Over the many years of presence on the Russian market, the brand of the Latvian manufacturer of electrical equipment “RESANTA” has become popular. The company's products always incorporate innovative technologies and circuit solutions.

In the production of electrical appliances, welding machines are separated into a separate production and received the brand name “Resanta”. Resanta presents machines for argon welding, ballast assemblies and inverters. Inverters are designed for manual electric arc welding and are represented by devices ranging from household use with a power of 160A to professional ones with a power of 260A. The numbers after the brand name indicate the strength of the maximum arc current under the electrode, for example, Resanta 160 pn, Resanta 260 prof.

[content-egg module=GdeSlon template=list limit=3 offset=0]

One of the features of these devices is the ability to operate on reduced mains voltage, as evidenced by the letters “mon” after the name. The designation “prof” after the name means that the device is intended for professional use.

Application of manual electric welding

Electric welding as a method of connecting metal parts to each other is widely used in repairs and construction where welding of metal workpieces is necessary. Moreover, with the invention of inverter machines, welding has become much easier. First of all, the inverter differs from the welding transformer in its low weight, making it easy to move the device to hard-to-reach places. With the use of the latest circuit developments, electricity consumption has decreased to the level of household appliances: electric kettles or microwave ovens - this is very important when working at home. One of the popular household welding machines is the inverter welding resanta sai 250

Block diagram of the inverter

Welding with the Resanta Sai 250 inverter welding machine is carried out with direct current, which is converted from a household alternating voltage network of 220 V. Let's take a closer look at how the inverter circuit works.

The purpose of welding transformers is to form a metal melt in the arc burning zone under the electrode, usually the edges of the metal parts being connected. The very first machines - welding transformers - have low efficiency, are heavy and quickly overheat under load. Inverters operate on a different principle, which has made it possible to increase the number of characteristics and make them smooth and convenient.

Principle of operation

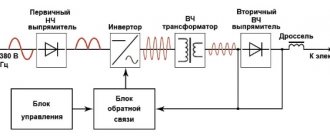

The operating principle of the inverter is multi-stage conversion of alternating mains voltage. The first stage consists of converting alternating current into direct current, but having a pulsating component; the pulsation peaks are smoothed out by a special reactor. After the smoothing reactor, the rectified current goes directly into the inverter circuit, where at the first stage it is converted back into alternating current, but with several high-frequency harmonics. It is at this stage, through the feedback block, that the possibility of adjusting various output characteristics of the arc at the output opens up.

[content-egg module=GdeSlon template=list limit=3 offset=3]

At the final stage, high-frequency alternating current is converted into direct welding current using avalanche thyristors and a transformer. Due to the development of technology of structural elements, in particular power thyristors, the weight of the inverter can be reduced to several kilograms, and the power consumption is 2-5 kW with an arc power of 250 A.

Specifications

This device has the following characteristics:

| Model | 250 |

| Operating voltage range, V | 140-240 |

| Effective current consumption, A | 29 |

| Open circuit voltage, V | 85 |

| Arc voltage, V | 30 |

| Welding current control range, A | 10-250 |

| Duration of loading, % | 70% 250A |

| Maximum electrode diameter, mm | 6 |

| Protection class | IP21 |

| Operating ambient temperature range, C | from -10 to +40 |

| Weight, kg | 5.0 |

Before using any such power unit, you should carefully study the instructions, which are also included in the case with the unit. It will also describe all the technical characteristics and capabilities of the device:

- The welding current control limit is from 10 to 250 A.

- The load duration or PN is 70%, this indicates that with a welding current of 160 Amps you can work without stopping. If the current is maximum, then there should be a break in the operating interval, amounting to approximately 20-25%.

- Permissible voltage deviation in the network. For these devices it can change down to -30, and up to +10%. In voltage readings this will be from 154 to 242 V.

- Also, when purchasing, you can pay attention to such parameters as cable length, device dimensions and even weight. But this does not affect the operation of the device.

- The diameter of the electrode used can range from 1.6 to 6 mm.

- The output voltage of the unit in idle mode is 80 V, under load during welding - 29 V.

Useful and necessary functions:

PFC (Power Factor Correction)

One of the important parameters of the welding transformer is the power factor correction function PFC (Power Factor Correction). With its help, voltage stabilization on the inverter increases and the load on the electrical network is reduced to 30%, a stabilized voltage is maintained, which ranges from 60 to 200 Volts on the transformer, and reduces the load to the pulse generator and output transformer. This allows for 15% more power output with the same grid load. PFC is mandatory for devices with the “prof” index. First of all, when purchasing a welding inverter Resanta Sai 250 for the first time, in addition to the price and reviews, you need to decide on the operating conditions and frequency of its use.

