power without increasing the current.

Varieties

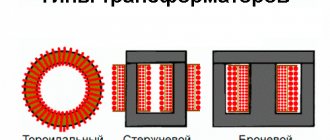

Industrial three-phase devices come in three types: transformers, rectifiers, inverters and semi-automatic devices. Let's take a closer look at each of them.

Transformer

A 380 volt transformer is the simplest and classic type of welding equipment. Its basis is a transformer with three coils. Hence the name of this welding machine. Thanks to the use of three phases, the arc burns stably and the voltage practically does not change during welding. And the design of these machines is so simple that it allows you to repair the transformer literally “on the knee”, and without extra costs.

Transformers only supply alternating current, so you cannot use direct current in your work. This needs to be taken into account. Transformers are very bulky and heavy and require a cart to move them. But the price of such devices will please any professional.

Rectifier

A rectifier is the same transformer, only with one significant difference. A rectifier unit is built into its body (hence the name “rectifier”), which converts alternating current into direct current. This is their only difference. Such devices are more versatile than transformers, since they allow you to cook on any type of current.

Also, thanks to the rectifier, the arc burns more stable and is easier to ignite, including re-ignition. If you are a beginner, you have probably encountered difficulties in igniting the arc when using a transformer. The rectifier unit slightly, but simplifies this task. Otherwise, there are no differences between a rectifier and a transformer.

Inverter and semi-automatic

Semi-automatic welding and inverter are devices of a new generation. They are complex in design, have built-in microcircuits and additional functions. Their weight and dimensions are significantly smaller than those of a transformer or rectifier. But all the advantages come at a price. An inverter and semi-automatic device are significantly more expensive than other types of industrial devices.

The difference between an inverter and a semiautomatic device lies in the scope of application. The inverter's path is manual arc welding with electrodes. But the semi-automatic machine is used when welding using gas and filler wire. The semi-automatic machine has a filler material supply mechanism, which often operates in semi-automatic mode. Hence the name.

Welding inverters 380 V

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Pages: previousnext

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Pages: previousnext

Page 3

Inverter device KEDR Ultra mm A 200 in case 8009728

Mains voltage, V: 220 Frequency, Hz: 50/60 Operating mode, PV%: 60 Open circuit voltage, V: 70 Welding current range, A: 10-200

Page 4

Universal welding inverter CT 416 (R40)

Country of origin: Spain Maximum power (kW) : 0.4 Maximum productivity (l/min) : 550 Total pressure (m) : 3.3 Maximum operating pressure (bar) : 10 Mains voltage (V) : 380 Protection level: IP44 Class

Page 5

Welding inverter FoxWeld Summer resident 210

Can operate at reduced voltage, which is important when used in places where the voltage is unstable and drops to 140V; it features a simple control panel on which you can easily set the required welding current value

Page 6

Air plasma cutting inverter CUT 40

Manufacturer: Mealer (China) We offer a wide range of welding, construction, pumping equipment, power plants, stabilizers, air conditioners, metal furniture.

Page 7

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 8

Capacitor 6.3UF, 400V KEMPPI

We truly have the widest range of products. All items are located in warehouses in Krasnoyarsk and Moscow, delivery of TC to any city in the shortest possible time. For those who have questions about our products, we offer specialist consultation.

Page 9

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 10

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 11

Welding inverter (TIG) REDBO PulseTig-250 AC/DC

Mains voltage: 380±15%V, PN TIG/MMA-35%, no-load voltage 42V, purge before/after welding 0-2/1-10s., welding modes 2/4-stroke, high-frequency arc ignition , frequency 50/60 Hz, protection class IP21S,

Page 12

Welding inverter, BISON, MASTER, ZAS-M1-170

-Welding type: MMA -Transistor type: IGBT -Power: 5.7 kVA-Max. current consumption: 26 A - Welding current type: constant - Electrode diameter: 1.6-4.0 mm - Open circuit voltage: 82 V - Operating voltage: 26 V - Min. supply voltage: 160 V-

