Design features and brief characteristics

If you look at an electric engraver through a magnifying glass, it will turn out to be nothing more than a type of drill.

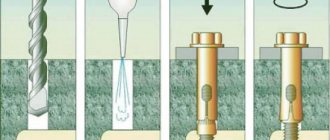

It’s just that the dimensions of the tool are much smaller, and the functionality is significantly expanded. Like conventional drills, engravers are equipped with a relatively powerful electric drive. The electric drive not only creates sufficient torque, but also a very high rotation speed of the nozzle. The majority of engravers are based on the rotational principle. But there are also impact varieties in which electrical energy is transferred into the kinetic energy of the impact. A special nozzle made of a fairly hard material knocks out particles of the material, leaving the required pattern or inscription.

The main characteristics of engravers come down to several:

- tool weight;

- motor rotation speed;

- number of universal nozzles.

The preference of craftsmen is given to a lighter tool, with a shaft rotation speed of up to 20 thousand revolutions per minute, with a set of a wide variety of attachments. Typically the weight of the engraver does not exceed 1 kg. This is due to the fact that engraving work is done by hand, and tools heavier than 1 kg are difficult to work with for a long time. It is better to work with a light tool for a long time.

The variety of attachments determines the range of functionality of the tool. Therefore, this range depends proportionally on the number of nozzles. The list of attachments may include:

- collets, couplings, jaw clamps;

- engraving attachments;

- cutting and polishing wheels;

- miniature drills;

- burs of different configurations and sizes.

In addition to attachments, it is possible to attach flexible shafts, which allow, by lengthening the drive shaft, to perform additional work without experiencing discomfort.

For a home workshop, for household needs, an engraver with a rotation speed of up to 20 thousand revolutions per minute and a power of about 200 W is sufficient. Professional engravers have a speed of up to 30 - 35 thousand and a drive power of over 250 W.

Electric engravers are produced by many companies with well-known brands: Dremel, Bort, Sturm, Einhell, Hammer, Bosh, Makita and many others. Such a serious attitude towards such an unenviable instrument is expressed in constant work to improve the design and offer new attachments.

Nuances of processing different materials

Processing of materials using drills and engravers is carried out either by cutting, that is, milling, or by abrasive grinding. A special processing mode is implemented in engravers; they are essentially micro-perforators, that is, they process the material with a high-frequency impact method. And if when working with an engraver, the processing mode is determined mainly by the force of pressure on the tool, then the efficiency of cutting and grinding with a drill depends on the speed and torque.

Working with burrs requires the most accurate and correct selection of the cutting mode. As the radial distance of the cutting edges from the spindle axis increases, the angular velocity increases; accordingly, it is necessary to reduce the spindle speed. The rotation speed of the cutting tool must be high enough to effectively reject chips, but not too high so that the edges have time to cut portions of the material and do not rub against the surface to no avail.

Photo youtube.com / Axminster Tools & MachineryProxxon Battery-Powered Drill/Grinder IBS/A

You also need to take into account the viscosity, fusibility and hardness of materials. Almost no type of milling equipment is designed to operate at speeds above 30–35 thousand rpm, and at extreme speeds, needle cutters are used predominantly. The maximum speed indicated above is determined for hard metals such as steel and stone, but for fluoroplastic or polyethylene this level is reduced to 4–6 thousand rpm; at higher speeds the chips simply melt. Working with burrs requires fairly accurate and smooth speed adjustment, which allows you to adjust the cutting mode on waste samples of material.

Photo lp.sharplase.ru

Abrasive grinding, on the contrary, is designed for high rotation speed, which contributes to better cooling of the working surface and effective removal of removed microchips. For this mode, drills capable of delivering 50 thousand revolutions or more are optimally suited. Torque for this type of processing is not of fundamental importance, because grinding and polishing are the final types of processing, where the material removal is absolutely negligible. A separate position from grinding and milling is occupied by the work of diamond burrs, which require the highest possible spindle speed - from 100 thousand revolutions per minute.

The most accurate engraver

Not every engraver is suitable for particularly delicate and even miniature works. Many inexpensive models suffer from the fact that their shaft “walks” freely. So they are clearly not suitable for fine engraving.

However, there are also models that are not too expensive and worthy of attention.

DREMEL 3000-1/25

According to user reviews, this is one of the most accurate engravers. It is even suitable for creating jewelry and jewelry. In short, for work with fine finishing it is hardly possible to find a better model.

Advantages:

- convenience: fits in the hand “like a glove”;

- there is no noticeable shaft vibration that could interfere with operation;

- low noise;

- nozzles can be quickly changed without using a wrench;

- practically does not heat up;

- The kit includes a sufficient number of unique attachments necessary for everyday work, a case for storage and carrying, as well as very detailed instructions.

Minuses:

- not exactly cheap;

- If you purchase original consumables and attachments, the purchase will cost a pretty penny.

Electric engraver - features, main tasks, types

An electric engraver is very similar in shape and general operating principle to a drill. The main difference between the engraver is its miniature size (you can work with one hand) and high speed, that is, the number of revolutions per minute. This tool also allows you to perform work with high precision. An electric engraver, as the name suggests, is primarily designed for engraving - applying letters, lines, backgrounds to a surface. But it's not that simple.

