The welding shop is considered, perhaps, one of the most unfavorable places for human work due to the fact that during the technological process a huge amount of harmful substances is released. Welding work provokes the saturation of the surrounding air with fluoride compounds, ozone oxides, nitrogen oxides and carbon oxides, which provoke the development of dangerous (so-called “occupational”) diseases and are harmful to the environment. That is why a well-designed and balanced welding shop ventilation system is a priority.

The key tasks of the ventilation system are the following:

- Minimizing the concentration of harmful substances that are released during welding operations through the use of effective local suction;

- Ensuring recommended microclimatic indicators, in accordance with the “Sanitary Rules for Welding, Surfacing and Cutting of Metals” No. 1009-73.

- Elimination of chemical emissions and emissions that have already spread beyond the premises through general ventilation;

- Ensuring a sufficient flow of fresh air into the welding shop in order to reduce the maximum permissible concentration of harmful impurities and hazardous substances.

Ventilation of the welding station

Calculation - online calculator and basic formulas

Calculations of the speed and quality of air exchange in welding shops are based on several standard formulas approved by designers and state-level architects. The results obtained after their application comply with sanitary requirements in the field of labor protection. Inmik specialists are guided by them in their work, but approach each project individually.

The calculation stage and its results are regulated by GOST 12.2.003-86. It contains a list of basic rules for organizing ventilation. Basic requirements:

- Only standalone installation is allowed,

- recirculation of air flows and masses in the welding shop is unacceptable,

- Thermostats are installed at the supply air input.

At the initial stage of calculations, a team of Inmik surveyors and analysts goes to the site, who collect complete information about the workshop - determine its actual dimensions, get acquainted with the design documentation of the structure, study the features, intensity of operation, and the technologies used.

The calculations will be based on the volume of air exchange, the amount of mass that needs to be removed from the room per hour. The figure will depend on what method of welding or cutting metals is practiced in the workshop. Legislative acts indicate clear parameters for the rate of exchange of air masses. If manual welding is used, then at least 4500 m3 must be removed from the room per hour. For automatic welding, the figure is lower - 2 thousand m3/hour, and if the main technological process involves the use of flux-cored wire - 5400 m3/hour.

The most accurate method for calculating the amount of exhaust and intake air among designers is the so-called table of sanitary rules. It is based on several factual indicators - classification of technological operations, welding materials and equipment. The table results are adjusted by our specialists using the calculation system and formulas for a specific room or welding shop.

The primary formula for calculating the installation is taken from the legislative act SNiP 2.04.05-91 (Heating, air conditioning, air ventilation. Design standards). It is based on a previously calculated quantitative indicator of the air exchange rate, the level of harmful substances in the atmosphere of the room and outside it, obtained experimentally using special equipment, and the concentration of chemical compounds harmful to humans permitted by law.

The welding shop can have not only workplaces, but also administrative, sanitary premises, and rest rooms. For such compartments, local (spot) ventilation is also calculated. If air inlet and outlet points are not created in the premises, then harmful substances will penetrate there, accumulate and stagnate, harming the health of workshop employees. We will take into account all the nuances of the functionality of your enterprise or workshop when developing ventilation for them.

Requirements for ventilation of a welding shop (SNIP II-33-75)

According to the standards developed and set forth in SNIP II-33-75, the following requirements are imposed on the ventilation of the welding station/shop, which must be strictly observed in order to avoid injury and poisoning.

The flow rate at which the air moves when installing local ventilation should be in the range of 0.8-2.1 meters/sec;

If the consumption of welding materials is more than 0.21 g/h, mandatory installation of general ventilation is required. If this indicator is lower, you can get by with a local air exchange system;

The permissible air velocity in the area of welding varies from 0.4 to 1 meter/sec;

The direction of the fresh air flow is strictly for welding;

If the welding machine is used in closed tanks, or the intensity of connection work is increased, the inflow is supplied to the worker’s mask, and the temperature of the supplied air masses should not be higher than +19C;

It is mandatory to install general ventilation in the cabinet for storing the gas cylinder.

