The phrase “spindle for a CNC milling machine” usually means a motor with a self-clamping collet chuck installed on it (like on a manual milling machine), which serves to fix a cutting tool, such as a milling cutter, whetstone, drill, etc. and transmitting rotational motion to it at high speed.

Classification

They can be divided into 2 small groups - domestic and industrial:

- Household ones include various drills, small household milling cutters or drills.

- Industrial engines include engines designed to withstand high loads during operation, having ceramic bearings and often equipped with a complex liquid or air cooling system and a lubricant supply system directly to areas with high levels of friction and heating.

When using a drill as a spindle in a home CNC machine, you need to understand that its bearings are not designed for high lateral loads and will very quickly begin to “howl”, which can lead to high heating of the windings, a decrease in power on the shaft, and subsequently such a spindle will simply will burn.

In this case, cooling will not help, and it is necessary to modify the drill itself, namely: replace the ball bearing of the shaft with a roller bearing (preferably with ceramic rollers), firmly fix it in the body and take care of the constant presence of lubricant in it.

Features of the spindle depending on the type

Basically, during the operation of milling machines, all loads are perpendicular to the spindle axis, and parallel loads appear only at the moment of cutting into the body of the workpiece. That is why it is necessary to choose an engine that can withstand such loads over a long period of time, since the operation of milling machines can be continuous for a day or even more.

Spindles intended for industrial purposes do not require constant cleaning and lubrication of bearings throughout their entire service life, but if you begin to notice extraneous sounds in its operation at idle, it is still better to disassemble the motor housing and blow out all contaminants from the inside with compressed air (if such are present) and lubricate the bearing well with a special lubricant that does not lose its properties at high temperatures.

In addition, the industrial spindle is equipped with a high-quality collet chuck that has minimal runout during operation, ensuring the necessary processing accuracy, a minimum difference between the actual and actual size of the cutter, and allowing the clamping of cutters with a conventional cylindrical shank.

Collet clamps

Basically, the most common are collets of the ER11 and ER16 types, into which a drill or cutter with a shank diameter of 2.5 to 3.2 mm is inserted, even if it is made with a cone. There are also chucks designed for a larger tool diameter, but they are used for rough metal processing or steel milling and have a hole for tool clamping of 6 millimeters or more.

Why can't I install it on my home CNC machine, you ask?

If you clamp a cutter with a diameter of 2 mm with a shank diameter of 3.2 mm into a collet chuck, then during processing you will hardly notice the difference, but if you install a cutter with a diameter of 10 mm and a shank of 3.2 mm on an amateur machine, then you can easily deform the guides, since the load on in this case increases significantly. In a machine, all parts must fit perfectly together, otherwise there will be more problems with it than quality work. Therefore, we recommend that you opt for the EP-13 collet; it is quite sufficient for small volumes of work and is suitable for almost any working tool used in processing various materials.

Spindle selection: rotation speed

The selection of a spindle based on the motor power characteristics should also be made based on the type of material that is planned to be processed. Each manufacturer publishes a range of speeds at which the router can be used to carve metal or wood. The following are usually considered average values:

- For shallow wood engraving, low-power spindles capable of performing up to 25 - 35,000 revolutions per minute are recommended. When choosing a spindle, it is recommended to choose a model that demonstrates the maximum in a given range. That is, if you only need 24-30 thousand revolutions, but there is an opportunity to use 35, it is better to opt for the latter option.

- For soft metal alloys (aluminum) you will need 13 - 8,000 rpm.

Why does wood require more turns than metal? The answer is actually obvious. For each type of material, cutters of different sizes are used. For metal, for example, solid plates made of hard alloys with a diameter of no more than 16 mm are used. The second aspect is the type of milling. High-speed is used for wood processing . It implies high torque, but low feed. For metal, power milling is used, which requires fewer revolutions, but with a more intense feed.

Spindle power

When choosing spindle power, you must be guided by the golden rule - the more, the better. Basic rules when choosing power:

- If you plan to use milling machines only for drilling or engraving small parts, then a spindle with a power of up to 600 watts will be quite sufficient.

- For milling hardwood and metal, you need to consider a motor with a power of 600 to 1400 watts.

- If you plan to further modernize the machine (there are machines with two spindles or more) or you need a large power reserve, you need to look towards spindles with a power of over 1.6 kW, they will allow you to process almost any materials, and the quality of work will depend only on the reliability of the mechanical part of CNC machines.