Kinds

Trying to find a suitable model for yourself, it doesn’t take long to get confused. In catalogs and in the names of manufacturers there are many names: “engraver”, “mini-” or “microdrill”, “dremel”, “drill”, “straight grinder”. What should you consider? What to miss? I want certainty. A review of models depending on their capabilities, as well as reviews from those who already use the tool, will help solve this problem.

Shock

The Dremel Engraver 290 works on the impact principle

In a very strict sense, an engraver is a percussion instrument; the operating principle is similar to a hammer drill. It is designed simply. It is accurate in operation, but noisy and produces an unpleasant sound. An impact engraver is designed for a small range of work - namely, dot engraving or, if you can get creative with the attachment, carving; it is perfect for working on metal and inscriptions. Dot engraving produces a silky finish

You can also make contour drawings on stone or work on glass, but you must be careful with this material - there is a high risk of breaking the surface. Among impact engravers, Dremel models are the most represented on the market, there are Chinese analogues, they are inexpensive, but the quality of their work is a big question

Network devices with motor and tip in one housing

Many manufacturers and craftsmen also call mini-drills, drills, and straight grinders engravers. These are tools that work on the principle of rotation: the motor turns the spindle, a chuck is attached to the spindle, into which the equipment (attachments) is installed. The peculiarity of such a device is the abundance of attachments for it; you can either purchase them or make them yourself. They can perform a huge number of operations - grinding, polishing, drilling, milling, sharpening. The devices within this huge group differ depending on the structure of the case and the method of power supply. But all of them are united by miniature size and precision processing.

Corded tools operate from an electrical network and are more similar to a small drill than others. As a rule, they are made in a plastic case. The group is very large, the scope is very wide. Most cheap Chinese models with rather modest characteristics belong to this type of instrument. A special cable with a tip - a flexible shaft - and a special stand make it possible to expand the functions of such devices, turning them into an analogue of suspended machines.

Electric engraver Sturm. The included flexible shaft allows for greater accuracy

Suspended machines

The tip of these devices is connected to the body with a flexible cable. The speed is controlled not by a switch, but by a pedal.

The speed of the Dremel Fortiflex pendant electric engraver is controlled by a pedal

Mobile electric engravers

The peculiarity of such devices is that they receive power not from the mains, but from batteries. You can work with them anywhere. Such a device will be especially useful for a craftsman working with wet material - battery-powered power tools are the safest in such cases.

The Dremel 7700–30 engraver can be used even where there is no access to power.

Which engraver to choose

First you need to choose a manufacturer whose engraver will fully satisfy your requirements. For example, you can consider the company Defort, whose devices are widespread in our country. Their popularity comes from a combination of two factors – functionality and price.

If you are going to use the tool exclusively for home work, then almost all engravers from this company are ideal for you.

Dremel devices can be used not only for home decoration, but also in small businesses. The power and reliability of their tools amazes with their technical performance, which is why they are often used as grinders. Devices from this company are often used in automobile workshops.

However, low cost does not mean poor quality; on the contrary, people buy devices from this company if they do not use them very often.

The manufacturer Sturm also boasts a low price and power; moreover, all machines are equipped with many attachments, so there is no need to purchase additional ones.

When choosing an electric engraver, it is important to take into account its features and the ability to work on a specific material, since each requires its own technical parameters, as well as attachments.

What is the difference between drills and engravers?

An engraver is a percussion instrument, and a drill is a rotary instrument. A simple example. Classical. Classic drill. Chinese ordinary household. That is, there is a motor that rotates the shaft and equipment. But the engraver directly performs reciprocating movements. In fact, the main working movement, the main function, is to make a point on the material.

What is an engraver?

Since, as a rule, an electromagnetic tool in which there is a core, an electromagnet. He strikes the striker and it strikes the material. This is an electric analogue of a hammer drill only without a motor, namely, with an electromagnet. As a rule, engravers have the ability to switch the impact force. Here the state of the core actually changes to the moving element of the electromagnet. On/off button, there are no other adjustments here.

Characteristics of engravers and drills

The vibration of these instruments is not very strong, but the sound is very unpleasant; it is impossible to work with it without headphones. Where are engravers used? For example, winding the surface, that is, blows, when we apply a pattern with dots and create a silky coating on the material, have proven themselves very well when working on metal. You can, of course, do metal carving, that is, this is a classic type of engraving. But in this regard, engravers are much better.

An electric engraver is a very simple and cheap, but not very functional tool. What materials can they work on? For example, a stone. If it is a stone subject to chipping, then it is quite possible to work with a needle tip and chip away, creating some kind of shapes.

Aggressiveness, productivity is not very high, therefore, as a rule, only a contour drawing is applied, the surface is wound or similar functions are performed. But if you want to carve on a soft material, for example, try your hand at carving something new, then you will have to install a chisel made of high-strength steel. As a rule, a tip with a diameter of 3.2 mm is installed in the engraver. Be sure to come with the original tip. It has a slightly more obtuse angle and is designed to work on other materials.

