Although household sewer lines made of cast iron pipes became obsolete several decades ago, due to their high service life they are still found in residential communal buildings. Replacing them with popular polymer materials is not always rational from a financial point of view and in terms of labor costs, so many specialists or owners who independently carry out repair work have to solve the problem of how to connect a cast iron pipe with a plastic sewer.

The main problem when connecting pipelines made of different materials is the discrepancy between their dimensional parameters and the different design of the connecting pipes. Therefore, methods for joining cast iron and plastic pipelines are a little more complicated than connecting identical pipes. It is worth noting that the task of connecting cast iron and plastic sewers is greatly facilitated due to the availability on the market of shaped elements and cuffs specially designed for these purposes.

Rice. 1 Indoor sewage system made of old cast iron and polymers

Types of rubber cuffs for connections

When carrying out renovations in houses of old buildings, it often becomes necessary to make a drain from some modern plumbing fixture into a cast iron sewer riser.

For ease of work, there are several types of PVC adapters; using them, you can lay a pipeline of any configuration.

Connection cuffs are sold in specialized stores

Types of PVC adapters:

- Transition coupling.

- Crosspiece;

- Tee;

- Bypass;

- Compensator.

But when installing pipes, you often have to connect pipes from different materials. Often you need to switch, for example, from a cast iron to a plastic pipe. Then you will need a rubber insert (cuff) for the adapter.

Types of rubber cuffs:

- Cuff of internal transition. It is usually inserted into the socket of a cast iron pipe. Then a plastic pipe of the required diameter is inserted.

- Outer cuff. Its cross-section should correspond to the diameter of the cast iron socket, then there will be no need to use sealant.

If there is no socket in the sewer, an external adapter will be required. You can use it to make a connection. Then it will be possible to continue installing the rest of the plastic sewer system. Plumbing elements, without which it is practically impossible to lay communications, are adapters for water supply, heating and sewerage pipes. All problems arising during the repair process regarding the connection and routing of pipes of different diameters can be solved practically without restrictions with the help of PVC adapters.

Dismantling an old pipe

The cast iron pipeline must be dismantled very carefully to prevent chips or cracks.

We recommend that you read: The purpose of electric welded couplings and the necessary tools for connecting polyethylene pipes

In the past, joints were often sealed using cement and tow, so it may take a lot of effort to release the joints.

It is necessary to disconnect the pipes by twisting, and in no case by rocking. If you are not sure that the socket of a cast iron pipe can be released without damage, it is better to carefully cut it with a grinder.

It is important! You should not try to break off a cut cast iron pipe. Most likely the break will be uneven and you will have to cut again. It is better to work with the grinder a little longer and cut the cast iron product completely.

Requirements for sewer pipe joints and connection angles

When creating a sewer system yourself, you should remember the rules for laying the pipeline. It is laid at a slight slope. This is necessary to prevent water from stagnating in the system. The slope must be at least 2 cm for each meter laid. The correct installation of pipes is checked by level.

Installed sewerage system in the floor on a slope

The weak point when laying a sewer system is the joints. Therefore, their sealing is of particular importance. After completing the assembly of the structure, the system is checked for leaks. To do this, the drain is completely filled with water. During testing, temporary plugs are placed in the revision. There shouldn't be any leakage.

What are the benefits of plastic sewerage?

Plastic pipes (made of PVC or polypropylene) have several advantages:

- light weight, which makes it easy to work with pipes; installation of plastic sewerage does not require special equipment; ideal smoothness of internal surfaces reduces blockages of the riser; are not afraid of corrosion.

There is one drawback: the sound insulation characteristics of plastic are noticeably lower than those of cast iron.

If you are sure that you can handle sewer replacement, carefully understand the process. There are some subtleties of preparation and the work itself.

You can also hire professionals. Then knowledge about the entire process will be needed just in case

To understand what to look for and how to accept a job

Coinage

This method of transition between plastic and cast iron pipes relates more to the installation of cast iron pipes, and caulking involves performing sealing work using flax or other winding materials, followed by filling with sealant or cement mortar. The connection of pipes is made, as in the previous case, by introducing a pipe of a smaller diameter (made of PVC) inside a pipe or socket of a larger diameter (made of cast iron).

The connection technology is performed in several stages. First, a layer of glue and sealant is applied to the PVC pipe, then a layer of flax is wound and the pipes are connected, additionally embossing and stuffing of flax along the diameter is carried out for better sealing. After which the joint is filled with sealant, plumbing silicone or another composition. The difference from chasing cast iron pipes is that this method does not use hot bitumen mastics, which can damage the PVC pipe.

