Aluminum is a non-ferrous metal with low density. The surface of the alloy is silver-white, matte. It is very light and soft, due to which it has a low melting point - approximately 650 degrees. It has found its application in all spheres of human life. It is actively used in the food industry, including for the manufacture of various tableware. It ranks second in production among all metals in the world, after iron.

Aluminum is susceptible to the aggressive effects of acids. Able to dissolve in concentrated alkali solutions. To avoid such phenomena, all aluminum products are covered with protective films. In a crushed dusty state, being in an oxygen environment, it supports active combustion.

Food grade aluminum. Brands according to GOST

Aluminum grades are produced and designated in accordance with GOST 1583-93 and GOST 4784-97.

The documents define interstate standards for the production of alloys and contain links to current regulations. Food grade aluminum is the name given to grades of alloys that are permitted to be used for the production of food products. Such alloys are characterized by the following impurity content: lead - no more than 0.15%, zinc - no more than 0.3%, arsenic - 0.015%, beryllium - 0.0005%. Thus, the following grades of alloys are classified as food grade aluminum: AK7, AK5M2, AK9, AK12 and AMg2 (for packaging).

Aluminum food foil is produced in accordance with GOST 745-2014 from primary aluminum of grades A6, A5, A0 and alloys AZh0.6, AZh0.8 and AZh1. In the production of aluminum cans, GOST 33748-2016 is used.

Food grade aluminum

The following alloys are used for the production of food grade aluminum:

- AK7, malleable aluminum with a metal content of 87.4 - 93.8% and silicon 6-8%. The alloy is of normal purity, has good mechanical strength and low ductility.

- AK5M2, aluminum-silicon-copper alloy (base content - 85.9-94.05%, silicon - 4-6%, copper - 1.5-3.5%) with normal ductility and high hardness.

- AK9, a silumin alloy for the manufacture of medium-duty parts, can be used for food purposes. Aluminum content 86.94 - 91.63%, silicon 8-10.5%, copper - up to 0.3%.

- AK12, with a base content of 84.3-90%, silicon 10-13%, copper - up to 0.6%. It has high strength and increased density, excellent for complex castings.

- AMg2 can be used in a wide temperature range. Aluminum content is 95.7-98.2%, silicon – up to 0.4%, copper – up to 0.15% and magnesium – up to 2%. As a food alloy, AMg2 aluminum is used in refrigeration equipment, for blanks of strips, sheets, pipes, and plates. It has high ductility and excellent anti-corrosion properties.

Food grade aluminum is a valuable raw material and a reusable product that should be used by humans over and over again.

Source

Decoding the grades of aluminum alloys

Primary aluminum is produced according to GOST 11069-2001.

Primary aluminum marking

| Brand | Chemical composition | |||

| Al | Fe | Si | Impurities, no more | |

| Special purity | ||||

| A999 | 99,999 | — | — | 0,001 |

| High purity | ||||

| A995 | 99,995 | 0,0015 | 0,0015 | 0,005 |

| A99 | 99,99 | 0,003 | 0,003 | 0,01 |

| A97 | 99,97 | 0,015 | 0,015 | 0,03 |

| A95 | 99,95 | 0,03 | 0,03 | 0,05 |

| Technical purity | ||||

| A85 | 99,85 | 0,08 | 0,06 | 0,15 |

| A8 | 99,8 | 0,12 | 0,12 | 0,2 |

| A7 | 99,7 | 0,16 | 0,16 | 0,3 |

| A6 | 99,6 | 0,25 | 0,2 | 0,4 |

| A5 | 99,5 | 0,3 | 0,3 | 0,5 |

| A0 | 99,0 | 0,5 | 0,5 | 1,0 |

Show table

High purity aluminum is used in the production of semiconductor devices and for research work. High purity aluminum is used for cladding parts of electrical and radio equipment. Technical purity aluminum is used for the preparation of aluminum alloys, the manufacture of wires, and gaskets.

After deformation of semi-finished products (production of sheets, plates, strips, strips, profiles, panels, rods, pipes, wires, stampings and forgings), technical aluminum receives the designation AD (deformed aluminum). The numbers after the AD marking also indicate the percentage purity of the alloy as a percentage.

