Converting a brick or metal stove to gas processing is a difficult process that requires a serious analysis of all components. It is imperative to find out which types of gas burners are ideal for furnaces and which ones should not be installed. After all, the result must meet exactly your requirements.

It would seem that the choice of model can be entrusted to gas workers; they can also be entrusted with reworking the burner block and installing the burner itself. But where is the guarantee that the equipment that you will be offered to install will have the necessary operating parameters and desired functionality?

In this article we will tell you how to independently understand the types of gas burners, the basic rules for their installation and operation, so that you can consciously choose which device to install in your heating stove.

Pros and cons of using a burner for heating

A gas burner is a device that, by mixing air with natural or liquefied gas and supplying the mixture to the outlet, forms a torch and distributes the flame. It ensures efficient combustion of fuel and regulation of the combustion process.

Advantages of using gas burners for heating stoves:

- Ease of use. Gas burners greatly simplify the process of heating furnaces, eliminating the need to prepare solid fuel and constantly maintain combustion.

- Controllability of the heating process. Simple models, without automation, need to be turned off independently as soon as the temperature reaches the required level, leaving only the wick lit. Burners with a control panel make life much easier by more accurately setting the temperature.

- Security. Automatic nozzles have overheating protection functions and turn off the gas supply in case of poor draft or lack of flame.

- Minimal contamination of the chimney duct. A scheduled inspection of the chimney is carried out once a year, mainly for prevention - little soot is formed from the combustion of gases.

The transition from solid fuel equipment to heating with gas burners greatly simplifies life, freeing up a lot of time for more interesting and useful activities.

Gas burners are intended for heating private houses, baths, industrial buildings - the purpose must be taken into account when choosing the type of equipment

The main disadvantage of converting a stove by installing a gas block is that the energy efficiency is not very high. High fuel consumption is especially noticeable if the gas heating system in a country house is designed by an amateur.

In addition, it is not always possible to obtain permission to install a gas burner - if the stove is outdated, the chimney is of incorrect design, or the room parameters do not meet fire safety standards.

Indications for cleaning

HBO is a complex fuel system consisting of many units and components, among which the most important element is the gas nozzle (injector). It is responsible for the dosed supply of fuel into the intake tract during engine operation. Its design is similar to gasoline and includes the following components:

- frame;

- electromagnetic coil;

- rod with seal;

- springs;

- fitting.

Unstable engine operation and increased fuel consumption are due to the fact that the injectors lose their performance when exposed to high temperatures, resulting in a difference in the dosage of the gas mixture. Less gas enters the cylinders. Because of this, based on the readings of the lambda probe, the electronics perceives this composition as depleted, increasing the supply to normalize the process. Cylinders forced to run on a rich mixture under the influence of elevated temperature cause the valves to burn. This leads to premature engine repair. It is recommended to regularly check the LPG system and timely clean its components so that the difference in their performance does not exceed 10%.

For efficient performance of engine parameters, it is recommended to service the injectors after every 20 thousand kilometers.

Selecting a gas burner: types and characteristics

The main elements of a gas burner are a mixer and a burner nozzle with a device that stabilizes the flame. Depending on the purpose, the models differ in design.

To make the most of gas injectors, you need to install equipment with automation. You can also choose a device that can operate not only on gas, but also on diesel fuel and fuel oil

When choosing a gas burner for installation in a furnace, pay attention to the following characteristics:

- coefficient of performance (efficiency);

- heating device power;

- energy efficiency;

- flame length;

- safety;

- optionality.

The operating parameters of the gas burner must take into account the chemical composition of the fuel, the purpose and characteristics of the room, the conditions of use - a house or a bathhouse, an industrial stove or a homemade wood-burning stove, for constant or periodic heating, etc. The technical data sheet for the burner indicates the scope of application of the device.

Types of stove gas burners for home or bathhouse

The design and operating principle of gas burners for household heating stoves should be studied more carefully, separately considering the two main types of equipment - atmospheric and forced-air options. They are distinguished by the method and speed of mixing gas with air.

Atmospheric gas burners

The design of the atmospheric burner is simple and consists of one or more hollow tubes into which gas is supplied under pressure. The gas, mixing with air coming directly from the room, forms a fuel-air mixture and is ignited using piezo ignition or electric lighters.

The design of an atmospheric burner using the example of an AGG gas burner device designed to operate on natural gas and be installed in sauna stoves

For normal operation of an atmospheric gas burner, it is necessary to ensure good draft and an effective ventilation system. The main disadvantage of the device is that any change in air movement leads to changes in the proportion of the gas-air mixture, and therefore to an uneven combustion process.

