Not all people know what a gas cutter is, but it will be useful for everyone to understand it, especially for people working in the construction industry. The petrol cutter is a very powerful, but at the same time quite effective tool, the appearance of which resembles a large angle grinder. The petrol cutter is distinguished by the use of powerful gasoline engines and cutting wheels (diamond or abrasive) having a fairly large diameter, namely from 30 to 40 cm. Thanks to this, we can say what the petrol cutter is used for, namely: for cutting stone materials; concrete, ceramic, metal materials; asphalt and other materials, and to a sufficiently large depth.

Decide on the purpose of use

By type, gas cutters are divided into:

- Professional;

- Household.

These tools have different options for operation, reliability and quality. For example, household models should be used no more than 30 hours per month. They are quite simple, and at the same time have the lowest cost. The scope of application of semi-professional gas cutters is more diverse, and such a tool can be used for 8 hours a day, while a household one is used for up to 50 minutes a day. In terms of operating time, professional options are tens of times faster than household ones.

Based on the materials that gas cutters work with, they can be divided into:

- Petrol cutter for concrete;

- Petrol cutters for metal;

- Universal.

A chain cutter for concrete has a power of over 4.5 kW, while the speed is limited to 4200 rpm. These indicators are due to the need to prevent jamming in dense processed materials.

A petrol cutter working with metal has a power not exceeding 4.5 kW. These indicators are due to the low resistance of metals.

A universal gas cutter is used when working with almost any type of material. These indicators are due to high power and a large number of revolutions.

Preparing the tool for work

The structure of a typical gas cutter with a disk as a cutting element is shown in the following photograph.

In addition to gas-powered disc cutters, there are chain models, the design of which is almost identical to that of a chainsaw. There are also specialized modifications, such as wall chasers and rail cutters.

Preliminary configuration of gas-powered tools is carried out at the manufacturing plant. In most cases, nothing needs to be adjusted. All types of units are prepared for operation in the same way. The actions are performed in the following sequence:

- visually inspect the technical means and the cutting attachment for external damage;

- install the protective casing in the required position, securing it securely;

- check the existing switches and buttons for free movement, and the throttle lever (when you press its release) for ease of rotation and return to its original position;

- install a disk suitable for the job;

- check the installation of the spark plug - it must be screwed in all the way;

- remove foreign objects and debris from the workplace;

- prepare a fuel mixture consisting of gasoline and oil mixed in a certain proportion;

- check the presence of fuel in the tank of the gas-powered tool, refueling it if necessary.

The ratio between gasoline and oil in the fuel mixture, as well as a detailed description of the safe refueling process, are contained in the user manual for the product model used.

If you plan to use the tool using the wet cutting method, then additionally carry out the following actions:

- connect a tube to the connecting node of the equipment through which water will flow from the water supply or from the tank;

- use a special lever to turn on the water supply (after completing the work, its supply is stopped).

The operating unit must not have any mechanical damage. If they are found, then you need to first repair the device. The discs used should not have chipped cutting edges, cracks or other defects. Do not use wet abrasive wheels or those that have fallen from a height.

Changing a disk is done like this:

- the drive shaft is fixed motionless;

- using a wrench of the required size, unscrew the fastening bolt;

- remove the bolt, washer, as well as the outer flange, leaving only the inner one;

- put the disc on;

- put all the elements in place in the reverse order, tightening the bolt tightly (but not excessively, without unnecessary effort).

When installing a new disk, you must ensure that the rotation speed for which it is designed is greater than that of the tool . The equipment used must not be equipped with working attachments if they are intended for use at lower speeds.

Choose the right cutting type

The safest and highest quality option is “wet cutting”. Petrol cutters designed for this type of cutting have a water cooling system. Thanks to this, the casing of the device is watered with a special liquid, it ensures cooling of the circle and reduces the amount of dust.

However, it is worth noting that this type of gas cutter is more expensive and if you plan to carry out the work “dry”, do not throw money away. Buy a simpler model and remember to pause every 30-50 seconds. work, their duration should be at least 20 seconds. This will prevent damage to the saw blade.