It is more convenient to use digital marking. The principle is outlined below for alloys.

If in aluminum intended for the production of wrought Al-Mg alloys, the Na content

Marking of technical aluminum for the production of semi-finished products by hot or cold deformation

| Alphanumeric marking | Digital marking |

| HELL | 1015 |

| AD0 | 1011 |

| AD00 | 1010 |

| AD00E | 1010E |

| AD0E | 1011E |

| AD1 | 1013 |

Show table

“E” - in brands with guaranteed electrical characteristics.

Alloys

For domestic aluminum alloys, alphanumeric and numeric designation systems are used. There is no system laid down in the alphanumeric marking (although these alloys were later assigned a digital marking, but it did not “take root”).

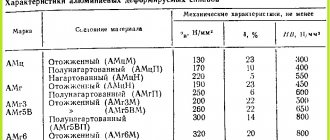

The letters can symbolize aluminum and the main alloying component - AMts (Al-Mn), AMg1 (Al-Mg), the purpose of the alloy ( AK6, AK4-1 - forging aluminum), the name of the alloy ( AV - avial, D16 - duralumin), can be associated with the name of the institute that developed the alloy ( VAD1, VAD23 - VIAM - All-Russian Institute of Aviation Materials, wrought aluminum), etc. The numbers after the letters do not reflect the chemical composition.

At the end of the sixties, four-digit digital marking was introduced. The first number indicates the aluminum alloy base. Aluminum and alloys based on it are marked with the number “1”. The second digit indicates the main alloying component or main alloying components.

The second number “0” denotes various grades of aluminum, sintered aluminum alloys (SAS), various grades of aluminum foam.

The number “1” denotes alloys based on the Al-Cu-Mg system; number “2” - alloys based on the Al-Cu system; number “3” - alloys based on the Al-Mg-Si system; number “4” - alloys based on the Al-Li system, as well as alloys alloyed with slightly soluble components, for example transition metals (manganese, chromium, zirconium); alloys marked with the number “5” are based on the Al-Mg system and are called magnalium; alloys based on the Al-Zn-Mg or Al-Zn-Mg-Cu systems are designated by the number “9”. Numbers 6, 7 and 8 are reserved.

In the Russian Federation, GOST 4784 “Aluminum and wrought aluminum alloys.

Marki" provides marking of alloys in three ways: both in alphanumeric form and only in digital form, as well as taking into account the requirements of the international standard (international marking) ISO 209-1 (ISO 209-1 Wrought aluminum and aluminum alloys -Chemical composition and forms of products -Part 1: Chemical composition). At the same time, the digital marking according to GOST does not coincide with the international marking of aluminum alloys.

Digital marking of wrought aluminum alloys

| Brand | Group of alloys, main alloying system |

| 1000-1018 | Technical aluminum |

| 1019, 1029, etc. | Powder alloys |

| 1020-1025 | Foamed aluminum |

| 1100-1190 | Al-Cu-Mg, Al-Cu-Mg-Fe-Ni |

| 1200-1290 | Al-Cu-Mn, Al-Cu-Li-Mn-Cd |

| 1300-1390 | Al-Mg-Si, Al-Mg-Si-Cu |

| 1319, 1329, etc. | Al-Si, SAS powder alloys |

| 1400-1419 | Al-Mn, Al-Be-Mg |

| 1420-1490 | Al-Li |

| 1500-1590 | Al-Mg |

| 1900-1990 | Al-Zn-Mg, Al-Zn-Mg-Cu |

Show table

The last two digits in the digital designation of an aluminum alloy are its serial number.

The last digit carries additional information: alloys ending in an odd number are wrought, alloys ending in an even number are casting, 7 is a wire alloy, 9 is a metal-ceramic alloy. If the alloy is experimental and is not used in mass production, then the number “0” (01570, 01970) is placed in front of the mark and the marking becomes five-digit.

To indicate the condition of deformed semi-finished products made from aluminum alloys, an alphanumeric designation system is used after the alloy grade. Without designation means without heat treatment.