Page 13

Welding inverter Fubag IN 206 LVP

Confident operation at reduced voltage in the range of 130 - 265 V in a very compact package and light weight of 5.5 kg. Microprocessor intuitive control, high arc stability, operation from a 16A network in intensive operating mode, including

Page 14

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

Page 15

Welding inverter TSS SAI-400PROF

Country of origin: Spain Maximum power (kW) : 1.26 Maximum productivity (l/min) : 434 Total head (m) : 18 Maximum operating pressure (bar) : 10 Mains voltage (V) : 380 Protection degree: IP44 Class

Page 16

Welding inverter REAL TIG 200 (W223)

Afalina Chelyabinsk is a company offering traditional and technically new construction equipment to Russian organizations. We offer not only equipment, but also modern high-tech solutions. The range of equipment is dynamically expanding

Page 17

Semi-automatic welding inverter 10-200A + torch, FUBAG INMIG 200SYN LCD

current in MIG/MAG mode 25-200Ak at duty cycle 60% and t=40 degrees. C, 165% Digital display Coil diameter, 200 mm / weight 5 Wire diameter 0.6-1.0 mm Welding current range 10-200 AN Open circuit voltage 67 V Voltage 150-260 VPV at max current 40%

Page 18

Inverter welding machine SAI 140 Resanta

Protection degree IP: 21 Weight: 4.3 Load duration: 70.0 No-load voltage: 75.0 Maximum current consumption, A: 20 Maximum electrode diameter, mm: 3.2 Operating voltage range, V: 140 - 260 Arc voltage, V: 25

Page 19

Products and servicesCompanies

By ratingBy price (cheaper first)By price (higher first)

0

Welding inverter (TIG) REDBO PulseTig-200 AC/DC

Mains voltage: 220±15%V, PN TIG/MMA-35%, no-load voltage 65V, purge before/after welding 0-2/1-10s., welding modes 2/4-stroke, high-frequency arc ignition , frequency 50/60 Hz, protection class IP21S

1

Advantages

So, we now know that industrial welding machines are three-phase equipment. And this is their main characteristic, from which we will start when comparing an industrial device with other equipment.

To begin with, any three-phase device is automatically classified as professional equipment. Such welders can work continuously, their efficiency is close to 100%. But this cannot be achieved when using household or semi-professional devices. In some industries this advantage plays a major role. Because frequent interruptions in work are fraught with loss of profit.

Three-phase transformers and rectifiers are not sensitive to operating conditions. They may gather dust or be stored improperly, but they will still perform their task properly. Inverters and semi-automatic machines are more capricious in this regard due to the built-in microcircuits, but if they have a dust- and moisture-proof case, they can work in any conditions.

Experienced craftsmen will probably argue that an ordinary single-phase transformer is also unpretentious. And they will be right. Only the current pulsation frequency on a single-phase device is much higher, so the quality of the welds is noticeably worse. Compared to a three-phase transformer, of course.

Also, a standard stationary single-phase transformer or rectifier is not capable of welding metals of any thickness and using thick electrodes. But three-phase machines are truly universal and are used for welding of any level of complexity.

Industrial MIG/MAG welding machines | buy in Moscow with delivery throughout Russia

Nutrition:

220V

Welding current:

20-185A

Synergic:

stainless steel, steel, aluminum, copper soldering.

Pulse mode in the basic version!

Certified for car manufacturers. Country of origin: Italy. 24 month warranty.

Cebora EVO SPEED STAR 520 TS PROMOTION! Pulse and Double Pulse functions as a gift! Industrial semi-automatic Power supply:

380V

Welding current:

10-520A

Synergic:

stainless steel, aluminum, steel.

Pulse, Double Pulse

Country of origin: Italy. 24 month warranty.

Cebora Synstar 270T SRS Edition Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-270A

Synergic:

stainless steel, aluminum, copper, steel.

Full functionality already in the basic version: Pulse, Double Pulse, SRS (coolArc), TIG DC.

Country of origin: Italy. 24 month warranty.

Nutrition:

220V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy.

24 month warranty. Power:

380V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy.

24 month warranty. Power:

220V

Welding current:

20-250A

Synergic:

stainless steel, aluminum, steel, copper and galvanized soldering.

