Anyone who grows oilseeds needs to purchase special equipment for the production of raw materials. It is an oil press. Such devices come in different types, differ in characteristics, and have their own advantages and disadvantages. In today’s article we will analyze popular options for such equipment, and also tell you how to make the simplest but working device yourself at home.

Dimensional press for extracting oil Source marcato.com.ru

Features of choosing equipment for the home

To prepare oil at home, you need to be able to choose the right device so that it does not take up much space and can be transported if necessary. The entire selection is based on several criteria. Let's look at them in more detail:

- Type of device. There are manual oil presses and electric ones. The first requires some effort to obtain a quality product. At the same time, the cooking process in this way takes longer. As for the electrical one, this device does everything independently, but higher quality raw materials need to be selected for it.

- Performance. This parameter determines how much the device is capable of processing raw materials in a certain period of time. The most optimal indicator is 2.5 kg/hour. When the task is larger-scale processing, then you can give preference to options with 3-6 kg/hour.

- Availability of different modes. It is believed that the more modes there are in an oil press, the more practical and functional it is. For example, the cold mode allows you to squeeze oil without necessarily heating the product, and when hot, it heats up to 100 degrees or more. In such a situation, the finished oil will contain a smaller amount of nutrients and vitamins, since they are not destroyed during heat treatment.

- Features of operation. The simpler the design of the equipment, the more convenient it is to operate. In order not to get confused about the functions available in the device, it is better to give preference to simple options with an intuitive interface.

- Product material. They come in plastic and stainless steel. The first ones are simple and mobile, as they do not have much weight. But here it is important that the design of the device can withstand mechanical stress. Models made of stainless steel can be combined with other materials, such as plastic, cast iron and others. These options are much more difficult.

Preparation of sunflower oil in an oil press Source maslodav.rf

When choosing a home oil press, be sure to be guided by the given nuances. After all, the main thing is to purchase a convenient, practical and durable device.

Scope of application

The oil is widely used in cooking. It is also needed:

- for food preservation (meat, vegetables, fruits);

- for creating paints and varnishes (drying oils, paints);

- When does soap making take place?

- creation of medical and cosmetic products (creams, ointments, lotions, lipsticks).

In these cases, you cannot do without refined oil - that is, purified from the pronounced aromas of sunflower. Therefore, it is better to purchase equipment for refining. The likelihood of purchasing refined sunflower oil is higher, since the scope of application is wider.

The production of refined sunflower oil itself is waste-free, because sunflower processed products can also be sold. Cake is required on livestock farms as biofuel. Miscella is needed to create paints and varnishes, husks are needed to create fuel briquettes.

Rating of the best options

There can be many models that fit the criteria discussed above. We still recommend choosing options from the prepared rating, since it is based on real user reviews and the popularity of purchases.

Screw manual oil press Piteba

A practical hand-held device that can perform hot and cold oil extraction. It will be an ideal purchase for those who support an extremely healthy diet. The device is capable of working for a long time without rest. There are no difficulties in using the unit.

Press for squeezing oil, manual screw type Source vsesoki.ru

Advantages:

- the most simple design;

- fast heating when using hot mode;

- continuity of work;

- light weight.

Minuses:

- no additional components;

- may become clogged if processed too intensively.

The design of the device contains all the necessary regulators and mechanisms to achieve optimal spin quality.

What is needed to open a business

In this business plan for oil production, we have selected the equipment that is optimal in price and quality, which will allow a small enterprise to be loaded with work and create a high-quality product. The purchase of equipment is the largest expense item. Every month, most of the money is spent on the purchase of raw materials.

Table 2. The amount of initial costs for a vegetable oil production business.

| Expense item | Cost, rub. |

| Registration, certification | 30 thousand |

| Premises for rent, 600 sq. m | 360 thousand |

| Equipment (plus costs for delivery, start-up, setup) | 8.5 million |

| Raw materials (per month) | 6 million |

| Wage | 400 thousand |

| Additional expenses | 150 thousand |

| Total | 15.34 million |

The calculations are relevant for a city with a population of about 1 million people. Additional expenses include the costs of utilities, advertising, and cosmetic repairs.

How to make an oil press yourself

As it turns out, preparing oil at home is done using strictly natural ingredients. But to achieve real quality, you also need to have a good oil press. If you can’t purchase it, you can always make it yourself. Now let’s look at what needs to be taken into account during the production process and tell you about the step-by-step sequence of actions.