Air enters the atmospheric burner under the influence of natural draft. Final mixing occurs in the combustion chamber, where the gas gradually burns

If there is a lack of oxygen, the burner does not completely burn the gas, which leads to the release of a significant part of the unused fuel into the atmosphere through the chimney duct serving the heating unit.

An example of technical characteristics of atmospheric gas burners UGOP 12, 16, 30. Pay attention to the main parameters: thermal power, nominal gas pressure, shutdown time in case of ignition burner extinguishing or lack of draft, size of the gas supply fitting

Pressurized gas burners

Pressurized gas burners, or, as they are also called, blower, fan, air blower, are devices where gas is mixed with air using a fan, the gas-air mixture enters a closed chamber and burns there.

The operation of the nozzles of a gas burner installed in a closed combustion chamber depends little on the state of the atmosphere in the room. The air supply intensity is adjusted by changing the fan rotation speed.

Blast gas burners can be adjusted to any power, and also use liquefied gas as fuel

High-quality air supply and mixing with gas ensures more complete combustion of fuel. Pressurized burners are on average two times more efficient than atmospheric type equipment - their efficiency is 95-98%. The equipment operates stably even at low gas pressure and does not require the installation of a bulky chimney.

Instead of a standard chimney system, a coaxial chimney works in tandem with a blower burner, which can be led outside through the wall located next to the stove.

Air for the operation of forced-air burners is pumped using a fan, which also creates the necessary pressure and regulates the flame pressure

The main disadvantage of the device is its dependence on the energy source, high noise level, and higher price than atmospheric burners. But short-flame models of fan gas burners can be installed in wood-burning stoves. The main condition for use, in this case, is that the flame should not rest against the walls of the firebox.

In fact, there are many more ways to supply air and gas to burners. There is no need to study everything for installation in a home oven, since only a few of them are used in the production of small household appliances.

a — diffusion burner b — injection burner with central gas supply, single-flare; c — injection multi-flare; g - injection, with central gas supply, multi-nozzle; d - the same, but flat-flare; e - injection with peripheral fuel supply; g - with air supply, central gas supply and axial swirler; h - the same, with a snail air supply and peripheral fuel supply; and - the same, with tangential air supply

Having decided on the type of gas burner, you can continue to study the features of individual models and their functionality.

Differences in the way power is controlled

The ability to adjust the thermal power of the burner plays an important role when organizing the process of heating a room. This is especially true for those houses where permanent residence is planned.

From a controllability point of view, gas stove burners can be divided into two categories:

- Single stage. Gas is supplied to the injector without the ability to influence power. If the device is automated, then when a certain temperature level is reached, the burner will turn off and then turn on again when the room becomes cooler.

- Two-stage. Two combustion modes, normal and economical, are automatically adjusted and allow you to maintain a more or less stable temperature in the room. Fewer turns on and off reduces wear on parts and extends the service life of the device.

Two-stage devices are divided into floating or modulated models. The power can vary from 10 to 100% or more, and accurately set a comfortable temperature in the house. The gas burner device can be automatic, mechanical or pneumatic.

The ability to regulate thermal power allows you not only to set the optimal temperature regime, but also to save energy. For example, fuel savings when using a modulated gas burner reaches 15-20%.

Additional design options

In order not to use lighters or wicks to ignite the stove, the design of the gas burner provides two methods of ignition:

- electric ignition - requires connection to the electrical network;

- piezo ignition - used in simpler burner models and does not require power.

Installing special sensors that monitor oxygen levels makes it possible to detect flame extinction and turn off the fuel supply. This function protects against gas leaks and emergency situations.

Some equipment models require working not only with natural and liquefied gas, but also with diesel fuel. When choosing such models, pay attention to how easy and quickly this transition is made.

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types. It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults.

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts.- Pipe rupture. It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems.

- Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler.

- The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes.

- A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

Safety rules when using burners

Failure to comply with precautions when installing and using gas burners for heating premises can lead to emergency situations and accidents: fire in the house, carbon monoxide poisoning.

When operating gas equipment, you should adhere to the following rules:

- Observe the service life. The burner's service life, depending on the model, can range from 8 to 15 years. Then it must be replaced.

- Use models with a function that automatically turns off the device in the absence of draft or flame.

- A stove equipped with gas burner units must meet safety requirements.

The design, installation or repair of a gas burner must be carried out by certified gas service workers, with whom an agreement has been concluded for the supply of fuel and maintenance of the units.