Certified for car manufacturers

Country of origin: Italy. 24 month warranty.

Nutrition

: 380V

Welding current

: 20-270A

Synergic

: stainless steel, aluminum, copper, steel.

Pulse mode.

Country of origin: Italy.

24 month warranty. Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

15-330A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse in the database!

Country of origin: Italy.

24 month warranty. Industrial welding machine

MIG/MAG, TIG DC, MMA

Power

: 380V

Welding current

: 15-330A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse in the database!

Country of origin: Italy. 24 month warranty.

Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-400A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Pulse HD, Double Pulse, Doble Pulse HD, SRS (coolArc), WEB control, FULL TIG (TIG XP, APC,EVO START)

Country of origin: Italy. 24 month warranty.

Industrial welding machine

MIG/MAG, TIG DC, MMA

Power:

380V

Welding current:

10-520A

Synergic:

stainless steel, aluminum, copper, steel, powder.

Pulse, Pulse HD, Double Pulse, Doble Pulse HD, SRS (coolArc), WEB control, FULL TIG (TIG XP, APC,EVO START)

Country of origin: Italy. 24 month warranty.

Cebora Synstar TWIN 270 T Power

: 380V

Welding current

: 20-270A

2 spools with Synergic

: stainless steel, aluminum, steel.

Certified for VAG (Volkswagen).

Country of origin: Italy. 24 month warranty. Cebora Sound MIG 2060/MD Star Double Pulse

Nutrition:

2200V

Welding current:

15-200A

Synergic:

stainless steel, aluminum, copper, steel.

Pulse, Double Pulse OEM certified;

Country of origin: Italy. 24 month warranty.

Cebora EVO 350 TC Synergic Power:

380V

Welding current:

35-400A

Synergic:

stainless steel, aluminum, copper, steel.

Country of origin: Italy. 24 month warranty. Cebora EVO 350 TS Synergic Industrial semi-automatic Power:

380V

Welding current:

35-400A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Cebora EVO 450 TS Synergic Industrial semi-automatic Power supply:

380V

Welding current:

40-500A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Power:

220V

Welding current:

20-200A

Synergic:

stainless steel, aluminum, steel.

Country of origin: Italy. 24 month warranty. Are you looking for modern, reliable, and most importantly high-quality welding equipment? The Italian company Cebora, which produces welding machines using advanced welding technology and supplies its products to 120 countries around the world, !

"Cebora - Russia" offers to buy professional and industrial semi-automatic welding MIG-MAG with synergetic control, optimizing welding processes of various metals: steel, stainless steel, aluminum, copper and various alloys. In particular, they significantly simplify the welder’s work and improve the quality of welds. Welding work is performed faster and with better quality than with conventional machines with manual settings. The welder does not waste time selecting parameters, because the synergic control does this independently. The experience accumulated by Cebora over more than 65 years of operation allows it to be one of the world leaders in the field of electric welding. Today, Italian Cebora welding machines are well known in Europe and other regions, including Russia, where they have proven themselves to be the best. The use of the most effective synergistic technologies, the widespread introduction of innovations and strict product quality control - all this, combined with its very reasonable cost (compared to competitors), have become powerful arguments in favor of purchasing Cebora equipment. In addition, our industrial welding machines and semi-automatic machines have high technical and operational characteristics, but at the same time they are very easy to operate. Each semi-automatic welding machine from Cebora has a set of synergetic programs for almost perfect welding of stainless steel, aluminum and its alloys. Setting is carried out only by selecting the wire and the thickness of the workpiece being welded. The device selects the remaining parameters independently! Need quality seams? Then buy Cebora and we will not disappoint you!

MIG/MAG welding equipment is divided into 2 types: inverter semi-automatic welding machines with synergetic technology and transformer machines also with synergic control.

Each Cebora welding machine, be it the professional Pocket Pulse, Synstar 200/270/330 or the industrial KING STAR 400/520, does an excellent job of welding stainless steel, black steel and aluminum.

Buying welding machines in Moscow from Cebora means providing your enterprise with reliable and modern welding equipment for many years.

