Home / Electrodes

Back

Reading time: 2 min

0

992

The Russian building materials market provides a choice of welding materials. They come to us from the machines of Russian factories and from manufacturers from other countries.

Parts vary in price adequacy, quality, and the ratio of positive and negative customer reviews. They are the ones we rely on when choosing a product. In most cases, the guideline will be value for money.

In this article we will analyze the pros and cons of electrodes familiar to many welders from the Sudislavsky Welding Materials Plant.

- general information

- Advantages and disadvantages

- A short summary

general information

Welding electrodes brand MP-3C are rods with a combined rutile-cellulose coating intended for manual arc welding of low-alloy steel carbon structures. These electrodes can be used for welding in any spatial position (except for the vertical position when welding from top to bottom). You can cook on both alternating and direct current, adjusting any polarity.

MP 3s electrodes are made of SV-08 type wire and coated. When welding, you can get both short and medium arc lengths. We recommend cooking on a short arc. With a certain skill, you can achieve a long arc if you need it. The arc itself burns stably, does not “walk”, the seams turn out beautiful and even. The slag separates easily.

Welding electrodes of the MP-3C brand can be used not only for amateur, but also for professional welding. They have proven themselves to be excellent when working with non-rotating pipe joints. It is also convenient to make tacks using these electrodes.

The main advantage is that there is no need to clean the metal before welding. Of course, cleaning won't hurt, but if you don't have the opportunity to remove rust and dirt from the surface of the workpiece, you can cook directly on top.

LEZ MR 3s electrodes ignite without any problems. Including again. This brand will appeal to beginners and gardeners who don’t want to bother with ignition and arcing. However, for home use, it is also recommended to calcinate the electrodes.

A little history

Tigarbo is a Russian company that produces electrodes for . Basically, products are sold in the Russian Federation, but sometimes they are exported to CIS countries.

The Latin name allows it to disguise itself as a foreign enterprise. Why is this good? You can place an order directly from the factory and without intermediaries. The bad thing is that customers in foreign countries can buy counterfeits rather than original products.

The Tigarbo brand belongs to the middle price category, and in the domestic market it occupies a leading position. Welders also speak well of it. The plant has an international quality control system. Its standard is ISO 9001-2000.

How are they different from MP-3?

Electrodes MP 3 and MP 3C are very similar. Their composition and characteristics are almost identical, with the exception of one feature. The MP 3C brand contains a number of additives, thanks to which the arc is easier to ignite and burns more stably when using a low-power household welding inverter. Also, this brand emits much less manganese during operation than MP 3. The seams are more uniform and easier to form.

From this we can conclude that the MP 3C brand is more likely intended for amateur welding at home, and MP 3 is more universal. They can be used both at home and in professional activities.

A short summary

The products of the Sudislav Welding Materials Plant (SZSM) are a good example of a product that meets all standards, regardless of the batch.

They make it easy to start learning welding and gradually move on to more complex levels of welding.

Also, SZSM products are suitable if you occasionally weld at home or in the country.

Have you tried the products of the Sudislavsky plant? If yes, tell us in the comments about your positive or negative experience using parts from this manufacturer.

Storage

Proper storage of electrodes directly affects the quality of the seams and the shelf life of the rods themselves.

The most important rule is to store electrodes in a dry, warm room. No need to leave a pack of rods in the garage all winter! Many people do this, and then wonder why the seams turn out defective. The room in which you store the electrodes should not be too humid. It’s better to take the rods to your apartment, if possible. If you have a large number of electrodes, then it is better to install a thermometer and a device that determines air humidity in the room.

Advantages and disadvantages

Naturally, any product has pros and cons. This also applies to electrodes from the Sudislavsky plant. Below we will look at them in more detail.

Of course, the most important thing for a part is quality. The plant produces electrodes and wire in accordance with all industry standards. The second plus is the wide variety of products.

The plant produces more than sixty types of rods. SZSM is a vivid example of streamlined production of parts with constant quality.

The product is well preserved during transportation. During production, it is packaged in high-quality cardboard, which preserves the characteristics of the products.

