This term has other meanings, see KNB.

Elbor (Leningrad + boron - source: Tekhnika-Molodezhi magazine for 1985)

,

borazon

(from boron + nitrogen),

cubonite

,

kingsongite

[1][2],

kiborite

are trademarks of superhard materials based on the cubic β-modification (sphalerite) of boron nitride, or cubic boron nitride (Soviet abbreviation - KNB, foreign - cBN ). In terms of hardness and other properties, it is close to diamond (10 on the Mohs scale).

Chemical formula: BN.

Properties of Elbor material

| Material | Microhardness, ×10² MPa | Temperature stability, °C |

| Diamond | 1000 | 650—700 |

| Elbor | 800—900 | 1100—1300 |

| Silicon carbide | 300—320 | 1200—1300 |

| Electrocorundum | 180—220 | 1500—1700 |

Appearance

Yellow, highly refracting transparent crystals, with good play of light, natural shape - octahedral.

Hardness

It is almost as hard as diamond. Its high hardness, 3-4 times higher than the hardness of traditional abrasives, is an important advantage, as it significantly reduces the wear of CBN grains during grinding and maintains their sharpness for a long time.

Thermal and chemical resistance

Another important property and advantage of CBN is temperature stability: noticeable oxidation of the surface of CBN grains begins at 1000–1200 °C, in contrast to 600–700 °C for diamond. Such temperatures during grinding are instantaneous and occur only under very harsh grinding conditions. Therefore, CBN grains wear out very little from thermal loads.

An important property and advantage of CBN is its high chemical resistance. Elbor does not react with acids and alkalis, and is inert to almost all chemical elements that make up steels and alloys. Particularly noteworthy is the inertness of CBN to iron, which is the basis of all steels, while diamond dissolves well in iron, which causes intense wear of diamond wheels when grinding steels.

Elbor: better than diamond bars?

The modern market for sharpening devices is rapidly growing and developing. New brands are emerging and community awareness is increasing. But the basic materials used for sharpening remain the same as decades ago.

In this article we will take a closer look at CBN abrasives and their differences from others.

But first, let’s briefly examine all the main groups of abrasives and their characteristics. There are two groups of abrasives: synthetic and natural .

Synthetic

Includes silicon carbide, aluminum oxide, diamond bars (organically or galvanically bonded), CBN bars.

Silicon carbide

This material is produced in electric furnaces by chemically reacting silicon with carbon. The raw material is quartz sand. In terms of hardness, silicon carbide is inferior to CBN and diamond.

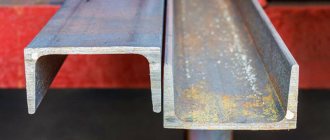

Stone Boride CS-HD 25x6x152mm silicon carbide F220 on blank

Aluminium oxide

Aluminum oxide is a compound of aluminum and oxygen. It is widespread in nature as the main component of alumina, a mixture of aluminum oxides and elements such as potassium, sodium, magnesium, etc. For sharpening, both on electrical equipment and on sharpeners, and for manual sharpening, electrocorundum is mainly used. Electrocorundum (alundum, aloxite) is crystalline aluminum oxide, which is artificially obtained by remelting alumina. This is done in a continuous manner in arc furnaces, followed by crystallization of the substance.

Stone Boride T2 25x6x152mm aluminum oxide F600 on blank

CBN bars

Superhard material based on the cubic β-modification (sphalerite) of boron nitride, or cubic boron nitride. In terms of hardness and other properties, it is close to diamond (10 on the Mohs scale). It is obtained by heating equal amounts of boron and nitrogen at a temperature of 1700–1800 °C and a pressure of 8–12 GPa.

CBN block PAZ 40/28 150x25x3 mm

Natural

These are stones of natural origin. They are one of the most reliable abrasives created by nature itself.

One of the most popular types of natural stone for sharpening is Arkansas stone . The unique deposits of this stone are located in the American state of the same name. This is an excellent tool for fine and durable sharpening of cutting tools. Arkansas stones have a rectangular shape and differ in the level of abrasiveness, and therefore they are divided into 4 groups depending on the grain size of the surface. Arkansas whetstones are indispensable when working with kitchen and hunting knives, household and industrial scissors. To improve the quality of sharpening, special oil is often used.

Another excellent example of high-quality natural abrasives are Belgian stones Belgian Stone . The small pomegranate crumbs used in production are their calling card. The perfect geometric shape of garnets gives waterstone another unique characteristic - the smooth edge of the stones means they polish the metal without leaving tiny burrs behind. This results in a perfect polish without any roughness.

So, let's move on to the topic of the article - CBN abrasives .

History of appearance

Cubic boron nitride was first prepared in 1957 by Robert H. Wentorf Jr. for General Electric. Robert H. Wentorf was a staff scientist at the General Electric in Schenectady, New York, and a professor of chemical engineering. in engineering from Rensselaer Polytechnic Institute.

