Properties of cast iron

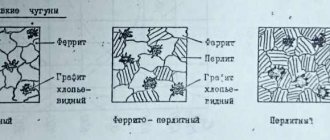

Cast iron is a compound of iron and carbon. Among the main properties are the mass, shape, volume and placement of graphite impurities. In a state of thermodynamic equilibrium, the structure of iron-carbon alloys can be described by a diagram. During the modification of the composition, the following changes: • eutectic temperature (oC) T = 1135 + 5*Si - 35*P - 2*Mn + 4*Cr; • eutectic carbon saturation (%) C = 4.3 – 0.3*(Si+P) – 0.04*Ni – 0.07*Cr; • eutectoid transformation temperature (оС) T = 723 + 20*Si + 8*Cr – 30*Ni – 10*Cu – 20*Mn; • saturation of the eutectoid with carbon (%) C = 0.8 – 0.15*Si – 0.8*Ni – 0.05*(Cr+Mn).

The placement of critical points depends on the degree of heating - in the case of cooling, they move slightly downward. The most accurate simple formulas have been established for the vast majority of grades of cast iron that do not contain alloying components:

• eutectic saturation with carbon C = 4.3 – 0.3*(Si+P); • saturation of the eutectoid with carbon C = 0.8 – 0.15*Si.

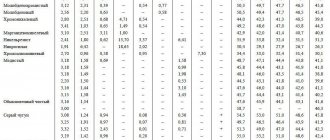

The effect of compounds on the structure can be seen in Table 1. The coefficients that determine the conditional graphitizing effect can be taken into account only in the presence of carbon (C) (about 3%) and silicon (Si) (about 2%).

Table 1. Approximate influence of elements on the structure of cast iron

| Elements | Content in % | Influence | Relative graphitizing action | ||

| To the main metal mass | To graphite | When hardening | In solid state | ||

| Silicon | up to 3.0 | Reducing perlite content | Increase in number and consolidation | +1,0 | +1,0 |

| Carbon | more than 1.7 | Reducing perlite content | Increase in number and consolidation | +1,0 | from +0.2 to +0.5 |

| Manganese | more than 0.8 more than 1.0 | Grinding of perlite Formation of manganese sulfide | Weak grinding The same, but a decrease in quantity | -0,2 | -0.2 to +0.5 |

| Phosphorus | up to 1.0 | Formation of manganese sulfide | The same, but decreasing the quantity | -0,2 | -0.2 to +0.5 |

| Sulfur | up to 0.2 | Sulfide formation | Decrease in quantity | -2,0 | -2 to -4 |

| Nickel | up to 1.5 | Grinding perlite | Increase in quantity and weak grinding | +0,4 | from +4 to -0.2 |

| Chromium | up to 1.0 | Grinding perlite | Reducing quantity and weak grinding | -1,2 | -1.2 to -3.0 |

| Copper | up to 1.0 | Does not affect | Not installed | +0,3 | from +0.3 to -0.2 |

| Molybdenum | up to 0.5 | Grinding perlite. Formation of a needle-like structure | Reducing quantity. Significant comminution | -0,5 | -0.5 to -1.5 |

| Vanadium | up to 0.5 | Grinding perlite | Reducing quantity. Significant comminution | -2,0 | from -2 to -3 |

| Aluminum | up to 0.5 | Reducing perlite content | Increase in number and consolidation | +3,0 | +10 |

| Cerium and magnesium | — | — | Spheroidinization | — | — |

Physical and mechanical properties

The most important indicators of the physical and mechanical properties of the microstructure of cast iron can be found in table. 2, physical properties - in table. 3. Indicated in the 3rd table. the specific gravity can vary greatly due to fluctuations in the volume of combined carbon and changes in the number of pores. The specific gravity of cast iron at the moment of its melting is 7 ± 0.1 g/cm3. When adding various simple impurities, it decreases. The coefficient of thermal expansion indicated in Table 3 is influenced by the structure of cast iron.

A strong irreversible increase in volume occurs in the event of a change in temperature at which an equilibrium phase transition occurs in a physical system. The indicator can reach 30%, but often it does not exceed 3% when heated to 500 °C. The increase in volume is facilitated by components that form graphites, and components that form carbides interfere, as well as coating of cast iron by enameling, metallization and galvanization.

