The history of the creation of the first machine in the world

The history of the appearance and development of the lathe dates back to 650 BC. e. This is documented by an engraving found by archaeologists. It depicts people in tunics watching master Fyodor work on a foot-operated lathe. The part was fixed between 2 centers and driven by a lever.

The workpiece in such a machine rotated alternately several revolutions towards the tool, then back, away from it. The cutter was held in the hands. The cutting force was weak and the accuracy was low. On such a machine they could process:

- tree;

- horn;

- bone;

- non-ferrous metals;

- bronze

Historians have found jewelry made using similar equipment.

Reference! A lot of time was spent on making the simplest product; half of it was spent on reverse rotation. But compared to manual processing, the technology was highly productive and distinguished by high precision in creating a round surface.

First mentions

The first images of lathes were found in ancient Egypt. The beam drive mechanism is clearly visible on the frescoes. The string was wrapped around a part clamped in the center at one end and pulled onto the bow. The slave moved the device back and forth, rotating the wooden piece in one direction or the other. The master sits on the floor and guides the tool.

Over time, a longitudinal ruler appeared on Egyptian bow lathes. It had divisions and the cutter rested on it when working. Now it was possible to create relatively identical parts, for example, table legs and columns.

Over time, foot-operated lathes appeared. They worked like archers, but they could do without a slave. The elastic force of a living tree branch was used. One end of the rope wrapped around the part hung in a loop below, the other was tied to a branch on the tree. The master inserted his foot into the loop and pressed down. The part made several turns in one direction. Then he released the rope, the branch straightened and rotated the structure in the opposite direction.

In the drawing from 1400, a wooden machine is installed indoors and has movable heads for working with workpieces of different lengths. In 1518, the machine tool of Emperor Maximilian was made. It had metal centers and a movable rest that moved along guides. All body parts were covered with patterns imitating ancient towers and castles. The handles are made in the shape of warriors.

Reference! The first machines with continuous rotation in one direction are described in the Book of Solomon in 1615. The helper rotated the handle of a large wheel connected by a belt drive to a pulley on the machine. On such machines, not only the surface was processed, but also the ends of the part, and boring was done.

Scientists inventors, who invented?

Drawings of lathes and individual components developed by Leonardo da Vinci have survived to this day. But not a single unit was built according to them. Around 1570, Charles IV, as king of France, commissioned Jacques Besson to create a lathe for cutting threads. He installed a third headstock, which held the cutter and retracted it during reverse rotation.

Scientists and inventors of the lathe include:

- Andrey Konstantinovich Nartov, mechanic of Peter the Great, mechanized thread cutting.

- Alexey Suponini and Pavel Zakhava, Tula mechanics, improved the design of the caliper.

- The Frenchman J. Vaucanson created the prototype of a universal machine on a powerful frame with metal components.

- The Englishman D Ramedon designed 2 types of thread cutting machines.

- The French mechanic Senault created equipment for cutting screws.

- Mondsley built a universal lathe, which eventually became the basic model.

- D Clement installed the lead screw at the front of the bed and pulled it through the apron.

- D Vivort is the author of automatic cross feed.

- American Fitch designed and built a turret machine.

- K Vipil and T Sloan created automatic woodworking machines.

- HR Spencer built the first universal machine gun.

Henry Mondsley improved the caliper, automated thread cutting, and was the first to raise the issue of unifying some parts. He developed the main standard sizes and standardized the threads.

The Americans picked up Mondsley's idea, and soon began to produce standardized parts. This allowed them to launch conveyors, significantly increase labor productivity, reducing most of the workers.

Important!

Before the discovery of Nartov, a strip of paper equal in width to the pitch was wound onto the shaft for cutting threads. Then, with a sharp tool, a helix line was marked in the gap between the strips. After this, the threads were turned by hand using files.

The device of the first models

The first models that can be confidently called lathes were designs with a cable-hand drive and a machine described in 1671 by Cheruben. It had a foot drive and a crankshaft, thanks to which the rotation was in one direction. The step-pulley drive made it possible to change the rotation speed of the part.

With the advent of the water wheel, machines were switched to mechanical drive. A long shaft with a large number of pulleys stretched across the workshop. Each machine was connected to the drive shaft by a belt drive.

Control

After the introduction of Nartov's invention in 1712 - a self-propelled caliper, the problem of attaching and moving the tool was solved. Now the rotation of the part was turned on and the belt was thrown onto a pulley of the required diameter.

The longitudinal movement of the caliper was carried out from a screw connected to the drive. The feed pitch was controlled by a copying finger. He adjusted the pitch and feed ratio of the caliper. Then came the invention of Vaucanson and the caliper received a mechanical transverse transmission and at the same time could be controlled manually.

Since 1800, lathes have all modern components and control units. Torque is transmitted from the drive through a belt drive. The rigid dependence of longitudinal and transverse feeds on rotation speed is ensured by gearing. Handles for switching to different cutting modes appeared on the support.

Metal parts

The first metal parts on a lathe appeared on the model of Emperor Maximilian in 1518. These were rotating centers in which the workpiece was clamped. Nartov created a thread cutting machine in 1712. In it, torque was transmitted through gears and a screw shaft. All parts were iron.

The first all-metal lathe was made by Vaucanson in 1751. The French mechanic treated his invention as a tool and removed all decorative decorations, leaving only functional components and parts. His machine looked simple, had a massive cast-iron frame and could withstand heavy loads when processing metal.