Rating of the best gas cutters

Polycarbonate roof for a home: pros and cons, installation, step-by-step instructions

We present to your attention a list of the best models of this equipment. These include:

HUSQVARNA K760 350-25. The Husqvarna petrol cutter is considered a universal type of equipment. The tool can easily handle metal and concrete surfaces. There is an additional cleaning filter that controls dust emissions during operation. The comfortable handle ensures proper use of the structure at any angle.

Makita DPC6430. The Makita petrol cutter is equipped with a quick start. The equipment has a tight fastening, which ensures reliable fixation of all elements together. There is a function here that provides a two-level arrangement of the cutting element.

Thanks to this, there is unobstructed access to the surface being treated. The design can work up to 2 hours without interruption. There is automatic air filter cleaning here.

Still TC 420. The petrol cutter still has an automatic system for tensioning the belt drive during operation. The design has a large air filter. It reduces the amount of dust generated when cutting hard surfaces.

The only drawback of this model is the budget materials in the body. Basically, it is dense plastic that is not able to withstand constant mechanical stress. It is used for both professional types of work and household needs.

The powerful motor provides the maximum number of revolutions per minute. It can handle iron and concrete structures with ease. In the process of contact with an object, the tool produces minimal vibration. In addition, the device consumes a minimal amount of fuel.

Find out everything about the engine

When choosing a gas cutter, the first thing you need to know is whether the torque and power correspond to the weight of the engine. An important step will be to find out about the quality of the internal elements. It is also worth paying attention to the electronic ignition system and semi-automatic beam valve, whether they are available in the model you choose. It is worth noting that a high-quality engine has a “summer-winter” switch. And do not forget to pay attention to the amount of gases that are released during operation.

What can be cut and what is the cost?

Below is a table of fuel consumption using the example of a Vognik-182 gas cutter.

As you can see, the consumption is quite small. Therefore, even if you use a gas cutter as the main tool, and a gas cutter as an auxiliary one, you will definitely be able to save carbide.

Today, a gas cutter is not a very common tool. People treat it with distrust both because of its flammability and because of the difficulty in setting it up. However, the tool has its own niche. It is lightweight, compact, and works where a gas burner fails due to low temperatures.

Pay attention to ergonomic indicators, as well as the convenience of the gas cutter

A petrol cutter is a tool that has a fairly large mass, so when choosing its weight you should definitely pay attention. A lighter model will provide better control and less hand fatigue. Another important parameter is streamlining; it affects the maneuverability of the gas cutter.

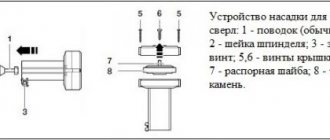

Don’t forget to look towards the handle of the unit, it’s very good if there are 2 of them. At the same time, the distance between them should be quite comfortable and equal to the width of your shoulders. Also pay attention to the quality of vibration damping. It would be great if a special elastomer was applied to the handles, which would provide vibration damping. Don't forget about the different attachments on your gas cutter.

Petrol cutter Echo CSG-680

The semi-professional Japanese model CSG-680 petrol cutter is a productive and versatile unit. The manufacturer has provided the ability to change disks. It is possible to cut wood, plastic, concrete, and metal products. You can also work with a diamond cutting disc. The design is equipped with a powerful 1-cylinder internal combustion engine (2-stroke type) and is complemented by an air cooling system. The equipment is supplied as standard.

Advantages of Echo CSG-680:

- Convenient belt tension system. The manufacturer has provided additional mechanisms to simplify the belt tensioning procedure.

- Power transmission system. Thanks to the addition, the tool cuts any materials accurately and accurately.

- The presence of a diaphragm carburetor. Allows you to perform cutting operations on materials at the required angle.

- Classic filtration system.

- Innovative starting system. To increase cutting efficiency parameters, the manufacturer used an innovative ignition system - automatic change in ignition timing.

- Convenient location of control units, which facilitates the operation of the tool and makes it safer.

- Availability of additional security systems. The manufacturer has supplemented the unit with a right-hand shield, a special vibration and noise suppression system, a muffler with a spark extinguisher, and a metal screen with a rubberized coating to protect the operator’s hands and face.

Disadvantages of Echo CSG-680:

- Very heavy equipment. My hands get tired after 10-15 minutes of work. Carrying the instrument is also inconvenient due to the bulkiness of the case.

- High price.

- Unbalanced design.

- No smooth start.