What else can an engraver do?

For example, glass engraving is often shown. They strike and break off a microparticle of glass. But one cannot reach the point of fanaticism. With a certain amount of pressure you can simply break the glass.

Therefore, be sure to be careful when working with glass. Do not press too hard on the surface and use glasses

You need to use glasses.

Next in the video from 4 minutes on how to still choose a good drill, for example, this one.

Next part 2. We will talk about networked drills

Part 3. Hanging drills

Part 4. Micromotors

Buy an inexpensive engraver and drill in Ukraine

If you don’t know where to buy a good engraver at an affordable price, we invite you to the online store of TD Ukrservice. This is a large selection of household and professional construction tools from leading global and domestic manufacturers.

The online catalog of TD Ukrservice presents the best engravers and drills TM Dremel (from ]Bosch[/anchor]), which confidently hold the lead in user ratings. This is impeccable German quality, reliability and functionality. Each product is provided with a guarantee and a quality certificate. Delivery of goods is carried out throughout Ukraine.

Call right now and get the opportunity to purchase high-quality tools at the best price.

How to choose an engraver + (Video)

When choosing such a tool, it is necessary to clearly understand the purpose of use. It is necessary to take into account the quality of the material being processed, the list of functional operations, the necessary and sufficient volume of attachments and devices. First of all, you need to decide what you plan to do.

A mini drill differs from impact engravers in that it can be used for more than just engraving. It can be used to cut and drill, clean and polish. You need to carefully familiarize yourself with the equipment, because for such work it will be more expensive to purchase attachments separately. For hard-to-reach places, a model with a flexible shaft is useful.

You also need to decide how often the engraver will be used. If the work will be performed every day, then you need to select the most reliable model. This could be Dremel, Proxxon or Foredom. And it is better to select a power reserve for professional work from 250 W. The power reserve will allow you to work at low speeds due to the large torque. For handicrafts and hobbies, the Einhell, Hammer, Bort, Storm or Skil models are quite sufficient. Their declared power is in the range of 100 - 200 W.

The material with which to work is also important in the choice. Glass, wood and soft metals can be easily processed with a mini-drill with speeds up to 20,000. Precious stones, steel and hard alloy materials can be processed with a mini-drill with speeds of up to 30,000 and their mandatory adjustment. This will allow for precise tuning. Otherwise, you will have to use an impact engraver.

After determining the purpose of use, the tool is selected according to technical characteristics - power, shaft speed and weight of the tool. And the selection is completed based on such indicators as the noise of the tool, its ergonomics, workmanship and price. But, even without experience working with an engraver, you can choose a tool according to the above criteria.

How many revolutions does the engraver have?

Shaft rotation speed A cutting and sharpening of the tool is carried out at high speeds

.

The number of revolutions

in modern models is in the range of 15000-35000 rpm.

Interesting materials:

How are batteries marked? How has the world's population changed? How to change the background in tik tok? How to change the tape in an Atol cash register? How to change the position of the armor stand? How to change playback speed? How to get sober instantly? How does migration affect population structure? How many cents are there in a dollar? How much vitamin C is in kiwi?

What to look for when choosing an engraver

In the descriptions for each model you can see special symbols and abbreviations, which are usually understandable to the master, but not clear to the average person who has decided to purchase an engraver. First of all, you need to pay attention to:

rotation speed rpm is the most important indicator that displays the number of revolutions per minute. Usually this figure ranges from 15-35 thousand, but when choosing a tool you need to remember for what purposes the engraver will be used

If you need to process high-density material, then you need a tool with a high rpm, and a low rpm is suitable for polishing various surfaces; power, W – this is the second important designation. This indicator means the operating life of the engine, which can range from 35 to 300 W

If you plan to perform complex construction work using an engraver, then you need to choose a product with a high power rating, while an engraver with low power is suitable for performing jewelry work.

When choosing an engraver, its weight plays an important role. Usually it does not exceed 500 grams, but some models reach a weight of 1.5-2 kg. To work with such a tool, you will have to constantly stop to rest your shoulders and wrists. But it is worth understanding that a heavier tool is more powerful, with a good cooling system that will prevent the working shaft from overheating, and this also contributes to a long service life of the working parts.

Engravers are especially in demand when laying communications, performing car repairs, manufacturing original products, collectible weapons, etc.

There are a large number of models on the tool market, both Russian and European: Sturm, Dremel, Ryobi, Zubr, Kalibr, Energomash, etc. Tools manufactured by these brands are usually suitable for performing the same work, but have their own characteristics (for example, the presence of a special stand, a special design of the product, thanks to which it is convenient to hold the product, etc.).

What work is planned to be done

In our educational program we will give answers to most popular questions regarding hand drills and engravers. The most important of them is what determines such a variety of instruments and what is the specialization of individual varieties. The first thing a novice engraver or micromachining enthusiast needs to understand is that a drill is not a universal tool. Before purchasing it, you need to know exactly what operations will be carried out during the work, and what specific materials will be processed.

