Copper is a metal that has low activity and for this reason is often used for decorative purposes. Copper is used to make jewelry, home decoration, art, furniture and much more. The metal surface oxidizes under the influence of oxygen, but due to its low activity, this may take decades. The consequence of this reaction is patina - a surface film that most often has a greenish tint. Patina prevents the metal from being damaged, so it is important to know how to blacken copper at home.

Copper before and after blackening

There are two types of reactions that lead to the formation of films on the surface of copper:

- oxidation - the process of formation of oxides and oxides, elements containing oxygen;

- patination - a film is formed under the influence of sulfur and chlorine.

If you dip a copper piece in a solution designed to create a patina on its surface, it will immediately be transformed and, while sparkling new, will look like an antique. There are two main types of methods by which this effect is achieved, some are based on improvised means, while others require chemical solutions. They can be dangerous, so you need to work in compliance with all safety regulations. The room must have a fume hood.

Before you start blackening, you need to prepare the metal: clean, degrease, rinse and dry. For drying, do not use the towel wiping method. This can lead to fabric residues on the products, water in the recesses of the relief, and damage to the decorative part. You can use sawdust for this purpose.

How to change the color of metal?

How to change the color of metal to make it look like antique? Since time immemorial, craftsmen have used the methods of oxidation, bluing and patination.

Various methods are used to carry out the work:

- Metal processing over an open fire . This method is one of the most popular and ancient among jewelers. For a more beautiful and even color, it is recommended to calcinate the wire over an open fire in advance, even before creating the decoration. This is due to the fact that the heating rate of the metal may differ in different areas, therefore, there is a danger of burning it out and making it brittle. In addition, if the original working metal is varnished, the fire will remove it and pre-prepare the wire for work.

- Treating metal with a sulfur liver creates a patination effect. Typically a proportion of 50 ml of water/1 drop of product is used. It is recommended to use water at 20-23 degrees, close to room temperature, since with hotter water the patination reaction occurs faster, and the resulting patina becomes less stable and will begin to wear off when it touches clothing, skin, or the surface of the box.

- Ammonia solution (in the first case, exclusively its vapors are used). To process, place the decoration in a jar with a lid, into which pour 1 ml of ammonia of 5% concentration. The color of the metal changes relatively quickly; it can be adjusted by observing the changes over time.

- Ammonia solution (in the second case it is used together with water). For processing, the product is sprayed with water or placed directly into the solution for 1 second, and then it is sent to a container where ammonia vapor is formed. Under the influence of water and ammonia in steam, the color of the patina becomes close to blue.

Oxidation in ammonia vapor

A 10% ammonia solution will help give copper a brown, olive or even bluish tint. If you are trying to achieve a result with blue flecks, place the product in a solution of table salt before processing. In this case, oxidation occurs quickly, in ten or fifteen minutes. For a more noble and deep olive color, the item should be kept for six to eight hours in an airtight container with a solution poured into a small bowl.

Copper coin before and after patination

What does it mean to “patina” a product?

What does “patina” mean in terminology? This means coating metal products with a special coating that will give the item an antique appearance. Metal products can be patinated using chemical compounds, solutions, vapors, after contact with which the product changes color and becomes special.

The film that forms on the product after the patination process is protective and, when used, protects the metal from environmental influences and external aggressive conditions.

Various natural shades of patina on copper products are known. Green, olive, blue, brown, reddish, close to black. These colors appear on copper and copper-containing alloys - brass and bronze. The patina that forms naturally on metal looks beautiful and even has the epithet “noble”.

Aesthetic and practical effects prompted jewelers and decorators to invent ways to create artificial patina as a way of aging a product. There are two ways to patina metal: random and stable.

With a stable method, the result of patination can be accurately calculated. For example, if you use liver sulfur, the coating will turn out to be brown in color; the degree of its saturation can be adjusted by exposure time.

With a random method of applying patina, the result cannot be predicted, since it will depend on how the metal behaves in reaction to certain agents. But this method always produces an interesting and artistically valuable result.

There are a variety of agents and reagents available for plaque formation. Let's consider the most popular ones for patination of copper and brass.

Patina on aluminum coins

Aluminum was often used in coinage in the 20th century. Basically, small denominations were made from it (for example, Hungarian fillers). In the GDR, the entire line of coins, with the exception of the heavy brass 20 pfennig used in the machines, was aluminum. The oxidation process quickly deprives the aluminum coin of its stamp shine. It becomes dull and inconspicuous, acquiring a matte gray coating. And if the protruding parts of the relief are still mechanically cleaned during circulation, then the coin field very soon begins to look dirty.

Patination of brass: means and methods

When patination of brass with ammonia vapor, it should be taken into account that this metal is more fragile, and prolonged exposure can trigger the process of destruction. It is not recommended to leave the product for longer than 20-25 minutes, otherwise the wire will be broken.