In general, consumers called the equipment safe and functional. Many consider this equipment to be the best in its class - reliable, powerful and safe. A small percentage of buyers who tried the equipment in use indicated a high noise level and a weak filtration system. About 20% of buyers were dissatisfied with the quality of the case and its design features.

Video review of the Echo CSG-680 gas cutter:

Pay attention to the quality of cleaning filters

The gas cutter equipment must include at least a two-level air dust cleaning system. The external filter provides rough and preliminary cleaning of the air from larger particles, and the second filter removes remaining contaminants. Also prevents fuel backflow.

Opening the filter cover should not require much effort. Pay attention to how well the cutting parts and the engine are protected from dust and moisture.

To prevent injury from sparks and dust, gas cutters are equipped with protective covers. Make sure they are made using durable and reliable materials. For greater efficiency and ease of operation, it is necessary to check the belt tension, as well as the presence of the saw blade guard.

The most expensive models are those equipped with a hydraulic drive, which increases power with the same weight. There is also a reduction in smoke and noise.

Design and principle of operation of a gas cutter

The main component of a gas cutting tool is an engine, mainly a 2-stroke engine, which runs on a fuel mixture of oil and gasoline. The unit is mounted on a housing equipped with special handles and controls. The functional part of the gas cutter is the drive, on which a cutting disc with a diameter of 300-400 mm, protected by a casing, is installed. The transmission of torque from the engine to the drive is carried out via a belt.

The main feature of modern gas cutters is the presence of a multi-stage dust protection system. It prevents contamination of the carburetor, cylinder-piston group and bearings. In addition, dry cutting uses water cooling of the disc. It effectively neutralizes the main flow of dust and prevents a number of negative consequences of overheating, in particular, premature wear of the cutting element and destruction of its structure, and also reduces the load on the engine.

When working with a gas cutter, it is necessary to maintain a right angle between the cutting disc and the surface being processed. This reduces the load on the drive and prevents slippage from the cutting line and damage to the cutting edge. The maximum insertion depth of the disk for various models is in the range of 10-30 cm. When cutting dry materials, you should not use a gas cutter for more than 30-50 seconds - within 15-20 seconds after making the cut, it is necessary to ensure free rotation of the disk.

Powerful models weighing more than 15 kg are equipped with transport trolleys with a remote control system or special legs, which allow the tool to be firmly fixed when cutting.

Note the adjustable cutting wheel angle and guide carriage

Usually the cutting wheel is located in the center of the gas cutter, which provides the best balance. However, it is possible to move the disk to the extreme left position. This can provide a more comfortable experience.

Purchasing a guide trolley will provide more convenient work with the tool. The device is intended for gas cutters that have a lot of weight and power. The trolley allows you to adjust the depth of the painting. The fuel consumption of a gas cutter is around 1 l/h. The tank has a volume from half to 1.3 liters.

Security requirements

To avoid injury during operation, gas cutters are equipped with cast protective casings made of hard metal alloys with high impact resistance. In addition, global manufacturers use a system for blocking the disk when it gets stuck in the material being processed, and also supply the manufactured tools with belt and casing tensioning devices.

When working with a gas cutter, it is recommended to use protective gloves, glasses and headphones, and when dry cutting - respiratory protection.

Rules for selecting additional saw wheels

There is a high probability that when working with gas cutters you will need saw wheels of various modifications and diameters. When choosing a wheel, do not forget that the characteristics of the greatest rotation should correspond to those of a gas cutter or be even less.

Diamond wheels are divided into several types:

- Marked SPECIAL, which is a designation for wheels intended for specialized use. Such circles have increased performance indicators.

- Marked SUPRA, which means circles used for professional work. These wheels have higher wear resistance and are suitable for high cutting speeds.

When choosing abrasive wheels, you should pay attention to the materials that will be cut. The choice of wheels varies when cutting asphalt, stone or metal.

Rules for cutting materials

Concrete and metal, as well as their connection (reinforced concrete structures) are the main materials that most often have to be cut using a gasoline cutter. Working with a gas cutter requires compliance with the following general rules.

- It is first necessary to apply marking lines on the working surface.

- Sawing must be carried out at maximum engine speed, which should be reached before the disc comes into contact with the material.

- Cuts should only be made in straight lines.

- The instrument should be held firmly with both hands, without allowing springy movements or swings. It is necessary that the cutting edge of the nozzle contacts the surface of the material smoothly.