What is a spindle for a CNC machine and its main parameters

Any spindle is a motor with a self-clamping collet chuck installed on it. It is necessary for reliable fixation of a cutting tool, which is a whetstone, milling cutter or drill, as well as for transmitting rotational motion to it. To choose the right CNC spindle, you should take into account the type of machine, its power, rotation speed and other characteristics reflected in the operational passport.

You need to understand that the correct choice of spindle is important for high-quality and safe processing of any part, and therefore for a successful production cycle. For large diameter tools (face mills, end mills), spindles with low rotation speed are selected, which allows for deeper cuts and efficient chip removal.

It is necessary to understand that the wrong choice of spindle can lead to rapid wear and breakdown of the equipment. In this case, spindle repair will be required, including replacing defective and worn parts, restoring the shaft geometry, rewinding the stator, and balancing the rotor and spindle assembly.

Cooling

As mentioned above, spindles can be equipped with either air or liquid cooling. The air blower is a conventional impeller mounted on the motor shaft and blowing air over its windings.

The big disadvantage of this type of cooling is the fact that the impeller not only forces air onto the hot motor, but also sucks chips, dust and everything that the cutter cuts out of the workpiece into its housing. Also, when processing at low speeds, air cooling is ineffective, since it directly depends on the rotation speed of the spindle shaft.

The water cooling system does not have such a disadvantage, but when using it, a separate place is required for the reservoir with coolant and proper fixation of the tubes with it on the body of the milling machine, which greatly complicates the design if it is a two-spindle milling machine.

It is much more efficient than an air cooling system, since the speed of fluid flow through the spindle is the same all the time thanks to the use of a special pump. The main condition that must be observed when having a water-cooled spindle is that you cannot turn on the engine without turning on the pump, since in this case it will not cool at all, will overheat very quickly and, as a result, will burn out.

Overview of spindles for CNC routers

Article views: 1050

There are many types of motors that can be used as spindles for wood and metal milling machines. Many of them are quite specific and are manufactured specifically for machine models.

The review is intended for beginner DIYers to provide a general understanding of the most commonly used spindles.

But if we talk about small-sized CNC milling machines, they mainly use two types of motors, asynchronous (frequency modulated) and commutator. Each type of spindle has its own advantages and disadvantages, let’s look at them using ready-made examples.

Main types of spindles

The main types of spindles for small CNC milling machines are divided into:

- Collector, air-cooled - shaft speed from 0 to 35,000 rpm.

- Asynchronous air-cooled (controlled by a frequency-modulated power supply) - shaft speed from 0 to 24,000 rpm.

- Asynchronous with water cooling (controlled by a frequency-modulated power supply) - shaft speed from 0 to 24,000 rpm.

Air-cooled commutator spindles

Collector spindles (in fact, these are milling machines, but are used in CNC milling machines) are used in home-made and industrial machines (but mostly in home-made and small-sized ones), when the main task is to make the machine as simple and cheap as possible. A lot of the shortcomings of commutator motors are covered by their ease of installation and low price (although not all models fit the low price parameter). It is difficult to single out the main drawback, because they are all very unpleasant. Due to the presence of brushes, commutator spindles make a very loud noise during operation; the shaft rotation speed can vary, which often depends on the load (as well as on the input mains voltage). This makes it difficult to accurately set the required milling modes; as a result, the margin is always left on the smaller side (that is, for the sake of the margin for non-constant speed, there is an increased processing time of the product).

“Collectors” require regular maintenance; long-term operation of the spindle requires frequent replacement of brushes. If in a drill you change the brushes once every 2-3 years, with moderate use, then in a machine you will have to do this once every 2-3 months, if not more often. Commutator brushes emit strong electromagnetic interference, and worn brushes can spark strongly, which can become a source of accidental ignition (at a minimum, commutator motors should not be left unattended for long periods of time). Collector spindles are installed because of their low cost and ease of connection. In addition to erasing the brushes, the commutator cord itself with the contact plates is also erased. If there is significant wear, the commutator must either be replaced or another spindle (milling cutter) installed.

Below are the most common commutator models of milling cutters (for spindles) from 50 W to 800 W:

A milling machine (drill or engraver is also often used in small-sized milling machines).

- Proxxon milling machine from 50 to 120 W (depending on the model), at 5000-20000 rpm.

- Prices from 1000 to 2500 rubles (models are presented just for review).

Other milling machines (Dremel, drills, engravers, all “Buzz” in one way or another).