Connection methods

Let's figure out how to replace a cast iron sewer with a plastic one. Since, unlike a water supply system, a sewerage system is a non-pressure system, welded joints are rarely used when installing a pipeline.

As a rule, “socket” connections are used. Special fittings are used less often. First, we will describe connection methods that can be used if the socket of cast iron pipes remains intact.

Rubber seal

This pipe connection is done quite quickly and simply. The connection can last 8-10 years, after which the rubber gasket will most likely need to be replaced. Before connecting a plastic pipe to a cast iron socket, you need to perform the following operations:

- thoroughly clean all parts, it is necessary to remove remnants of previous sealing materials and dirt;

- Next, you need to prepare a rubber seal; sealant is applied to it (on the outside;

- the prepared seal must be inserted into the cast iron socket.

Now all that remains is to forcefully insert the smooth end of the plastic sewer pipe into the socket. The depth of insertion is 5-8 cm.

Caulking

This is a traditional method and has been used for many years to create cast iron pipe joints. But caulking is also suitable if you plan to connect a plastic pipe with a cast iron pipe that has a socket. How to do the work:

- a flax winding is wound onto the smooth part of the prepared plastic pipes, and the material is wound in several layers;

- Now you can insert the polymer element into the cast iron pipe;

The advantage of this joining method is that it is very durable. If the rubber seal has to be replaced after a few years, this connection will last much longer.

The disadvantage of this method is that the solution needs to be given time to dry, so you can use the sewer only after a couple of days, and you won’t have to wait when installing a rubber seal.

Silicone

This method of connecting cast iron pipeline parts to plastic ones is used if, after inserting the plastic part into the socket, a gap of no more than 2 mm wide remains. In this case, it is irrational to use caulking; it is much more convenient to use plumbing silicone. Work order:

- The plastic part, as well as the inside of the cast iron socket, must be cleaned as thoroughly as possible. In addition, the joint must be dried;

- the plastic element is inserted into the socket, after which, using a construction gun, the gap between the pipeline parts is filled with silicone. You need to try to ensure that the silicone is located not only on the surface of the socket, it should fill the gap. Moreover, the deeper the material penetrates, the more reliable the connection will be;

- Now you need to let the silicone harden, this will take 3-5 hours depending on the thickness of the layer.

If the bell is damaged

If the bell is damaged, then the methods described above are not suitable. When performing installation, you will need to purchase an additional part - an adapter that allows the transition from a cast iron pipe to a plastic one. The procedure for connecting pipeline elements is as follows:

- the damaged socket is carefully cut off with an angle grinder;

- the edges are processed;

- a rubber sealing ring and a rubber cuff are put on the prepared part of the cast iron pipe;

- the edge of the rubber part is lubricated with sealant, then a plastic adapter is put on;

- lubricate the adapter pipe with sealant and install another rubber O-ring;

- After this, you can insert the plastic part into the adapter.

How to make the transition?

New sewer lines are usually installed to replace old ones, using the same channels and installation locations to minimize repair costs. PVC pipes are selected to be approximately the same diameter as those used for repairs and therefore ensure ease of installation, passage through walls and ceilings, if necessary. But the most important thing is to correctly make the transition between a plastic pipe and a cast iron pipe (bend, coupling). At this time, we can name several methods of joining cast iron and plastic, which are used in construction:

- Installation of a rubber gasket (coupling) which ensures correlation of sizes and tightness of connections of pipes of different diameters.

- Embossing using sealing agents, including flax, cement mortar, bitumen-based sealants and adhesives.

- Using plumbing silicone.

- Combining methods.

Basic methods

There are the following methods for connecting cast iron sewer pipes to plastic ones:

- flanged;

- fitting;

- using rubber gaskets;

- pressing tow or sanitary flax.

The main options for connecting a cast iron pipe to a plastic one

Application of fitting

Cast iron fittings for sewer pipes

From a technical point of view, the optimal solution is to use a fitting, a special adapter made of durable polyvinyl chloride. It has a thread on one end and a socket for inserting a plastic pipe on the other. Fittings are used if the cast iron pipe does not have a socket at the end, or its use is impossible.

You will need a die for cutting external threads, a fitting of a suitable caliber, FUM tape or plumbing flax or tow. It is necessary to cut off the cast iron socket with a metal grinder or a hacksaw. During this, you need to make sure that the cast iron does not crack.

It is necessary to clean the cast iron from dirt and paint and cut a thread of 3-5 cm on it. Re-clean it from dust and metal residues and wind several turns of FUM tape or flax to seal the thread and screw the fitting.

After this, all that remains is to insert the end of the water or sewer pipe into the fitting collar.