The three most important criteria for any drill are power consumption, speed range and torque. Power is a very relative concept; the real performance of the working part of a drill depends both on the efficiency of the engine and on the efficiency of the speed control system. However, it is by power that one can quite accurately determine the suitability of a drill for processing parts of various sizes:

- For engraving and texturing - up to 50–70 W.

- For artistic carving - 100–150 W.

- For cutting and grinding small parts - 100–250 W.

- For multidisciplinary work with massive parts - from 200 W.

Photo forum.guns.ru

The ratio of spindle speed and torque is determined solely by the properties of the materials being processed. Thus, for milling plastic and tough metals, low speeds with high torque of 3.5–5 N/cm are required. In turn, stone carving, bone carving and grinding require a rotation speed of at least 35–40 thousand rpm, and torque is a secondary parameter that determines the amount of material removed in one pass. All these nuances will be discussed during our review.

Repair - what you can do yourself

In case of serious damage, of course, it is better to contact a workshop. But in many cases you can handle it yourself. If we are talking about a Dremel tool, then disassembling it is not difficult - just unscrew the screws and pry off the body parts with a screwdriver. They come apart easily.

Electric engraver device

The machine consists of a motor (stator, armature), a spindle (shaft), brushes, a cooling system, and a tip to which the equipment is attached. Some models are equipped with a speed switch, impact force switch, and electronics (screen showing the number of revolutions). But the general principle remains the same.

The electric engraver is easy to disassemble - just unscrew the screws and, using a screwdriver, pry the case apart

Internal structure of the electric engraver: 1 — speed switch, 2 — brushes on the sides, 3 — motor, 4 — “fan” on the armature, 5 — stop button; 6 - tip.

Photo gallery: components of an electric engraver

The device makes an uncharacteristic sound, the air flow from the fan increases

Perhaps the armature is catching on the stator. One of the reasons is the failure of the rubber ring - the coupling; over time it can wear out or even break. In order to replace the clutch, you need to disassemble not only the housing itself, but also the engine.

Video: disassembling the electric engraver motor, replacing the coupling

Overheat

If the machine heats up too much and too quickly, the bearings may be clogged with dirt and need to be cleaned and lubricated. It is necessary to remove the armature; there is no need to remove the bearings from it. First, use an awl to carefully remove the anthers, then wash the bearings with kerosene. Rinse very thoroughly. For this, as for lubricant, you can use a syringe. If the anthers become deformed during disassembly, they need to be straightened - a small flat-head screwdriver is convenient for this.

Video: cleaning and lubricating bearings

Poor speed shifting

The switch may be faulty due to clogged dust - small particles flying during operation. To do this, you need to disassemble the device and clean it. It is very effective to blow out the insides of the instrument with compressed air from a small cylinder. Remove remaining dust with a brush.

How to work with it: correct operation

To avoid damaging the product when operating the device, you need to know the rules of use and safety precautions.

Preparing the workplace and tools

- Designate a table with free space.

- Install a powerful lamp so that all small details can be seen.

- Cover the work surface with paper or cloth. Dust and chips are generated during cutting and grinding.

- Stock up on carpenter's tape, a pencil or a felt-tip pen for drawing. Scotch tape is needed to secure the draft to the surface. The paper tape is easy to peel off and leaves no marks. To apply patterns on a metal, plastic or glass workpiece, degrease the surface with alcohol so that the felt-tip pen does not wash off. Apply the initial drawing on the wood with a pencil.

- Prepare all necessary attachments. To do this, read the instructions for the device. There is a description of the purpose of all consumables.

- If you bought an engraver complete with a suspension, then install it in a convenient place. It helps eliminate vibrations during operation and reduce errors. When installing the gimbal, be guided by the placement of the flexible shaft. He shouldn't get in the way.

How to use

- Wear fabric gloves so that the hand with the tool can easily glide over the surface of the workpiece and stains will not appear on the product.

- If you are a beginner, select the minimum RPM. Then the pattern will be even, the strokes will be of the same depth, and the material will not be damaged. Turn on the engraver.

- Trace the outline of the drawing. Once completed, move on to drawing small details.

- When the pattern is completed, use a soft felt attachment. It usually comes complete with the engraver. This equipment removes roughness.

Safety precautions

- before work, check the integrity of the network cable and working elements;

- use safety glasses to prevent sparks and dust from getting into your eyes;

- To drill and cut materials, hold the device firmly with your entire hand. This way you will avoid arbitrary movements, damage to your hands and working material;

- If the equipment is jammed, do not pull it out of the workpiece. First unplug the engraver or remove the battery. Then remove the nozzle;

- If the engraver body heats up, turn it off and wait until it cools down. If the device does not have a cooling system, then it will have to be interrupted often. This way, you will avoid engine overheating. The instructions describe the operating time;

- When purchasing consumables separately, make sure they match your instrument. They must have the required shank size and match the speed of the engraver.