The basic rule is ease of connection, built-in speed control and the same speed from 500 to 30,000 rpm.

The price of such little ones is from 900 to 3000 rubles (we are considering Chinese models).

The main disadvantage of all commutator milling cutters is the high noise they produce during operation. One of the advantages is the low weight (although this does not particularly affect spindles for the machine).

- Milling cutter Kress 800 FME, 800 W, 10,000-29,000 rpm.

- Price is about 11,000-12,000 rubles.

- Chinese analogues will cost 2 times less.

Let’s take, for example, more “massive” models that have almost the same characteristics as those listed above.

GKF 600 W 33,000 rpm milling cutter, although this model cannot be called cheap, since its price is about 13,000 rubles.

It is worth taking into account, of course, that the lower the power of the router, the less productivity it will have.

And naturally, if we consider the Chinese analogues of some models, then a quite reasonable price will be 3-4,000 rubles for 600-800 W.

- This Chinese baby will cost only 3,500 rubles, at 800 W and 30,000 rpm.

Air-cooled asynchronous spindles (brushed and brushless)

In CNC machines, such spindles are used in conjunction with an inverter - a device that converts 1 phase 220 volts into 3 phases of 200 volts, and converts the network frequency of 50 hertz to a higher one, which is regulated at the output by the inverter. Typically, the adjustment range is from 0 (the first frequency threshold can be 100 Gy) to 400 hertz, and this allows you to control the spindle speed using a frequency ranging from 0 (3,000) to 24,000 rpm. The inverter allows you to achieve a stable rotation speed, regardless of the load on the cutter, and almost constant power on the shaft, regardless of the rotation speed. These spindles have no wear-out brushes, allowing them to be used for years without maintenance. Disadvantages include the dependence of the spindle temperature on the ambient temperature, significant heating of the spindle body, and the “buzzing” of the air-cooling impeller, which can cause a whistle at high speeds. In addition, when using such a spindle with the aspiration system (chip suction) turned off, the flow from the spindle cooling fan can strongly blow chips around the room. But, due to the lack of need for supply and circulation of coolant (as is done on water-cooled spindles), this is often the reason for choosing this particular design.

The disadvantages of brushless asynchronous spindles, both air- and water-cooled, include their high price, plus it is worth considering an additional inverter with a power supply). But there are still more positive characteristics:

- Low noise level.

- Low vibration level.

- Long-term uninterrupted operation.

- High torque on the shaft.

- Maintaining constant speed at different loads.

The disadvantages of collector asynchronous spindles include several points:

- Wear of brushes (300-500 hours of operation).

- Wear of collector copper plates (~1000 hours).

- *Wear times are indicated based on examples, although everything depends on the manufacturer and may differ by 1.5-2 times.

Asynchronous air-cooled spindles are essentially produced specifically for milling machines, that is, they are not used in other areas.

The bulk are made in China; you can find hundreds of sellers on Aliexpress, but there are only about a couple dozen models.

Air spindles are mainly produced up to 800 W, although there are also 1.5 kW models, although they are used less often (they can get very hot, plus the high speed of the cooling fan will create unpleasant noise at speeds above 12,000).

Although they are simpler in design and easy to operate, therefore there are also 800 W and 1.5 kW models with air cooling on sale.

Basically, there are four models of spindles for 200, 300, 400 and 500 W, which have the same size characteristics, the only difference being the length.

- 200 W 3000-12000 rpm, torque 230 Nm/m.

- Price on Aliexpress from 1200 to 1600 rubles.

- Low power models are also brushless and brushed.

- *Excluding mounting and power supply!

- 500 W 0-12000 rpm, torque 500 Nm/m.

- Price on Aliexpress from 1800 to 2500 rubles.

- There are collector ones, and there are brushless ones.

- *Excluding mounting and power supply!

All spindles in this category have the same diameter - standard 52 mm, which simplifies their use in small-sized milling machines for wood and metal. And they differ only in length.

The spindles are equipped with an ER11 or ER16 collet chuck; a standard drill chuck can also be used. Small-sized models come mainly with an ER11 collet.

The collet puller model can be viewed here.

Almost all spindles from this line are 52 mm thick, so their installation is included in a certain pattern.

Since it is not possible to increase the length of the spindle indefinitely to increase the power, air asynchronous spindles of 800 W and above have a different diameter.

Models from 800 W and above have a diameter of 62 mm and above.