Table 2. Physical and mechanical properties of the structural components of unalloyed cast iron

| Structural component | Specific gravity G/cm3 | Coefficient of thermal linear expansion a*10 - in 1/оС at temperatures 20 -100 оС | Heat capacity in cal/G*oC at temperature in oC | Thermal conductivity in cal/cm*sec oC | Electrical resistance in µOhm 9 cm | Tensile strength σ in kg/mm2 | Elongation σ in % | Hardness HB | ||||

| 100 | 200 | 400 | 600 | 900 | ||||||||

| Austenite | — | 17-24 | 0,12 | — | — | — | — | 0,1 | — | — | 50±10 | — |

| Ferrite | 7,9 | 12-12,5 | 0,11 | 0,12 | 0,13 | 0,13 | 0,17 | 10 | 40±10 | 40±10 | 40±10 | 85±35 |

| Perlite | 7,8 | 10-11 | — | — | — | — | — | 0,12 | 20 | 100±30 | — | — |

| Cementite | 7,7 | 6-8,5 | 0,15 | 0,15 | 0,15 | 0,16 | 0,19 | 0,017 | 140 | 4±1 | 0 | 600±100 |

| Graphite | 2,2-2,3 | 7,5-8 | 0,2 | 0,22 | 0,27 | 0,31 | 0,36 | 0,036 | 150 | |||

Thermal properties

The heat capacity of cast iron of a specific composition can be determined according to the law of mixing, using the information given in Table 2. It can be equal to 0.00018 kcal/(g•oC) when the temperature overcomes the phase transition threshold, up to the melting point. After overcoming the melting point – 0.00023 ± 0.00003 kcal/(g °C). The thermal effect during solidification is 0.055 ± 0.005 kcal/g, and in the case of eutectoid decomposition of austenite, it is determined by the volume of included pearlite, and can reach 0.0215 ± 0.0015 kcal/g at a eutectoid concentration of 0.8% SS.

The heat capacity per unit volume of this substance can be used for aggregated calculations: for cast iron in the solid state - approximately 0.001 kcal/cm3 oC, and in the liquid state - 0.0015 kcal/cm3 oC.

Thermal conductivity cannot be determined by the law of mixing; indicated in the table. 2 its indicators for elements, with an increase in their sizes in disperse systems, decrease. Typical thermal conductivity indicators are shown in table. 3. The role of the components included in cast iron in changes in thermal conductivity can be seen in deviations in the level of graphitization. The thermal conductivity of iron decreases with increasing volume of various additives included in it.

Cast iron in the molten state has a thermal conductivity of about 0.04 cal/cm·s·оС. Using aggregated calculations, the thermal conductivity coefficient of cast iron in the solid state is equal to its thermal conductivity, and in the molten state - to 0.3 mm2/s.

Table 3. Typical physical properties of cast iron

| Cast iron type | White | Grey | Malleable | Note, with increasing temperature: “+” - increases; “-” - decreases |

| Specific gravity G/cm3 | 7,5±0,2 | 7,1±0,2 | 7,3±0,1 | — |

| Coefficient of thermal linear expansion a·10-в1/оС, at temperatures 20-100 оС | 8±2 | 10±2 | 11±1 | + |

| Actual shrinkage in % | 1,8±0,2 | 1,1±0,2 | — | + |

| Thermal conductivity in cal/cm sec oC | 0,08±0,2 | 0,10±0,02 | 0,13±0,02 | — |

| Dynamic viscosity at liquidus temperature dyn sec/cm2 | 0,08 | 0,04 | — | — |

| Surface tension in dynes/cm2 | 900±100 | 900±100 | — | + |

| Electrical resistance in Mc ohm cm | 70±20 | 80±40 | 50±20 | + |

| Heat capacity in cal/G oC | 0,13±0,02 | 0,12±0,02 | 0,12±0,02 | + |

| Coercive force in e | 13±2 | 10±1 | 1,5±0,5 | — |

| Residual magnetism in gs | 5000±1000 | 5000±1000 | 5000±1000 | — |

Hydrodynamic properties

Absolute viscosity indicators can be found in table. 4. Viscosity tends to decrease with an increase in the proportion of manganese, as well as in the case of a decrease in the proportion of sulfur and additives of non-metallic origin, due to temperature indicators.