Release of pollutants from metal welding

Welding method and brand of welding material Pollutant emission, g/kg of welding material Other pollutants welding aerosol manganese compounds chromium fluoride hydrogen oxides nitrogen oxides carbon oxide name quantity Manual arc welding of steels with electrodes UONI-13/5518.60.97—0.93—fluorides 2.6 UONI-13/657.5 1, 41—1.17——fluorides 0.8ANO-46.00.69——————ANO-616.31.95——————ANO-1122.40.87——————EA- 606/1111,00,680,60,41,31,4——M33-III40———————TsT-157,90,550,351,61——nickel oxides0.39Manual arc welding of cast ironTsCh-413,80,43—1, 87—vanadium0.54Manual arc welding of copperSHCHZCh-114.70.47—1.65—copper4.42Tungsten under helium20—————tungsten0.08copper2.1СрМ-0.75 (wire) Manual welding of aluminum17.10.44—— —copper15.4ОЗА-138.1—————aluminum oxide20 aerosolWireEP-24512.40.54—0.36—iron oxides11.5PP-106, PP-108120.7——0.8—iron oxides0.7WireSV-08G2S9 ,70.50.02—14iron oxides7.48SV-Kh19N9F2SZ70.420.03——14iron oxides0.04SV-10Kh20N7ST80.450.03—————SV-16Kh16N25M61521——nickel oxides—EP-24512.40.61— ——3.2——SV-O8KhGN2MT6.5—0.03—0.811 titanium oxides0.4copper11WireMNZh-KG5-1-02-0.2180.3————nickel oxides0.8KMTs8.80.6————copper6WireD- 2010.90.09————aluminum oxides 7.6AMTS22.10.62——2.45——20AMG-6T500.25—0.33——8.5 Aluminum 10———0.9———Titanium 14.7 —————titanium oxides 5 Non-consumable electrodes 61—————aluminum oxides 28 OZA-2/ak, OZA-138.5—————— 20 Welding steel with fluxes OSB-450.090.03—0.20.006—other fluorides 0.36 FC-2 , FC-6, FC-70.090.01—0.050.005—silicon compounds 0.03 FC-11, FC-120.090.05—0.02———0.05AN-220.120.01—0.02————AN-26 , AN-30, AN-420,080.05—0.03————AN-60, AN-640,090.02——————AN-348A0.10.03—0.20.006—other fluorides 0.16ANK- 300.260.12—0.018——silicon compounds 0.05ZhS-4505.80.142—0.18—22.4——K-10.060.023—0.15—0.5——K-84.90.13—17.8— —K-111.30.089—0.140.6———Types of welding shop ventilation systems. Exhaust ventilation

One of the most important points that receive increased attention when organizing ventilation in the workshop is the construction of high-quality devices for the local removal of all harmful substances released during the welding process. A high-quality hood for a welding station is not just about caring for the health of the employee, but also reducing harm to the environment.

The better the ventilation of the welding table is organized and the welding area is well fenced off, the fewer harmful substances will enter the workshop atmosphere. In addition, the required welding hood power is reduced.

In practice, local suction is capable of catching and absorbing up to 2/3 of the volume of all toxic substances emitted; to remove the remaining third, the general ventilation system of the workshop is used.

*IMPORTANT! The ventilation of the welding station (SNIP II-33-75) must be equipped with powerful exhaust systems, based on the power distribution according to the following scheme: 25% are directed to the upper tier of the production workshop, 75% to the lower.

Local suction

Installation design

Inmik has its own design department, staffed by highly qualified and experienced employees. They not only prepare basic documentation, but also monitor compliance with the technical specifications by the installation team, advise the customer, and conduct training for personnel who will service the workshop ventilation system. Inmik design engineers constantly analyze innovations in the field of ventilation for all types of objects and successfully implement innovations.

Above the place where welding work is performed, the concentration of harmful substances is highest. One of the main elements of the air exchange system in a workshop where metal elements are connected by welding is lifting and rotating devices. They are installed at every workplace. Design begins with determining their number and calculating the power of each point.

Then the paths along which the pipelines for pumping and supplying air will be laid are schematized. The channel should not create obstacles, interfere with enterprise employees, or pose a threat to life in the event of emergency situations. It is imperative to take into account that the number of bends in the air ducts in the system should be minimal. At this same stage, the so-called laying of materials occurs - what and in what quantity the installation team will need to form the ventilation system.

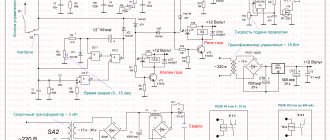

After developing a diagram of air exhaust and intake paths, design engineers begin selecting equipment to service the installation. This list includes motors, fans with and without electric drive, air intake ducts, filters, thermostats, flow distributors, local systems that will be used to complete lifting and rotating devices at each workplace.

Employees of the design department calculate the compatibility of pipelines and channels with the selected equipment and try to achieve the optimal price-quality ratio. They understand that the performance of the system and its durability directly depend on how responsibly they approach their work.