- During long working periods, it is necessary to take periodic rest breaks, during which the equipment will also cool down.

- Do not apply excessive force to the power tool so that its disk does not jam and overload occurs.

- During work, it is necessary that the body is in a stable position.

- The depth of cut should not immediately be maximum when sawing massive parts: you need to cut the groove in several approaches.

- When cutting large pipes, the circular cut should also not be made straight through, so that the disk does not get pinched and the gas cutter is thrown off.

- You cannot hold a working unit over your head.

- Whenever possible, materials should be cut securely, or large workpieces should be positioned so that the cutting attachment does not become pinched.

- Discs cannot be used for grinding.

Working with metal and concrete has its own characteristics. First of all, various cutting attachments are used in the cutting process:

- concrete is sawed using steel discs with a diamond-coated cutting edge;

- Abrasive wheels are used to cut metal.

It should also be taken into account that working attachments can be designed only for cutting materials using a wet or dry method, or both at once. The purpose of cutting wheels is indicated on the labels affixed to their front side. Manufacturers indicate that for diamond discs, the direction of rotation is an important point: if it does not coincide with that indicated on the label, the diamond coating will wear out much faster. The remaining nuances of cutting concrete and metal should be considered separately.

Working with metal

Cutting metal does not require the use of such powerful gas cutters as when sawing concrete. Typically, gas powered tools up to 4200 W are used.

When working with metal, you should follow these recommendations.

- Hold the tool at a 90 degree angle to the surface of the material being cut while making a vertical cut.

- The protective cover must be tilted so that sparks fly forward (away from the worker).

- You must first touch the metal with a disk rotating at medium speeds, and only after creating a guide groove, cut in at maximum speed.

- To achieve a smooth, even cut, the tool must be moved in a leisurely, forward motion without unnecessary pressure.

- Thin metal pipes, sheets, rods can be sawed immediately with a vertical cut.

- Iron corners or I-beams must be cut in pieces, working especially carefully in places where structural elements touch at angles, because the slightest distortion will cause the disk to jam, followed by the gas cutter being pulled out of your hands.

- If the material is under tension, then first make a cut from the working side, and then from the opposite side to avoid pinching.

In the cutting area, the metal gets very hot (and sometimes melts), so you should not touch the cut area until it cools down, otherwise you can get a severe burn.

Concrete cutting

Gas cutters with a power of 4200 W and a blade speed of approximately 4700 rpm are designed for sawing concrete. Such characteristics are necessary to ensure high performance.

Concrete cutting is performed using two methods:

- dry;

- wet.

When sawing concrete, which is a mineral material, a lot of dust arises. The dry method does not involve supplying water to the cutting site. For this reason, when working with this method, the use of safety glasses with a respirator is required. Approximately every 30 seconds it is necessary to take breaks in operation to allow the disk to cool.

Gasoline tools designed only for dry work are cheaper than analogues with the possibility of wet cutting, but the process of sawing concrete with their help lasts much longer, accompanied by significant dust. Periodic watering of the cutting area with water helps to partially reduce the amount of dust. The dry sawing method is only suitable for small volumes of work.

The wet cutting method differs in that water enters the cutting area through tubes attached to the protective casing. It cools the disk and suppresses dust. The duration of the work process is significantly reduced due to the fact that frequent breaks are not required. Also, the presence of a water cooling system allows you to increase the service life of not only the cutting attachment, but also the gas cutter itself. The wet method is used for significant volumes of work.

When starting to saw concrete, you should consider the following.

- If the concrete structure exceeds 100 mm in thickness, then it is most likely reinforced, and this must be taken into account when choosing a suitable disc.

- To evaluate the performance of the gas cutter, it is recommended to first make a cut up to 1 cm deep. This will allow you to determine the approximate amount of time that will need to be spent on the work.

- The insertion will be simplified by attaching a wooden block along the cutting line (especially if the monolith is of significant strength), which will need to be removed after creating a groove of the required depth.

Regardless of the cutting method you choose, you must follow the general rules discussed above. Concrete is also often sawed with hand chain saws. They work like chainsaws.

Choice of gas cutter manufacturers

When purchasing a gas cutter, every buyer should pay attention to the kit with which the tool is sold, namely, what is included in it. The kit must be equipped with:

- A screwdriver for adjusting the carburetor;

- Angle and universal wrench.