P - semi-finished product (alloys for cold stamping from wire);

M - soft annealed;

N - hard-worked;

H3 - three-quarters hard-worked;

H2 - hard-worked to one half;

H1 - one-quarter hard-worked;

T - hardened and naturally aged;

T1 - hardened and artificially aged for maximum strength;

T2, T3 - artificial aging modes that ensure overaging of the material (softening artificial aging modes);

T5 - hardening of semi-finished products from the end temperature of hot pressure treatment and subsequent artificial aging to maximum strength;

T7 - hardening, enhanced tensile straightening (1.5-3%) and artificial aging for maximum strength;

A – normal cladding;

B - sheets without cladding or with technological cladding;

U - thickened cladding (8% per side);

B - increased quality of rolling out hardened and aged sheets;

O - increased quality of rolling out annealed sheets;

GK - hot-rolled sheets, slabs;

TPP - hardened and aged profiles of increased strength (for D16).

At the end of the brand there may be letters characterizing the features of this alloy:

“ch” – clean;

“pch” – increased purity;

“och” – special purity;

“l” – casting alloys;

“s” – selective.

Food grade aluminum

Aluminum is one of the most important non-ferrous metals of our time. In terms of global production, aluminum is in second place after iron. In terms of prevalence in the earth's crust, it ranks 1st among metals and 3rd among elements after oxygen and silicon. Aluminum occurs in nature in the form of compounds. The main minerals from which aluminum is obtained are bauxite, nepheline, alumina, and feldspar.

Aluminum was discovered as a compound in 1805. It was obtained in its pure form in 1825 by the Danish physicist Oersted by electrolysis.

An interesting fact is that before the discovery of the industrial method of production, aluminum was more expensive than gold.

The modern production method, the Hall-Heroult process, was developed in 1886, but due to the high energy costs it remained unpopular for a long time. Industrial production began only in the 20th century.

A little about the properties and alloys of aluminum

The thermal and electrical conductivity properties of this metal are comparable to gold, silver and copper. Very common in electrical engineering. Multicore wires and cables are made from it, and windings for electric motors and transformers are created. Aluminum is very ductile, but very fragile. It can be rolled out to a translucent foil. Aluminum ingots can be easily planed and cut. By introducing appropriate additives, the strength of the alloy can be significantly increased, thereby expanding the range of its applications.

A similar alloy was developed in 1911 by German craftsmen in the town of Düren. This is where the name of the alloy consisting of aluminum, copper, magnesium and manganese comes from - duralumin, or duralumin. This combination and long-term hardening made it possible to increase the strength characteristics and maintain the same lightness (aluminum is 3 times lighter than steel). Duralumin alloy has found great use in aircraft construction, due to which it has been nicknamed “winged metal”. To maintain anti-corrosion characteristics, it was coated with pure aluminum.

To eliminate such sputtering, another aluminum alloy with silicon inclusions was developed - silumin. Due to its shine and silvery color, aluminum is used in the production of mirrors, both industrial and technical (for example, for telescopes), and household ones.

Features of aluminum

- Light and soft, has a low melting point - about 650 degrees.

- It is not subject to corrosion - a thin film of aluminum oxide is formed on the Al surface, protecting it from destruction. Thanks to this, equipment and products made from sheet aluminum can be exposed to water for a long time without any consequences.

- It is not destroyed by most food acids and alkalis.

- Very plastic. This property allows it to be rolled into very thin foil.

- High thermal and electrical conductivity with a low coefficient of heat capacity determines the absence of deformation when exposed to high and low temperatures and the preservation of high rigidity of products.

- It does not affect the composition of products and components in contact with the surface, which helps preserve the nutritional and beneficial properties of products, vitamins and original microelements.

- Not harmful to health.

- Easy to manufacture, post-process and subsequently use – it polishes, pours, molds, and also cleans and washes well.

