End mill sharpening angles

To properly sharpen an end mill, you first need to study the geometry of the teeth. They are backed and pointed.

Image No. 1: pointed (a) and backed (b) teeth

The back surfaces of the backed teeth are made in Archimedean spirals. Sharpening of such cutters occurs along the front surfaces.

In pointed teeth, parts of the rear surfaces are planes. Most often, such cutters are sharpened along the rear surfaces. The front ones are treated if necessary.

Let's talk about the geometry of the teeth in detail. Each of them has 4 important parameters.

Image #2: tooth geometry

Surfaces and sharpening angles of end mills.

- Site f. It is this that undergoes the main wear and is sharpened when processing the back surface. The size of the pad directly affects the friction force between the tool and the workpiece. Therefore, the width must be maintained within a certain range.

- Auxiliary clearance angle α1. The cutters are sharpened along it at certain levels of wear and a strong increase in the size of the pads f.

- Main relief angle α. This is the angle between the tangent to the flank surface at the point in question on the main cutting edge and the tangent to the circle of rotation of that point. The purpose of this angle is to reduce friction between the tool and the workpiece.

- Main rake angle γ. Located between the axial plane and the tangent to the front surface. For cutters designed for processing viscous materials, the size of this angle varies from 15 to 20°. Mills for processing steels have an angle of 0 to 5°.

Note! The teeth are either straight or helical. The amount of inclination is characterized by the angle λ. It is located between the axis and the deployed screw edges.

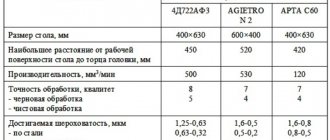

Specifications

When choosing machines for sharpening cutters, you should pay special attention to the technical characteristics. The main indicators include:

- Operating voltage. Many models operate on a standard 220 Volt network. Options with a higher power rating operate at 380 Volts.

- Power consumption is also an important indicator. It can vary in the range from 200 to 5,000 watts.

- Spindle rotation speed without load. This figure can vary from 900 to 3,000 rpm.

- The accuracy with which cutters can be sharpened. The accuracy indicator often depends on the design features of the model.

- Abrasive feed rate.

- Feed type: mechanical and electric. Some models have an electric drive, others mechanical. The electric version significantly makes the design more expensive, while the mechanical version requires certain skills from the master.

- Range of sharpening angle. The angle can be called the most important indicator. The cutting edge is formed by two planes located at a certain angle.

- The presence of special water baths that allow you to cool the abrasive material while the machine is operating. An increase in the temperature of the abrasive material can lead to significant heating of the cutting edge, causing it to change its performance.

- Availability of ventilation. During sharpening, the metal layer is removed from the cutters, and the abrasive material also flies off. This moment determines whether the workplace is clogged, and the ventilation system will help keep the equipment clean.

- Noise indicator during operation. The drive and motor make noise when running. High noise levels make work much more difficult.

- Availability of a protective casing. During sharpening, abrasive chips and metal fly off, which can get into your eyes. It is the protective casing that protects the craftsman from chips and abrasive crumbs.

According to the layout, machines for sharpening cutters are also available in floor-mounted versions. The traditional drive involves the use of an electric motor and a V-belt drive.

Manual sharpening of end mortises designed for processing tough materials

To sharpen an end mill designed for processing tough materials (such as wood), you will need the following tools, equipment and materials.

- Table or workbench.

- Diamond beam.

- Soap solution.

- Solvent.

The end mill is sharpened according to the following scheme.

- Soak the diamond bar in soapy water and secure it to the edge of the table.

- Remove the guide bearing (if equipped) from the cutter.

- Clean the cutter with solvent.

- Sharpen all cutters.

Image No. 3: cutter sharpening diagram

Please note the following features.

- Before sharpening, be sure to make sure that the diamond stone has the correct shape.

- To achieve uniform sharpening of the cutters, make the same number of movements with approximately the same pressure.

- If you don't have a diamond wheel, you can use sandpaper to sharpen it. Glue it to a solid piece of wood or strip of steel.

Machines for sharpening end mills for metal

To sharpen end mills for metal, special machines are used that provide translational and rotational movement of the tool being processed.

Image #4: Precision end mill sharpening machine

Let's talk about the features of sharpening end and side teeth.

Grinding of end teeth

To sharpen the end teeth, the cutters are installed horizontally. If the machine does not have a graduated ring specially designed for this, horizontality is checked using a square.

During the sharpening process, the operator moves the edge of the abrasive wheel along the edge of the tooth. The sharpening angle is adjusted either by tilting the spindle with the cutter, or by moving the wheel vertically.

Photo #1: sharpening the end mill teeth

Sharpening side teeth

The side teeth are sharpened according to the following scheme.

- The cutter is fixed in a collet.

- The copier needle is set to its highest position, where the tip touches the outer edge of the groove.

- The abrasive wheel moves to a position where the outer edge coincides with the needle.

- The machine starts.

- Using the direct feed handle, the circle is brought to the cutter (before sparking begins).