How to distinguish a commutator spindle from a brushless one

(Description and title added to article 08/10/2021)

Since most sellers on Aliexpress do NOT indicate in the parameters of collector spindles that it is a collector (yes, it is) - an uninformed buyer will understand this only after the spindle starts working intermittently...

(Based on my own experience).

So, everything is quite simple:

Collector spindles have one power supply and are mainly produced up to 800 W (although this is not an indicator). But basically, most inexpensive models of 200-400 Watt come with a collector (brush) design.

Brushless spindles have an inverter and a power supply (although there are models with a one-piece unit that includes the inverter and power supply in one box).

Examples in pictures:

Collector (brush) with a simple power supply, with parameters of 48 Volts and a current frequency of 400 Hz:

Below are brushless spindles.

*The inverter in this design serves as the main operating condition. Unlike commutator-brush motors, here the commutator (rotor) itself consists of a flywheel with magnets, and the windings are located on the stator. Thanks to the operation of the inverter, a shift of the electromagnetic field is created in the coils. The rotor magnets seem to be drawn in by a constantly shifting electromagnetic field, thus creating rotation. (This is a simple explanation for general understanding...).

As can be seen from the pictures, brushless spindles have a separate inverter and a separate power supply. 800 W and higher electric motors have a speed of up to 22,000 and are structurally designed with four bearings (at a minimum, you should pay attention to this).

They cost 30-40% more than collector models. The price is higher partly due to the presence of an inverter unit, and technologically they are somewhat different. Let’s say a 500 W collector with a power supply will cost about 6,000 rubles, the same brushless one will cost about 8,000 rubles (the price is for a set with power supplies).

Pay attention to the design when purchasing, as I already wrote, sellers often do NOT indicate that the spindle has brushes, that is, a commutator spindle. This is understandable, the service life of such a motor before repair (at least replacement of brushes) will be from 300 to 1000 hours, that is, wear and tear is good for the seller, since there will always be new sales... Although brushless motors do not last forever, this is also worth understanding.

By the way, the cost of peripherals, that is, the power supply and inverter, costs about 40% of the total cost of the spindle. Therefore, let’s say a set costs 10,000 rubles (500 W spindle with inverter and power supply + delivery) and the spindle itself costs only 4,500. Therefore, if one of the components fails, the cost of replacement will be lower than the total set. It’s also worth asking the seller if he will include an additional engine separately in the kit, well, as an option. Let’s say my machine works 20 hours a day, 6 days a week, and if something fails, downtime is expensive, and sometimes it’s expensive to wait for components from the store.

Water-cooled asynchronous (brushless) spindles

Water-cooled asynchronous spindles have the same data as air-cooled spindles, but they also have their undeniable advantages:

The absence of an impeller makes such a spindle almost silent; the water pump usually operates very quietly). The noise from such a machine usually comes from the cutter and stepper motors.

Water cooling maintains a low temperature of the engine itself, which has a positive effect on the long-term operation of the built-in bearings.

Also, most spindles with dropsy have a speed of 0 to 22-24,000 rpm. Which in the case of air cooling will create a high noise level.

Of course, there are disadvantages - the need to equip the system with cooling hoses, a water tank and a water pump. It is also worth considering that the water in the container will still heat up and it needs to be replaced periodically. It is recommended to use antifreeze rather than plain water in the cooling system - this reduces the formation of scale and prevents the appearance of algae in the water.

- Asynchronous spindle with water cooling at 800 W and 0-24,000 rpm.

- Price on Aliexpress 8,500-9,500 rub.

- *The cost of the Inverter, power supply and pump is not taken into account!

The disadvantages of asynchronous spindles, both air- and water-cooled, include their high price.

Although, judging by the prices on Aliexpress, the cost of 500-800 W spindles is even lower than some expensive collector analogues. In small-sized machines, do-it-yourselfers often use burrs, dremels, drills, and similar milling tools, sometimes secured even with simple nylon ties... Although do-it-yourselfers are still maniacs

If CNC is used in high-precision jewelry work, then sometimes high-speed spindles are used with a shaft frequency of up to 60,000 rpm. But all of them can be classified as special equipment and are usually not used by crazy people.

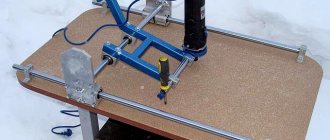

And here is an example of crazy hands. Although it is worth giving credit, obviously the owner of the “crazy hands” is only 15-16 years old and this is commendable for such work. Of course, such a machine has practically no accuracy - but for getting acquainted with CNC milling technology - it is quite acceptable and commendable.