“Arc Force” function

Another parameter, the Arc Force function, allows you to adjust the rigidity of the arc when working with thin-sheet steel sheet profiles.

A welding transformer equipped with this function allows you to comfortably work with low voltages and low currents - this is very important for welding thin sheet metals or even sheet metal. Without this function, to perform such work efficiently, experience and daily practice are required. The electrode sticks at low currents, and inaccurate contact with the metal can lead to burnout.

It is to eliminate such cases that the inverter contains “Arc Force”. On the Resanta Sai 250 Prof welding machine, this function is set manually using the arc stiffness adjustment knob. On the Resanta Sai 250 pn welding machine, which does not have the abbreviation “prof” on it, the adjustment is performed automatically when the welding mode value is set

Load duration indicator

[content-egg module=GdeSlon template=item next=1]

When choosing an inverter for work, less experienced users pay attention only to the maximum welding currents; on the one hand, this is correct, because the higher the welding current, the greater the functionality of the device, for example, you can cut a corner or profile with a high-power arc. And many do not pay attention to such a concept as load duration (LOD), or as it is also called - the duty cycle. This indicator is key in determining the duration of use of the device.

The coefficient is described using percentages, in proportions (10 minutes - 100%, 5 minutes - 50%). That is, at 100%, the converter operates for 10 minutes out of 10 possible at the maximum declared current without turning off the overheating protection. Accordingly, if only 5 minutes, it will be 50% of the working hours. In the line of inverter welding machines Resanta Sai 250 and other modifications, the coefficient reaches 70% - this is one of the best PN indicators among existing household inverters.

Hot-star - hot start (Hot-star)

With this function, the electrode is ignited at the beginning of welding with increased voltage and automatically decreases when the arc is ignited.

Anti-stick – anti-sticking (Anti-stick)

This function automatically reduces the short circuit current when the electrode gets stuck, which can then be easily torn off with a slight movement of the holder.

Operating principle of welding machines Resanta 250

Even a beginner can work with such a device with his own hands, but only if he follows some recommendations. The device works as follows:

- You plug the unit into a socket specially prepared for it. The installation diagram and recommendations on this matter are in the instructions. In a nutshell, let's say that it should be separate from the panel and connected to its own circuit breaker, equipped with a third grounding wire. In this case, the wiring must be designed for a maximum current of 40 Amps. It is important to know that a regular household outlet will not work, because it can withstand a maximum current of 25 A.

- The device charges the input filter and the soft start circuit turns off, at the same time the fan starts.

- The user selects the desired current ranging from 10 to 250 A.

- The electrode is installed in the holder, the mass is connected to the parts being welded. The welding area must be cleaned and sharpened if necessary.

- The master begins work by choosing the optimal location of the holder with the electrode to the plane of the parts, in accordance with the thickness of the parts and the diameter of the electrode.

Review of Resanta with SAI index – 250k and SAI – 250 pn

[content-egg module=GdeSlon template=item next=1]

Inverter manufacturers are constantly searching and adapting products to any consumer request. The differences between the presented converters with different indices have a slight difference: Resanta SAI - 250k has a compact body, with a maximum electric arc current of 250A. And it is designed to work with electrodes from 2 to 6 mm in diameter. Resanta SAI - 250 pn is designed for unstable mains power supply, that is, it can operate at an unstable voltage from 140 to 250 Volts. This is especially true in garages or at remote sites. And with a small-sized and lightweight body it is much easier to do installation work. The converters are universal in their application and have all the functions inherent in Resanta inverters.

The body has a compact rectangular shape measuring 130×260×190 mm and is made of galvanized sheet 0.4 mm in size. This design is multifunctional:

- has additional heat dissipation;

- the iron has stiffening ribs, the body is very durable and can be easily removed to inspect internal parts;

- electrical safety according to class IP 21 (the inside of the device is sufficiently protected from falling from 2 meters, not protected from slanting rain).

Connectors for connecting power cables are located on the front panel. Also on the front panel there is a voltage and arc stiffness regulator. The digital indicator will easily help you set the required welding current. To perform work with forward and reverse current, it is enough to change the terminals on the panel. The panel also has temperature sensors that warn of overload shutdowns with a special indicator.