In 1969, the company registered the trademark " Borazon " for the crystal obtained by Wentorf.

Robert H. Wentorf

In our country, cubic boron nitride was first synthesized in 1960 at the Institute of High Pressure Physics of the Academy of Sciences under the leadership of Academician L.F. Vereshchagin and was named elbor (Leningrad borazon). Since 1965, CBN has been synthesized on an industrial scale using Abrasive technology (St. Petersburg). In 1980, a state standard was adopted for grinding wheels made using Borazon.

Characteristics

CBN has no analogues in nature; its chemical formula is BN .

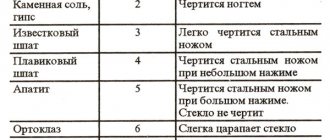

The table below shows the main parameters of CBN and other popular abrasives

It can be seen that the hardness of CBN is only slightly less than that of diamond. So, if the microhardness of diamond is 1000×10^2 MPa, then for CBN this figure is (800-900)×10^2 MPa, and compared to other traditional abrasives, it is three to four times higher. Accordingly, wear of CBN grains will take several times longer.

Comparison of crystal lattices of diamond and CBN

If in terms of hardness, elbor is slightly inferior to diamond, then in terms of thermal and chemical resistance, it is quite superior.

For example, elbor begins to oxidize at a temperature of 1000-1200 °C, and a similar process in diamond begins at 600-700 °C. The material is also chemically resistant, it does not react with alkalis and acids, and is also inert to many chemical elements that make up alloys and steels. It is especially important that CBN is inert towards iron, which cannot be said about diamond, which dissolves very well in it. Because of this feature, diamond abrasive wheels wear out quickly when grinding steel.

In progress

Directly during sharpening, CBN bars show themselves very well. On the one hand, CBN abrasives are softer than diamond abrasives, this is due to the fact that the crystals themselves have more cutting edges. Thanks to this, each pass with a stone leaves a cleaner mark. The next advantage is the presence of polishing options among CBN bars, which allow you to sharpen knives “in a mirror”.

CBN abrasives can withstand very high processing speeds and high temperatures. Just like diamonds, CBNs are best used for working on steels with a hardness of more than 55 HRC .

The bar retains the sharpness of the grains for a long time (high wear resistance), withstands high thermal loads, does not require the use of water or oil, and is slowly salted.

Conclusion

CBN whetstones for sharpening knives are gaining popularity and will definitely occupy their niche in the field of sharpening, both among amateurs and professionals.

We remind you that we have opened a new retail department! It is entirely dedicated to sharpening equipment, as well as tools and materials for making knives. We are waiting for your visit.

You will also find all the tools necessary for sharpening in a special section of our website.

Application

It is used in industry in grinding tools for processing various steels and alloys. Elbor as an abrasive material has the following advantages when grinding:

- maintains the sharpness of the grains for a long time (high wear resistance), which determines the high cutting ability and durability of the wheels;

- withstands high thermal loads, which allows intensifying grinding modes;

- allows you to grind complex alloy steels and alloys without adhesive and diffuse wear of CBN grains.

The use of CBN grinding wheels compared to other abrasive ones, including diamond ones, contributes to a significant increase in productivity, accuracy and quality of machined surfaces of parts in various grinding operations.

CBN tool

Borazon is used for the manufacture of individual elements and components of grinding machines, as well as as an independent tool for surface treatment. In terms of service life, CBN tools are superior to tools made from diamond and other abrasives. A characteristic feature of CBN is a softer grinding of surfaces.

Elbor circle

Borazon grinding wheels are produced in accordance with the requirements of GOST 24106-80. The document indicates the values of all quality indicators. Its tables for each brand indicate the following information:

- relative concentration of CBN;

- degree of hardness;

- maximum deviations of circle height;

- bore diameter;

- width height;

- graininess of the layer.

CBN circles are marked with these parameters indicated in turn. This makes it easier to select the required grinding wheel.

As information about the sizes and types of circles, you can use the information from GOST 17123 - 79. However, it must be taken into account that this document has lost force in the Russian Federation.

The marking of abrasive equipment must have the following designations:

- type, sizes;

- material;

- granularity of the abrasive layer;

- hardness;

- operating speed;

- CBN concentration;

- link used.

For circles with a diameter greater than 225 mm, the listed information is applied to the body. On a tool of smaller diameter there are indicators of primary importance. For products up to 50 mm in size, the use of labels is provided.

The body of the circle is made of metal or ceramics. The maximum speed directly depends on the material used. For a metal case it is 125 m/s, for a ceramic case 60 m/s, for a metal-ceramic case 80 m/s.

