A surface grinding machine is used to process the surface of metal products. The main purpose is the finishing and finishing of flat surfaces of products using diamond or abrasive wheels. Product blanks can be mounted on a magnetic plate or table mirror. The method of serving, longitudinal or circular, will depend on the shape of the table.

A flat metal surface can be polished with high precision using such a device. The degree of roughness corresponds to GOST and ranges from 0.63 to 0.16 micrometers after processing. After processing on such equipment, the surface cleanliness will correspond to class 9-10. For precision work and obtaining high-quality products, it is better to purchase a machine made at an enterprise than to assemble it yourself from scrap materials. A self-assembled device may take longer to process parts and will have greater accuracy.

General information

To process shaped surfaces, installation of additional equipment is required. Modern surface grinding machines are capable of processing even cone-shaped elements. All general purpose devices can be divided into categories:

- Manual devices.

- Semi-automatic devices that support active control of the operation of a desktop device.

Modern industry allows you to purchase various versions of devices, which will allow you to process parts of various shapes. To process the periphery of a circle, you will need a machine with a support, a horizontal spindle and a rectangular table.

Such a device is ideal for grinding the boundaries of the end surfaces indicated by the device casing. Typically, such devices are purchased for tool shops.

Universal machines with a rectangular table can have a horizontal and vertical spindle They are not characterized by the highest grinding accuracy, but they are characterized by high productivity due to the installed powerful electric motors, large grinding wheels and increased rigidity design. This is precisely the main difference from machines with a cross support.

high quality of work

An increasing number of manufacturing companies and individuals give preference to processing metal products, since metal processing services are provided at a high quality level. Among the main positive factors of cooperation are:

- Seven years of experience in high-quality professional work;

- Offering a diverse range of services related to professional metalworking, that is, one enterprise performs all the necessary technological operations from cylindrical grinding of metal products to the assembly of pipe structures;

- In the process of providing services, exclusively high-tech modern equipment is used, which ensures high accuracy parameters;

- There is an overhead crane with a lifting capacity exceeding 10 tons. This makes it possible to quickly load large metal parts and structures. This is also a great opportunity to save time for a large number of clients;

- The ideal quality of the work performed is confirmed by a large number of positive reviews.

Grinding Techniques

When working on a surface grinding device, the following techniques can be distinguished:

- Multi-pass processing. This technique requires fixing the element on the surface. The speed of its movement during processing reaches 45 meters per minute. The processing method is reduced to repeatedly moving the product under the circle until the allowance is completely removed. In this case, the machine performs the last moves without feed or with a small vertical feed.

- Single pass processing. Used for machines with round tables. With this method, the machine passes vertically to its entire depth in one go. As a result, the entire allowance from the part is removed in one revolution. Devices with three heads allow you to remove large allowances with maximum grinding precision. Such devices are used mainly in mass production.

- Double-sided processing. This technology involves grinding two ends of a part at the same time. With this method, more than one pass of the product will be required to completely remove the allowance. The essence of the method is linear or circular feeding of the part. Due to the rotation of the tool, metal is cut. The periphery of the circle should be used to process products with medium hardness. With the end processing method, productivity will be higher than with the peripheral method.

Aluminum polishing

Polishing aluminum is not the most common task. Aluminum is often painted or not treated at all because it is used in technical products.

But those who have experienced polishing it know that it is a rather capricious material that is difficult to polish.

As in polishing any other material, the most difficult thing is polishing the planes - here you can see all the defects and flaws in the processing (a round surface forgives many flaws).

We decided to describe in detail the technology that will allow you to polish large surfaces of aluminum.

Primary type of workpiece.

Before us is an already processed aluminum profile, 100 mm wide. There were welds on it at one point and they were removed using a Cibo RAF .

Now the surface needs to be leveled (made completely flat) and brought to the same roughness, all large defects and scratches removed.

Grinding large defects, leveling the plane.

In the first step we must remove a large amount of metal, for this we need a powerful angle grinder.

To level the plane, it is convenient to use a soft support plate art. 50099 (it “holds” the plane perfectly) and the most economical Velcro circles with aluminum oxide from Deerfos P120 .

Now our surface is smooth and has the same roughness.

Next, we must reduce the risks on the profile surface to make it easier for us to further process the part.

For this we use the same tool and Velcro circles Deerfos P220 .

Reducing surface roughness with Velcro circles P220.

Now we can move on to more delicate surface treatment using an orbital sander.

Reducing roughness using OSM

Processing flat surfaces using an angle grinder has undeniable advantages over traditional grinding using an angle grinder:

- Compliance with surface geometry, without plane distortion.

- Absolute uniformity of processing.

- Easy control of processing due to moderate aggressiveness.