- The thickness of the metal layer to be removed is set (25–50 µm).

- The tooth is sharpened to its full length. To do this, the spindle with the cutter is retracted until the tool comes off the needle.

- The passage is repeated.

Photo #2: sharpening the side teeth of the end mill

Next, the remaining teeth are sharpened using the same pattern.

Machine Applications

A sharpening machine is a device with which you can sharpen cutting tools: cutters for wood, for metal. The range of sharpening machines varies from large industrial models to versions that can be used in home workshops. The machine can be used for sharpening cutters for wood or metal.

The machine is often used in established industrial production, when there are many cutters available and they are often used. If only burrs have formed on the cutting edge due to incorrect processing modes, then the problem can be corrected using a whetstone or file.

Selection of devices (abrasive wheels) for sharpening end mills on machines

To sharpen end mills, machines are most often equipped with devices made from the following materials.

- Diamond and green silicon carbide. Wheels made from these materials are suitable for sharpening carbide tools.

- Elbor. This is a superhard material based on the cubic sphalerite modification of boron nitrite. CBN wheels are used for sharpening cutters made of high-speed steels with increased productivity.

- Electrocorundum. It is a chemically resistant solid material based on aluminum oxide. Electrocorundum wheels are used for sharpening cutters made of tool and high-speed steels of normal productivity.

- We list the characteristics of devices that must be taken into account when choosing.

- Heat resistance. With increasing temperature, the microhardness of abrasive materials decreases. Therefore, sharpening end mills on machines necessarily requires the use of coolant. Plain water will not work. Its use will lead to corrosion of machine elements. Soap and various additional additives (soda ash, sodium silicate, potassium nitrite, etc.) are added to the water. For the heat resistance of materials used to make abrasive wheels, see the table below.

Image No. 5: heat resistance of materials used for the manufacture of abrasive wheels

- Grain. It is selected depending on the required class of cleanliness of the surface to be sharpened. The higher the grit, the better the performance of the wheels. This increases the service life of the devices.

- Form. To sharpen the rake corners of end mills, disc or flat jigs are used. The back corners are treated with cup and disc models.

Image No. 6: Shapes of grinding wheels used for sharpening end mills

Another important parameter for sharpening end mills is the rotation speed of the wheels. Carbide tools are processed at high speeds, and cutters made from high-speed and tool steels are processed at lower speeds.

Classification

Conventionally, the following classification can be made:

- The universal machine is suitable for sharpening not only cutters, but also other cutting tools.

- A specialized machine is used to process only one type of tool, for example, cutters.

The universal machine is equipped with normal and special devices that are used to secure and install the tool, additional measuring mechanisms that allow you to maintain the sharpening angle of the cutters.

Universal sharpening machine with accessories for sharpening cutters

Specialized sharpening machine for sharpening end and cylindrical cutters

Sharpening quality control

After sharpening, you need to ensure its quality. There are various technologies and devices for this.

- You can make sure there are no marks, cracks or chips using a magnifying glass. When monitoring the quality of sharpening carbide cutters, kerosene is additionally used. If there are cracks, it protrudes. This makes it easier to detect defects.

- Pendulum and special protractors are used to measure front and rear angles.

Image No. 7: measurement technology with a pendulum inclinometer

Note! It is not recommended to leave nicks on the surfaces of the teeth. Milling cutters with defects quickly fail. When sharpening, strive to ensure that the surfaces are perfectly smooth.

Sharpening technology

There are a number of parameters that affect the sharpening angles of cutters, primarily the shape of the tooth: sharpened or backed. Characteristics of each cutter:

- front angle, formed by the tangent to the front surface and the plane of the axis;

- rear angle, formed by a tangent to the rear surface and a tangent to the circle of rotation of the reference point;

- the size of the area that is processed when sharpening along the back surface;

- the angle of inclination of the teeth relative to the central axis.

The sharpening angles of cutters for metal depend on the material and brand of the product; they are indicated in special reference books and GOSTs. When processing workpieces made of high-alloy steel, they are practically zero or negative. Failure to comply with the recommended parameters will lead to rapid destruction of the cutting edge without the possibility of restoration.

During the sharpening process, the area of the teeth decreases, so it is extremely important to perform all operations in the same way for everyone. Distortions will lead to a change in the shape of the cut and strong beating, which is critical when working with viscous materials - you can simply break the cutter. After sharpening, a check is necessary: visual inspection for cracks, chips and deformations using a magnifying glass; for angles, a deviation of 1 degree is acceptable, determined by a pendulum inclinometer.

Using the machine

You can restore the cutting properties of almost any tool. Sharpening of carbide cutters is carried out only on machines. For example, for the end, the first stage will be circular grinding to remove possible chips and defects of the cutting edges; after this operation, the diameter will change depending on the degree of wear of the surfaces. Then, for the pointed side teeth, sharpening is done along the back. For this, a special needle-shaped device is used, which ensures a uniform sharpening angle throughout the entire length of the tooth during translational movement along the abrasive. By adjusting its position, you can change the clearance angle, and this is important for reducing friction and increasing service life. Sharpening of the end teeth begins with their installation horizontally, the wheel is fed at the required angle. Using the machine, it is easy to update tools for a manual router.