If a cast fitting without thread is used, then first an O-ring is placed in the socket, securing it with special glue, and then a narrow fitting pipe is inserted into it.

Press fitting for connecting metal and plastic pipes

Rubber gaskets

It is possible to simplify installation with the help of rubber gaskets, if the cast iron part is well preserved, its edges and inner surface are smooth, not rusted and without chips. As a rule, the sockets of strong and thick sewer pipes remain in this state.

The bell is pre-cleaned from dirt and rust.

A rubber adapter gasket of a suitable caliber must be well coated with silicone sealant. Insert into the connection until it stops, but not less than 3 cm. After this, insert the pipe of the connected water supply into the cuff. The work is finished.

Scheme of connecting pipes using a rubber gasket

Linen winding

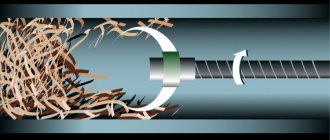

Sealing joints of cast iron sewer pipes using linen strands

Press-fitting with linen winding is used if other connection methods are not available, or as a temporary measure. Several layers of plumbing flax or tow are tightly wound onto the plastic pipe at the junction. It is inserted into the sewer connection, the flax is pressed into the gap with a knife or spatula and sealed with silicone sealant or a mixture of cement and PVA glue. All you have to do is wait a day, and you can use the connection.

This connection of sewer pipes can be used for a limited time (up to a year) until it becomes possible to install a more reliable structure.

Installing the rubber gasket

This is the most correct and high-quality method of transition between plastic and cast iron used in plumbing.

The essence of this method is to connect two pipes using a rubber gasket selected according to the diameter. Typically, the diameter of the new sewer pipe is smaller than the internal diameter of the cast iron pipe, so PVC is required to be inserted into the cast iron pipe. Before installation, it is necessary to thoroughly clean the installation site on the side of the cast iron pipe. After which a rubber adapter is installed into it, which will act as a holding and sealing device. To install it, you may need a sealant, as well as a certain amount of force to drive it into the outlet of the cast iron pipe for the connection. Once the adapter is installed in the cast iron pipe, the new plastic pipe can be easily inserted and ensure a secure transition between plastic and cast iron. It is advisable to ensure that the new pipe enters the old cast iron pipe at a distance of five to ten centimeters.

In addition to internal cuffs, you can also find on the market external connecting rubber couplings that can be used for pipes, the difference in diameters does not allow them to be connected by inserting one into the other.

Installation rules

The connection is made in several ways. The choice depends on the possibility of caulking the fasteners. In addition to rigid fittings, rubber sewer products are used - cuffs or reductions. They find their application when connecting washing machines and dishwashers whose drain holes have a diameter of 32 mm.

Experts do not recommend using silicone, linen cables or sealants when joining plastic products. They are successfully replaced by rubber sealing rings. If leaks appear after installation, the skewed ring should be corrected.

Elastic seals have quite high rigidity, so installation difficulties arise. In this case, the end on which the seal is placed is coated with liquid detergent.

Rubber cuff

If the old pipe was pulled out of the socket easily and the integrity of the cast iron surface was preserved, the end of the plastic pipe is inserted into the extension by 3 or 8 cm. A quick and high-quality connection can last 8 years.

For plumbing fixtures that are located close to each other, there are 2 outlets to the riser. One with a diameter of 100 mm is used when connecting drains from a bidet and toilet, the second - with a diameter of 50 mm, for sinks, bathtubs and showers.

Algorithm for connecting polymer wiring to a cast iron socket:

- the inside of the cuff is cleaned of rust and dirt;

- to prevent leaks, sealant is applied to the outside of the rubber product;

- insert the tape.

At the last stage, a connection is made to the polymer pipe.

Plastic fitting

Sewage adapters from cast iron to plastic are used in cases where the cut of the metal pipe does not have a socket. In addition, cast products often have diameters that differ from the standard, for example 60 mm. The connection is made using a 50/72 mm taper.

According to the diagram, the assembly looks like this: plastic pipe, coupling 50/50, rubber ring, adapter itself 50/72, elastic cuff, seal, cast iron pipeline d 60 mm.

Procedure:

- the old metal pipe is cut evenly;

- put a rubber cuff on the stripped end;

- apply sealant to its inner edge and the top of the plastic fitting;

- insert the adapter into the seal.

All that remains is to insert the polymer pipe into the prepared end through the coupling. The size of the cuff and taper must match each other.

Caulking with asbestos cord

Asbestos cord

The method is used when connecting cast iron products, since the configurations of casting fittings are limited. Operating procedure:

- the rope is wound on plastic;

- the wrapped end of the pipe is inserted into the cleaned hole, using a screwdriver to help close the cracks with asbestos material;

- prepare a solution from water, cement and PVA glue;

- coat the joint with a cementitious composition.