Reducing surface roughness using Bosch OShM and P220 wheels.

Since this processing method is less aggressive, we will start with the same grain size that we finished the previous stage with - P220.

Then we will reduce the surface roughness using OSH and using Deerfos Velcro circles :

This alternation of steps will allow us to quickly and easily make the surface absolutely uniform and prepare it well for polishing.

You can use fewer steps, but then you will spend more time on each step and it will be more difficult to control the quality of the sanding.

The product after grinding with P800 wheels.

Now our product is prepared for the last, most important stage.

Polishing.

To obtain the highest quality surface, we will carry out polishing in two stages: preliminary and finishing.

Pre-polishing of aluminum.

This combination of felt and paste allows you to remove all risks from preliminary grinding of the surface and prepare it for final polishing.

Final polishing will be performed with the same tool and the softest flannel polishing wheels assembled on a special adapter (or use a ready-made set).

One of the best pastes for finishing polishing of any metals is 3M Marine Polishing Paste 09019 .

Final polishing of aluminum with flannel wheels (2500 rpm)

The combination of flannel wheels with finishing paste removes the smallest defects from the surface from pre-polishing, makes it uniform and gives maximum gloss.

This is what we end up with.

Detailed video of aluminum polishing:

Methods for grinding with the periphery of a wheel

Existing grinding methods:

- Deep method. This method allows you to remove significant allowance from parts with each stroke. In this case, the minimum longitudinal feed speed is noted. With this method, rapid abrasion of the wheel is observed due to the weight of removal on the abrasives located at the end.

- Continuous feed method. This method is used for processing products whose height is greater than their width, and the surface being processed has edges. This method is characterized by low operating accuracy and the absence of transverse feed. The master has to constantly adjust the machine due to uneven wear of the tool.

- Method with transverse intermittent feed. This method allows for high-quality processing of parts. This method is used for surface grinding machines with a horizontal spindle and a round table. This technique is characterized by high accuracy. The height of the grinding tool should be higher compared to the cross feed.

Use of electropolishing

Polishing aluminum can be done in another way. In this case, it is possible to obtain a sparkling and smooth surface, and cleaning is characterized by high quality. Electrolytes for such work in most cases contain sulfuric and phosphoric acid; the remaining components will depend on the material.

Electrolytes allow you to achieve shine after completion of work. For the process, the temperature must be lower than in the case described above; the temperature limit will be from 60 to 90 °C.

Polishing must be carried out for 5 minutes, while the current density can be 10-50 A/dm². The polishing process involves the use of lead cathodes, but there are other alloys that require the use of stainless steel. Polishing requires the use of duralumin pendants, as well as electrolyte baths with polyethylene, lead or fluoroplastic treatment. You need to prepare alkaline electrolytes, they will cost less.

The process parameters will be influenced by the composition of the electrolyte, the temperature limit can vary from 40 to 95 °C, as for the exposure, it lasts from 3 to 6 minutes, while the current density at the anode is a limit of 3-20 A/dm². When choosing cathodes, you should prefer nickel-plated ones.

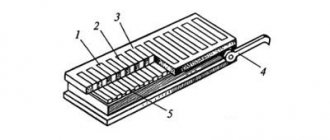

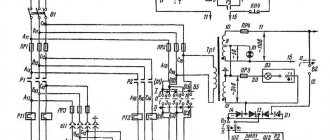

Design features of the equipment

The machine is a device with a cast frame mounted on a stand with a bed cast in the form of a solid tool. Vertical guides are located on the sides of the opening in the center of the frame. For hydraulic or manual movement of the grinding head there is a moving carriage with guides. This arrangement allows you to increase the rigidity of the unit.

Kinematic short chains ensure stable feeding. On the device they look like a rolling nut, a screw and guides. The vertical movement of the grinding headstock and carriage is ensured by a special automatic device, which is mounted on the front wall of the bed.

Rapid vertical movement is ensured by a similar mechanism located behind the machine. Among the main elements of a surface grinding machine are: guard blocks, locking mechanisms, rebound devices (in case of failure of the grinding head). All these devices allow you to work with the machine at the proper level of safety.

Basic machine parameters

When purchasing a metal grinding machine, you should pay attention to the following parameters:

- Table size.

- The rotation speed of the grinding wheel and its diameter.

- Grinding method: with the periphery or the end of the wheel.

- Machine power.

- Supply voltage.

- Work table size.

- Diameter of grinding tool.

- Nominal speed.

- Dimensions.

- Machine weight.

- Price.

An assessment of these parameters is necessary depending on the purpose of the device (for personal use or industrial work) and the required amount of processing of parts.

