Hi all. The second stage of construction of the mechanical winch is almost complete. Briefly about the work done:

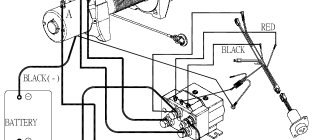

1) at the industrial workshop, the neck for the rear bearing was cut off, a hole was machined, a part with splines from the secondary shaft of the gearbox was pressed into it and welded. 2) the output shaft is made from the rear axle drive shaft 3) the engagement clutch is made from the axle drive shaft flange, the fork is homemade 4) the body is turned on a lathe

Both axles can also be switched off; the PTO can operate either separately or together with the axles.

Using a car starter is the most popular and effective way to make a homemade winch. The device is distinguished by a powerful high-torque electric motor, the supply voltage of which is 12 volts. These characteristics allow the manufactured winch to be used on an SUV. How to make a winch from a starter with your own hands, and what needs to be done for this?

The winch is the most popular lifting mechanism. Its purpose is to move the load in a horizontal plane. Drivers of off-road vehicles need this mechanism first of all, since such vehicles are used to travel on roads without asphalt coverage and urban comfort. Such conditions lead to the fact that the machine may get stuck in sand or mud and fail when climbing to a hill. For such situations, SUVs are equipped with a winch on the front bumper, but if you don’t have one, you can do it yourself. How to make a winch from a starter yourself, and what recommendations should you follow?

Types of winches

Depending on the situation, you can use different types of winches, which differ in the energies driving the mechanism. The principle of operation in this case is the same - the steel cable is wound on a drum, which can be rotated manually or through an engine gearbox. Both factory and homemade winches from the starter can be manual, hydraulic or electric.

- The action of a mechanical or manual winch is based on the force of the motor. In terms of reliability, this option has no equal. However, those who like to relax in off-road conditions are not particularly fond of such a mechanism due to its large dimensions. If such a winch is initially provided in the vehicle, the driver will feel as protected as possible, but will not choose this option when installing the mechanism on his own. Despite the fact that a DIY hand winch will be powerful, it takes up too much space in the car.

- Electric options are the most popular among SUV drivers. The drum is rotated by an electric motor powered by a car battery. When working with such mechanisms, it is important to monitor the battery charge and leave enough battery life to get home. These winches are practical and are designed to lift loads weighing up to 4 tons. It is the electric option that is most often chosen if you do the winching yourself.

- The design of a hydraulic winch is the most complex due to additional elements in the form of an oil pump, an oil tank and a hydraulic drive. Assembling such a mechanism yourself is more difficult than others, and the winch turns out to be too bulky. Nevertheless, this option also has advantages, including minimal energy consumption combined with high power. The feasibility of using hydraulic winches is observed when operating walk-behind tractors, tractors or SUVs.

Gearbox selection

The next problem is the choice of gearbox. Any 220 V electric winch with your own hands must contain a mechanism that will transmit rotation with a large traction force. There are the following types of gearboxes:

- Worm drives transmit rotation at an angle of 90 degrees and do not require braking devices, as they have good self-braking properties.

- They are not used for winches due to the complexity of the perpendicular arrangement of the main drive and secondary shafts.

- Cylindrical, are one or more pairs of gears in one plane, meshed. Rotation is transferred from the smaller wheel to the larger one. They have high reliability, but less tractive effort. Convenient for use when constructing homemade winches.

Planetary gearbox, the most common at the moment. It usually consists of 3 satellites, a sun gear, a ring gear and a carrier. They have an increased working life and transmitted power, but are complex in design.

Read also: Homemade CNC machine from printers with your own hands

The simplest solution when manufacturing a unit, an electric winch for 220 V, of course, you can always use a converter, especially since ready-made high-power devices are available for sale. An asynchronous motor can be used as a drive motor, but it is better to use a motor from a washing machine. Modern models are quite powerful and productive.

What does a homemade winch look like?

A garage-assembled winch is a device capable of moving, moving and pulling heavy vehicles out of the mud. Initially it looks like the photo below.

- winch with manual mechanism;

- device with a hydraulic motor;

- mechanical (gross);

- with electric drive.