In addition to technical data about the object and its functionality, designers take into account the climatic features of the area where it is located. The duration of the warm and cold seasons, temperature conditions mean a lot when organizing ventilation systems for industrial premises. The power of thermostats, the frequency of their activation, and the adjustment scale of the equipment depend on them. We design systems that can be controlled, reducing the costs of their maintenance and service. After installation and commissioning, we train the workshop staff and are ready to provide consulting support throughout the entire operation of the ventilation system.

Under no circumstances should you create an air exchange installation in a welding shop on your own. She will not cope with the assigned tasks. The level of concentration of harmful substances in the air will exceed the indicators established by law, which will affect the health of workers and will threaten the decommissioning of the premises for violation of sanitary and hygienic standards.

General ventilation

Equipping working welding stations with a local removal system is effective only when it comes to stationary tables. If there are no permanent posts and shop workers have to constantly move/perform work on mobile welding tables, the local exhaust system simply becomes ineffective. In such situations, it becomes relevant to install a general ventilation system with an air exchange rate of up to 10 units.

When choosing the optimal general exchange scheme, all important points are taken into account, including the exit of convective flows to the top of the production room. Convective currents can, if necessary, be enhanced by directed supply jets or directed by these jets to the air intake panels.

Taking into account the fact that these flows are not particularly stable and can be disturbed by the movement of aeration air masses or cooled inflows, difficulties may arise in the fight for clean air. And if we add to this the fact that the process of welding metals is accompanied by a large emission of dust, the only way out lies in installing a mechanical general ventilation system of the supply and exhaust type with the option of mandatory heating of the supply air in cold seasons.

General ventilation

Our works

We have experience of successful cooperation with industrial enterprises on the basis of which welding shops operate. We created and installed ventilation at the Naro-Fominsk production of metal structures, and we worked not at a separate facility, but at the entire complex.

We collaborated with the Balashikha metalworking plant, the Podolsk cable production enterprise and other enterprises working with metals. All air exchange systems designed and installed by us function and cope with the tasks assigned to them. If you also need our help, call or come to us in person.

Category: workshop ventilation

Supply ventilation: features of air flow supply

When installing a ventilation system in a welding shop, air supply can be carried out both vertically and horizontally. Let's look at each of them in more detail.

With horizontal air exchange, the ventilation system is installed so that it covers the entire area of the production room. The formation of stagnation of air masses is absolutely not allowed, and the air exchange rate must exceed at least 0.1 m/sec. This is the optimal solution for small welding rooms, or for workshops where the distance between the exhaust and supply does not exceed 100 meters.

With vertical air exchange, the ventilation system is organized by installing powerful fans in the basement so that they provide a powerful flow of air through the ventilation shafts. The outlets are mounted in the floor and covered with special grilles, the diameter of the cells does not exceed 5 centimeters. The speed of air movement at the exit from the fans should be within 4.5 m/sec and about 0.1 m/sec at the entrance to the room. Exhaust fans in this scheme are usually installed on the roof. Such a system works very effectively in industrial premises of welding shops with a large area, thanks to the ability to very quickly and effectively reduce the concentration of harmful substances to the parameters required by GOSTs and SNiPs.

Go to the ventilation equipment catalog

Go

DIY hood installation

In everyday life, welding work is most often carried out in the garage. Therefore, a garage system is slightly different from the ventilation system in a welding shop. It includes an umbrella with an exhaust fan, which is installed above the welding table. The exhaust vent is installed in the wall opposite the gate, and if this is not possible, it is brought out onto the roof. The air duct is made of corrugated pipe.

When installing a homemade hood, you should provide a supply duct in order to carry out welding with the garage door closed. The effectiveness of the system is tested experimentally. Low-power 220-volt motors are used as a stimulus. As practice has shown, a home-made hood allows you to ventilate a room to a level acceptable for work.

Regulatory mechanism for local ventilation

It is necessary to periodically clean fans and filters from accumulated dirt.

According to sanitary standards N 1009-73, a number of requirements are put forward for local ventilation devices:

- local suction must be installed at stationary and non-stationary welding stations;

- when manual welding, the workplace must be supplemented with rotary-lifting panels, the bottom of which should be no higher than 350 mm from the welding machine;

- when welding medium-sized products, it is necessary to install a fume hood, which is a type of local suction;

- the air speed when using manual welding and a device powered by carbon dioxide must be more than 0.5 m/s and 0.3 m/s when welding in inert gases;

- fume hoods must localize up to 90% of harmful substances from air masses, other types of local ventilation - up to 75%;

- 10-25% of harmful components in the air must be eliminated using a general ventilation system.