Care

In order for the tool to work fully for many years, it is necessary to monitor the condition of the working equipment. If visual inspection of the attachments reveals various damages, replace them with others of the same brand as the engraver itself. This is the only way the tool manufacturer can guarantee the device’s operating efficiency and long service life.

After each cycle, clean the ventilation holes in the housing. With their help, the engine is additionally cooled. But when processing wooden, plastic or glass workpieces, the holes become clogged with dust. The resulting contaminants affect the performance of the tool and cause its failure

To avoid this nuisance, you need to remove debris carefully using a damp, clean rag. It can be soaked in soapy water

To avoid damage to the housing, do not use products based on alcohol, thinner or gasoline. The equipment that was used in the process also needs to be cleaned.

By following these simple tips, you will use your engraver for a long time and get high-quality results.

How to choose an electric engraver: what to look for

By and large, the approach to choosing a mini drill is standard - any other tool is chosen in the same way, regardless of its purpose

You need to pay attention to the following things

- Tool power. It goes without saying that the more power a tool has, the more load it can be placed on. On average, this tool can have a power of 150 to 400 watts.

- Equipment. Most models are sold in kits, which include both cutting tools and special attachments. The problem with such kits is that the cutting and cleaning tools they contain are not of particular quality. In principle, these are also suitable for a start, but for professional work it is better to purchase high-quality cutters.

- Ergonomics. The engraver should fit comfortably in the hand - it should not be too large or too small. The choice in favor of a large unit can only be made when you plan to work exclusively with a flexible shaft.

- Manufacturer. There is nothing to say here - everyone understands perfectly well that the quality of the instrument directly depends on the manufacturer.

In addition, you should pay attention to such a point as the purpose of the engraver - in this regard, they can be designed for domestic and professional use. The difference between them lies in the duration of work - household tools must rest more often

In contrast, professional engravers are able to work for hours without stopping - they are made from high-quality materials and components.

To conclude the topic about which electric engravers to choose for your home, there is only one thing left to add. In addition to such well-known tools of this type as Dremel, there are other, no less high-quality and good tools - they can be found even among Chinese products. For example, ROYCE is manufactured in China for the domestic market, but has already made its way to Europe and has proven itself well there. In general, there are a lot of good tools of this type, and they are not always expensive - read reviews, ask your friends. This is not a new instrument, and in most cases people have long formed their opinion about a particular manufacturer.

Author of the article Alexander Kulikov

Buyer's Guide

The term "dremel" can cover a wide range of hand tools. Generally speaking, there are two categories of this tool.

Handheld tools are typically small, lightweight tools with small motors. They are suitable for jobs that require more control and fine detail, such as engraving, polishing, shape cutting and the like. Cutting Tools – These devices have larger motors and are better suited for cutting various building materials.

Why you might need a rotary saw

Dremels have a variety of uses and are used in a variety of home improvement projects. Different brands have their own unique features, but regardless of their differences, they are equally effective at cutting, polishing, sanding, shaping and finishing wood.

- Cutting Engravers have special attachments that can be used for small cutting tasks such as wood, plastic, fiberglass and pipes.

- Polishing They are ideal for polishing jewelry, silverware, coins and more.

- Sanding For projects that require meticulous tasks, such as removing rough edges, rotary power tools are suitable. You can sand a piece of wood or remove rust from a metal area using the appropriate accessories.

- Milling A router can cut grooves and holes into a piece of wood, plastic, rubber, and even metal.

- Woodworking Woodworkers use Dremels to carve wood to create complex designs.

- Engraving wood / glass / metal With the right accessories, you can use the engraver to create patterns on the surface of various materials.

Key Considerations

Rotary tools are designed to perform efficiently on any home improvement task. Whether you are a professional or a hobbyist, you need to learn some of its basic features to get the most out of this tool. Here are some key features worth paying attention to:

- Applications Although rotary tools generally operate in the same way, there are differences in their applications. Heavy duty tools are designed for professional work because they are larger. They tend to be heavier and a little larger, but are well suited for demanding tasks. On the other hand, smaller tools are used for woodworking, small parts and crafts.

- Wireless/Wired You can find both wired and wireless devices. Cordless tools are more convenient because the user does not need to plug them into a power source, but corded tools are usually lighter because they do not have a built-in battery. Therefore, when it comes to mobility and short-term use, cordless tools are preferred, but in terms of unlimited power consumption and continuous use, a corded tool has the advantage.

- Speed Engravers have different speeds, and the wider the range of speeds, the more versatile the tool becomes. In this case, you should pay attention to the stability of revolutions throughout the entire speed range.

- Equipment / Accessories The number and availability of accessories depends on the manufacturer. Some models are immediately equipped with a large set of accessories and can immediately perform a huge range of tasks, others have 3-5 attachments in the basic configuration and require additional investments to purchase accessories. An important aspect here is the interchangeability of devices between other brands.

- Easy bit changes When performing complex jobs, you may need to change bits frequently. That's why; some models have multiple spindle locks. Consider the tasks you intend to perform and purchase a tool that allows you to easily change the accessories you require.

- Ergonomics Check whether the tool has a comfortable shape. Vibration may occur during operation, so it is important to ensure a secure grip in various positions.