Production of utensils and equipment for cooking made of aluminum

Food grade aluminum and its alloys are used in many types of food preparation equipment. Since this metal is distinguished by its ability to form all kinds of alloys, it, as mentioned above, is actively used for the manufacture of a variety of kitchen containers. In addition, it is indispensable in the production of all kinds of heat-resistant products. For example, equipment for kitchens and various frying surfaces of electrical household appliances.

Aluminum has excellent heat conductivity with low heat capacity. In addition, it practically does not deform at high temperatures or during temperature changes. Due to its low melting point and its ductility, aluminum is actively used for casting various products used in the kitchen. It is suitable for the manufacture of various surfaces that are distinguished by deep relief, all kinds of complex shapes and products with a large area. For example, it is great for all kinds of baking dishes.

Grades of food grade aluminum according to GOST

Do you have a large amount of old aluminum scrap accumulated at home and you don’t know what to do with it? The best option would be to recycle it at a non-ferrous metals collection point. At our VtorBaza collection points you can hand over collected scrap at a competitive price. We accept different grades of food-grade aluminum according to GOST in any unlimited quantity. Leave a request on our website at any convenient time. To determine the requirements for aluminum in contact with food, we have provided you with tables.

Use of aluminum for food packaging

Foil and special forms are produced from sheet material, which are increasingly used and used in the form of packaging. This allows you to maintain the temperature and excellent taste of dishes, as well as reheat or freeze them without losing quality or beautiful appearance.

The metal is harmless to health and does not adversely affect the properties of dishes. Aluminum packaging, which can take on and retain any shape, is used for transporting semi-finished products, fast food, meat and fish, as well as other products.

The use of aluminum alloys in products in contact with food

This metal is used to produce a variety of dishes, meat grinders, containers for storing liquids and mixtures, cutlery, machines for workshops and conveyors for moving products, various types of accessories and other products.

The raw materials are also used for the production of heat-resistant surfaces and a variety of kitchen equipment. Dishes made from such alloys do not change the properties of food products, they retain the beneficial substances present in them, as well as the original properties and microelements important for the body.

Grades of metal alloys, including aluminum

You can also use metal alloys that contain aluminum. These include brands AB, AVM, A0, AD1, AD1M, AL22, AL23, AMg22. All these alloys are actively used for making spoons.

Quite often, products made from food-grade aluminum or its alloys must subsequently have a special coating applied. But this can be done with the AMts brand, since its chemical composition fully complies with GOST.

Food grade aluminum has long been firmly established in our daily use. It is impossible to find a kitchen that does not have utensils made from this metal. Reviews about it are only positive, and, apparently, its popularity is not going to decline.

GOST food grade aluminum and grades

All brands of raw materials used, permitted for use, are strictly specified in GOST. Each of them has its own chemical composition. Various alloys listed below can come into contact with products.

Grades of food grade aluminum (basic requirements)

In accordance with GOST 1583-93

Aluminum casting alloys:

- clause 3.3

For the manufacture of food products, alloys AK7, AK5M2, AK9, AK12 are used. The use of other grades of alloys for the manufacture of products and equipment intended for contact with food products and environments must be permitted by health authorities in each individual case. Also on this matter, see the next section below: Brands of food-grade aluminum for dishes and cutlery. In aluminum alloys intended for the manufacture of food products, the mass fraction of lead should be no more than 0.15%, arsenic - no more than 0.015%, zinc - no more than 0.3%, beryllium - no more than 0.0005%. - clause 4.1.6.1

Ingots intended for the manufacture of products and equipment in contact with food products are marked, in the absence of color markings, with an additional letter “P”, which is placed after the designation of the alloy grade.

In accordance with GOST 4784-97

Aluminum and wrought aluminum alloys:

- clause 3.4.1

In the AMg2 alloy intended for the manufacture of tape used as packaging containers in the food industry, the mass fraction of magnesium should be from 1.8 to 3.2%. - clause 3.8

In aluminum and aluminum alloys, semi-finished products from which are used in the manufacture of food products, the mass fraction of lead should be no more than 0.15%, the mass fraction of arsenic should be no more than 0.015%. Grades of aluminum and aluminum alloys for food use are additionally marked with the letter “Ш”.

