An important element of PPE for welding work

The respirator is a convex half mask, the design of which includes the following elements :

- adjustable nose clips;

- inhalation valves;

- filter material that performs a protective function;

- two- or four-point fastening system.

Respirators provide protection against the following harmful and dangerous influences:

- oxides, oxides and aerosols;

- water vapor;

- welding fumes;

- gaseous compounds;

- industrial dust;

- hot sparks and heat from welding;

- reducing the intensity of unpleasant odors.

In addition, respirators should not make breathing difficult and should be compatible with the welder’s mask.

It is recommended to try on a half mask before purchasing. It should fit snugly to the face, which provides reliable protection. Feeling discomfort and pressure on the head is unacceptable. The internal material should be soft, pleasant to the body, and not cause allergic reactions.

Video

The following video is, of course, an advertisement, but it allows you to get an idea of the importance of protection and the design of this PPE.

A respirator for a welder must have a protection class of at least FFP2, which means operation in conditions of up to 12 MPC (maximum permissible concentration) of chemical elements and their compounds. Manufacturers also offer half masks with protection classes FFP1 and FFP3 .

First class respirators are designed for work on grinding stone or wood, the maximum permissible concentration does not exceed 4 units.

Third class half masks will protect workers from contact with powders and biological agents, 50 MAC. Important! Respirators with protection class FFP1 are not suitable for welding, as they do not provide protection against all harmful and dangerous influences.

Class 3 half masks make it difficult to breathe when working on metal, so they should also not be used when welding. 3M 9914

- Manufacturer: 3M (USA).

- Protection class – FFP1.

- The combined action respirator protects against aerosols, dust, mists, pollution and has additional protection against organic vapors.

- The half mask is designed for working with organic solvents and is used for painting and polishing.

- Presence of an exhalation valve.

- The filter layer is made on the basis of activated carbon.

- The ergonomic shape ensures comfortable wearing.

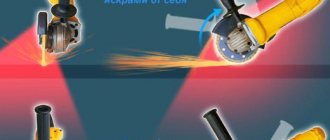

Carefully! A welder's respirator does not protect the performer from high temperatures and thermal radiation, so you need to use a welding mask. Also, a half mask does not provide safety from highly toxic substances and agents that enter the human body through the skin.

[ads-pc-2][ads-mob-2]

Will regular anti-dust masks protect against welding aerosols?

Dust respirators provide respiratory protection from various types of dust, dusts, powdered fertilizers, acids and alkalis. These types of PPE do not perform the full range of protective functions for the welder . Therefore, you should not choose them as a replacement for special respirators. This may result in injury or illness. Anti-dust half masks are suitable for construction work, for example when cutting concrete or sand-lime brick.

DIY mask

A means of protection used from time to time can be constructed with your own hands. The standard shield is used as a basis. Air supply unit - car or aquarium compressor (with the required performance), options are possible. The soft shell is made of tarpaulin fabric and attached with glue. This design can protect the respiratory system for 1–5 minutes, but no more. The air from the compressor, without additional cooling, will quickly heat the space under the mask, creating unbearable working conditions.

An intermediate option is to use separate factory components and assemble them into a full-fledged product. But for constant work, it is more advisable to buy a ready-made factory mask with forced air supply.

Request to readers: if you have interesting information on the topic, then share your experience in the “comments” block.

Which one is needed for welding zinc

When welding zinc, zinc oxide is released, which can cause short-term and long-term harm to health. Inhalation of large amounts of fumes can lead to poisoning of the welder. Zinc vapor entering the bloodstream leads to an increase in body temperature, chills, weakness in the body, and nausea. Acute poisoning can lead to disruption of the liver and blood circulation, as well as the occurrence of cancer. Therefore, when welding zinc and galvanized steels, you should use a special respirator with an anti-aerosol filter . An example of such a means of protection is presented below.

3M 9925 welding respirator FFP2, class 2

Manufacturer: 3M (USA).- The Premium class respirator provides protection against dust, ozone, smoke, aerosols, mists, and organic vapors.

- The basis of the product is soft hypoallergenic material.

- Reliable protection against welding aerosols is provided due to the presence of a multi-layer filter of a special design.

- The soft and comfortable gasket is leak-proof and fits well to the face.

- The exhalation valve helps remove moisture and heat when working at elevated temperatures and under high physical stress.

- The half mask does not impede speech and maintains its fit during facial movements.

- The use of respirators of this model reduces the risk of occupational diseases by 90-95%.

- The half mask can be used at ambient temperatures from -30 to +70°C.

- Has a long service life.