Materials for the manufacture of abrasives

The grinding material must remain sharp when interacting with metal and not become dull. The quality of the work performed and the duration of operation of the wheel depend on this. When choosing grinding wheels, you should pay attention to such product characteristics as hardness, impact resistance, chipping resistance, and sharpness.

There are several common materials used in the manufacture of abrasive wheels. The most common of these is aluminum oxide - a compound of aluminum and oxygen, which is valued for its hardness, fire resistance and anti-friction properties. Wheels made of this material are actively used in the processing of steel and its alloys, cast iron products, wrought iron, bronze and other non-ferrous metals. When choosing such a grinding wheel, you should pay attention to the type of work in which its use will be most effective. Each product is marked with a special code of letters and numbers that indicate the type of processing.

Zirconia alumina wheels use some amount of zirconium oxide. Therefore, such a tool is used only for rough machining of a wide range of aluminum parts.

Silicon carbide is mostly used in grinding soft aluminum, gray cast iron, brass, rubber and stone products.

Ceramic aluminum oxide is one of the latest advancements in the grinding wheel industry. The production of this abrasive component is carried out through gel sintering. This makes it possible to use it for high-precision grinding of small particles, difficult-to-cut metal components.

Machine repair and modernization

During operation and production of parts put into production, all mechanisms begin to wear out over time . Parts are replaced after the service life of each specific element has expired. This attitude towards equipment increases the accuracy of work and personnel safety. Machines are subject to major overhaul after twenty years of operation.

The manufacturer provides a service life warranty for each element of the machine, but depending on the workload of the equipment, replacement may be required earlier. Modernization of equipment makes it possible to increase the number of parts produced.

Using a polisher

A polishing machine is a very convenient tool for giving aluminum its original shine. To do this, you can use a 1000 polishing wheel, which is wetted with water. Use a sponge or rag to apply water to the area to be treated. Next, the polishing machine is turned on at 1400 rpm. At this speed, the spray will scatter 1 m around.

The surface of the aluminum will begin to heat up, the liquid will evaporate. You must be prepared for the circle to become clogged with aluminum “porridge”. Therefore, the machine should be stopped every minute to rinse the abrasive wheel with a wet sponge under running water. To do this, some craftsmen use a regular spray bottle.

The “porridge” should also be removed from the part. You will get a mirror shine if you additionally use felt. This stage is one of the most important. 80% of the final result will depend on it. The felt should protrude 10 mm beyond the base; the circle should be moistened by spraying it with a spray bottle. The part is wetted with a damp sponge. The polishing paste used is coarse; it should be applied to the part, not to the wheel.

How to make a grinding machine yourself

For home use, you can make the machine yourself if you have the available parts. The grinder is the most common model for home use. Its structure and assembly method are extremely simple. For assembly you will need the following parts:

- The frame is made of thick metal corners.

- Engine.

- Rollers in the amount of 4 pieces.

- Springs - 2 pieces.

- Sanding tape.

The inconvenience of using this device for permanent use is the constant stretching of the tape. To regulate the tension of the tape, install springs and use the handle to adjust their length. The handle also serves as a lifting bar for one roller.

Installing crossbars together with such a device allows you to replace the tape less frequently. If the rollers are made of titanium or durable steel, then they will not require replacement. The roller bushings are secured to the frame with strong bolts until they are stationary. The rotating part of the roller is made according to the bearing principle.

Such a machine in your home arsenal will allow you to process metal and wood products. When assembling the machine yourself, special attention should be paid to the engine power. The motor power from the washing machine is enough to process wood. This device can be used to sharpen and polish home tools. To process products that require high precision grinding, it is better to purchase a factory-made machine.

Specifics of using surface grinding machines in modern conditions

In modern conditions, in production and in everyday life, there are countless effective technological processes for creating both parts of the required surface quality, size, shape, and for creating workpieces.

Today, all modern industrial enterprises, as a rule, use machine tools for this purpose. Today, grinding on a surface grinding machine is not only one of the frequently used methods of work, it is also a guarantee of the result of accurate dimensions of parts.

The advantage of using a surface grinding machine is, first of all, the minimum amount of working time spent on fastening and installation.

So, a modern surface grinding machine is a metal-cutting unit that uses an abrasive to process the surfaces of metal products.

A surface grinding machine is usually used for such types of work as:

— cutting of materials;

— peeling of workpieces;

— high-precision surface treatment of parts;

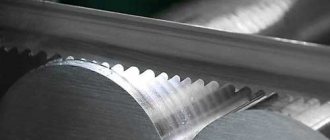

— finishing of various threads;

— cleaning of gears, etc.

It should be noted that a specific feature of these units is the finishing of parts; therefore, fine-tuning the shapes of parts is impossible on this machine.