If possible, it is still necessary to use gas boilers or special furnaces that are designed to work with natural or liquefied gas

To obtain permission to install and connect to the main gas network, a number of conditions must be met:

- compliance with the rules for connecting a gas burner;

- appropriate design of the smoke channel, its high-quality insulation;

- installing a spark arrester at the top of the chimney.

This is the minimum requirement for installing forced-air gas burners.

For atmospheric there are additional requirements:

- presence of adjustable traction;

- ensuring good ventilation;

- the volume of the room in which the gas burner is installed is from 12 m3.

If equipment is converted to use liquefied gas, it is necessary to ensure safe storage of the gas cylinder. This can be a separate room or a metal cabinet. If you plan to store gas reserves in a gas tank, then the tank is installed underground at a distance of no closer than 5 m from the building.

What could be the consequences?

Contaminated injectors can cause breakdowns and various deviations in the operation of the equipment. It is also worth remembering that during operation the injectors are exposed to different temperatures, which means they work differently and have different performance indicators. At the first sign of imbalance, larger problems should be expected. The very first thing that will appear is unstable engine operation, then the level of gas consumption increases.

If one or a pair of injectors supplies less gas, then the problem should be looked for not in them, but in the electronics. In this case, additional problems may arise - excessive heating of the engine, increased load on the cylinders, burning of valves.

In order to promptly identify the need to replace or clean injectors, it is worth regularly diagnosing the gas equipment. Injector performance deviations should not exceed 10%.

It is better to entrust the cleaning of gas injectors of an LPG installation to professionals who have not only the appropriate skills, but also special equipment. The process itself, depending on the type of design of this part, can be carried out in assembled or disassembled form. Typically, cleaning is carried out in several stages, always using a special device and liquids.

There are some recommendations from experts regarding the regularity of scheduled cleaning - this is every 50-60 thousand kilometers. However, some manufacturers of these parts give their recommendations for routine inspection of injectors - the number of kilometers varies (from 20 to 300 thousand). It is worth noting that the cheaper the injectors, the more often problems arise with them and the more expensive their maintenance is.

Their performance largely depends on how a specialist cleans gas injectors. The master must be attentive and consistent, and also not forget about the completeness of the cleaning procedure.

To clean the injectors correctly, you should follow the following procedure:

- Close the gas cylinder supply valve.

- Eliminate gas from the line completely, that is, the car should run out of gas fuel and automatically switch to gasoline. To be completely sure, you need to force the car to switch to gas to make sure there is no mixture in the line.

- Mark the wires and coils so as not to confuse them later - you can do this with insulating or adhesive tape.

- After this, carefully remove the ramp.

- Take a 12mm wrench and unscrew the calibration jets.

- Then you need to remove the retaining rings and the coil, unscrew the guides with a 14 key.

- We remove the rods, springs and seal. To make assembly easier, you should sort all the parts at the end of cleaning.

- Carry out the cleaning itself using a rag and a special liquid. It is advisable to use lint-free cloths. It is also worth making sure that liquid does not get on the rubber seals.

- We clean the inside of the injector body - we do it carefully and carefully, in several steps.

- Now we assemble the parts in the reverse order - for this the previously organized marking system will come in handy.

All this ends with the installation of the ramp in the car in its regular place. Be sure to check the functionality of the system. To check the connection points for leaks, you can use the old method - soaping, that is, lubricate the connection points with a soap solution. If the cleaning process is carried out at a service station, the craftsmen first adjust the working units and only after that install the equipment in place.

You can also read on this topic:

How to perform car body repairs without painting

Replacing the front crankshaft oil seal Nissan Micra (K12)

How to choose a car service in Minsk

Cardan shaft: device, main functions and malfunctions

Restoration and repair of flywheels - various clutch options

Dmitry Seregin March 25, 2020

Posted in: Car Repair

Installation of a gas burner in a heating furnace

We remind you that it is prohibited to install gas equipment yourself. However, it won’t hurt to familiarize yourself with the nuances of installing a gas burner in a stove.

So, installation of a gas burner is permissible in furnaces in which the length, shape, nature and temperature of the flame can be adapted to the nature of the material of the combustion chamber. The flame should not touch the walls, but should be freely located in the combustion space. If it is a brick wall, then the firebox should be made of refractory bricks.

Before installation, check the walls of the stove for cracks, voids, and unsealed seams through which combustion products can enter the room. The room into which the firebox door opens must have an opening window, a ventilation duct and a gap in the door for air to enter from below.