It is recommended to wait a day to dry before using the sewer. This method is highly reliable and guarantees leak-free operation for a long time. This is how cast iron sinks are connected to a plastic pipeline.

Installation and joining of sewer pipes

What characterizes the joining of cast iron pipes in a drainage system?

Let's look at the most basic ones:

When installing cast iron sewer pipes, attention is paid to error-free joining of pipe products. For everything to work out perfectly, you need to prepare tow in a timely manner that does not contain impurities and wood waste. Before you start filling the socket with an asbestos-cement mixture, you need to fill it with tarred hemp strands, which you then roll into a rope and caulk into the cracks of the socket of the cast iron pipe.

The thickness of the strand should be slightly larger than the width of the socket slit, and the length should be such that the strand enters the socket no more than 30 mm from the edge. To obtain a mixture of asbestos and cement, it is necessary to mix Portland cement grade 400 or more (70% by weight) and asbestos fiber, grade at least 4 (30% by weight). Before use, almost 30 minutes before use, the mixture must be moistened by adding water (10-12% of the total mass). Fittings are joined to cast iron pipes by sealing the gap that has arisen between the inner surface of the socket and the outer side of the shaped part or the end of the pipe inserted into the socket. When installing cast iron pipes, the direction of the sockets is ensured in the opposite direction of fluid movement. To make the pipe shorter, you need to place it on wooden blocks, use a chisel to punch a groove, the depth of which is a third of the wall thickness, and divide the pipe into parts with a hammer. The tail component of the tubular product is placed into the socket of another so that a gap of 5-6 mm is obtained, which can be controlled with a special hook. Further actions include: centering the pipes, sealing the annular gap with tarred strands of flax or hemp rope, previously greased. The initial sealing layer is laid in a ring so that the edges of the strands or rope do not end up in the pipe. Continue the compaction procedure until the socket is two-thirds full. Moreover, the outer sealing layer is covered with a strand/rope without fat/resin to ensure excellent adhesion to the cement mixture. After the sealing layer has settled, it will be necessary to center the pipe in the socket using wedges. The third part of the depth of the socket, which is still empty, now needs to be filled with cement (grade 300-400), maintaining a ratio of 9:1 (cement and water). Then they begin to tamp the cement, which is best covered with a wet rag to ensure reliable hardening. By the way, instead of it you can take bitumen mastic, a mixture of asbestos and cement, clay or other materials coated with oil paint.

Features and subtleties of work

Understanding the technology of how to connect a cast iron pipe to a plastic one, you should pay attention to the following subtleties:

Since cast iron pipes are quite fragile, when working with them you should use only a wooden or rubber hammer, so that in case of a careless blow you do not break off a piece of cast iron and clog the lumen of the channel. Although working with a grinder with cast iron pipes is much faster and more convenient, an ordinary hacksaw for metal will still do. The quality of work will be similar, however, much more time will be required. When installing plastic pipes, we must not forget about inspection hatches

They may be needed in emergency situations so as not to waste time and money and not to cut the plastic pipe for diagnosis and repair.

Switching from cast iron to plastic

Within reasonable limits, all the described sealing methods can be combined with each other. No matter how paradoxical it may sound, often a combination of various methods greatly increases the reliability of connections. For example, a gap that is too wide can be eliminated with a rubber cuff with simultaneous caulking, and a classic caulking can be sealed not with a polymer cement mixture, but with plumbing silicone. The main thing in the process of work is to be guided by the principle of reasonable sufficiency and to understand that the plasticity of the sealing elements is the key to reliable and durable operation of the entire sewer system.

Hello! Today I will tell you how to make the transition from a cast iron pipe to a plastic one.

Video description

About connecting to a cast iron sewer in the following video:

Flange connection

The flange has proven itself well when joining large-diameter pipes, where previous methods are not suitable. Sections of the sewer system are connected using flanges: flat parts that look like a ring or disk. The holes are evenly spaced on the flanges; bolts (less often studs) are usually used as fasteners.

To switch from plastic to cast iron in the sewer system, welding work will be required, since the metal flange part must be welded to the main pipe pipe. The flange parts are connected using a crimp coupling and bolts; the space between them is filled with a sealant.

Installation of flange connection Source technicalservice59.rf

How to seal the connection between a cast iron sewer pipe and a plastic one?

Since cast iron pipes have lost their popularity to PVC products, at this stage of technology development there is increasingly a need to assemble combined cast iron and plastic sewer channels.

In the context of the situation considered, a completely reasonable question arises: how to make the joints of parts made of different materials airtight?