Grades of food-grade aluminum for dishes and cutlery (table with GOST standards)

Grades of food-grade aluminum for cookware regulated by GOST 17151-2019 Household cookware made of sheet aluminum. Valid from 01.11.2019, replacing the old GOST 17151–81

| Manufactured product | Acceptable grades of aluminum | Regulatory document |

| Dishes | A7, A6, A5, A0 | GOST 11069 |

| Sheets and tapes AD1, AD | GOST 4784 | |

| Bimetallic aluminum tapes AD1, AD | ||

| If the cookware has an internal coating, it is allowed to make it from sheets and strips of aluminum alloy AMts | ||

| Fastening parts for cookware that come into contact with food | The requirements are the same as for dishes (lines above) | |

| Utensil fittings (handles, arms and ears) | Sheets and tapes used for the manufacture of reinforcement must be cold-worked | GOST 4784 and GOST 11069 |

| The interior surface of the cookware must be etched, brushed, ground, enamelled, stainless steel clad, anodic oxide coated, or non-stick (non-stick) coated. | ||

Grades of food-grade aluminum for cutlery, regulated GOST 51016–97 Cutlery made of carbon steel and aluminum alloys

| Manufactured product | Acceptable grades of aluminum | Regulatory document |

| All-metal forks and the working part of combined forks | A0, AVM, AD1M | GOST 21631 |

| AD1, AB, AMg2 | GOST 4784 | |

| AK7, AK5M2, AL22, AL23 | GOST 1583 | |

| Spoons | A0, AVM, AD1M, AD1, AB | GOST 21631 |

| AMg2 | GOST 4784 | |

| AK7, AK5M2, AL22, AL23 | GOST 1583 | |

| Handles of combination knives and forks | A0, AVM, AD1M | GOST 21631 |

| Fittings for combined products (rings, caps, washers, rivets) | AD1 | GOST 4784 |

Aluminum scrap: alloy sorting

The steady increase in prices for primary aluminum, as well as increasingly stringent environmental requirements for aluminum production, make it increasingly important to improve the efficiency of recycling aluminum scrap into new high-quality aluminum. The challenge is not only to maximize the recovery of the aluminum itself, but also to effectively reuse the alloying elements already present in the aluminum scrap.

Aluminum: primary and secondary

Aluminum is second only to steel in terms of production and consumption in the world. The attractiveness of aluminum as a material for the manufacture of various products and structures is due to its unique properties, such as:

- light weight,

- fairly high strength properties,

- good corrosion resistance,

- ability to be processed by all methods of cold and hot forming,

- high electrical and thermal conductivity;

- high reflective properties.

The natural raw material for extracting primary aluminum is the fossil mineral bauxite. The production of primary aluminum requires large amounts of electrical energy.

Recycled aluminum is aluminum that is produced from waste and scrap aluminum. This consumes only 5% of the energy and, accordingly, only 5% of greenhouse gases are released compared to the production of primary aluminum. Abroad, secondary aluminum is often called more “tolerantly”: “recycling aluminum”.

Aluminum grades and alloys

Aluminum is used mainly in the form of grades of aluminum and aluminum alloys:

- Alminium grades are unalloyed aluminum with an aluminum content of at least 99.00%, as well as with specified limits for the content of impurities and contaminants.

- Aluminum alloys also have limits on the content of impurities and contaminants, as well as specified ranges for the content of one or more alloying elements. These alloying elements provide the aluminum alloy with special properties compared to unalloyed aluminum, as well as other aluminum alloys.

Aluminum alloys are divided into two large groups - wrought alloys and cast alloys:

- From wrought alloys, final aluminum products are produced by metal forming methods: rolling, pressing, forging, stamping, etc.

- Products from cast alloys are produced by various casting methods (in sand molds, under pressure, in a chill mold, etc.).

Alloying elements of aluminum alloys

Most wrought alloys are at least 90% aluminum, and most are 95% aluminum. The remaining percentages are occupied by alloying elements, impurities and impurities. The exception is some alloys of the 4xxx series.