Main settings

Personal protective equipment used with forced air supply has a number of technical parameters:

- Overall dimensions of the main sight glass. The parameter should provide the welding machine operator with complete visual information about the technological process.

- Darkening level of the main viewing window. Allows you to see the area where the weld pool is formed without harming the welder’s eyes.

- Darkening time. Protects the organs of vision from bright radiation without creating the effect of “sun bunnies”.

- Possibility of smooth adjustment of the darkening level of the filter.

- Equipped with light sensors - for reliable operation of sensors there must be at least 2 pieces.

- Power supplies. In addition to the built-in solar battery, it is equipped with two batteries operating in parallel.

- Mask body material. Must withstand fire and mechanical stress.

- Product weight. The optimal value is about one kilogram.

- Power. It is measured by the amount of air supplied per unit of time. The optimal range is 150–200 l/min.

- Air filter. Provides purification from solid impurities (smoke) and harmful gases (carbon dioxide and carbon monoxide, nitrogen compounds and others).

- Ergonomics. The design of the mask, including the soft shell, should create comfortable working conditions for the operator.

- The structure of the system as a whole. The material of the components must withstand the effects of drops of metal heated to thousands of degrees. Be able to securely and conveniently mount an autonomous air supply unit on the human body. Have minimal weight without losing your basic functions.

Reusable and disposable

Depending on the service life, disposable and reusable respirators are distinguished. Half masks of the first category must be disposed of immediately after the first use, since the filter attached to the model becomes clogged, and it is not possible to change it.

Reusable respirators can withstand 2 or more work shifts.

Long service life is ensured by the presence of replaceable absorbers. Replacement should be made when the performer begins to experience difficulty breathing due to contamination of the filter. After changing the absorber, the mask is ready for further use. Professionals who constantly use protective equipment need to choose reusable models. Home craftsmen and performers of periodic work should pay attention to disposable respirators; they have a more affordable price. The level of reliability of a welder from harmful factors does not depend on the service life of the respirator. Therefore, when choosing the type of masks, you should take into account the frequency, intensity and level of complexity of the work. [ads-pc-3][ads-mob-3]

3M 9928

- Manufacturer: 3M (USA).

- Molded (bowl-shaped) shape.

- Protection class – FFP2, the respirator provides protection against dust, fumes, ozone, and organic vapors.

- The outer material protects against sparks and does not support combustion.

- The presence of an additional seal along the entire soft obturation line.

- The exhalation valve removes heat, ensures ease of breathing, reduces the risk of glasses or masks fogging, and guarantees comfort.

- Durable material ensures shape retention.

- The filter half mask is a reusable protective equipment, marked R (reusable/reusable).

- Weight – 30 gr.

North 7190N99

- Half mask in a plastic frame with a filter included.

- The respirator is convenient when using a welding helmet.

- It is possible to change the filter.

- The patented valve system prevents heat and moisture from accumulating.

- Reusable respirator model.

In addition, we will consider a budget option for a disposable respirator.

NRZ-0102

- Country of origin: Russia.

- Protection class – FFP2.

- A filtering respirator without an exhalation valve, with elastic bands for fastening on the head and a comfortable nose clip.

- A half mask made of non-woven material protects against all types of aerosols.

- The model is an analogue of ZM 8102 and 3M 9320, as well as Alina-200.

Main technical characteristics of the welding helmet

Specific mask specifications may vary depending on the specific model and brand of the manufacturer. You can consider them using the Optrel E650 mask as an example:

- the overall dimensions of the glass in the welding helmet are 90x110x7 millimeters;

- The darkening level in normal condition is 4 DIN;

- in working condition it can take values from 6 to 13 DIN;

- the response speed of the light filter is thirty-five hundredths of a second;

- dimming adjustment during operation is carried out smoothly without jerking;

- the mask has two sensors;

- two lithium-ion batteries are used in parallel as power sources;

- the body is made of impact-resistant and fire-resistant materials;

- the weight of the mask is approximately half a kilogram;

- The mask can be used at ambient temperatures ranging from -10 to +70 degrees Celsius.

Welding mask with respirator

A welding mask with a respirator, unlike a standard half mask, protects the entire face from hazardous influences. A welder's mask with air supply consists of the following elements:

- Welder mask (shield) with a light filter and a protective casing for a tight fit.

- The air duct (hose) that connects (collet connection) the mask to the fresh air supply unit.

- The air supply unit (turboblock) consists of a fan, a filter and an autonomous battery (power source).

The removable battery needs to be recharged periodically using the included charger. Depending on the model of the respirator, the power source can operate without recharging for a different amount of time, at least 8 hours. The device can withstand about 1000 recharges .