- Replaceable brushes The ability to replace motor brushes when worn will extend the life of the tool without capital investment.

Choosing accessories for working with an engraver

To ensure the safety of your eyes from particles of the material you will be working with, you need to buy glasses with polycarbonate lenses. Optics made from this chemical compound are more impact-resistant and have good light transmittance (does not distort the image). To protect your respiratory tract, buy a filtering respirator. It is light and does not make breathing difficult. But you will need stronger lung protection if you intend to work with metals. A cloth half mask will not be a significant barrier to metal dust. When working with paint and varnish coatings and metal, it is better to purchase a half mask, supplied complete with replaceable filters, or a full face mask. A full mask simultaneously protects the eyes, face and respiratory tract from harmful influences.

How to choose an electrical appliance

To avoid making a mistake with your purchase, determine two things: what kind of work you need the tool for and the type of workpiece material. Then analyze the following selection criteria:

electric engraver or battery. Consider whether you need an outlet nearby; The main parameter of the tool is power. The greater the value of this characteristic, the better the tool will perform the task and better process hard materials; the second parameter is important for selecting accessories. This is the collet size. It is designed to clamp and hold engraver attachments. The most common collet diameter is 3.2 mm. The minimum is 0.8 mm. If you find collets of several sizes in the kit, then this is a big plus. Since you will have the opportunity to use a wide variety of attachments; number of revolutions and the possibility of their adjustment. This is a very important parameter because there are attachments that cannot be used at low or high speed. Therefore, engravers with a large maximum number of revolutions and the ability to adjust them are preferable. Since they can use various attachments, which means they can perform a wide range of work; tool weight. It is advisable to choose a lightweight engraver, because the work of making patterns and polishing takes a lot of time

Holding a heavy instrument in your hands for a long time is quite uncomfortable. When choosing a tool, considerable attention should be paid to the configuration: the presence of a flexible shaft in the kit will save you from the need to purchase it separately. The flexible shaft itself is very useful and increases ease of use.

You can hang the tool on a hook and take the flexible shaft by hand and work; the presence of a variety of attachments will also be a plus. There is a complete set with a whole suitcase of accessories. You may not need some at first, but later you will already know what you need. And don't waste money on the right attachment; packaging matters. It would be good if it was a high-quality case that would hold the engraver with all the accessories.

Rating of the best with photos

The leader is the Dremel 8200-1/35 cordless engraver. This tool weighs only 600 g, high rotation speed with variable speed control. The battery at maximum load will last for 15 minutes of operation. Not so much, but the user rarely uses the highest speeds. And the device charges in one hour. After switching off, the automatic brake is activated.

Dremel 8200-1/35 - lightweight engraver, high adjustable rotation speed. Charges quickly and has an automatic brake

In second place is the Dremel 200-5 network engraver. This is a powerful and lightweight tool. Operates quietly without overheating or vibration. It is suitable for artists and home craftsmen.

The Dremel 200-5 engraver is powerful, quiet, does not overheat or vibrate. Popular in everyday life and among artists

The third position is occupied by the Hammer MD 135 A network engraver. A lightweight, convenient, inexpensive tool. The set includes 40 different attachments and three collets. This engraver comes in second place due to its rapid heating and unstable operation at the lowest speeds.

The Hammer MD 135 engraver comes with 40 attachments and three collets. Due to rapid heating and unstable operation at the lowest speeds, it ranks third

The fourth place was the Hitachi GP10DL cordless engraver. Accelerates to 35 thousand revolutions. Weighs less than 500 g. Works for a long time on one battery charge.

The Hitachi GP10DL engraver is powerful and lightweight, runs for a long time on a single battery charge

In fifth place is the network engraver Caliber 160. A powerful and resourceful tool. Has 100 nozzles. Supplied with a case and flexible shaft. It comes with Dremel attachments. Disadvantages: vibrates at high speeds, and standard attachments are not of the best quality.

The engraver Caliber 160 is equipped with a case, a flexible shaft, and has 100 attachments

The best engravers

Dremel 8220-1/5

It's no surprise that Dremel tops our list, as the brand has an excellent reputation among woodworkers, hobbyists, and professionals alike. And even the name of the brand itself has become a household word. The 8220 lithium-ion battery is, in our opinion, not only the best model in the Dremel line, but also the best rotary tool overall.

It is equipped with a high-speed ( 5000-33000 rpm ) spindle with good torque. Power is supplied by a lithium rechargeable battery, which can be fully charged in just one hour.

Being cordless is a huge benefit to this engraver, as it allows you to get into hard-to-reach areas without having to pull a cord or find an outlet to plug into.

The basic version includes only 5 attachments, however, it is worth considering that the Dremel 8220 can be used with accessories and attachments from most major manufacturers.

In addition, the range of the 8220 line includes more equipped models: 8220 (8220-2/45) and 8220 (8220-5/65) with up to 65 attachments placed in a durable and capacious plastic or metal case.

No matter what you need a rotary saw for, the Dremel 8220 is definitely one of the best engravers around.