Let's talk about the cons. Oddly enough, there is only one thing - quality. The electrodes from the Sudislavsky plant, although not bad, may be inferior to their imported competitors. Large Russian factories also surpass SZSM in product quality.

Advantages and disadvantages

The technology of welding with OZS brand electrodes is distinguished by the following positive qualities.

- When making a weld , no pores or cracks are formed, and there are no slag components . The seam is characterized by a smooth transition from the welding bead to the base metal, which makes it invisible on the surface of the workpiece.

- Welding can be done on edges that have not been cleaned of rust, soil, or with traces of moisture.

- The slag crust is easily separated from the weld surface.

- Steady arc combustion ensures minimal losses due to spatter.

- Rutile coating of OZS electrodes does not create toxic elements in welding gases.

Electrodes ESAB OZS-12 d3 mm. 5 kg. Photo Petrovich

The main disadvantage of OZS consumables is the strict requirements for the moisture content of the rutile coating . When the moisture content in it is more than 0.7%, all the positive qualities of the electrodes are lost. Therefore, special conditions are imposed on the premises where OZS consumables are stored.

However, even special warehouses do not guarantee the content of the required amount of moisture in the coating. Therefore, before the welding operation, it is imperative to calcinate the electrodes at a temperature of about 180°C for at least half an hour. The complexity of using OZS consumables increases greatly. Equipment for calcining electrodes is not always at hand.

Comparison with OK, ANO, MP-3, what are the differences, which is better

A wide variety of designs made from low-carbon steels stimulates the development of welding technologies in the development of the production of consumables for their manual arc welding. In addition to OZS brand electrodes, the market is replete with a variety of other consumables with rutile coating : domestic ANO, MP-3, the Swedish brand ESAB OK 46.00 and others. It is not easy for the average consumer to navigate the huge number of brands and models.

We can recommend taking two factors as criteria for the best choice: objective and subjective .

Objective information is provided by testing electrodes in real conditions by independent experts and comparing technical characteristics. For example, the calcination temperature of Swedish brand electrodes is several times lower than that of Russian ones. Some sources cite cases of high-quality welding with “damp” ESAB OK.46 consumables. Experts do not find a significant difference in the welding characteristics of electrodes of the OZS, MR-3, ANO and OK 46.00 brands.

Subjective, but very real information is provided by reviews of ordinary welders , since they use the same brands in their work, but made by different manufacturers. The technological process on some of them leaves room for improvement. As an example (information taken from the forum of the website Forumhous.ru), the results of a user survey to the question “Which electrode do you like?” gave the following results:

- OK 46.00 - 57.5%;

- MR – 3 – 26.1%;

- ANO – 21 – 20.9%;

- OZS – 12 – 11.2%.

How to choose electrodes for inverter welding

When choosing these products, the most important thing is to decide what material you will have to work with. That is, it is important to know what the products being welded are made of, and the composition of the electrode core must match them in composition.

Thus, electrodes can be classified according to a number of characteristics:

- for low-carbon metals, carbon options are used;

- for cast iron;

- for strong heat-resistant steels;

- for high alloy metal;

- for working with aluminum or copper versions of products;

- for surfacing and repair work;

- universal options.

Electrodes for cast iron

Electrodes used for work must not be damaged. It is also important that they are dry. Special ovens are used to dry products.

Advice! To dry the electrodes at home, you can use a conventional oven. But it is best not to let the products get wet and store them in airtight containers in a dry and warm place. Otherwise, there is a high risk that the electrodes will begin to stick during operation.

Experienced specialists also take into account the conditions in which the work will be carried out. For example, humidity, ambient temperature, etc. It is also important to consider the diameter of the selected electrode, the thickness of the parts and the current strength. It is important to understand that if the product is selected incorrectly, the current density can be reduced. As a result, the quality of welding will leave much to be desired, the seam will be thick and wide. Typically, electrode manufacturers immediately indicate for what current strength the product is best suited. For complex and massive structures, it is better to take thick electrodes, while profile products are welded in versions up to only 2 mm thick. We suggest estimating the approximate ratio of metal thickness and diameter using the figure below.

Ratio of workpiece thickness and electrode diameter

And here are the recommended current values depending on the thickness of the product.