The best option to purchase would be tools from well-known manufacturers, because they adhere to basic standards and rules. They also provide an extended warranty and service, so finding and replacing gas cutter spare parts will not be difficult.

Advantages and disadvantages compared to a gas burner

The petrol cutter is not very popular among specialists. Many people still use gas cutters. And there are a number of reasons for this. Let's compare the advantages and disadvantages of both technologies. Advantages of a petrol cutter:

- Mobility. The gasoline cutter is quite easy to carry. The compressed air container is smaller in size and weight than oxygen cylinders. Fuel is easy to get, it is available in any garage, or you can buy it at a gas station.

- Ability to work at low temperatures. According to manufacturers, a gas cutter with a spray operates at temperatures of -40 and below. The cutting torch does not work in the cold.

- Simplicity of design. A gas burner is not a super complex device. But a gasoline cutter is easier in any case. If you know how to solder, making repairs will not be difficult.

The disadvantages are no greater than the advantages. But they are more significant:

- Difficult to set up. The fuel supply constantly needs to be calibrated, and the injectors have to be cleaned periodically. A gasoline cutter cannot be used out of the box. Quality work requires practice and skill.

- The need to maintain pressure in the tank. It is unlikely that you will be able to work with a gas cutter for a long time. It is necessary to constantly maintain the pressure in the oxygen tank. The quality of the flame depends on the volume of air in the cylinder, and you have to constantly adapt to pressure changes, and therefore the power of the burner.

- Safety. Although oxygen cylinders for gas cutting are considered to be explosive, if used correctly, the risk of an accident is minimized. A gasoline cutter requires careful control and responsibility at all stages of work. Especially when it comes to models with an evaporator, where the fuel boils on the flame of an additional nozzle.

Rules of care and use

No matter how high-quality and expensive the instrument is, if it is not properly cared for, it will quickly become unusable. This is why you need to check every day:

- How tight is the drive belt?

- Is the throttle safe?

- Starter with its cable;

- Saw wheel with casing;

- Closing contacts;

- Tightening bolts and nuts.

If necessary, clean the areas around the air intake and pre-filter.

Every week you need to clean:

- Carburetor;

- Cylinder cooling fins, as well as flywheel;

- Spark plug.

Check and inspect:

- Return spring and starter;

- Handles;

- Main filter.

Every month you need to check:

- Connections and wires;

- Fuel supply hose and fuel filter;

- Clutch springs;

- Drive pulley and clutch drum for wear.

The inside of the fuel tank and the outside of the carburetor need to be cleaned.

Types of portable cutters

A portable gas cutter is a fairly simple design. The principle of operation is the creation of a directed jet of flame by mixing oxygen and flammable gas. The cutter is based on a cylinder and a burner that is attached to it. According to the type of fuel supply, portable cutters are divided into:

- Injection

- Injectorless.

The main advantage of injection-type cutters is their high combustion temperature. The main advantage of injection-free cutters is their high mobility and simplicity of design.

Injection portable cutters

- Combustible gas is supplied under high pressure through a twin tube

- Oxygen is supplied in the same way

- The gas mixed in a special chamber, without losing its initial speed, escapes from the nozzle

- Using an external source, or through a built-in piezoelectric element, a spark is supplied

The mobility of the injection burner is not high. The design of two cylinders is quite cumbersome. However, these burners are designed to be carried by one person.

Injectorless portable burners

A gas collet is one of the cheapest tools for gas welding. It consists of a gas cylinder with a capacity of up to 0.5 liters, to which a burner with a nozzle is attached through a collet connection. The advantages of the device are:

- Highest mobility. The entire structure weighs no more than 700 grams. No special containers or bags are needed for carrying.

- Versatility. In addition to their direct functions, such burners are used for heating car locks, as a blowtorch, etc.

- Ease of use. There is no need to fine-tune the fuel supply to the nozzle. To get started, just click the button with the piezoelectric element.

There are also quite a lot of disadvantages. The main ones include:

- The flame goes out easily. The injector-less design does not involve active oxygen supply. The strong flow of compressed propane creates an unstable jet of flame that is easy to knock down.

- High operating costs. Consumption is about 200 ml. gas per hour of work. Those. even the largest cylinder will be discharged after 2.5 hours of operation.

