Electric arc welding is carried out by two types of electrodes: fusible and non-fusible. Tungsten electrodes are infusible, that is, they are not consumed during the welding process, becoming part of the weld material. They serve only to supply electric current to the place where the electric arc is burning. Additives to the electrode material—tungsten metal—are used to optimize properties for working with certain alloys.

Mode of application

The products are used for submerged arc welding or in an atmosphere of shielding gases, primarily argon. Tungsten is the most refractory metal, so it is suitable for welding all others . By means of argon welding, non-ferrous and light metals are welded. It is almost impossible to cook titanium alloys using other methods.

A tungsten electrode is inserted into the torch, through which shielding gas and voltage are supplied to the electrode. A second cable is connected to the workpiece and an electrical circuit is completed through the air gap between the tip of the tungsten rod and the workpiece. The electric arc is ignited in it. The cloud of shielding gas displaces the air, preventing contact between the oxygen and nitrogen of the air and the molten metals in the weld pool. A rod of filler material is inserted into the working area from the side.

The welder holds the torch with his right hand and the rod with his left. They should be moved along the weld line synchronously, maintaining a sufficient flow of rod metal into the weld pool to form the weld material. This requires perfect coordination of movements.

The following is used as a current source:

- inverter;

- welding transformer;

- rectifier.

Multifunctional inverters are replacing obsolete current sources . They support different polarity modes: forward, reverse and alternating current.

When operating with alternating current, in addition to the current source, a high-frequency oscillator is connected. The high-frequency pulses it supplies to the working circuit help ignite the arc and maintain its stability.

Sharpening methods

There are several sharpening methods using special equipment:

- Specialized machine.

- Manual machine.

- Electric sharpener with a fine-grained abrasive wheel.

You can also use a grinder, emery or chemical action. It is recommended to use diamond wheels as their hardness is higher than that of tungsten.

Ideally, the surface of the sharpened part should be close to polished. This can be provided by a machine for sharpening tungsten electrodes, which includes a diamond disk, which actually sharpens tungsten consumables.

The machine is a stationary device, powered by an electric current network. It is possible to smoothly adjust the sharpening angle. Clamps for electrodes are supplied with the machine. Ease of operation is combined with high-quality results.

A good result will also be provided by a machine for sharpening tungsten electrodes, which also carries out this process using a diamond disc. A machine for sharpening electrodes will allow you to quickly and easily carry out this process, observing the selected angle parameters. Sharpening is carried out in a closed chamber, which avoids the scattering of tungsten dust.

It is easy to set the required sharpening angle using the provided scale. The process can be controlled through a transparent viewing window. The set includes an electrode holder that ensures its stable position and reduces the risk of injury to the welder. This device is of the portable type. Sharpening is done manually.

You can make a device for sharpening tungsten electrodes yourself. For this you will need:

- pipe section;

- electric motor;

- chuck;

- screw;

- drill;

- needle file

The equipment you will need is a welding machine.

Areas of use of different brands

Depending on the material of the rod, each brand has its own preferred area of use. To distinguish brands, an international system of names and color markings has been adopted.

- WP – green . Consist of almost pure tungsten (99.9%). for operation with alternating current. Suitable for joining Al, Mg, Ni, Cu and their alloys.

- WC 20 – gray . For direct current direct polarity welding of stainless steel and alloy alloys, Mo, Ta, Ti.

- WL – blue . Used to operate with direct polarity and alternating current. Recommended for surfacing work and welding of thin-sheet parts made of steel alloys.

- WZ – white . For welding with alternating current. Optimized for Al, AL-Cu, Mg, Ni alloys in various combinations.;

- WT 20 – red . Recommended for operation with direct current of reverse polarity on alloyed alloys, Cu, Ni, Ti.

Using electrodes for other purposes is very risky. It leads to a decrease in weld strength and increased consumption of energy resources and welding materials .

Criterias of choice

Tungsten electrodes used for TIG welding vary in tip colors. When selecting electrodes, one should proceed primarily from the material of the workpieces being connected. The differences and characteristics of different brands are summarized in the table.

It is necessary to take into account such parameters as:

- chemical composition, additives;

- rod diameter;

- pointed end shape;

- degree of sharpening.

The diameter is selected based on the thickness of the workpieces.