Relationship between electrode diameter and welding current

Marking, decoding

E46-MR-3 LUX-Ø-UD E 43 0 (3)-RTs11, where:

- E46 – type of electrode, in this case – for welding carbon and low-alloy steels with tensile strength up to 46 kgf/sq.mm.;

- MR-3 LUX – electrode brand;

- Ø – diameter of the electrode, the most popular rods are 4.0 mm;

- UD - materials for welding of which the rod (U) and coating thickness (D) are intended, in this case - for welding carbon and low-alloy steels and with a thick coating. There are also MP-3 rods with a thick coating of the second group - UD2;

- E – international designation of consumable coated electrodes;

- 43 – tensile strength, in this case – 430 MPa (44 kgf/sq.mm.);

- 0 – relative elongation, 0 = less than 20%;

- (3) – the minimum temperature at which the impact strength of the weld is at least 34 J/sq.cm, 3 = minus 20 degrees;

- RC – type of coating, in this case – rutile-cellulose;

- 1 – spatial positions of the rod at which welding is carried out, in this case – all positions;

- 1 – welding current and open circuit voltage, 1 – welding with direct current of reverse polarity and alternating current.

Electrode device

Design of a welding electrode

The electrode, which is necessarily used during welding, is a fairly thin metal product that resembles a knitting needle in appearance and has a special coating. During welding, the metal of the core begins to melt, and the coating applied to it protects the formed seam from exposure to oxygen. By the way, the coating of products can be very different.

Schematic illustration of the welding process

Table. Types of coating.

| Type | Description |

| Basic | Optimal products for working with so-called critical structures, pipes. During welding work, ductile and durable joints are obtained that are not prone to oxidation. Crystallization cracks rarely occur on the seam. Marking with the letter B. The coating contains carbon compounds of magnesium and calcium, there is practically no hydrogen, due to which a decrease in the characteristics of the metals being welded does not occur. Electrodes with such coating are used only on direct current. The main disadvantage is that a lot of slag is formed during operation. And one more thing - before working with such an electrode, the surface to be welded must be thoroughly cleaned of oils, rust, scale, etc., otherwise there is a risk of getting pores inside the weld, which reduce its strength. |

| Rutile | Such electrodes light up easily and practically do not splash metal around them. They are marked with the letter P. The coating is based on the substance rutile, there is also oxygen and silicon. This coating option is available on electrodes used in direct and alternating current conditions. It is important to work in conditions of moderate humidity, otherwise the quality of the seam will deteriorate greatly. |

| Cellulose | This coating contains a lot of organic matter (up to 50%). These are organic resins and cellulose itself. The marking of such electrodes is letter C. During work, they emit little slag, but form a lot of gases. It is easy for them to perform work in a vertical orientation. Options with such coating are used only on direct current. Disadvantages - a lot of splashes are generated, and the quality of the weld when working with steel may not be the best due to the high hydrogen content. |

| Sour | Such electrodes make it possible to obtain a welding seam with virtually no air channels; they can be used to weld elements with scale and rusty parts. It contains manganese, iron, silicon and a number of other elements. Such electrodes are marked with the letter A. This option is harmful to the health of the welder and requires work to be carried out exclusively in a well-ventilated area. There is also another disadvantage - the risk of hot cracks appearing in the seam. |

On a note! For novice welders, it is best to use rutile electrodes. For experienced people, it doesn’t matter what kind of coating is used.

Rutile electrodes

Also, all electrodes are divided into two main groups - melting and non-melting.

- Melting options may have a coated rod of different diameters. It is thanks to the latter that the arc during welding is optimal. Such electrodes are usually used for manual welding.

- Non-melting options are now quite rare, since they need to be worked in a special environment. They are difficult to select, so they are not recommended for beginners.

Current, diameter

| Diameter, mm | Spatial position of welding | |||

| lower | vertical | ceiling | Vertical top to bottom | |

| 2,0 | 40-60 | 40-60 | 40-60 | 40-60 |

| 2,5 | 60-80 | 60-80 | 60-70 | 70-90 |

| 3,0 | 90-130 | 80-110 | 80-110 | 120-150 |

| 4,0 | 140-180 | 120-160 | 120-160 | 150-180 |

| 5,0 | 170-220 | 150-190 | – | – |

Description

OZS electrodes are metal rods (material Sv-08, Sv-08A) coated with a rutile coating, which are used for welding low-carbon steels (with a carbon content of up to 0.25%).