Gas burners of any type are characterized by the creation of high temperatures - more than 1000 °C in the combustion chamber. When installing a gas burner in the oven, you must ensure that the flame does not touch the walls.

The installation process itself is not complicated and is carried out in the following sequence:

- Remove the firebox door.

- A burner is placed in the combustion chamber.

- The shield is secured in the door frame.

- Connect the automation according to the manufacturer's instructions.

At the end of installation, connect the burner to a hose, the other end of which is connected to a gas source.

Installing a burner using the example of an AGG gas burner device: the stage of installing a gas burner block in a furnace with dismantling the ash pan

The system is launched by a master from the gas service, he checks the operation of the nozzles, the automatic control and safety systems, configures and tests the response of the sensors.

Installation of a gas burner in an industrial furnace using the example of an AGG gas burner device. Connecting automation, placing the remote control and thermal cylinder

Another step is to check the tightness of all connections and the presence of traction. After successful startup of the system, the gas installer must issue a completed control certificate for the installation of the burner.

When starting the heating, you should first select the minimum thermal power, heating the stove continuously and little by little or, if there is no power adjustment, cyclically, turning the burner on and off. This is especially important for a brick kiln - strong continuous heating of a cooled brick can lead to cracking.

Product cost

| Gefest | 400 RUR |

| Moravia 1436 | 650 RUR |

| Indesit | 650 RUR |

| Hansa | 650 RUR |

| Flama | 550 RUR |

| Darina | 700 RUR |

| Ricci | 590 RUR |

From the above it follows that the operation of changing jets is not difficult and is quite within the capabilities of any person without special education. And installing the right nozzles will not only save gas fuel consumption, but will also rid the room of soot and unpleasant odors.

General rules for installing a chimney for a stove

Another condition for the normal operation of a gas stove is the installation of a chimney. For gas-fired stoves, smoke channels must be vertical, without ledges. The design of the chimney of a wood-burning stove is often not suitable for the removal of gas combustion products.

The slope of the chimney is allowed, but not more than 30°, and provided that the cross-section of pipes on inclined sections is not less than the cross-section of pipes installed vertically

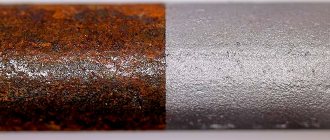

You can refurbish an old chimney by lining it. Upgrade options:

- Installation of a stainless steel pipe in the chimney duct. In this case, the diameter and height of the pipe should be selected according to the characteristics of the chimney duct. The gap between the walls of the chimney and the pipe is filled with non-flammable heat-insulating material such as expanded clay or foam glass.

- Application of FuranFlex technology. The method involves placing an elastic polymer tube inside the channel, which, under pressure, takes its shape and hardens. The protective layer serves to insulate, seal and internally protect the chimney.

If none of the chimney modification options work, you will have to install a new one. Depending on the location of the stove, two options for installing a chimney are possible: an external attached one or an internal one.

The influence of the characteristics of the chimney on the safety of heating is such that it will necessarily be checked by the Fire Inspection authorities with the subsequent issuance of a written certificate, without which the equipment will not be connected to gas networks.

Principle of operation

Water circuits are rarely connected to gas stoves. The room is heated directly by heated air from the stove. The only difference with a solid fuel stove is that natural gas is used, not wood.

Advice. It is very easy to install a water circuit with a heat exchanger or a water tank in gas furnaces; sometimes a system is connected that allows warm air masses to be discharged into adjacent rooms.

There are options for gas stoves combined with a solid fuel unit or powered by electricity. There are universal burners that run on diesel fuel if the need arises.

Important. All installation and repair work related to gas fuel must be carried out exclusively by representatives of a specialized organization that has the appropriate permit.

With your own hands

The easiest way to make the first type of burner, since it can be made from scrap materials.

To make it, you will need to use the following materials (almost all of them are available):

The valve from an empty oxygen cylinder (it will serve as a nozzle here). What kind of valve it will be is not at all important; you can use the most common VK-74.

So that the gas stream is directed as narrowly as possible. you will have to build a small cap that will fit on the valve

Carefully make a small hole in it and place a jet there (a part from a blowtorch would be perfect).

The injector will be the simplest - it will require a steel pipe, the thickness of which will not be higher than 2 mm. It is better to make it about 100 mm in length

The most reliable way to secure it is by welding. However, in this case, you will have to maintain a certain distance that should remain between the cap and the nozzle. This is done to ensure that a sufficient amount of fresh air enters there.

So that the flame ignites quickly. A piezoelectric element is installed next to the nozzle. You can do without it, and light the burner with matches and a piece of paper.