Considering the almost twofold difference in cost between the younger and older models, we recommend purchasing model 8220-1/5, which you can equip with the required set of accessories according to your needs.

A short review from the owner:

I give him Excellent! While repairing the car, I came across a stuck bolt. There was no way to get there with an angle grinder with a 125mm disc, and it was not possible to drill it out with a drill - the Boshev drills were lost in a heroic attempt to deal with the bolt. Fortunately, there is a hardware store nearby, where the Dremel was purchased. There were other models, but I’m kind of skeptical about the others, and wired tools don’t suit me at all. The bolt was cut off instantly, without any effort. Subsequently, he helped me more than once with car repairs.

Not long before this, I was looking for an oscillator, but there was no equipment in the kit, and after I bought a Dremel, buying a renovator no longer seems necessary...

Dremel 4300-5/40

This worthy representative of the tools has the most powerful motor in the Dremel line. The chuck rotation speed varies in the range of 5000-35000 rpm, and electronic feedback allows for stable operation regardless of the load. The rotating light makes it easier to see details when working in recesses. And the universal three-jaw chuck and collet system make using any Dremel accessory quick and easy.

Complete with a flexible shaft, router compass and cutting kit, it also comes with 40 different accessories, allowing you to use it for any application right out of the box. Longtime owners of Dremel products will immediately notice the increased size and power difference compared to the previous model. An important improvement for many consumers will be the introduction of separate power and speed switches, making it easier to save your preferred settings. And of course, the fact that you can use all your previous Dremel accessories with this tool is the icing on the cake.

We could put this engraver in first place, but there is a small fly in the ointment. Although you can always rely on the quality of Dremel, this tool is not perfect. Several owners have reported engine burnout. In addition, the mechanism's fastenings use plastic ties, which wear out faster than metal clamps.

Dremel 4000-2/30

One of the most popular engravers of all time is the Dremel 4000. It is still a great tool, but the newer Dremels are still slightly better. The spindle, as in the previous model, has a variable speed that can reach 35,000 rpm. Providing consistent power at any speed, this engraver allows you to cut, polish and grind any material with equal ease.

The Dremel 4000-2/30 set includes a wide range of tools and attachments that can handle any material. All accessories come in a hard plastic case to help you keep your supplies organized, but the set is compact enough to easily fit into a closet or under a desk for easy storage.

Regarding ergonomics, the only real complaint with the Dremel 4000 is that the switch tends to wear out quickly, possibly due to overheating caused by misuse. Please note that the Dremel 4000 is not intended for industrial use.

Running the spindle for long periods of time will cause this engraver to get very hot. Despite its brand name, this saw is intended for short-term use, such as light precision machining, part cleaning and polishing, and other similar tasks. Trying to use this model in more severe conditions may result in early failure.

Bosch GRO 12V-35

Well, what about the competitors?

Possessing a not quite classic Dremel-like shape, the Bosch Gro will be no less convenient. It can be safely recommended to those with small hands, and it can also be convenient when working in narrow openings, but the LED backlight did not seem convenient enough to us.

Supplied in a convenient ergonomic case, this engraver is equipped with two batteries, which allows you to charge one of them while the second is in use. Well, and, of course, Bosch was very pleased with the stated compatibility with old 10.8 V batteries.

Keeping up with the competitors described above, the Bosch GRO also revs up to 35,000 rpm and maintains good torque at low revs. Overload protection will help preserve the engine longer under high load conditions. Compatible with all Dremel accessories, you can easily expand your capabilities and purchase it in a minimal package.

Rubber pads are pleasant to the touch, but still do not help at all from vibration when using low-quality equipment.

And again a short review from the owner:

I was planning to buy a new Dremel, but since I had old blue Bosch batteries I chose Bosch Gro. Compatibility with old batteries is a huge plus in our time, when manufacturers do not think about using old spare parts and accessories. Now I have a set of two new and two old batteries.

The battery life is impressive, as is the power at high revs. I cut through an old 1.5mm steel tank with amazing ease.

Once, when he jumped out of his hands and flew onto his leg, some kind of safety mechanism turned on and stopped the engine almost instantly, doing it so quickly that there was not even a mark left on his trousers. Of course, these were rough, thick work clothes, but still.

Milwaukee 2460-21 M12

Unfortunately, Milwaukee tools are a rare guest in our area, but we couldn’t help but mention this model.

There are many engravers on the market, but one thing that only the Milwaukee 2460-21 M12 12-Volt Rotary Tool can offer is sheer power.

Weighing less than 600 grams, this small tool can easily handle heavier tasks than other rotary tools thanks to its powerful motor and variable speed ( 5000 to 32000 ). This 12-volt motor, combined with Milwaukee's red lithium battery technology, provides users with extended runtime. You can easily perform more complex or heavy tasks that other engravers simply cannot handle.

Users generally speak highly of the Milwaukee 2460-21:

My new Milwaukee arrived from the US last week and I finally got the chance to try it out. It produces much more torque than the Dremel 8220. I love it more than the Dremel and it really makes it easier for me to do all the jobs I used to use the Dremel for. The bonus is that all Dremel accessories work great with it too.