Before transportation, the grinding tool is wrapped in packaging material to protect the abrasive layer from damage, and placed in boxes with gaskets that protect it from moving inside.

The use of CBN wheels depending on the composition of the ligaments

The substance that transforms the abrasive grains of a grinding tool into a homogeneous dense mass is called a binder. For each type of processed material, its own type of connecting elements is used. These components determine what type of work the grinding equipment is intended for. There are three main types of ligaments.

- Organic. Equipment with such a binder is marked in the form of the letter “O”. This type of filler is used for the production of wheels intended for sharpening steel cutting tools, grinding guide frames, and flat grinding of hard-to-cut steels. Using a tool made of borazon on an organic bond, chip flutes are processed and grooves are cut.

- Ceramic. Denoted by the letter "K" or Latin "V". CBN wheels on this bond are used for grinding high-precision parts made of steels and alloys. They are used for round internal and flat processing of products with threads and teeth, holes, tracks of small-sized precision bearings.

- Metal . It is marked in the form of the letter “M”. Suitable for fine pitch thread grinding and fine honing of steels. Tools with this type of binding can be used for processing wooden, stone, ceramic and composite surfaces.

Borazon wheels can be used to level the surface of hot and cooled metals. They are suitable for finishing products. Grinding with tools of any type of bond is carried out with dry cooling or using liquids. Water, special emulsions and industrial oil are used as a coolant.

Advantages of CBN wheels

The octahedral structure of the material allows for gentle processing and brings polished surfaces to a mirror state.

Advantages:

- The structure of borazone is second only to diamond in hardness.

- The cost of equipment made from CBN is lower than that of circles made from natural minerals.

- High level of wear resistance due to long-term preservation of the sharpness of the grains.

- Resistance to high thermal loads.

- Ability to grind alloy steels with complex chemical composition.

The listed advantages contribute to increasing demand for this tool in industry, machine tool and mechanical engineering.

CBN cutter

This tool is designed for removing surface layers from parts. The shape of the cutter can be straight or radial. The sharpening angles of the leading and trailing edges are also different.

CBN cutters are available in lengths from 40 to 125 mm in increments of 20 to 80 mm or more. The size of the working part of the cutting element determines the diameter of the base; it has dimensions from 10 to 40 mm. The thickness of the inner core of the cutter is from 6 to 12 mm. Massive cutters are produced for rough processing and correction of the shape of the part. Technical characteristics are described in GOST R 50302-92 or GOST 13297-67.

Applications and advantages of CBN cutters

This tool is designed for cutting, making passes during milling, turning parts, grinding on lathes and boring machines, CNC equipment and built into automatic lines.

The shape of the cutting edges and the type of cutter depend on the purpose, type of machine and the material being processed. The properties of borazone cutters must be taken into account when choosing an effective method of application. The demand for CBN cutters and inserts provides the following advantages:

- preservation of sharpness during operation;

- self-sharpening ability of grains;

- high cutting ability;

- resistance to thermal loads, no burns to the workpiece;

- convenient removal of removed chips;

- The surface finish quality exceeds the accuracy class of diamond cutters.

Thanks to these advantages, when working with a tool made of borazone, it becomes possible to select an accelerated operation mode. This significantly increases labor productivity.

Qualitative characteristics of CBN cutters:

- The strength of the crystals and complete inertness to iron allows the cutters to be used for fine finishing and semi-finish turning and boring of parts made of hardened steels with increased hardness and cast irons.

- The high wear resistance of borazon makes it possible to process parts that require maintaining geometric accuracy.

- CBN tools polish and grind threads, teeth, hard alloys, heat-resistant steels, glass, and silicon. The cutters are used for processing ceramics, marble, granite, and precious stones.

It is not recommended to process metals with low hardness using borazone tools. During the grinding process of soft alloys, surface deformation may occur.

Notes

- [www.popmech.ru/article/13540-novyiy-mineral/ New mineral: Cubonite from the bowels of the Earth] (Russian). Popular Mechanics (August 3, 2013). “The International Mineralogical Association (IMA) last week officially confirmed the discovery made by an international group of scientists back in 2009: there is a natural cubic modification of boron nitride, called “qingsongite.” Retrieved August 4, 2013. [www.webcitation.org/6IqE4e6vj Archived from the original on August 13, 2013].

- Iqbal Pittalwala.

[ucrtoday.ucr.edu/16729 International Research Team Discovers New Mineral] (English). University of California (August 2, 2013). — “Geologists at the University of California, Riverside have discovered a new mineral, cubic boron nitride, which they have named “qingsongite.” The discovery, made in 2009, was officially approved this week by the International Mineralogical Association.” Retrieved August 4, 2013. [www.webcitation.org/6IqE7r9GU Archived from the original on August 13, 2013].