The main advantages of CEBORA welding equipment

Having purchased a mig-mag semi-automatic welding machine from a European manufacturer, you will appreciate its manufacturability. Unique functionality and welding technologies, as well as performance characteristics:

- Cost:

the price of Cebora inverter-type welding machines compares favorably in cost with other brands. - Reference quality welding of aluminum and stainless steel.

You can buy semi-automatic welding machines for stainless steel and aluminum, specially adapted for these types of materials, which allows you to obtain standard quality seams, in Moscow and the regions of Russia. Other, more specific types of devices are also available. For example, it will not be a problem to find and buy from us a welding machine for welding aluminum with two spools and wire feed mechanisms, ideal for the high standards of modern car service, as well as the consumables, welding torches, tools and accessories necessary for their operation.

- Synergetic technologies.

All semi-automatic welding machines have advanced MIG-MAG welding technology using synergetic programs. Settings take place in 2-3 clicks on the display or joystick. The digital intelligence of each model contains programs for welding stainless steel, steel, aluminum, as well as for soldering copper and various alloys. - Advanced welding technologies.

The new line of multifunctional MIG-TIG-MMA welding machines CEBORA King Star series has the most advanced technologies for welding various metals. For example, the Pulse HD and Double Pulse functions can significantly improve the quality of seams. Buy a semi-automatic welding machine and you can quickly adjust the process to the characteristics of the material and production. For example, minimize splashing thanks to SRS technology. - WEB interface and remote management:

the new hardware architecture allows the implementation of a web server, which, through LAN and Wi-Fi connections in addition to two USB ports, provides useful functions for remote maintenance, information system diagnostics, backup and recovery data, firmware updates and etc. and for all those activities that require data collection and processing. - Convenient delivery method throughout Russia

. You can buy a semi-automatic welding machine or a multifunctional welding machine both from us at Chebora-Trading LLC and from our regional dealers in Moscow, St. Petersburg, Nizhny Novgorod and other cities of Russia. Most devices are in stock. Delivery and commissioning is carried out up to 10 days. - Professional consultation.

When ordering a professional and industrial series of welding machines, our company’s specialists will provide advice and help with choosing a specific model based on the customer’s requirements. By purchasing welding equipment from us, you are guaranteed high professionalism, prompt service and an individual approach to each customer, without exception. - Long warranty.

All Cebora welding equipment is provided with a factory warranty of 24 months (2 years). An on-site warranty service is available. Therefore, having purchased industrial and powerful welding machines, you can be sure that any possible problems with them will be resolved as quickly as possible.

Where to buy professional and industrial Cebora welding machines?

You can buy semi-automatic welding machines manufactured by CEBORA from the official representative of Chebora-Trading LLC in Moscow, Moscow region, Rostov-on-Don.

And also from our regional dealers in Moscow, Moscow region, St. Petersburg, Vladimir, Voronezh, Nizhny Novgorod, Rostov-on-Don, Volgograd, Yekaterinburg, Kazan, Komsomolsk-on-Amur, Krasnodar, Krasnoyarsk, Norilsk, Novosibirsk, Perm, Ryazan, Simferopol, Smolensk, Tver, Tula, Ufa, Yakutsk, Yaroslavl and other cities of Russia.

Features of connection and selection

380V welding machines have a number of features that need to be taken into account. First of all, connecting a three-phase device is somewhat different from connecting a single-phase one. Three-phase welders have a four-pin plug, and sometimes a five-pin plug. Please take this into account before purchasing a power cable for your welding machine.

If you do not have an outlet with the required voltage at your production site or you simply work on the road, then think in advance about how you will connect a three-phase device to a substation or generator.

When choosing a three-phase device, give preference to equipment that can operate in two modes: RDS and MMA (or MIG/MAG). Such devices are the most versatile and allow you to perform any welding work. You can cook in a protective gas environment or using electrodes alone.

If you are a home welder and have the ability to connect to a 380V network, then we recommend purchasing a three-phase machine. It works much more stable than single-phase ones, evenly distributes the load on the network and does not cause power outages due to overvoltage.