Starting from this time, guides for the caliper and tailstock appeared on the frames. Machine tools began to be made from steel and cast iron parts. The models had all the components of modern turning equipment.

Position sensors

The first position sensors were copying fingers. They slid along the screw and set longitudinal and transverse movement. The ability to move the tailstock made it possible to install parts of different lengths and even machine wide workpieces from the end.

When the movement of the caliper and tailstock began to occur along the guides, rulers with divisions appeared that determined the position of the cutter. The production of precise carvings gave rise to the creation of limbs. Now it was possible to confidently say how much the caliper and tool holder would move per full revolution, and at what angle the knob should be turned to move by 1 mm.

Drive mechanisms

The lathe drive has gone through several stages of evolution:

- manual and foot with return rotation;

- manual rotation in one direction;

- movement from a water wheel;

- steam drive;

- electric motor

From 1837 to 1842, Robert Davidson designed electric drives, including for lathes. The asynchronous three-phase motor was invented by Dolivo-Dobrovolsky in 1891. But only after the 1917 revolution they began to install it on lathes and other equipment.

Dimensions and weight

The first machines processed parts with a diameter of up to 200 mm and a length of up to 1200 mm. The weight of the wooden equipment was 50–100 kg. The simplest tabletop lathes weigh 70–120 kg when assembled. They process metal workpieces weighing 12–35 kg. Industrial turning equipment weighs from 1.2 tons. Metal parts with a diameter of 200 mm and a length of 800–3000 mm are installed on it.

Metal parts

The main task of the machine tool inventors was to increase the rigidity of the units. The beginning of technical re-equipment was the use of metal centers that clamp the workpiece. Later, gear transmissions made of steel parts were introduced.

Metal parts made it possible to create screw cutting machines. The rigidity was already sufficient for processing soft metals. Individual components were gradually improved:

- workpiece holder, later called the main unit - spindle;

- the conical stops were equipped with adjustable mechanisms to change the position along the length;

- working on a lathe became easier with the invention of the metal tool holder, but constant chip removal was required to increase productivity;

- The cast iron bed increased the rigidity of the structure, which made it possible to process parts of considerable length.

With the introduction of metal components, it becomes more difficult to unwind the workpiece. The inventors thought about creating a full-fledged drive, wanting to eliminate manual labor. The transmission system helped to carry out the plan. For the first time, a steam engine was adapted to rotate workpieces. It was preceded by a water engine.

The uniform movement of the cutting tool was carried out by a worm gear using a handle. This resulted in a cleaner surface of the part. Replaceable blocks made it possible to implement universal work on the lathe. Mechanized designs have been refined over centuries. But to this day, the operating principle of the units is based on the first inventions.

What features did early models have?

Early models had a common drive for all. Rotation was transmitted through belt drives. The number of revolutions of the workpiece could not be set accurately. The longitudinal and transverse movement of the caliper depended on the number of shaft revolutions and was regulated by rearranging the gears in the feed box. The spindle rotation speed was set by throwing the belt onto a pulley of the required diameter.

The accuracy of the transverse and longitudinal feed of the tool was 0.1 mm - the error of manual movement along the dial. It was not possible to automate the machining process on early models and produce large batches of parts with high accuracy of fit.

The lathe has a long history. It reflects the technical level of development of peoples, their desire to simplify the manufacture of parts and create beautiful things of the correct shape.

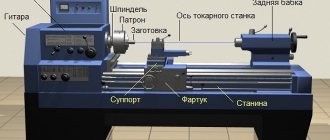

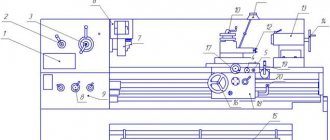

Main nodes

Lathes are ideal for machining 3D parts using rotary cutting. An overview of a modern machine contains the parameters and characteristics of the main components:

- The bed is the main loaded element, the frame of the machine. They are made from durable and hard alloys; perlite is mainly used.

- A support is an island for mounting rotating tool heads or static tools.

- Spindle - acts as a workpiece holder. The main powerful rotation unit.

- Additional components: ball screws, sliding axes, lubrication mechanisms, coolant supply, air intakes from the working area, coolers.

A modern lathe contains drive systems consisting of complex control electronics and a motor, usually a synchronous one. Additional options allow you to remove chips from the working area, measure the tool, and supply coolant under pressure directly to the cutting area. The mechanics of the machine are selected individually for production tasks, and the cost of the equipment depends on this.

The support contains units for placing bearings, which are mounted on a ball screw (ball screw). Elements for contact with the sliding guides are also mounted on it. Lubricant in modern machines is supplied automatically, and its level in the tank is controlled.

In the first lathes, a person moved the tool and chose the direction of its movement. In modern models, all manipulations are carried out by the controller. It took several centuries to invent such a knot. Electronics have greatly expanded processing capabilities.

Control

Recently, CNC lathes for metal - with numerical control - have become widespread. The controller controls the cutting process, monitors the position of the axes, and calculates the movement according to the specified parameters. Several cutting stages are stored in memory, right up to the finished part.

CNC lathes for metal can have process visualization, which helps to check the written program before the tool begins to move. The entire cut can be seen virtually and code errors can be corrected in time. Modern electronics control the axle load. The latest versions of the software allow you to identify a broken tool.

The technique for monitoring broken plates on a holder is based on comparing the graph of axle loads during normal operation and when the emergency threshold is exceeded. Tracking occurs in the program. Information for analysis is supplied to the controller by a drive system or a power sensor with the ability to digitize values.