I must say that for a long time I have not had a tool with which I would be satisfied in every way. But this is exactly the case.

However, we should note that there have been complaints about the saw overheating, although this may be the result of completely careless use. We would put it, if not in first place, then on par with the Dremel 8220, but the lack of a “normal” opportunity to purchase it in Russia does not allow us to do this.

Bison ZG-160EK

Just as in the case of Milwaukee, we are not able to purchase engravers such as DeWalt DW660 , Black+Decker RTX-B or WEN 2305 , so we decided to make a choice among domestic manufacturers.

Unfortunately, we didn’t find anything worthy with a similar weight and speed adjustment range, but we still chose the engraver that was closest in characteristics. Weighing about 800 grams, the Bison ZG-160EK has a very controversial shape, more like a drill. This solution may make it difficult to work in narrow openings. At the same time, the body is quite narrow and the grip is quite confident. The rpm range ranges from 15,000 to 35,000, while today's competitors offer a range from 5,000. As you approach the lower limit, the rpm begins to noticeably float, a hum appears and vibration increases. User reviews on build quality vary, indicating inconsistent quality control. When working for more than 15 minutes, the engraver heats up noticeably, which forces you to take 5-7 minute breaks.

Taking into account all the described shortcomings, the main competitive advantage of the Bison is its significantly lower price and it can be recommended not as a professional tool, but as a device that may be needed from time to time.

Electric engraver device

To understand the principle of operation of the engraver, and also, if necessary, quickly replace parts, you need to become familiar with its structure. Typically, the tool consists of:

- A fixing nut, thanks to which the nozzle is secured to the rotating shaft.

- Locking keys, which prevent arbitrary shaft movements after finishing work.

- A spindle collar that you need to hold on to when changing attachments.

- A switch with a regulator necessary to adjust the speed of rotation of the shaft.

- A switch used to turn the tool on/off.

- An electrical cord through which electrical energy is supplied from the power supply to the tool’s motor.

- A hook that secures the cable to prevent accidental disconnection.

The optimal weight of an electric engraver is about 500 grams

Additionally, inside the body there is a collet chuck with clamps, thanks to which the nozzle is fixed in the desired position. Collets, in turn, can be of different diameters - depending on the type of work, you need to select specific nozzle sizes.

The operating principle of such a tool is quite simple: each engraver has a separate motor with a motor, thanks to which the shaft rotates. Attachments are attached to the shaft, used to perform a variety of work (for example, drawing a picture, cutting holes for laying communications, etc.). Depending on the work, there are several types of nozzles.

Technical characteristics of the engraver and drill

The question of how much an engraver costs or the price of a wood drill largely depends on the technical parameters of the device. The main selection criteria are:

- Power consumption.

- Operating voltage.

- Frequency and number of revolutions (torque).

- Noise and vibration levels.

- Ergonomics and weight. For fine processing of parts, it is better to choose tools with minimal weight. Thus, your hand will not get tired during long-term work.

- Manufacturer (it is better to trust trusted brands that provide a guarantee and quality service).

- Complete set (depending on the scope of application, you will need various attachments for the tool).

Pay special attention to the packaging. The presence of a case or a special box for the engraver (drill) greatly facilitates its storage and transportation.

Criterias of choice

When choosing an electric engraver, buyers are guided by various criteria. Some rely on reviews from more experienced users or the rating of a certain model among professionals, while for others, an important indicator is the cost of the device or the brand under which it is manufactured. Meanwhile, it is necessary to choose a specific model of such equipment based on how intensively it will be used and for solving what technological problems. The required technical characteristics and equipment of the purchased electric engraver will depend on the answers to these questions. Naturally, for intensive daily use and for use several times a week, you need to purchase different models of electric engravers.

When buying a budget engraver, inspect and feel the spindle and flexible shaft for play, turn on the tool and check for vibration

The modern market offers a wide variety of electric engravers, differing in their technical characteristics, functionality and, accordingly, cost. This allows you to choose a device that will cope with exactly the tasks that you are going to solve with its help. In this case, you should focus on the power of the purchased device. So, for household purposes and practicing favorite hobbies, engravers with a power in the range of 100–200 W are quite suitable, but for more professional tasks it is better to choose more serious units with a power of 250 W or more.

When evaluating electric engravers by their functionality, you should be guided by common sense and the real need for certain options that the equipment in question is endowed with. For numerous functions of a professional device, most of which you may not need, you will have to seriously overpay.

Scope of application of the engraver and drill

Today, “buy an engraver with attachments” is a very popular request from users on the Internet.

And all because this tool is very useful and in demand. It is used to process various materials and also apply text or images to them. At the same time, for wood carving or for performing very fine (jewelry) processing of parts, it is better to buy a drill. Despite the fact that these tools have a similar design and operating principle, they still have functional differences that determine their scope of application. The drill is more versatile. It can often be found in construction, repair, cosmetology, and technical modeling. The engraver is primarily used for artistic purposes or for applying numbers, inscriptions, and memorial signs.