The work in question should be carried out within the framework of the following scheme:

This is what it looks like

- You should start by purchasing the necessary spare parts, in this case we are talking about adapters. To achieve optimal results, it is recommended to use products made from polymers or rubber.

- Traces of corrosion must be carefully removed from the surface of the cast iron pipe; the presence of other contaminants is also unacceptable.

- After degreasing and cleaning the bell, silicone must be applied to its surface.

- After the sealant has dried, the adapter is also carefully processed (cleaned and coated with silicone) and fixed in relation to the cast iron pipe.

Preparatory work

The first step is to carefully measure the area to be replaced in order to know the number of pipes and what diameter you need to buy. The diameter is also an important aspect, for example, when replacing an internal pipeline, pipes with a diameter of 50 mm are used, and when replacing a riser or a section coming from the toilet - 110 mm. In addition, you will also have to purchase a certain number of adapters, angles and other fittings.

Before starting work, prepare the material and tools:

- plastic pipe of the required diameter;

- a coupling that will be used to make the transition from cast iron to plastic;

- wooden or rubber mallet;

- grinder or hacksaw for metal.

It is advisable to complete the replacement of the sewer pipeline within 1 day.

Video: Installation of a transition from a cast iron sewer pipe to a plastic one.

Advantages and disadvantages

Advantages:

- ease of formation of sealed joints, characterized by reliability and good quality;

- wide selection of types of pipe fastenings;

- wide selection of standard adapter sizes.

Due to differences in the coefficients of thermal expansion of the two materials at their junction, the tightness begins to deteriorate over time. This is facilitated by the high heating of the transported medium, which causes the plastic to melt through.

Cast iron rusts when pumping liquid, which also negatively affects the life of the adapter.

Preparatory stage

The entire complex of work can be divided into four stages:

- Preparing the work site and the necessary tools.

- Dismantling of the old pipeline.

- Installation of plastic pipes.

- Connection of elements.

To make the connection between a plastic pipeline and a cast iron pipeline reliable and durable, you should prepare all the necessary tools and materials in advance:

- A special hammer with a rubber or wooden head. An ordinary iron hammer will not work here, since it can easily damage cast iron, which is so durable in appearance but very sensitive to impacts.

- Cutting tool. This could be a grinder or a hacksaw.

- Adjustable wrenches.

- Depending on the chosen connection method, you may need a hand press, thread cutter or welding machine.

- Plastic pipes of suitable size. To connect the toilet to the riser, you will need elements with a diameter of 110 mm; for laying pipes to the bathtub and sink, plastic with a diameter of 50 mm is best suited.

- Necessary adapters, gaskets, couplings, seals, sealing agents.

Step-by-step connection instructions

When connecting a PVC pipe and a cast iron product, take into account the diameter of the metal section of the system, since this element cannot be dismantled. This means that there is only one option when choosing a section in this case. For this reason, PVC pipe should be selected according to the size of the metal product.

Before installing polymer communications, it is necessary to dismantle a section of the cast iron pipeline. To do this, use a flat screwdriver. The joint is cleaned and the sealing material is removed from the socket.

This connection is quite strong, so the communications should be rotated when performing work. If the sewerage system has been in operation for a long time, the probability of disconnecting the elements is low. In such cases, you need to cut off the metal socket. But then we will have to consider methods for socketless connection of communications.

Set of tools and materials

To work you will need:

- welding machine;

- Bulgarian;

- pipe cutter;

- chamfer;

- thread cutting tool;

- marker;

- ruler;

- screwdriver;

- mallet.

The materials used are FUM tape, silicone, tow, fittings or flanges, and rubber seals.

Work progress

The sequence of actions may vary depending on the material used.

General installation steps:

Before starting installation, it is necessary to remove contamination from old communications.

- Prepare communications. The metal product is cleaned, since rust between the seal and the surface of plastic structures causes a decrease in the reliability of the connection. Old metal communications are often covered with a thick layer of contaminants (on the inside), which leads to a narrowing of the lumen and a decrease in the speed of fluid flow.

- If a socket connection is made, all surfaces are treated with silicone (metal and plastic products on the outer and inner walls).

- The elements of the system are joined. Additionally, the joints are protected with a sealing compound. This step can be skipped if you are making a flange connection or installing fittings.

We assemble a sewerage system for a house or apartment

The process of connecting pipes

Before you understand how to connect sewer pipes, you should understand the principle of assembling the entire sewer system.

So, all work should begin with creating a drawing on which you should depict your future system. Take a piece of paper and draw on it schematically all the plumbing fixtures that need to be connected to the sewer (sink, toilet, shower or bathtub, etc.).