Casting alloys are distinguished by a higher content of alloying elements, as well as impurities and contaminants. Thus, in some aluminum alloys the content of alloying elements exceeds 20% [1].

Based on the main alloying elements, all alloys - both wrought and cast - are divided into series. For example, wrought alloys are divided into eight such series with the corresponding main alloying elements:

- 1xxx – grades of unalloyed aluminum

- 2xxx – copper, as well as magnesium

- 3xxx – manganese

- 4xxx – silicon

- 5xxx – magnesium

- 6xxx – magnesium and silicon

- 7xxx – zinc, as well as copper

- 8xxx – iron, as well as other elements.

The main alloying elements and impurities of the most popular wrought aluminum alloys in the aluminum industry are presented in Table 1. The features of these alloys in terms of compatibility with other alloys or their differences from other alloys are highlighted in blue.

Table 1 - Popular wrought aluminum alloys

The role of recycled aluminum

Mass production of aluminum products, including for domestic consumption, began in the 1940s. Since then, the world has accumulated a huge amount of aluminum products that have reached the end of their service life - aluminum scrap.

The majority of recycled aluminum, about 70%, traditionally goes into the production of aluminum-silicon casting alloys, which are used mainly for the manufacture of automobile parts. The second largest share of recycled aluminum goes to the production of wrought aluminum alloys for the production of rolled sheets and extruded products, including extruded profiles.

Currently, the share of recycled aluminum is about one third of the total global production of aluminum and aluminum products [1, 2].

Categories and groups of aluminum scrap

For a long time in the USSR, and then in Russia and other CIS countries, GOST 1639 was in force, which in its latest edition in 2009 identified 32 categories of aluminum scrap: from Aluminum 1 to Aluminum 32.

Currently, GOST R 54564-2011 has been introduced in Russia, which even contains 38 categories of aluminum scrap: from A1 to A38. The European standard EN 13920 defines 15 categories of aluminum scrap: from pure unalloyed aluminum to aluminum slag. The American classification system divides aluminum scrap into 44 categories (see more here).

In practice, aluminum scrap collection points usually use only about a dozen different groups of aluminum [3], such as:

- electrotechnical

- food

- profiles

- cables (without insulation)

- mixed

- radiators

- shavings

- boats

- banks.

Sorting at sight?

Typically, aluminum scrap is supplied from collection points to a company for sorting metal scrap as part of scrap of other non-ferrous metals and their alloys. The typical picture here is the manual sorting into several boxes of individual scrap components according to their appearance, origin and typical use.

The most popular – and expensive – categories of aluminum scrap are “electrotechnical aluminum” (“electrotech”) and “food grade aluminum.”

These grades of aluminum scrap are considered the purest and are usually used in the smelter charge to dilute excessive levels of one or another alloying element, such as magnesium or silicon, as well as iron, in the preparation of an aluminum melt for casting pillar ingots from secondary alloys 6060 or 6063. These ingots are used for pressing aluminum profiles.

However, as will be shown below, these categories of aluminum scrap can be very heterogeneous and uncertain in chemical composition. Therefore, using this scrap without preliminary instrumental control of its chemical composition is very risky: you can ruin the entire aluminum melt that is in the furnace.

Electrotech

Electrical aluminum includes such aluminum products and materials as wires, bare cable cores, and electrical busbars [2]. Electrical aluminum is generally considered to be various grades of unalloyed aluminum.

- Indeed, according to GOST 22483, aluminum wires and cores were made mainly from grades of primary aluminum A7E and A5E according to GOST 11069.

- However, according to GOST 15176, extruded electrical busbars can be made from various grades of aluminum (A5, A5E, A6, A7, AD00, AD0) and from aluminum alloy AD31 in the T, T1 and T5 states.

- Abroad, for example, in the USA, electrical busbars are also made from both aluminum grade 1350 (AD0E) and aluminum alloy 6101, as well as alloys 6063 and 6061 [1].

- It is also worth noting that abroad, wires and cables are made not only from aluminum grade 1350, but also from alloys 8030 and 8176. These alloys can have an iron content of up to 1.0% and copper - up to 0.30%. Such wires and cables have also begun to be produced in Russia (see more details here).