Various materials can be used as a filter .

Modern models have different levels of air flow - from 140 to 250 l/min .

A light indicator or sound sensor notifies the welder of problems or deviations from the normal mode, for example, a decrease in air flow. The reasons for this may be a clogged filter or a decrease in battery charge level.

Put on the mask and start the feed unit immediately before welding. Earlier use will result in rapid battery discharge.

You should consider the principle of operation of the mask . The clean air generated by the fan enters the filter, and then through the hose under the mask, directly into the welder’s breathing zone. The exhaust air exits through a non-return valve.

Most models are additionally equipped with a fire-resistant belt for attaching the unit, an air pressure indicator and a replaceable filter.

Speedglas 9100FX Air

- Manufacturer: 3M (USA).

- Speedglas 9100FX Air welding helmet with Adflo purified air supply system.

- The presence of an auto-darkening filter (size 54 x 107 mm) with a degree of darkness of 5, 8 and 9-13. The welder can record any degree of darkness.

- The air supply system allows you to protect the performer from aerosols (up to 500 maximum permissible concentrations) and gases.

- The battery capacity allows continuous operation for 7-9 hours.

- Filter type – anti-aerosol.

[ads-pc-4][ads-mob-4]

Design

A distinctive design feature of a welder's mask with forced air supply from other protective shields can be considered its sealing. The casing is made of fire-resistant soft materials, designed taking into account the geometric shape of the head. In the neck area there are adjustable seals with locks.

Air supply welding helmet design

The filtration system, which ensures full breathing of the worker during welding, is remote, the unit is located on the back side, and is connected to a sealed protective device by a hose. The design includes a fan powered by an autonomous, fast-charging battery. Often, for these purposes, a solar battery is used, powered by the luminous flux of an electric arc.

Welding mask with air supply

Replacement filter cartridges become unusable as they become dirty. Manufacturers produce these consumables with different performance characteristics and service life.

A light element with a large viewing angle is built into the front part of the helmet; a “chameleon” window is usually used; it darkens under the influence of ultraviolet radiation; the components of such a screen significantly reduce its throughput in a certain part of the spectrum only at the time of welding. The use of a color-changing liquid crystal filter allows you to control the quality of the weld without removing the protective mask.

Gas mask for welder

A respirator-gas mask is a full-face mask that protects the organs of vision and breathing. The welder's view is provided by a panoramic lens . The mask is attached to the worker's head using adjustable buckles . The presence of an exhalation valve prevents fogging of the lens and effectively removes exhaled air. Russian and foreign manufacturers offer similar models of masks.

SPIROTEK FM9500

Manufacturer: Vostok-Service.- The degree of protection against organic, inorganic and acidic vapors and gases, ammonia and its organic derivatives, solid and liquid aerosols, dust, mercury vapor, formaldehyde - up to 400 MAC.

- Panoramic lens made of polycarbonate with anti-scratch and scratch-resistant coating. Additional lens protection can be provided through the use of disposable films.

- The body of the product is made of gray silicone, the lining is made of transparent silicone. Both materials do not cause allergic reactions.

- The oil pan has a special hole to drain moisture at elevated temperatures and physical stress.

- Filter with bayonet mount.

- 5-point harness with plastic buckles.

- The presence of one exhalation valve and two inhalation valves.

- The intercom allows you to communicate with colleagues without raising your voice.

- Universal size.

- Weight – 540 g.

Manufacturers

3M is an American diversified company with a rich history, producing a wide range of unique products. The company is one of the market leaders in the production of protective devices for welders.

Vostok-Service company is one of the leaders in the field of providing individuals and industrial enterprises with modern products. The manufacturer offers personal protective equipment of the following brands: SPIROTEK, OPTEX, I-SPECTOR.

Purpose of the mask

A protective mask with forced pumping of fresh air is classified as personal protective equipment. Performs several functions:

- Protects the welder's eyes from the bright, harmful light radiation created by the electric arc.

- Protects the organ of vision and face from drops of molten metal or hot charge.

- Isolates the human respiratory system from harmful gaseous products and solid impurities formed during the welding process.

Where can I buy

Manufacturers, authorized representatives, suppliers and specialty stores offer a wide range of respiratory protection devices. American factories occupy the leading position in this segment. In addition, performers are provided with a large selection of products from Russian enterprises.

You can familiarize yourself with the proposed list of respirators and other products for welding in the “Where to buy electrodes” section. Trading companies sell goods at retail and wholesale. Organizations actively cooperate with individuals, individual entrepreneurs and enterprises of various profiles.