The efficiency and quality of processing will be much higher when the machine is equipped with a liquid cooling system - when overheated, the cutting edges become covered with microcracks, which cause chips during operation, which greatly reduces the service life.

Also, with increasing temperature, the hardness of abrasive materials decreases, which increases the processing time of workpieces and provokes rapid wear of expensive wheels. For sharpening, abrasive wheels of cup and disc shapes are used to grind the back corners of the teeth; for the front corners, flat ones can be used.

The abrasives used are:

- electrocorundum (well suited for tool steel);

- CBN (standard and high-performance high-speed steel);

- diamond and green silicon carbide (for carbide cutters).

When processing hard alloys on a wheel, the surface is heated unevenly, microcracks form, leading to deformation of the teeth. For finishing, you can use cast iron whetstone, use boron carbide as an abrasive, and it can also be used to quickly eliminate irregularities without removing the cutter.

Industrial machines are expensive, but for a home workshop you can make one yourself by combining an electric sharpener and a feed mechanism for the cutter being sharpened. It is impossible to make a universal device in this way, but it is quite suitable for performing several operations with acceptable quality.

Using sharpening wheels

With experience, you can sharpen cutters of simple shapes on a conventional sharpener, but you should understand that a large number of curved surfaces and the need to comply with angular parameters can negate all efforts. It is necessary to work at low speeds, otherwise there is a risk of overheating the cutting edges - the ejection cutter.

Using improvised means

All that is required is the presence of abrasive materials of different grain sizes. During work, the bars must be moistened with soapy water, rinsed and dried when finished. Sharpening cutters for wood with your own hands is possible, but it requires a lot of practice - the main difficulty lies in uniform processing of all the teeth, for this it is necessary to control the pressure and the number of movements. All costs are covered by the word “free”, and the cost of the sharpened items is low if the attempt is unsuccessful. The quality of such work is usually not very high, but within the framework of a home workshop it is acceptable.

How to achieve high quality end mill sharpening

The rules listed below are aimed at complying with the established standards of permissible runout and obtaining tools without defects.

- The total runout of the machine spindle, mandrel and fixture must be less than the permissible runout of the cutter being sharpened.

- It is necessary to ensure accurate seating of the grinding wheel. Otherwise, vibrations will not only lead to sharpening defects, but will also accelerate wear of the abrasive device.

- Feed mechanisms should not jam.

- The fixed cutter must be moved as smoothly as possible.

- Machine spindles must have sufficient vibration resistance.

- They need to be well lubricated to ensure they rotate as easily as possible.

- Axial and radial runout should not exceed 0.01 mm.

Finishing of end mills

If, after sharpening, microcracks are found on the surfaces of the end mill, fine-tuning is applied. Its main purpose is to remove the defective layer. The second task is to improve the cleanliness of surfaces. In addition, during finishing, blockages of the tooth surfaces are eliminated.

Such operations are carried out on sharpening and finishing machines with cast iron discs. With their rotation speeds of 1 to 1.5 m/sec, the best results are achieved. For finishing, boron carbide paste is most often used. Grit size - from 170 to 230.

Photo No. 3: sharpening machine

Diamond wheels can also be used for finishing. When using them, productivity increases by 1.5–2 times.

Design Features

Despite the fact that there are quite a few models of machines, their design is somewhat similar. Features of the typical design include:

- The main part of the body is represented by an electric motor.

- If it is necessary to change the rotation speed, a V-belt drive can be included in the design.

- An abrasive wheel is fixed to the shaft.

- The stand is necessary to secure the tool being processed.

- There is a block with a button to turn the equipment on or off, as well as elements for adjusting operating modes.

Other elements may also be present.

Advantages of use

Many people decide whether it is worth spending money and purchasing special sharpening machines. Their use can be defined as follows:

- The process is significantly accelerated: the high speed of rotation of the circle speeds up the process of removing the required layer of metal.

- A more accurate result can be achieved. The sharpening angles have clear limits; without the use of machines it is almost impossible to maintain them.

- The quality of the work performed is much higher.

- Even an untrained master can do the job, since the work is almost completely automated.

The machines are used in workshops for medium and large-scale production. Only in this case is their purchase justified.

Disadvantages of use

You can also highlight some disadvantages of the application:

- The electric drive consumes quite a lot of energy. With constant use, the cost of paying for electricity will be very high.

- The cost of the machines is very high. At the same time, we note that the price depends both on the main performance indicators and on which company is the manufacturer.

- It is necessary to carry out constant maintenance of the equipment to keep it in proper condition.

- You need to find a place to install the equipment and equip it correctly. Some models require rigid mounting.

Similar disadvantages can be identified when considering sharpening machines.

In conclusion, we note that there are quite a few types of cutters, each with certain qualities that are worth considering. That is why you should purchase not a specialized, but a universal version of the sharpening machine.