The decrease in viscosity indicators and the ratio of the absolute temperatures of the experiment and the moment of solidification are in direct proportion. During the transition of the temperature of the onset of solidification, viscosity indicators rapidly increase.

Data on the surface tension of cast iron for larger calculations can be taken from Table 3. It increases with a decrease in the proportion of carbon and changes rapidly when components of non-metallic origin are added to the composition.

To determine electrical characteristics, you can use Kurnakov's law. Approximate amounts of impurities can be found in table. 2, and specifically cast iron - in table. 3. The effect of incoming components on the electrical resistance of a solid can be conditionally placed in the following sequence, in descending order: silicon (Si), manganese (Mn), chromium (Cr), nickel (Ni), cobalt (Co).

Table 4. Viscosity coefficients of cast iron

| Temperature in °C | Viscosity coefficient in (dynes sec/cm2) of cast iron with carbon content in % | ||||||

| 1,0 | 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | |

| Cast iron solidifies white | |||||||

| 1250 | — | — | — | — | — | 0,029 | 0,021 |

| 1300 | — | — | — | — | 0,028 | 0,024 | 0,018 |

| 1350 | — | — | 0,029 | 0,026 | 0,024 | 0,02 | 0,016 |

| 1400 | 0,026 | 0,025 | 0,024 | 0,023 | 0,02 | 0,02 | 0,016 |

| Cast iron hardens gray | |||||||

| 1280 | — | 0,043 | 0,041 | 0,04 | 0,039 | 0,037 | 0,035 |

| 1300 | 0,043 | 0,042 | 0,041 | 0,04 | 0,038 | 0,037 | 0,035 |

| 1350 | 0,04 | 0,04 | 0,039 | 0,038 | 0,037 | 0,036 | 0,035 |

| 1400 | 0,038 | 0,038 | 0,037 | 0,036 | 0,035 | 0,034 | 0,035 |

Mechanical properties

Statistical characteristics. The tensile strength (threshold of mechanical stress) of cast iron can be calculated qualitatively, based on its structure according to the indicators indicated in Table 2. The strength of the components included in the structure of cast iron increases with increasing their weighted sizes in dispersed systems. The mechanical stress threshold is most influenced by the structure, number, volume and location of the graphite components; the structure of the total mass of the metal is not so important.

The maximum reduction in strength is observed when placing chain-like graphite components, making the metal structure less continuous. The spheroidal structure of graphite gives the metal maximum strength. As the temperature of the test process increases, the mechanical stress threshold remains essentially unchanged up to 400 °C (in the range from 100 to 200 °C, the strength decreases slightly, within 10 - 15%). After exceeding 400 °C, a constant loss of mechanical stress threshold indicators is recorded.

The plasticity characteristics are determined by the structure of the total mass of the metal (according to the indicators given in Table 2), but even more significantly by the form of graphite impurities. If the shape is spheroidal, then the elongation can reach up to 30%. In gray cast iron, such elongation almost never reaches even a tenth of a percent. Elongation in baked gray cast iron (ferritic) can be approximately 1.5%.

Elasticity is determined, by and large, by the graphite structure. It does not change during the thermal impact on cast iron, unless changes are made to the form of graphite impurities. Bending tests show a proportion of elastic deformation equal to 50–80% of the total deformation.

The creep of cast iron should not be confused with the case of growth (an irreversible increase in its volume). Cast iron, which contains no alloying components, when heated above 550 °C, is characterized by residual deformations, depending on its growth, prevailing over the deformations acceptable when determining creep. If its speed is 0.00001% per hour, then over 1 thousand hours at a load within 3 kg/mm2, gray cast iron without alloying components exhibits stability at temperatures within 400 °C, and cast iron containing alloying components - up to 500 °C . An increase in creep resistance can be achieved with austenitic cast iron, as well as with cast iron with the addition of molybdenum or with an increased presence of nickel and chromium.