The above types of winches have a simple and clear principle of operation: a steel cable of a certain diameter is wound onto a drum mounted on a car. This “rope” is wound by the gearbox or by the person himself (using, say, a crowbar). Externally, such a winch (this device can be attached to the UAZ 469) and its other varieties are very similar, but differ significantly in operating speed, gearbox power and size.

Features of different types of winches

Model “Octopus 9000”

A mechanical winch has a number of advantages, including increased stability and high traction power. Its power supply is not connected to the electrical system of the SUV; the operating principle is based on interaction with the transmission. The mechanical winch is driven by the vehicle's transfer case. High power is achieved using engine torque. The device cannot operate autonomously; it requires a running motor. The performance of the mechanism directly depends on the speed of revolutions inside the engine.

Electrical traction devices are most often driven by a starter or generator for loading. An electric winch can also operate on a dedicated electric motor, which is installed separately in the car. But basically, a homemade winch is mounted on a converted structure of a loading generator or starter. It should be taken into account that such a device must operate at high speeds, otherwise the mechanism will not be able to cope with a massive SUV.

The basic reserves of electricity are stored in the car's battery, so many owners equip the car with batteries with a large energy reserve. The engine that drives the traction mechanism must have balanced power, otherwise even the strongest battery will not cope with its appetite.

The hydraulic mechanism has a complex type of design that even a mechanical winch cannot compare with. As a rule, its work is closely related to the functioning of the oil piston. Despite the volume of the device, we can confidently speak about its high reliability and powerful power traction. At the same time, the energy costs are not as significant as for electric mechanisms. Because this design has high performance, it is often mounted on tractors.

A homemade winch can also be of the manual type, in which case its power directly depends on the physical strength of the owner of the SUV. The manual mechanism is made in the same way as other types of construction. In this case, there is no need to connect it to vehicle devices. For convenience and simplification of the traction procedure, you need to ensure the presence of an extended handle of the mechanism. This not only makes rotation easier, but also improves the performance of the device.

How does a hand winch work?

The manual winch (built into the UAZ Bukhanka, for example) has the simplest design. The cable is wound onto the drum using a lever (you can use a small crowbar or a pry bar). This device has its advantages:

- independence from energy sources and other resources;

- fairly small dimensions and light weight;

- availability (low price);

- As the lever increases, the winch's thrust increases.

Disadvantages include discomfort when working in unsuitable conditions (rain, snow, frost, dirt).

Electric winch

This type is the most popular among many car enthusiasts. The main part of this winch is an electric drive, which is powered by on-board wiring. It's quite easy to operate. The advantage of an electric winch is that it can work without a running engine, that is, autonomously. The principle of its operation is simple: you need to unwind the required length of the cable, fix it and start the electric drive. It is attached to a special power bumper (its diagram is shown below).

- sufficiently high operating speed of the electric drive when winding the cable;

- independence from running engine;

- ease of use;

- the ability to equip the device with additional sensors.

Disadvantages include moisture intolerance, relatively low battery charge and high cost.

Now let's move on to the pressing issue. How to make a winch on an UAZ with your own hands?

Making a homemade part is quite possible. To do this you need to have the necessary tools, materials, skills and patience. An installed winch (on a UAZ), made by yourself, must have a high torque in order to pull heavy vehicles out of mud or sand. Some car owners do not believe that a reliable device can be made at home. But it's real. And most importantly, this will save money and not buy an expensive item.

Pros and cons of self-pullers

The attitude of SUV owners towards self-extractors is ambiguous. Some consider them to be a completely worthy replacement for a winch, while others, on the contrary, speak extremely negatively about these devices. Let's try to highlight the main pros and cons that a self-extractor for a UAZ or other SUV has.

So, the advantages:

- simplicity and reliability of design;

- low cost or ease of self-production;

- takes up little space in the trunk;

- does not require special fastening or professional installation;

- When used correctly, the traction force is limited only by the engine power.

Perhaps the device has other advantages. Now let’s list the obvious disadvantages of self-pullers:

- risk of damage to the vehicle (especially steering rods);

- limited functionality (the winch can be used for many other tasks besides pulling out a car);

- uneven winding of the cable;

- inconvenient to use (it’s easier to pull the car out with a winch).