Electrodes OZS-12

The basis of the coating is titanium dioxide , which creates protection from slag for the welding seam and drops of metal of the rod located in the arc gap. The resulting surface film of titanium dioxide has good conductivity , which creates conditions for easy re-ignition of the electrode.

GOST, certificates of conformity

The quality of the electrodes is confirmed by compliance with state and industry standards, technical specifications and other norms. The packaging must contain a link to the above documents.

Electrodes of the OZS brand are manufactured in accordance with GOST 9466 - 75 AND GOST 9467 - 75 . In addition, special requirements for individual modifications are prescribed in technical specifications , for example, TU 14 - 4 - 782 - 76 or in industry standards, for example, OST 5.9224 - 75.

Welding electrodes OZS-3

As an element of consolidating their positions in the domestic market of welding materials, manufacturers receive certificates of compliance with Russian regulatory documents. Among the independent expert organizations authorized for this are: Russian Maritime Register of Shipping, NAKS (national welding control agency), Gosatomnadzor, accredited by Rosstandart to obtain a GOST R certificate of conformity and others.

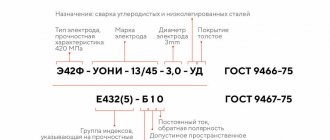

How letters are deciphered, markings

In the name of the electrode brand, the developers indirectly indicate any of their characteristic features. The abbreviation OZS corresponds to the following decoding:

- OZ is a pilot plant, as noted in the labeling of the company that developed SpetsElectrod;

- C - construction, as one of the industries where electrodes of this brand are used.

On the packaging, OZS electrodes are designated in accordance with GOST 9467 - 75. The designation consists of letters and numbers , each of which corresponds to certain technical characteristics and scope of application. An OZS-12 brand electrode with a rod diameter of 3 mm will have the following name:

E46 – OZS – 12 – 3.0 – UD / E430(3) – P25.

All OZS brand consumables belong to the type of electrodes with an ultimate tensile strength of 46 kgf/sq.m. mm (E46). Other dimensional, welding, technological parameters, as well as purpose, can be determined from GOST information.

Manufacturers: ESAB and others

“Manufacturer of high quality electrodes”, including the OZS brand - this characteristic is instantly associated by welders with the Swedish brand ESAB.

However, some Russian enterprises: BOR-ELECTROD (Nizhny Novgorod region), SpetsElectrod (Moscow) and others, as well as the Russian-Swedish joint venture ESAB-SVEL (St. Petersburg) produce OZS consumables, competitive in terms of “price-quality” parameter.

What are they intended for, areas of application

The ability to qualitatively weld workpieces from low-carbon steel even without special skills has led to the widespread use of OZS electrodes both in industry and construction, and in everyday life. Most sheet metal and various types of rolled products are made from such steel.

Pipe welding with OZS-6 electrodes

As the best technologically, OZS consumables are used in welding T-joints - with the help of tacks you can obtain geometrically accurate perpendicular joint surfaces. They successfully cope with the task of welding pipes of small diameter and with thin walls . A large number of units, lifts, and other equipment operating in explosive industries are welded with OZS grade electrodes.

TIGARBO products

The company cannot boast of a wide range of products, but produces all popular brands. They supply electrodes for beginners and professionals.

Here are some available models: ANO 21, ANO 24, UONI 13 55, MR-3. The product is sold in packages weighing from 1 to 5 kg.

What are the good and bad things about TIGARBO?

Let's start with the advantages:

- High-quality raw materials are used for electrodes. These are not only rumors from the manufacturing company, but verified by experience.

- Their arc burns stably and is easy to ignite. That is, they are suitable for different types of work.

- Tigarbo rods melt evenly, so the final connections are reliable and stable, and no defects are detected.

- Welding with Tigarbo is quick and the electrode coating is reliable.