If cast iron contains additives in the form of graphite, then its elastic modulus will be only conditional. This indicator is not determined by the structure of the main volume of the metal, and is characterized by the proportion of graphite additives and their structure: it decreases with an increase in the proportion of graphite additives and with a decrease in their similarity to the globular structure.

Impact strength is not an entirely accurate characteristic of dynamic properties. It increases with an increase in ferrite inclusions, in the case of a decrease in graphite inclusions, and also when the structure of the graphite component is as similar as possible to the spherical one. With an uneven period of loading, the fatigue limit reaches a maximum due to an increase in stresses arising in the direction of application of the load. The fatigue limit increases with increasing mechanical stress threshold and load repetition.

Technological properties

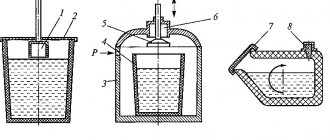

Fluidity is determined by metallic properties and structure. It often depends on the length of the casting being filled, and increases with a decrease in viscosity indicators, an increase in overheating (at the same time, fluidity is most affected by overheating above the solidification temperature), a decrease in the solidification interval and is determined by the latent heat of fusion and heat capacity, expressed by volume.

Chemical properties

The degree of resistance to oxidation is determined by the structure of cast iron and the environment (chemical composition, temperature and its course). The elements that make up cast iron have electrode potential. By decreasing this value, they can be arranged in the following sequence: graphite (iron carbide), double or triple phosphide eutectic - oxypher.

The voltage between graphite and oxyfer (ferrite) is 0.56 volts. The degree of corrosion resistance decreases with a corresponding increase in the level of dispersion of the components included in the composition. However, reducing the dispersion level of iron carbide too much reduces the degree of resistance to oxidation. Alloying components affect the ability of cast iron to resist oxidation along with their effect on the structural composition. Excessive resistance to oxidative processes is observed in cast iron castings with preserved crust after casting.

High-strength cast iron with nodular graphite

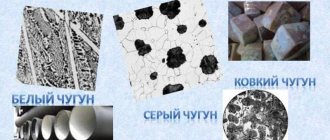

Ductile iron is produced by introducing magnesium (up to 0.9%) and cerium (up to 0.05%) into liquid gray iron before pouring it into molds. The main part of these modifiers evaporates, oxidizes and turns into slag, so that no more than 0.01% of these elements are found in the solid metal. Magnesium and cerium actively remove sulfur from cast iron. But their main role is to change the flake-plate shape of graphite to spherical. After modifying the cast iron with magnesium or cerium, 75% ferrosilicon (an alloy of iron and silicon) is added to the ladle. Unlike modified gray cast iron, ductile iron has a higher carbon and silicon content and a lower manganese content.

The metal base of ductile iron consists of ferrite and perlite or only perlite. This cast iron combines the valuable properties of steel and cast iron. It has relatively high strength with sufficient ductility and toughness. High-strength cast iron successfully replaces steel casting and even steel forgings, which gives a great economic effect. Products made of high-strength cast iron, due to its increased wear resistance, can work under friction conditions. High-strength cast iron retains its strength better than gray cast iron when heated, so it can be used for work at temperatures up to 400°C (gray cast iron can withstand temperatures up to 250°C).

Introduction

Cast iron is an alloy of iron with carbon and other elements containing more than 2.14% C.

In metallurgical production, cast iron is smelted in blast furnaces. The resulting cast iron is divided into: conversion, special (ferroalloys) and foundry. Converting and special cast irons are used for subsequent processing into steel. Cast iron (about 20% of all cast iron) is sent to machine-building plants for use in the manufacture of cast parts (castings).

Structural unalloyed cast iron for the production of castings in mechanical engineering has the following chemical composition,%: 2.0 - 4.5 C; 1.0 - 3.5 Si; 0.5-1.0 MP; impurity content: no more than 0.3% S; no more than 0.15% S.

The widespread use of cast iron in industry is due to the optimal combination of various properties: technological (casting, machinability), operational (mechanical and special) and technical and economic indicators.