The list may also not be complete; perhaps self-pullers have other disadvantages.

Stages of making a winch for a UAZ with your own hands

- We take a grinder and cut a square pipe, and then use welding to connect the parts. We check their perpendicularity, equal angles, and dimensions. The platform for the winch on the UAZ is fixed, then we make special holes in it with which the motor will be attached. The essence of the next stage is to clean, prime and paint the resulting structure. Then we start making the drum.

Yes, regarding the time spent on work. As a rule, installing a winch on a UAZ is not too long. Ten hours is enough.

DIY ratchet winch

For a device of this type we will need a brake mechanism from a KamAZ truck. This mechanism can withstand loads of up to six tons.

We disassemble the gearbox, take out the gears, disassembling the so-called “worm mechanism”. To do this, we need to knock out the splined shaft with a hammer. You can squeeze it out with a press, but not everyone has it.

We weld the resulting parts together according to the plan. We remove the gear and fix the pipe vertically in a vice. Between the slots and the tube we drive nails opposite each other. This will help center the mechanism relative to the gear.

After this, we cut off the heads of the nails to the root and strengthen the structure by welding. We insert the gear into the body of the gearbox, simultaneously with the “worm”. The shaft gets hammered into the “worm”. To install the drum, take two washers and weld them to the drive shaft.

The work is finished, now you can install the winch on the UAZ and use the useful device.

From a wheel rim

For a car with stamped wheels, you can make your own device that will help the car get out of the mud or snow on its own. The device works like a reel that winds a rope around itself. Its free end is fixed to a tree, a pole, or a metal peg driven into the ground. The main thing is that such support is held as firmly as possible.

The manufacture of the device must be carried out according to the following algorithm:

- First you need to assemble a spool from any wheel rim. It is important that its size is smaller than that of the standard wheel installed on a particular car.

- Make special hooks in the shape of the letter G.

- To make the correct markings, it is better to take out the spare tire and attach the future spool to it.

- You need to make marks on the workpiece opposite the holes of the spare wheel rim.

- L-shaped hooks made of round steel wire must be welded to these marks. They are necessary in order to ensure strong adhesion of the modified spool to the car wheel. Here it is enough to make one hook through one hole of the wheel rim.

To avoid inaccuracies, you can first lightly grab the wire, try it on again, and only then thoroughly scald the product.

- At the last stage, it is advisable to paint the product, since it will have to be transported inside the trunk.

The manufactured device is quite simple to use in practice. If the car is stuck off-road, then you need to act as follows:

- First you need to hook the spool onto the drive wheel of the car.

- Insert a strong rope into the hole in the camera nipple on the spool disk and tie a knot at its end.

- Its free edge must be tied to a tree or a peg driven into the ground.

- Start the engine, engage first gear and start driving. The car will pull itself out.

While driving, it is unacceptable to rotate the steering wheel, since in this case the likelihood of chafing the rope due to it coming off the spool increases.

This device is ideal for cars with front-wheel drive when moving forward. For a car with rear wheel drive, it is better to drive backwards.

If a peg is used, special attention must be paid to the reliability of its installation. Otherwise, he may be thrown out by the weight of the car.

DIY motorcycle winch

You won’t believe it, but a winch can be made from an old motorcycle lying around, or rather, from some parts that are great for making a “homemade” mechanism.

As in previous versions, we fix the motor to the frame. The working part of the winch is made of the main sprocket (it is located on the engine). A motorcycle chain is perfect for our needs. We secure the drum with previously prepared nuts and bolts. If the design allows, then longitudinal holes can be made on the frame. They will allow the drum to move, which will help regulate chain tension.

Conclusion

In some cases, a self-retractor is quite capable of replacing a winch. Of course, if the car participates in competitions or is used on very difficult off-road conditions, where it needs to be pulled out of captivity every few minutes, then it is better to use a winch, and of considerable power. If the car is used for fishing, hunting or other rides on not very difficult off-road conditions, then a self-extractor is quite suitable. Of course, a winch is in most cases more convenient and preferable, but given its cost, it is not always available. A self-puller will cost a ridiculous amount, but it is quite capable of coping with tasks that are usually assigned to a winch.

Another design option