Food grade aluminum scrap

“Food grade aluminum” usually includes stamped aluminum cookware: pots, kettles, bowls, spoons, mugs, frying pans, etc. A popular type of “food grade aluminum” is also 40-liter milk flasks. Sometimes cast kitchenware is also included in food-grade aluminum (Figure 1).

Figure 1 – Food grade aluminum scrap [3]

Stamped kitchenware

According to GOST 17451 for stamped aluminum cookware, all components of the cookware that are in direct contact with food products are made from aluminum grades AD1, AD, A7, A6, A5 and A0.

However, according to the same GOST 17451:

- If there is an internal coating, the dishes can be made from sheets and strips of aluminum alloy AMts (3003), which contains from 1.0 to 1.5% manganese.

Handles, arms and ears can be made:

- from any aluminum alloys according to GOST 4787

- made of stainless steels, non-ferrous metals, steels with protective and decorative coatings.

Aluminum milk flasks

According to GOST 5037, for the manufacture of stamped aluminum milk flasks, which are often called “cans,” the following is used (Figure 1):

- body and cover: – aluminum grades A7, A6, A5, A0, AD0, AD, AD1, AD0 in various states;

- support hoop: – steel sheet 2 mm thick or – aluminum grade AD1 or – aluminum alloys AMts, AMg1 and AD31;

- handles, top hoop and fittings: – thin sheet steel or – any grades of aluminum and aluminum alloys according to GOST 4784.

Figure 2 – Aluminum 40-liter milk flask [GOST 5037-97]

Therefore, aluminum milk flasks require labor-intensive preparation to remove all “non-aluminum” parts before they are sent to “food grade” aluminum scrap. It is worth noting that steel milk flasks, which have a similar appearance, are also made according to the same GOST 5037.

Cast kitchenware

Cast aluminum kitchen utensils (pots, pans, cauldrons, spoons and forks - Figure 3) consist of the following cast aluminum alloys:

- housings and covers: made of casting alloys AK5M2, AK7, AK12

- covers also: made of aluminum grades AD1, AD, A7, A6, A5, A0.

Figure 3 – Cast aluminum cauldron [GOST R 51162-98]

Casting alloys are characterized by a high silicon content. AK5M2 alloy contains up to 3.5% copper.

Unalloyed aluminum scrap

This category of aluminum scrap typically includes sheets, strips, pipes and sometimes profiles. In appearance and strength, they can easily be confused with similar sheets, tapes, pipes and radiators made of aluminum-manganese alloys of the 3xxx series, which contain up to 1.5% manganese. The strength level of these alloys is about 20% higher than that of unalloyed aluminum grades.

Note that the erroneous use of alloys of the 3xxx series instead of grades of unalloyed aluminum, for example, for the preparation of alloys 6060 and 6063 will lead to an excessive content of manganese in the melt, which is an undesirable impurity in them with a content limit of up to 0.10%.

Scrap aluminum profiles

Among extruded aluminum profiles, there may be alloys from several different series, which may not be compatible, for example, with the most popular alloys for profiles - alloys 6060 and 6063:

- 2014 and 2024 – copper content up to 5.0%, manganese – up to 1.2%. Not suitable for preparing alloys 6060 and 6063: too much copper and manganese. Used in aircraft construction. They are very difficult to press, so they have simple cross-sectional shapes with thick walls.

- Alloys of the 5xxx series: magnesium content up to 4.0% and manganese - up to 1.0%. The increased manganese content limits the use for preparing, for example, alloys 6060 and 6063. The higher the magnesium content, the more difficult it is to press. They have simple cross-sectional shapes.

- 6060 and 6063 (AD31) – content of manganese, copper, chromium and zinc not more than 0.1%. They can have complex cross-sectional shapes, including those with several cavities and thin walls. They are widely used for the manufacture of window and door frames, as well as facade structures.

- 6061 (AD33) – iron content up to 0.7% and copper – up to 0.40%. silicon and magnesium are 1.5-2 times higher than that of alloys 6060 and 6063. The difficulty of pressing is average, the profiles have simple cross sections.