Excerpt characterizing Elbor

“We deigned to lie down and put out the fire, your Excellency.” “No reason, no reason...” the prince said quickly and, putting his feet into his shoes and his hands into his robe, went to the sofa on which he was sleeping. Despite the fact that nothing was said between Anatole and m lle Bourienne, they completely understood each other regarding the first part of the novel, before the appearance of pauvre mere, they realized that they had a lot to say to each other secretly, and therefore in the morning they looked for an opportunity see you alone. While the princess went to her father at the usual hour, m lle Bourienne met with Anatole in the winter garden. Princess Marya approached the office door that day with special trepidation. It seemed to her that not only did everyone know that her fate would be decided today, but that they also knew what she thought about it. She read this expression in Tikhon’s face and in the face of Prince Vasily’s valet, who met the hot water in the corridor and bowed deeply to her. The old prince that morning was extremely affectionate and diligent in his treatment of his daughter. Princess Marya knew this expression of diligence well. This was the expression that happened on his face in those moments when his dry hands clenched into a fist out of frustration because Princess Marya did not understand the arithmetic problem, and he, getting up, walked away from her and repeated the same words several times in a quiet voice. the same words. He immediately got down to business and started the conversation by saying “you.” “They made me a proposition about you,” he said, smiling unnaturally. “I think you guessed,” he continued, “that Prince Vasily came here and brought with him his pupil (for some reason Prince Nikolai Andreich called Anatoly his pupil) not for my beautiful eyes.” Yesterday they made a proposition about you. And since you know my rules, I treated you. – How should I understand you, mon pere? - said the princess, turning pale and blushing. - How to understand! – the father shouted angrily. “Prince Vasily finds you to his liking for his daughter-in-law and makes a proposal to you for his pupil. Here's how to understand it. How to understand?!... And I’m asking you. “I don’t know how you are, mon pere,” the princess said in a whisper. - I? I? what am I doing? Leave me aside. I'm not the one getting married. What do you? This is what it would be good to know. The princess saw that her father looked at this matter unkindly, but at that very moment the thought came to her that now or never the fate of her life would be decided. She lowered her eyes so as not to see the gaze, under the influence of which she felt that she could not think, but could only obey out of habit, and said: “I wish only one thing - to fulfill your will,” she said, “but if my desire it was necessary to express... She did not have time to finish. The prince interrupted her. “And wonderful,” he shouted. - He will take you with a dowry, and by the way, he will capture m lle Bourienne. She will be a wife, and you... The prince stopped. He noticed the impression these words made on his daughter. She lowered her head and was about to cry. “Well, well, just kidding, just kidding,” he said. “Remember one thing, princess: I adhere to the rules that a girl has every right to choose.” And I give you freedom. Remember one thing: the happiness of your life depends on your decision. There's nothing to say about me. - Yes, I don’t know... mon pere. - Nothing to say! They tell him, he doesn’t just marry you, whoever you want; and you are free to choose... Go to your room, think it over and in an hour come to me and say in front of him: yes or no. I know you will pray. Well, maybe pray. Just think better. Go. Yes or no, yes or no, yes or no! - he shouted even as the princess, as if in a fog, staggered out of the office. Her fate was decided and decided happily. But what my father said about m lle Bourienne - this hint was terrible. It’s not true, let’s face it, but it was still terrible, she couldn’t help but think about it. She walked straight ahead through the winter garden, seeing and hearing nothing, when suddenly the familiar whisper of M lle Bourienne woke her up. She raised her eyes and, two steps away, saw Anatole, who was hugging the Frenchwoman and whispering something to her. Anatole, with a terrible expression on his beautiful face, looked back at Princess Marya and did not release the waist of m lle Bourienne, who did not see her, at the first second. "Who is here? For what? Wait!" Anatole’s face seemed to speak. Princess Marya looked at them silently. She couldn't understand it. Finally, M lle Bourienne screamed and ran away, and Anatole bowed to Princess Marya with a cheerful smile, as if inviting her to laugh at this strange incident, and, shrugging his shoulders, walked through the door leading to his half. An hour later Tikhon came to call Princess Marya. He called her to the prince and added that Prince Vasily Sergeich was there. The princess, when Tikhon arrived, was sitting on the sofa in her room and holding the crying Mlla Bourienne in her arms. Princess Marya quietly stroked her head. The beautiful eyes of the princess, with all their former calm and radiance, looked with tender love and regret at the pretty face of m lle Bourienne. “Non, princesse, je suis perdue pour toujours dans votre coeur, [No, princess, I have forever lost your favor,” said m lle Bourienne. – Pourquoi? “Je vous aime plus, que jamais,” said Princess Marya, “et je tacherai de faire tout ce qui est en mon pouvoir pour votre bonheur.” [Why? I love you more than ever, and I will try to do everything in my power for your happiness.]