Updated: 02/21/2021 13:15:09

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Laser machines are used for engraving and cutting cardboard, plastic, leather, plywood, wood, metal and other materials. This allows you to create serial products or use it as a hobby. Depending on this, it is important to know the basic parameters for choosing a laser cutting machine, with which our experts will help. We have also prepared a list of the best models that customers liked in reviews and impressed professionals with their characteristics.

Scope of application and operating principle

Laser cutting machines are often used in enterprises that produce advertising materials. They are also used in such areas as construction, mechanical engineering, aircraft manufacturing, shipbuilding, and light industry.

This is not to say that this equipment is too difficult to operate. First, the necessary drawing of the workpiece is made manually. The base is then mounted on the laser engraving and cutting machine table. The necessary work is carried out by a special laser head. In this case, there is no mechanical contact between the tool itself and the workpiece.

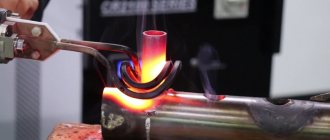

The beam, which is heated to a high temperature, produces cutting. At the cutting site, the metal will melt and be removed by a stream of gas.

Types of laser heads

Various tools are used in such equipment. For laser cutting, 3 types of heads are used:

- Solid state. This head is heated using a high-voltage discharge lamp. They operate either in pulsed or continuous generation mode.

- With diode pumping. This is new equipment. Discharge lamps are not used here. Instead there are LEDs. These are more expensive mechanisms, but safer and easier to use. There are no high voltage elements in machines with such heads.

- CO2 lasers. This is the most modern equipment. It is also used for cutting aluminum.

Main functions

The table of modern laser equipment is usually end-to-end. On such tables you can process workpieces of various lengths. Modern machine designs can be supplemented with various elements to increase functionality.

It can be:

- lifting table, thanks to which you can increase the height along the Z axis;

- rotating mechanisms that are used for processing cylindrical products;

- honeycomb surfaces designed for working with small workpieces.

The laser engraving machine can be automated thanks to the use of CNC. Such mechanisms will be expensive, but they will be more productive and convenient to use.

Using CNC machines, errors in engraving or cutting can be minimized. We can say that they are simply impossible to allow, since control occurs thanks to special software specially developed for such equipment. Difficulties can arise only due to errors made during the development of sketches.

There is no need to perform any manual work on such equipment. The operator’s main task is to monitor the smooth operation of the equipment and monitor the quality of the workpieces produced. Such machines are usually equipped with remote control.

Lens

An important point in machine tool building: the sum of the components of a laser machine does not always guarantee a good result.

Let's take the example of a car manufacturer. If we replace some elements on a Lada: engine, wheels, gearbox, then we still won’t get a BMW. In order to create something complex and of high quality, you need competence.

Some Russian manufacturers make their own optics and calculate optical channels. For what?

In the movement system, the final unit is the lens; it consists of several glasses. Each glass is a source of reflection, i.e., light passing through the glass is reflected back to a small percentage (the better the glass is made, the less).

The lens has some curvature, and when reflected, the light can be focused. If the situation is unsuccessful, a reverse glare appears, which will focus on the mirror.

Example of damaged mirrors

Example of damaged mirrors

Photo of the scanning head lens with cloudiness

The distance between the lens and the mirror should focus either before or after the mirror. If you screw in a lens that does not fit a given optical path and expect everything to work perfectly, there is a huge risk of getting into an unpleasant situation where some expensive element is damaged.

Machine tools for metal

For cutting and engraving from this raw material, models with CO2 tools are often used. Laser equipment can be used for stainless steel, steel, brass, copper, aluminum. Such units have high beam power.

The modern market is filled with equipment of this type, designed for cutting metal sheets whose thickness is 2 cm. Each type of metal has its own cutting and engraving technology. For example, equipment for cutting stainless steel has units with which parts are treated with nitric acid. This substance can protect metal from fire and oxide.

For copper, machines with powerful working tools are used. Laser cutting on such equipment is done at low speeds. To work with copper, solid-state heads are used.

Processing steel or brass on a laser machine is the simplest. These metals do not require additional devices. Setting up the equipment is quite simple.

Emitter

In fact, this is the heart of the laser machine. Today we will look at fiber lasers for marking and engraving. Why they?

Fiber lasers with a wavelength of 1.06 microns are the best tools for metal processing. The high absorption coefficient, minimal focusing spot and the ability to transport radiation along a fiber to any point, characteristic of fiber lasers, make it possible to leave other types of emitters behind when processing any metals. As you know, metals are the basis of industry.

The main advantages of fiber lasers:

- High radiation quality (M2<1.2)

- The operating life of fiber lasers is more than 100,000 hours

- Ease of use (Flexible optical path)

- High power characteristics

- High efficiency (up to 40%)

Let us tell you a brief background on fiber lasers: at the end of 1998, the leading Soviet and American specialist in the field of laser physics and technology, Valentin Pavlovich Gapontsev, founded a well-known company that literally took over our planet. This company developed and introduced fiber laser technology into industry, occupying 75% of the global market.

Valentin Pavlovich Gapontsev

Despite the fact that fiber lasers are the main product in industry, there are not many manufacturers of this technology, because, firstly, it is a very expensive pleasure, and secondly, it is difficult to compete with the company created by Gapontsev. Several leading countries in the machine tool cluster can afford this luxury, one of them is China.