Brass after chemical patination gives amazing colors: from yellow and red to purple and black. Note that this variety can be formed on one product.

Using patination with sodium triosulfate (hyposulfite) and nitric acid, you can achieve gray shades in aging brass. The process goes as follows.

Half a liter of hot water is poured into the container, 25-30 grams of hyposulfite and 1-2 teaspoons of nitric acid are added. The solution acquires a yellow-green tint and a sulfuric odor. Place a brass product in this liquid for 15 minutes and observe the oxidation process. After obtaining the initial effect, use tweezers to remove the product from the solution and wash it with hot water.

The clean product should be wiped with sand and dipped into the chemical composition again. Repeated processing gives the final color and streaks. After rinsing again with hot water, the product is cleaned with pumice powder, which is washed off after wiping. Patinated brass is dried in a layer of sawdust, after which it is treated with velvet cloth, machine oil and varnished.

Thus, any new product made of copper, brass, bronze can be given a noble antique look using the patination method. Patina not only creates an additional color scheme for the decoration, but also protects the metal from adverse external influences, thereby increasing its service life.

Patina on gold coins

Pure gold is a metal that is practically not subject to oxidation. This section appeared only because pure gold was not used for everyday coins of past centuries because of its softness. To give gold strength, it was alloyed with a small amount of other metals (usually silver and copper, less often nickel or molybdenum). The five-ruble note of Nicholas II, taken as an example, is 900-carat gold. The alloying additive to it is still the same copper. Under certain conditions, copper can appear on the surface, and even such a small amount will cause the coin to darken in fragments (as in the illustration above).

More often on gold you can find rust stains, caused by the same oxidation process. During minting, chipped microparticles of the stamp may become pressed into the surface of the gold, and after a few years the coin will become unsightly. In Russian numismatics, the most famous are the rusty gold “Victory Bearers”. After the scandal with SPMD gold coins, Russian minting technology was improved, and such defects began to occur much less frequently. Both rust and patina always reduce the value of gold coins.

Visual results of pattinating copper, brass and nickel silver

Pattinating and oxidation

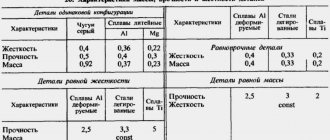

Change in color of metals in an aqueous solution of liver sulfur

Change in color of metals in ammonia vapor

Patina on zinc coins

Zinc patinated coins have the most deplorable appearance. Shown above is a selection of small denominations from Denmark, the Netherlands and Luxembourg from the First and Second World Wars. In difficult times, metal becomes a strategic raw material, so coins have to be made from the cheapest material. Patina causes zinc coins to darken to such an extent that it is sometimes difficult to make out the designs and inscriptions on them. It is not surprising that after economic recovery, all these countries abandoned zinc coins, choosing other metals and alloys.

About the use of sulfur ointment

Judging by the reviews, home craftsmen often have the opportunity to work with copper rings and other small items - pendants and earrings. In such cases, experts recommend blackening copper with sulfur ointment. According to many craftsmen, the ointment can be applied to the product and washed off after some time. However, in this case, the result is often unpredictable: you have to wait a long time for the color to change, and it also happens that darkening may not occur. In connection with this fact, many home craftsmen practice blackening with vapors of sulfur ointment. Patination is carried out as follows:

- To work you will need a glass container. A regular liter jar works well. It must be weighted down by placing a stone on the bottom. Metal objects should not be used, as the metal will react with sulfur, which is undesirable.

- Using a plastic or glass rod, scoop out ointment in the range of 1 to 1.5 cm. and place at the bottom of the container.

- Make a loop from the scaffolding, into which you then need to thread the patinated workpiece. The product should not touch the sulfur, but remain in a suspended position.

- Close the glass container tightly.

- Pour water into a large enamel pan, place a stand on the bottom on which the jar with the copper product will stand. It is not difficult to make a stand from a tin lid from a tea can. To prevent bubbles formed during boiling from raising the jar, it is advisable to equip the lid with several holes.

- Place the pan on a gas or electric stove. When the water boils, the heat can be reduced.

The copper blackening process can last for 2-3 hours. During work, you need to add water to the pan from time to time. In order to provide the product with an uneven patina, experts recommend shaking the jar periodically.

At the end, the copper jewelry being processed is removed from the loop, cooled and thoroughly washed in running water. The liter jar used should be tightly closed with a lid, since with the remaining ointment it will be possible to carry out about seven more patinations in the future.

About coloring with current

Judging by the reviews of home craftsmen, copper-ammonia solutions and sulfur alkalis are mainly used for blackening. According to experts, blackening copper using the electrolytic method is quite effective. Anodic treatment is carried out in an alkaline soda solution, the concentration of which is 80/about or more. A voltage of 2.5 V with a current density of 01-10 per dm is supplied to the bath with a copper product. sq. Electrolysis lasts for 10-20 minutes.