Typical sewerage diagram

Then connect them with lines to the main sewer riser. Every line is a pipe

The pipes will be connected to each other using fittings. Please note that sewer pipes in a house usually have only two types: with a diameter of 50 and 110 mm. Fifty millimeter ones are designed to drain waste from sinks, sinks, bathtubs and showers, as well as from washing machines and dishwashers

If there are too many plumbing fixtures on one line, then it is better to increase its diameter to 110 mm, otherwise you will often have problems with blockages. But the toilet is connected only through a pipe with a diameter of 110 mm, while the connection itself to the plumbing fixture is usually made using a flexible corrugation, which is inserted into the sewer pipe.

Connecting the toilet

Having figured out what elements your sewer system consists of, you can go to the store. Since it is almost impossible to damage sewer pipes when working with them, you should not purchase components in excess. The main thing is not to forget that each pipe at one end has an extension into which another pipe will be inserted. If you cut a long pipe with a hacksaw (the cut must be strictly perpendicular) into two parts, then the second element will not have such an expansion, and to connect it to another pipe or fitting you will first need to install a coupling. In this case, the cost of different sets of pipes (one with a coupling or two short ones) will be approximately the same.

Pipe replacement

- The first in the sewerage system will be a turning fitting, to which you will connect a flexible hose of a plumbing fixture (siphon) on one side, and a pipe on the other. You can, of course, do without this fitting by connecting the siphon directly to the pipe, but in this case, if the joint is not airtight, there is a possibility of the joint leaking.

- When inserting a pipe into a fitting (or vice versa), be sure to observe two conditions:

- a rubber gasket must be placed at the joint (it is sold as a set);

- the pipe must fit into the fitting (or into another pipe) to its full possible depth.

Sewage scheme in the apartment

- Next, in places where other plumbing fixtures are connected to this pipe, tee fittings are installed. If you need to connect pipes of different diameters, use a special adapter fitting.

- When assembling the sewer, do not forget about creating the necessary slope of the pipes, otherwise your system will not provide liquid drainage.

- Assembling the system must move from the plumbing fixtures to the main riser so that the flow of water is not interfered with by the joints.

Violation of pipe integrity

Another reason that causes the need for replacement is the formation of cracks, fistulas, and fractures. If such defects are present, the system is considered worn out and requires immediate replacement.

Operating standards for cast iron sewers for apartment buildings are 25 years.

If replacement is necessary, repair work is carried out centrally - in all apartments within a certain time frame. Dismantling and installing sewer pipes in only one apartment causes a lot of inconvenience to neighbors. But as the experts are convinced, this will not have much impact on the functionality of the system and the efficiency of wastewater passage. The reason, as a rule, is the formation of congestion at the junctions of cast iron products with plastic parts.

Application of cold welding

If the pipe is damaged in places where it is impossible to use a clamp or coupling, cold welding should be used. This technology involves mixing several substances without heating, when combined, chemical reactions occur with the subsequent formation of a working polymer mixture.

Cold welding consists of epoxy resin and filler (hardener). For this reason, the adhesive composition has:

- high adhesive qualities;

- plastic;

- quick hardening (the solution must be used immediately after preparation);

- excellent mechanical characteristics.

Sealing cracks and holes in the sewer system involves performing the following actions:

- cleaning the surface from rust and paint with sandpaper;

- preparing the working solution (you should get a homogeneous mass);

- applying the mixture with a spatula around the damaged area (the first layer is laid as carefully as possible);

- coating a crack or hole with a composition;

- grinding hardened material;

- degreasing the surface;

- applying a second layer of polymer substance.

If a leak appears in the damaged area, the plastic substance is rubbed in until it hardens. At the polymerization stage, the material is given the desired shape. This is done with a hand wearing a rubber glove.

To speed up the hardening process of cold welding, use a construction hair dryer (especially when repair work is carried out in the cold season). After using a hairdryer, the polymer is pressed onto the surface.

Most cold welding manufacturers produce two-component products. The first tube contains epoxy resin, which is mixed with a plasticizer and additional filler. The second tube contains a material that acts as a hardener. First, the contents of the first tube are applied to the damaged surface, and then the second.

The main advantage of cold welding is the ability to carry out quick repairs without shutting down the sewer system.

Preparatory stage

The entire complex of work can be divided into four stages:

- Preparing the work site and the necessary tools.

- Dismantling of the old pipeline.

- Installation of plastic pipes.

- Connection of elements.

To make the connection between a plastic pipeline and a cast iron pipeline reliable and durable, you should prepare all the necessary tools and materials in advance:

- A special hammer with a rubber or wooden head. An ordinary iron hammer will not work here, since it can easily damage cast iron, which is so durable in appearance but very sensitive to impacts.