Reliable operation and safety of the Resanta SAI-250K inverter converter is ensured by a special protective system. Temperature sensors detect the approach of dangerous overheating in advance and warn the user by turning on the emergency indicator.

Inverter welding machine SAI-250K (compact)

Description

Features and Benefits

- The inverter welding machine SAI-250K (compact) operates from a household electrical network and does not require a special connection method.

- The inverter system uses a relatively small transformer complete with IGBT transistors and ensures a small size and light weight of the device, which allows it to be easily moved to the location required by the operator. There is a special convenient shoulder strap for this purpose.

- The device is equipped with warning elements against dangerous overheating, which makes its operation safe and reliable.

- The unit has the functions “anti-sticking” (ANTI STICK) and “hot start” (HOT START), and the duration of its activation is 70%.

- A high-quality, durable housing protects the components of the welding machine from damage and at the same time ensures reliable cooling of the working transformer.

- The ability to convert high-frequency current (hence the small parameters of the transformer) and a wide range of regulation of the welding current power are the advantages of this device.

- It is possible to use AC or DC electrodes.

- The device does not require special training to connect and use it. It is enough for the user to have initial knowledge and practice.

general description

The Resanta SAI-250K device is a portable inverter-type device for manual welding, capable of providing full-fledged welding work at the household (and not only) level. The unit is simply connected to a household power supply with a voltage of 220+/-10% V and is designed to work with coated welding electrodes and a metal core diameter of up to 6 mm inclusive.

Welded joints of metal elements are quite common both in production and in domestic conditions. Welding transforms different iron elements into a single, strong, non-demountable structure, the strength of which is incomparable to anything else. As a rule, this connection method is used to obtain the most reliable connection where it is impossible or impossible to use a threaded connection. Manual welding is quite widespread both in everyday life and in production (any construction, installation, repair work, etc.). And if previously, to carry out such work, bulky and heavy units were required, then with the advent of inverter devices, these shortcomings were eliminated.

The described Resanta SAI-250K unit is one of the most convenient and compact tools for performing work of this kind. He can do almost any welding operation. Light weight and dimensions, a comfortable and durable shoulder strap allow the welder to easily move the device to the location required for work.

The system includes working cables (power with electrode holder and grounding cable). The length of each working cable SAI-250K is 2 meters. The system also has a power cable (170 cm) with a plug. If necessary, you can use an extension cord of the appropriate cross-section.

A special welding helmet and other personal protective equipment must be purchased separately.

To make the welder’s work easier (especially for beginners), the designers of Resanta SAI welding machines have created such a useful function as a “hot start” (HOT START). At the moment the electrode is sufficiently close to the elements being welded, the system automatically creates an increased operating current pulse, which contributes to the rapid formation of an electric arc. At the same time, the welding process is greatly facilitated.

The “anti-stick” function (ANTI STICK), also characteristic of all Resanta SAI devices, in turn is designed to facilitate the work of the welder, eliminating the phenomenon of electrode sticking during the arc burning period. In this situation, the device automatically reduces the welding current, facilitating easy tearing of the electrode. Immediately after this, the system restores operating parameters.

The main part of Resanta welding machines is made on the basis of high-tech IGBT transistors. As a result, it was possible to achieve a significant increase in the service life of the system, as well as significantly reduce its dimensions and weight. The transistor board is typically located in a vertical plane, which prevents the accumulation of dust and, as a result, unnecessary overheating.

Another characteristic feature of the system is the on-time (ON). This is a value that characterizes the ability of the device to operate continuously over a certain period of time. The basis was a 10-minute time interval. For the SAI-250K device, this parameter is 70% at maximum load. This means that welding can be carried out continuously for 7 minutes out of 10 and 3 minutes - a break at idle.

The welding machine of this model has a fairly significant open circuit voltage (80 V). This facilitates easy and quick ignition of the electric arc, which allows you to work with non-ferrous metals.

The creators of the welding machine also took care of its safe use. The main danger for devices of this kind is overheating, which can cause breakdown of the unit and other undesirable consequences. Resanta SAI-250K has a special warning system, which turns on (before dangerous overheating) an emergency indicator light. When the indicator lights up, it indicates the need to pause welding work. A 5-minute break is enough to restore the unit’s functionality. There is no need to disconnect it from the power supply.