The temperature in the container must be at least 50 degrees. The process can be improved by adding ammonium molybdate to the bath. This soda alkali does not precipitate and is a catalyst for oxidation processes. The amount of ammonium should be within 0.1 a-3/o. Electrolysis lasts no more than 5 minutes. The oxide film is formed in two stages. If the workpiece is removed from the bath in the first phase, you can see that its surface is covered with a steel-gray dense sediment that has a metallic tint. No gas is released. If the product is continued to be treated with current, the sediment turns from gray to black.

About the sun and tea, which in the workshop can be used not as tea

Let's go another way. With a slight movement of the hand we make a decorative nameplate from the strap.

Next you need to thread the elastic. The elastic band is only available in white and visually it doesn’t fit at all. No problem, we’ll tint it with improvised means. Well, tea, for example. What is? Earl Gray? Wonderful, it will do!

A few stitches and the case is almost like new. At a minimum, it serves the function and even the aesthetics are more or less preserved. Additionally, there is a preventive treatment of all surfaces with a mixture of Vaseline and wax: for additional protection from external influences and at least some protection from further drying out.

And let the little thing continue to live, work and remind you of the sun and warmth, which, unfortunately, are so little around now.

About homemade blackening solution

Judging by the reviews, many home craftsmen quite successfully blacken copper in vinegar, iodized salt and ammonia. Before patination begins, the copper product is washed in warm water and dried. You should work with gloves. The room must be thoroughly ventilated. Since harmful fumes and splashes are generated during blackening, the master will need protective glasses. To work you need to acquire the following ingredients:

- iodized salt (125 ml);

- pure ammonia (375 ml);

- vinegar (0.5 l.).

These substances are commercially available. The home craftsman can only go to the pharmacy or garden store to get them.

A simple life hack if the sensor on your phone is broken, but you really want to surf your favorite website

I remember there used to be a tradition on pikabu to post Friday’s “My”, and they also told me that life hacks work well everywhere. Here you go, a simple Friday life hack from me!

First in video format, and for those who prefer text, the text version is below.

Now the text version.

If your phone has stopped responding to touches on it, but you really want to surf your favorite website, then don’t be discouraged, there is a simple life hack!

Take the iDrive joystick from BMW, in my case from the F-Series. You probably have one of these lying around too.

Next we need to pair this joystick with our phone. To do this, take a Stm32f105 microcontroller or similar, install a printed circuit board for it and write the firmware. This microcontroller has only 64 legs and soldering it to the board does not cause any problems. We add the Can module, voltage stabilizer and USB connector. There are many lessons on programming the STM32, the code is intuitive and does not require additional explanation.

The result is a board that listens to the iDrive joystick and transmits commands to the phone via USB. It connects to the phone via an OTG cable.

After connecting, a cursor appears on the tablet screen, as if a mouse is connected to it. The joystick recognizes touches with 1 or 2 fingers, so both mouse control and 2-finger scrolling are available.

A method of blackening copper to obtain selective coatings. Based on Bari Alibasov.

Handicrafts

32.2K posts 47.8K subscribers

Community Rules

Trading, price discussion, links to sales pages, and author’s contacts in comments are prohibited in the community. Information about materials and tools in text form is required.

1. Be polite, try to write correctly.

2. Use clear and beautiful photographs in your publications.

3. The author of a post with the tag [my] can leave a link to his profile, group or channel on other sources, provided that the links ( active and inactive

) do not lead to direct sales. No more than four links are allowed and only at the end of the post (clause 8.5 of the basic rules).

-advertising/spam links;

-links leading to stores indicating the cost of the product/service;

-links leading to calls, purchases, sales, subscriptions, reposts, voting and the like.

(violation of the basic rules of the site, clause 8.1 and clause 8.2).

When following a link, the presence of active (clickable)

links leading to the above in paragraph 3, the content of such keywords as “product”, “sell”, “in stock”, “to order”, etc.

3.1 Posting the author’s contacts (by the author himself or other users) in comments is prohibited and subject to deletion (clauses 9.1 and 9.3 of the basic rules).

4. It is mandatory for authors to have the technical characteristics of the product in publications (materials, techniques, author’s techniques, sizes, time costs, etc.) in text

form.

Also tag your work with the tag “Crafts with Process”

or

"Handicraft without process"

.

5. Post-video, post-photo without text description are transferred to the general feed. Even if the video shows a detailed manufacturing process, provide a brief description for those who do not have the opportunity/desire to watch the video.

The administration reserves the right to decide to what extent the description complies with clause 5.

6. Posts with violations are transferred to the general feed without warning.

For repeated violations, the author receives a ban.

The author can post a new publication in the community without allowing previously received comments.

It seems that this was the most useful thing in Alibasov’s life