- Cutting tool. This could be a grinder or a hacksaw.

- Adjustable wrenches.

- Depending on the chosen connection method, you may need a hand press, thread cutter or welding machine.

- Plastic pipes of suitable size. To connect the toilet to the riser, you will need elements with a diameter of 110 mm; for laying pipes to the bathtub and sink, plastic with a diameter of 50 mm is best suited.

- Necessary adapters, gaskets, couplings, seals, sealing agents.

What is needed to replace cast iron sewer pipes

The best option for residents of apartment buildings is to reach an agreement with their neighbors and change the sewer system throughout the riser. This will help ensure the entire system operates efficiently. In addition, all residents will calmly accept temporary restrictions on the use of sewerage.

Before starting work, calculations should be made. If the new system exactly repeats the design of the existing one, there will be no problems. If you plan to install new plumbing fixtures or change the pipe laying scheme, then you definitely need to make calculations and double-check them several times.

After making sure that the drawing and calculations are correct, you can buy the required amount of materials, components, shaped elements, and also prepare tools. You will need a hammer, chisel, measuring instruments, and a marker. Additionally, you should buy plumbing silicone sealant, cement, and liquid soap.

It is highly advisable to provide an inspection hatch, even if there was none before. Thanks to this, the home owner has free access to inspect and repair the system. The choice is huge. You can purchase a decorative structure or find an invisible hatch and decorate it with the same materials as the walls.

Important: materials and tools

To simplify the dismantling of cast iron sewers, you need to prepare a large hammer or sledgehammer or grinder. Sometimes a gas torch is required to disassemble the system. A worthy alternative is a blowtorch. The number and type of tools depend on how the old pipeline is assembled.

Old sewer systems were assembled using cement-containing compounds. Over time, they only become harder, which makes dismantling very difficult. When installing the riser, sulfur filling was used. It is strong and durable, and can only be destroyed with a blowtorch or gas torch. To avoid poisoning from toxic fumes, you have to use gas masks.

Noise insulation and causes

Of course, pipes made of polyvinyl chloride and polypropylene are much better than cast iron. They will last longer, have an aesthetic appearance and are much cheaper. However, they have one significant drawback. It's noise. At first, even experienced specialists didn’t know how to deal with this. But today, as soon as the pipes are installed, they begin to deal with noise and sound insulation. It's not at all difficult to do this yourself. Therefore, do not be afraid! Having done this work, you will forget what the noise from the pipe is.

installation of a plastic pipe with a check valve and connection to a cast iron riser pipe

There is no one way to achieve the soundproofing effect yet. Therefore, different ones are used, depending on the design, acoustic features and the availability of certain materials.

Why do cast iron pipes make no sound, but modern plastic pipes are so noisy? After special research, several causes of extraneous sounds from the riser were revealed. Among them are:

- impact sounds occur when the contents hit the walls of the pipes, making noise;

- atmospheric phenomena occur when the wind howls, rain or, especially, hail;

- resonant manifestations appear when extraneous noise is transmitted;

- vibration sounds are transmitted from the entire structure, the movement of underground transport, and so on.

The pipe itself, due to its shape, suggests the possibility of perceiving and transmitting sounds of various natures. But the material from which it is made is also important. Those cast iron risers that still stand in old buildings do not make noise precisely for this reason. After all, it is not completely metal. It is an alloy that consists of different grains that differ in composition and properties. This ensures sound absorption, as the grains rub against each other and reduce vibration.

cutting old cast iron pipe

In addition, such pipes are covered with plaque from the inside, which in itself plays the role of an excellent sound insulator, despite the fact that the movement of wastewater slows down.

Soundproofing installation

The main task of sound insulation in an apartment is to reduce noise to a minimum and, if possible, dampen vibration.

The ideal option is to purchase special noise-absorbing pipes. Some companies produce and install such risers. They contain plastic with the addition of mineral powder. This provides a material that has similar properties to cast iron. However, these pipes are expensive and may not be affordable for many. In addition, their service life, as a rule, does not exceed twenty years.

Therefore, plastic pipes are mainly used for replacement, followed by insulation from noise and sound.

They are isolated from the walls using damper clamps, and from the ceilings - with polyurethane foam boards.

In order to eliminate unpleasant gurgling in pipes, polyurethane foam or polystyrene foam is used. Both the riser and the wiring are turned around so that sound is not transmitted.

Replacing a sewer riser is a difficult job, but even a beginner can handle it. However, if you are not confident in your abilities or the pipes in the house are very rusty, then it is better to resort to the help of specialists and entrust the work to them, since otherwise you risk flooding both your apartment and the neighbors below.