Design and functionality

The housing of the Resanta SAI-250K welding machine has a compact rectangular shape, dimensions 130×260×190 mm and is made of high-quality sheet metal with a protective coating. The flat base of the case allows it to be placed stably on any surface, even with a slight slope. There are specially made slots on the sides of the housing through which ambient air can easily circulate, cooling the main transformer. The electrical safety of the housing meets the criteria of class IP 21 (protection against the ingress of foreign objects, but work should be done in a fairly dry atmosphere).

The switch and power cable are located on the rear panel of the case, and the control panel is located on the front panel. It is very simple, understandable and will allow even a beginner to understand it. Here the designers placed a rotary regulator for operating current from 10 to 250 A, a network indicator and an indicator warning of the approach of emergency overheating. On the same panel there are terminals for connecting the power cable with the electrode holder and the cable that ensures the closure of the electrical circuit for the welding process. At the top of the case there are fastenings for a shoulder strap.

All components of the welding machine are located inside the housing, ensuring its safe functionality within the limits of technical capabilities. The main element in this matter is a conversion transformer with special equipment that converts alternating current with a frequency of 50 Hz (power grid) into direct current, followed by its reverse conversion into alternating current, but with a much higher frequency (more than 20 kHz). Thus, it is possible to increase the current to 250 A at a voltage of 80 V. These transformations make it possible to achieve significant quality of the weld, which is especially important for the final result. The transformer has a finned light alloy surface that promotes intense heat transfer and efficient cooling of the element. This is also facilitated by two built-in fans.

Reliable operation and safety of the Resanta SAI-250K welding machine is ensured by a special protective system. Temperature sensors detect the approach of dangerous overheating in advance and warn the user by turning on the emergency indicator.

The principle of welding is that between the edges to be joined and the electrode close to them, with the help of a working current, an electric arc lights up, heating them to the melting temperature. The molten electrode firmly welds the joined edges together, forming a weld seam. The hot start and anti-stick functions are provided by automatic adjustment of the operating current. The initial approach of the electrode to the edges provides an increased impulse for rapid ignition of the arc. Then the current drops sharply, preventing the electrode from sticking. The special coating of the electrode consists of a special flux and prevents direct contact of the melt with oxygen and nitrogen impurities contained in the surrounding air. The quality of the weld directly affects the strength of the joint, so it must be checked. To do this, you should beat off the slag deposit with a hammer and make sure that the seam is uniform and intact.

Preparation for work and safety measures

The Resanta SAI-250K inverter welding machine is not complicated. Almost any adult can prepare it for work and operate it. Initially, you should take into account and ensure some safety points in order to prevent electric shock and other unpleasant consequences. The device is grounded through the power cord, so you should make sure that the socket has the appropriate equipment. After the working cables have been connected to the required terminals, you can plug the power cable into the outlet (the “mains” toggle switch should be off and the operating current regulator should be in the lowest position). Now you can turn on the device and set the required operating current. After completing welding work, turn off the device in the reverse order.

If welding work is carried out indoors rather than outdoors, care must be taken to ensure that it is well ventilated and that there are no flammable materials or gases in it. When starting work, the user must use protective equipment (gloves, headgear, special clothing and a special mask to protect the eyes and face). In addition, it is necessary to strictly adhere to fire safety rules and requirements for the safe operation of equipment of this kind.

The manufacturer of the welding inverter Resanta SAI-250K provides a guarantee for its impeccable operation for 24 months from the date of its official sale.

Welding machine Resanta sai 250: opinions and reviews

Konstantin Khalturin : I am very pleased with the inverter. I use it in the garage where the voltage, to put it mildly, fluctuates in unpredictable amounts. Nothing, it works stably. I wanted to buy Resanta 230, but I bought it for 250A on sale. I mostly cook in threes and have never stopped due to overload. I've been using it for 3 years now. The only drawback is that it sucks a lot of dirt inside; about once every six months you have to clean the inside of the equipment. I am very pleased with my unit.

Vladimir Pshennikov : I have been working as a converter for 5 years, the conditions are the most severe. Used for industrial purposes to repair equipment, plows every day. The work is different, welding metal of different thicknesses, electrodes 3-4 mm. We worked in a humid gallery with 100% humidity. An indestructible device. Disadvantage: the wires are rigid, the insulation broke in the first winter, I had to replace it, and the wires are very short. The electric holder cable with the SKR insert is designed for operation from -10 degrees to +40. If the temperature is below -10, the cable will crack when bent. Replaced with Russian cable KG-16, KG-25 works fine.