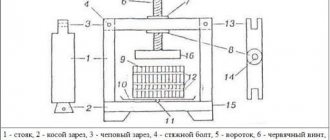

The design of the oil press and its assembly features

The most important thing that should be present in an oil press is a press barrel. It should be selected depending on the raw material that will be pressed. For example, to load black cumin into the chamber, a volume of 2 liters is sufficient, but for nuts and other types of seeds you will need a larger capacity of 3.2 liters.

Also, for the manufacture of equipment you will need a metal channel, the width of which is 12 mm. The frame will be made from it: 2 pieces - 68 cm and 4 pieces - 41 cm. Therefore, the length of the rental should be enough for this number of parts. You will need another 30 cm fragment of the channel, which in the future will be welded to the bottom of the frame.

DIY oil press Source tiu.ru

Brief market analysis

Sunflower oil is one of the popular products on the Russian market of oil and fat products. Among other oils, it occupies the maximum share - 86.8%.

Entrepreneurs who want to start producing and selling sunflower oil need to know about the main trends in the industry, which is highly competitive, capacious and saturated.

Enterprises operating on the market are the leaders of the country's agro-industrial complex. More than a dozen large manufacturers and wholesale companies dominate the market. The current situation can be called oligopolistic. To take market share and get your customers, you will have to make great efforts.

Vegetable oils are common in large quantities

There are simply a huge number of varieties of vegetable oils. Apricot, linseed, sesame, almond, palm, rice, tomato, and tung oils can be noted. It’s impossible to list them all at once, since the number is really large.

It should be noted that vegetable oil does not contain cholesterol. And this factor cannot but please those who adhere to a healthy diet. Note that the history of sunflower oil production dates back to the 19th century.

The traditions of its everyday use have determined that the demand for the product in Russia is very high. And this, in turn, influences the desire of many entrepreneurs to organize their own business in this area.

Marketing and sales

Focus on wholesale buyers. You can sell goods through your own store. Open a retail outlet in a favorable location and with a company logo - then people will quickly learn about the new product.

Sell your goods in markets, retail stores, supply them to bakeries and HORECA segment enterprises (cafes, restaurants, canteens).

Sunflower processed products can be sold wholesale to farmers and solid fuel producers.

To increase sales and improve competitive positions, reduce selling prices and conduct BTL promotions (promotions, discounts). Place advertisements in specialized publications, send mailing lists and send commercial offers by mail. It is not necessary to hire a sales manager to conduct negotiations - an entrepreneur can do this himself.

Raw materials

To make sunflower oil you need sunflower seeds. Finding raw materials in Russia is not a problem. More than 80 varieties and hybrids of the plant are cultivated in the country.

Almost all sunflower varieties are suitable for extraction, except white and gray ones. It is recommended to buy seeds of Maslenitsa varieties (such as “Gourmet”, “Orange Miracle”). Do not buy hybrids - varietal seeds make a tastier product.

A businessman is recommended to purchase raw materials about a month in advance and store the seeds in his warehouse in order to have a supply and avoid downtime.

By cold pressing, 1 ton can be obtained from 4.5 tons of raw seeds. If you squeeze roasted seeds, you will need approximately 2.5 tons of seeds to obtain 1 ton of product.

Room

Sanitary rules for enterprises producing vegetable oil are specified in SanPiN 1197-74. Studying and taking into account the requirements will allow you to obtain permits and positive conclusions from the sanitary-epidemiological, fire, gas, electricity and water utilities without unnecessary difficulties.

To organize production and place machines, you will need about 250 square meters. m of space. About 300 sq. m will be occupied by warehouse premises where raw materials, finished products, as well as processed products - cake/meal and peel (husk) will be stored.

We need space for administrative premises and rooms for workers. You will need to equip a bathroom. It is also necessary to create convenient transport access to the workshop and organize a place for loading and unloading operations.

To accommodate a small plant, a minimum of 600 square meters will be required. m area.

Staff

For a small plant you will need the following personnel:

- 6 workers - in the direct pressing workshop;

- 4 workers – in the refining shop;

- 2 workers – in the packaging department;

- 3 workers - for unloading and loading operations, in warehouses.

It is important to find a competent technologist with experience. He will monitor the production process and the quality of the finished product.

Director, accountant and driver required. At first, the function of director can be assumed by the businessman himself. An accountant is required if the form of legal entity is chosen for work. To begin with, you can hire him part-time or outsource. It is better to hire a driver with your own car. It will ensure delivery of goods to retail chains and private customers.

The workforce is 19 people.