- 6082 (AD35) - manganese content up to 1.0% limits the use for alloys 6060 and 6063. The profiles have simple cross sections.

- 7005 (1915) - profiles from this alloy were previously used for the manufacture of enclosing structures, for example, stained glass windows. Until recently, alloy 1915 was included in GOST 22233 as a material for enclosing structures. Contains up to 5.0% zinc.

Sorting of aluminum scrap with alloy identification

Currently, to sort metals and their alloys in “field” conditions, that is, directly at an aluminum scrap warehouse, two methods are used to analyze the chemical composition of aluminum alloys:

Portable X-ray fluorescence spectrometers have been used for metal identification and analysis for about 40 years. Over the years, these hand-held spectrometers have evolved from a heavy instrument that had to be carried on the back to a highly accurate instrument the size of a small drill.

Portable laser spectrometers have appeared relatively recently - in the last 10 years. Optical emission spectrometers (OES) are slightly larger than X-ray and laser spectrometers.

Therefore, it is more convenient to use them in the laboratory, rather than in the field conditions of a metal scrap warehouse or the charge yard of a foundry.

What does sorting aluminum scrap with alloy identification give:

- preventing loading of unwanted contaminants and alloying elements into the melt;

- adding the required alloying elements to the melt in specified quantities;

- separation of high and low value alloys;

- preparation of alloys within specified narrow ranges of chemical composition;

- identification within series of aluminum alloys with increasing the value of scrap from an individual alloy.

Sources:

Is this aluminum accepted for scrap and at what price?

The raw material is not the most expensive type of aluminum scrap, but not the cheapest either. Food-grade aluminum in Moscow is accepted for scrap metal at different prices per 1 kilogram. Ours sets the following cost per kilogram for the following types of scrap:

- Aluminum cans - 55-76 rubles;

- Foil - 70-101 rubles;

- Aluminum containers and utensils - 105-136 rubles.

The final cost of such products is influenced by:

- the degree of purity of the alloy and the presence of impurities present in it;

- volume of collected delivery lot;

- quality and characteristics of the alloy.

The scrap is melted down and reused to make kitchen items, accessories and equipment.

Use as packaging

Every home had or even has kitchen utensils made of aluminum - spoons, cups, ladles, pots, juicers, meat grinders and much more. Aluminum foil is very popular in the culinary world, which is used for baking meat and vegetables or simply storing and transporting food. This foil is great for packaging sweets, chocolate, ice cream, butter, cheese and cottage cheese.

Many creams and cosmetics, art paint (oil, tempera, gouache and even watercolor) are packaged in food-grade aluminum containers. Food for astronauts is also packed in them. It is safe to say that aluminum, including food grade aluminum, and alloys based on it have become firmly established in our everyday life.

Food grade aluminum is widely used in the production of containers for canned food. Due to this spread, the amount of aluminum waste, idle and decomposing in landfills, increases every year.

Chemical composition and certification of food grade aluminum

Food grade metal Al is produced in accordance with the current regulations and standards of GOST 1583-93, and its composition contains no more than 0.15% lead. The presence of zinc in the alloy of this metal does not exceed 0.3%, and the arsenic content is no more than 0.015%. The beryllium content does not exceed 0.0005%.

Products that come into direct contact with food are subject to mandatory certification. These are cutlery, jars and special foil used for packaging purposes. Such products require mandatory receipt of a hygiene certificate.

Advantages and disadvantages of aluminum cookware

Crockery and cutlery made from this material are present in any modern kitchen. Main advantages of kitchen items:

- good thermal conductivity – pots and pans heat up faster;

- uniform heating of prepared dishes;

- light weight of various kitchen accessories;

- absolute harmlessness to food due to the formation of a special oxide film on their surface;

- Convenient placement of items on shelves in the kitchen.

You can talk about the dangers of dishes made of this metal if they are used incorrectly. For example, if there is no non-stick coating, you cannot cook acidic dishes in it, as this leads to the release of metal into the dishes and to poisoning. See the video below for other shortcomings.

Source