But it is important to take into account one point: the best modern Chinese fiber lasers are an analogue of Russian-made sources ten years ago. Of course, not all Chinese manufacturers focus on Russia; there are representatives who offer lower prices for lasers, but, perhaps, in the field of lasers, Chinese manufacturers have nothing to offer other than low prices.

Advantages:

The life of diodes with single emitters from Gapontsev’s company exceeds 100,000 hours, which is several times longer than the recorded service life of options with diode matrices.

- Good laser radiation is considered to have a Gaussian energy distribution, when most of the energy is concentrated in the center. This distribution makes it possible to obtain the minimum dimensions of the processing zone. At Gapontsev’s company, the radiation source makes it possible to produce a small spot at the output; accordingly, many photons are focused in one place, thereby increasing the power density of the emitter.

- Gapontsev's emitters provide an output power of up to 100,000 W and the best beam quality at low energy costs.

Let's consider the segment of inexpensive pulsed lasers up to 100 W:

All inexpensive emitters have limitations on the number of changeable radiation parameters:

- The frequency range is smaller and worse: for Russian manufacturers, the frequency is adjustable from 1.5 kHz to 2 MHz, there are no restrictions associated with intermediate values, due to which you can select the purity range smoothly, unlike the Chinese emitter. In the Chinese emitter, the frequency is adjustable from 20 kHz to 80 kHz, and they do not have intermediate values (20, 25, 30, etc.), which is why the range of frequency selection is smaller, and accordingly, greater discreteness appears.

- On Chinese machines, the pulse duration is often not adjusted.

- Chinese emitters lack such an important thing as protection against back radiation. Let us explain the importance of this point in more detail: if the beam is not in focus, then this entire process is reflected and goes backward into the optical system, which leads to the destruction of the lenses.

For example, when processing copper (after all, it reflects best), there is a risk of burning the laser emitter, and repairs in some service center are impossible - only the manufacturer can fix the problem.

As a result, it turns out that the capabilities of a machine with a Chinese laser emitter are initially limited:

- There is no possibility to process reflective materials. Well-polished items made of silver or copper cannot be engraved if you have a machine with a low-quality emitter and a bad lens.

The beginning of the letters is “eaten” because the emitter does not have enough energy to treat the surface evenly.Color laser engraving is no longer required, because this process requires adjustment to the product, namely stable radiation with very fine settings. The Chinese emitter will distort the color, for example, purple will have a green tint due to unstable scanning, nonlinear movement of the beam and different pulses (must go one to one).

Example of color distortion

- The quality of photo markings is maximally distorted.

Poor example of photo markings - no detail, lines burned.

Moving system

Now we will look at fiber lasers with a movement system such as a scanner . Why she? Flatbed fiber lasers have not found a wide market, so most fiber marking and engraving systems move the beam by deflecting scanner mirrors.

At the moment, the scanner type is the fastest option for moving the beam, but the difficulty of this system is that everything in optics is distorted, and you need to properly configure the equipment so that the movement of the beam in it is linear and accurate (a deviation of 20 microns is already considered critical) .

Here we come to the quality of the components. Almost all countries are able to produce mirrors and movement systems - unlike creating fiber lasers, this is not so difficult. But the production of mirrors is a very important element of laser machine manufacturing, and the quality of this element greatly affects the operation of the machine. A coating is applied to the surface of the scanner, which is important in the process of reflecting radiation from the mirror. If the coating is damaged or the mirror is uneven, then the wavefront of the laser radiation is distorted, thereby the pulse arrives “smeared,” which affects the quality of the effect on the material.

Chinese systems often have mirrors of different quality, due to which you can end up in a situation where the coating on the laser machine comes off and the scanner stops performing its functions. After all, if a mirror has a poor-quality coating, then it cannot effectively reflect the beam, as a result of which part of the radiation begins to be absorbed, which leads to the destruction of the reflective surface of the mirror, thereby making it impossible to use this element in the machine for its intended purpose.

If mirrors with poor coating are placed in a system with a power of more than 30 W, then they can no longer withstand, collect a “cumulative effect” and stop functioning after a few months. And here it is difficult to prove that the owner of the machine is innocent; it is easier for the manufacturer to refer to his carelessness (“scratched”, “misused”, “dirty room” - the exploiter will still be the worst). There are also responsible manufacturers, but it is important to understand them, and this is not easy, because there are hundreds of them.

Machine cost

The price of such equipment is influenced by many factors. The cost of a small model ranges from 90 to 100 thousand rubles. A more powerful machine with various accessories will be more expensive - from 200 to 500 thousand rubles. and higher.

Modern laser machines are reliable, high quality and productive. They are convenient to use for medium and small workshops. The price for purchasing equipment of this kind can be quite high, but due to the savings in material and speed of work, the payback of the machine will be quick.

Content

- 1. History

- 2 Process

- 3 Types

- 4 Methods 4.1 Evaporation cutting

- 4.2 Melt and blow

- 4.3 Thermal stress cracking

- 4.4 Hidden cutting of silicon wafers

- 4.5 Reaction cutting

- 6.1 Pulsating