- Relatively low combustion temperature. Although mini-cutters heat up to 1300 degrees, they cannot compete with their injection counterparts. The gas exit velocity, as well as the efficiency of the mini-cutter, is lower.

Mini-burners, even similar in appearance, differ significantly both in flame quality and design solutions. For example, a mini gas cutter from KOVEA Fire-Z Torch is manufactured on a collet connector and has an operating temperature of up to 1500 degrees. And the HecatonTorch KT-2610 burner from the same company produces a flame of up to 2500 degrees.

Additionally, the Fire-Z Torch uses a collet connection for disposable cylinders, while the HecatonTorch uses a US thread. If you need a portable blowtorch with advanced functionality for the garage, it is better to purchase the first option. And if you consider the torch as a professional tool, it makes sense to overpay 1000 rubles and buy HecatonTorch with a US connection

Petrol cutter Stihl TS 420

In the class of semi-professional equipment, this model is considered the most convenient to use. It has a compact body, low weight (can be carried and operated with one hand) and reduced emissions (by 70%). The model also features a cutting abrasive disc - wear resistance and reliability. And the impressive power of the device maximizes its scope of application. The equipment is recommended for use in harsh operating conditions: increased loads, long-term continuous operation, cutting hard materials. Has standard equipment.

Advantages of Stihl TS 420 identified by consumers:

- ICE 2-mix. The gasoline unit at maximum loads shows excellent fuel economy - 20%. The peculiarity of the technology allows you to reduce costs.

- Air filter protection. The equipment uses a special cyclonic filter cleaning system, which simplifies the maintenance of the unit, increases the intervals between servicing and increases its service life by 45%.

- Ease of use. The unit can be used either manually or on a trolley. The kit with the gas cutter includes a set of keys for installation.

- Versatility. You can process granite and metal products/structures, concrete and asphalt in extreme conditions - rescue work, construction, dismantling of structures.

- High build quality. German technology has earned a reputation in the market for producing reliable and extremely safe equipment. This fact is confirmed by user reviews of the TS 420 gas cutter model.

- Disk protection. The manufacturer used magnesium disk protection.

- Ergonomic and balanced design. The correct location of adjustment buttons, handles, and gas tank caps ensure maximum comfort and safety in using the equipment.

- Excellent tool handling. Due to the balanced design, the unit is easy to operate, which guarantees precise and neat cuts.

- ElastoStart device. This is a trigger mechanism synchronized with the decompression valve and compensator. Working in tandem of these three components helps prevent oversaturation of the fuel mixture, which inevitably happens when the filter is significantly dirty.

- Anti-vibration mode. Ensures long-term operation of the operator with the device - hands do not get tired, preventing the development of occupational diseases.

- Belt tension system. A unique semi-automatic mechanism - unscrewing the proprietary clamping screws ensures automatic belt tension through a special spring assembly.

User-identified shortcomings of the Stihl TS 420:

- Difficulty replacing the filter. Many users note that the innovative filtration system does not provide for independent replacement of elements.

- Uncomfortable working with the unit on a trolley.

- The body is made of low quality materials.

A fairly large percentage of consumers noted the high build quality of the unit and the external elements of the housing that are unstable to mechanical loads. The equipment requires careful handling. Reviews also indicate the durability of the equipment - the service life without the need for repairs is (based on reviews) 1.5-2 years. There are some complaints regarding difficulties with servicing the machine. A small percentage of consumers indicate that equipment requires regular professional maintenance. According to other criteria, users called the unit powerful and functional equipment.

Video review of the Stihl TS 420 gas cutter:

Advantages and disadvantages

The special equipment market offers both models with an evaporator and spray-type gas cutters. However, there are a number of reasons to believe that a spray cutter is better. Namely:

- Spray cutters have up to 50% less weight compared to evaporative cutters, because there is no asbestos chamber and additional heater

- A sprayer is easier to maintain than an evaporator, because no need to clean the evaporation chamber

- The gasoline spray cutter heats up less. Due to the additional heater, the evaporative type cutter must be cooled during operation

- The evaporator is not suitable for operation at low temperatures due to the constant cooling of the vapor. (In winter, it is better to use a spray cutter)

- The atomizer, unlike the evaporator, is resistant to flame backlash.