Why plastic is considered the best option

There are several options for replacing cast iron sewer pipes, including the same good old cast iron. Modern cast iron products are more technologically advanced, easy to install and almost as durable as those produced half a century ago. But in most cases, owners of houses and apartments choose plastic. There are several reasons:

- Smooth inner walls. This is the most valuable property for sewer pipelines. Deposits do not form on smooth surfaces, the permeability of the pipes is high, and their diameter almost does not decrease over time. Replacing cast iron sewer pipes with plastic ones solves the problem of frequent blockages. If the pipeline becomes clogged, it is easier to clean it.

- Lightness of the material. Plastic is tens of times lighter than cast iron, so any products made from it are easier to transport, carry, lift up stairs, and install. Often it is chosen precisely for these reasons.

- Easy to install and dismantle. To install a plastic pipeline, you do not have to buy complex, expensive equipment. It is much easier to install than cast iron. If necessary, the structure can also be easily disassembled. If you need to replace a damaged section, there will be no problems; you can do everything yourself.

- Tightness. Homeowners who have had to install cast iron pipes themselves know very well how difficult it is to achieve tight connections. There are no such difficulties with plastic products. Manufacturers produce not only the pipes themselves, but also additional elements that facilitate installation.

The junction of cast iron and plastic sewerage

A few words about the shortcomings of the material

Whatever advantages plastic has, it is not perfect. To make an informed decision, it is worth understanding its shortcomings well. The main one is poor resistance to high temperatures.

In many ways, the operating temperature range depends on the quality of the material and manufacturing technology. Polymers with good performance characteristics are not cheap, so when choosing, you should focus not only on prices, but also on technical indicators.

Plastic drainage may not withstand prolonged exposure to hot liquid. So, at a temperature of 60 degrees, the pipeline sometimes becomes deformed. A temperature of 90 degrees can seriously disrupt the operation of the system and will require repairs.

Manufacturers of plastic sewer pipes are well aware of the problems that consumers have, so they offer products with special coatings that reduce risks. They are somewhat more expensive than traditional ones, but they withstand high temperatures better, are soundproofed, and have high throughput.

Method three - connection using a fitting

A fitting is a coupling where there is an internal thread on one side and a socket on the other, and most often this method is used when a flat plastic pipe is used. The reliability of the connection here is achieved on both sides, that is, using a rubber seal in the form of a ring on the socket side and sealing the threaded connection.

This type of connection is the most labor-intensive, since it will be necessary to cut threads on a cast iron pipeline. The edge of the pipe is leveled in any way with simultaneous chamfering. After that, the edge must be lubricated with machine lubricant and thread cutting must begin, the depth of which should not exceed 50 mm. Sealing the thread is achieved using tow or fum tape.

After cutting it, you need to install a press fitting with a socket. It is necessary to tighten the fitting by hand, since the use of wrenches can cause the thread to fail and leaks are guaranteed. After installing the fitting, you can install a plastic extension with a sealing collar.

Types and classification of cast iron pipes

Depending on the scope of application, cast iron pipes are classified into:

- pressure - VShChG (high-strength cast iron with nodular graphite);

- non-pressure - ChK (cast iron sewer);

- socketless - SML;

- pressure socket type - ChNR (cast iron pressure socket type).

Let's take a closer look at these varieties.

Pressure

The main area of application for cast iron pressure pipes is industrial production. By adding spherical graphite to cast iron, it becomes ductile and viscous. This allows it to replace products made of plain cast iron and cast or forged steel. Pressure pipes successfully compete with steel pipes, this is due to their high corrosion resistance and service life, which is 3 to 8 times longer.

They can be used in aggressive environments and at low temperatures, have high strength, and are therefore used for sewage systems at great depths and under highways. They are produced both with a socket connection and using rubber sealing cuffs.

Gravity

This type of cast iron pipe is not as durable as the previous one. Flake graphite is used for their production. Therefore, non-pressure cast iron pipes are used only in systems without high loads, for example when laying internal sewerage. The advantage of these products is the ability to combine with plastic pipes (rubber adapters are used for this) and reuse (with careful dismantling).

Socketless

For the manufacture of socketless products, cast iron with the addition of a large amount of graphite is used. Inside, they are coated with special compounds based on epoxy resin, which reduces the formation of deposits. This coating also protects the pipe from corrosion, which allows it to be used in aggressive environments.

The advantage of SML pipes is: there is no need for additional fire and sound insulation, high strength and resistance to high temperatures. Since they do not have a bell, they are connected using special clamps. The main scope of application is the installation of drainage systems.