For the Resanta Sai 250 welding machine, the price of 6-9 thousand is the best option. For domestic purposes, you can also purchase weaker ones, for example, 200A, which is correspondingly cheaper. You can buy the Resanta Sai 250 inverter welding machine at any dealership. When purchasing, you must clarify in which country the device was manufactured, its cost and equipment.

[content-egg module=GdeSlon template=list limit=3 offset=6]

Types and features of welding machines Resanta 250

Like many other manufacturers, the creator of the Resanta 250 inverter offers professional and amateur users several types of devices with which you can perform all the tasks assigned to the master. Let's take a closer look at the types of devices from this line.

Under the Resanta brand, 4 lines of welding inverters are produced, which differ slightly in design, but significantly in performance characteristics. For example, you can buy units with a maximum current from 190 to 250 Amperes in a case. The following series are distinguished:

- SAI-250K;

- SAI-250;

- SAI-250PN;

- SAI-250PROF.

At the same time, the series of 250 A devices includes 3 models: Resanta SAI-250, Resanta 250PN, SAI-250K. The latest modification is also Resanta Prof, as it is equipped with an improved arc ignition system without touching and additional protection of the inverter itself from overloads.

The devices have a convenient carrying handle and eyelets for pulling the strap over the shoulder. To prevent accidental violation of current settings, protective glass is provided on the front panel.

Reasons for failure of inverters

One of the main components of the converter is the power section. The power part consists of several parts, which includes power transistors, which are controlled by a reference oscillator with a frequency of several tens of kilohertz. That is, the control unit closes and opens the transistors with pulses of a certain frequency, and this in turn controls the amount of current passing through the transistors to the output transformer. It is on this effect that the adjustment of the inverter modes is based.

This method is called pulse width modulation (PWM). Voltage dips or surges, uncertain movement of the electrode are an important factor in stabilizing the work because In this case, the control unit has to sharply reduce or reset the welding current to maintain the arc current within the specified mode. Therefore, the reference transistors may overheat and fail.

Therefore it is important! make sure that the power source is sufficient to operate the device.

It is very important to use quality equipment. For example, if used

a clothespin type clamp with tin contacts, then very poor contact is formed with the “ground” of the product since the contact area is small, this can also happen due to poor cleaning of the connection surface with the “ground” because of this feedback sends a signal to the control transistors , which add current to the arc, for which it is necessary to increase the power of the device itself. And so - as it is taken from the primary circuit, hence the increased load on all systems, including the primary winding of the step-down transformer.

A “crocodile” can be considered good, which has completely copper jaws with the obligatory braided connection of 2 contacts. It is needed to remove current from two parts of the metal being welded. The same situation with electrode holders

Another problem is when there is weak contact in the bayonet connections. The connection of the welding wire with connection sockets has a unique

Known fasteners. As can be seen from the figure, to connect the terminal, simply insert the bayonet pin into the terminal block and turn it until it stops. And if this is not done, a weak contact results, and if there is a weak contact, current will pass through the resulting air gap and heat the connector. It is very important that all power connection terminals should be made of brass, but not aluminum or metal, such as steel.

Bayonet connectors are available in different types: 10-25 and 31-51, respectively 100-250A and 300-500 A. It is very important to use the correct cross-section of wires, the larger the cross-section of the wire, the better. Before each use of the device, it is necessary to check the tightness and fastening of the wires in the bushings of all connections.

When used correctly, the device has a good power reserve. All components and the Resanta Sai 250 welding machine can be purchased at any dealership. Another way to place an order is on available Internet resources.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Construction of welding machines Resanta 250

The Resanta 250A welding machine is a professional model that is capable of much. This is a professional device, but designed to be powered from a single-phase network capable of withstanding currents up to 35 A. Given the high amperage, this model is more suitable for workshops than for home use, since high currents can cause the network to fail.

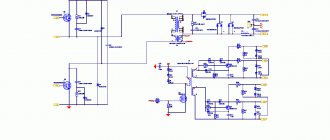

The circuit of such a device is an inverter assembled using special power transistors with frequency control. The process of regulating the output current occurs through pulse width modulation. Accordingly, its device can be divided into functional blocks:

- low current input rectifier;

- soft start circuit;

- filter and pre-charging capacity to stabilize the arc;

- logical part with PWM, feedback and overload protection logic;

- power unit with transformer;

- rectifier and choke.

It is equipped with standard connectors for MMA welding. You can also cook in TIG mode using a special sleeve with a hose, a torch and an adapter for connecting to the power supply.