Features of the welding process

Tungsten welding requires certain skills and experience. It is important not only to adhere to the correct working technique, but also to accurately select rods, focusing on the following parameters:

Tungsten welding

- chemical composition, color of the rod tip, indicating the presence of alloying impurities;

- diameter, which determines the width of the seam;

- the specifics of sharpening, which determines the quality of penetration.

When welding with a non-consumable tungsten rod, a special oscillator device is used. Tungsten melts at 5 thousand °C, so the rods do not burn during operation. In addition to the oscillator, additive material is also used.

Related video: Tungsten electrodes WR2 ABICOR BINZEL

Publications on the topic

Methods for cooking stainless steel with an inverter at home

Popular types of aluminum electrodes for arc welding

Purpose and description of characteristics of LB 52U electrodes

Markings and characteristics

Marking is carried out in accordance with DIN EN 26848 and the corresponding GOST 23949-80.

The marking begins with the letter - W - this is the symbol of tungsten in the Periodic Table of Elements . The next symbol indicates the additive added to tungsten. Additives are used to improve one of the properties:

- fusibility;

- ease of arc ignition;

- electrical conductivity;

- strength parameters.

The following number expresses the mass fraction of this additive in thousandths. So, the number 10 would mean 1% additive. The second number indicates the length of the rod. Lengths of 50, 100, 150, 175 mm are used. Additionally, a color mark-tip is used.

W.P.

A rod made of pure tungsten is characterized by poor arc ignitability and short service life . Does not withstand strong currents.

Modes for piling copper with WP brand.

WZ-8

Zirconium additives somewhat simplify ignition and increase service life . Used for welding aluminum and other light metals with alternating current with an asymmetric phase profile.

WT-20

Thoriated. Despite its low mass fraction, thorium, which is a radioactive element, poses a serious threat to the health of the welder, especially during prolonged work.

When working, it is necessary to organize high-quality exhaust hood, work in thick clothing and a respirator. It is recommended to use a welding mask with isolated air supply.

The use of thorium allows you to extend the service life of the electrode compared to pure tungsten. The maximum current strength also increases; The arc is easily ignited.

WY-20

Yttrium dioxide is used as an additive. This rare earth metal makes it possible to significantly increase the welding current and is not hazardous to health . Used for welding thick workpieces with strong currents.

WC-20

Cerium is used as an additive. It is not radioactive, and can significantly improve basic characteristics, primarily arc ignition and service life . The maximum welding current also increases.

Modes for joining titanium workpieces.

WL-15 and WL-20

The use of lanthanum made it possible to create a universal electrode suitable for alternating and direct current. These rods hold their sharpened edge particularly well, giving you more freedom to work without interruptions .

Operating modes recommended for WL brand rods.

In addition to the international designation, there are also traditional domestic designations. These include:

- VL/EVL-2 with 2% lanthanum, universal use;

- EVI-1/SVI-1 with 1% yttrium dioxide, recommended for stainless steel, Ti, Cu and structural carbon alloys.

Ittrated electrodes are used with direct current.

Categories

Classification of products involves dividing them into three main types:

- For alternating current . Constantly changing the polarity prevents the formation of an oxide film on the surface of the weld pool. Used for joining light metals.

- For direct current . Suitable for joining Cu, Fe, Ni, Ta and alloys in various combinations.

- Universal . They can work quite well on both alternating and direct voltage. Used for welding a wide range of metals and their alloys.

Universal electrodes are used for installation of main pipelines. They do not burn through thin sheets and produce high quality seams.

Sharpening

The shape of the electrode tip affects the stability and energy of the electric arc . They, in turn, determine the dimensions of the weld pool, the depth and width of the resulting seam.

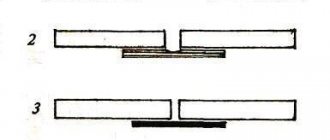

In addition to the workpiece parameters, when choosing a sharpening shape, the type of electrode is also taken into account. The common shape for all electrodes is a cone with an acute inclination angle. For grades P, L, a small ball is formed at the tip of the cone. This allows you to withstand high thermal loads. For rods with the addition of thorium (grade T), only a small semicircular protrusion is formed.

A machine used for sharpening electrodes.

Sharpening is carried out using several methods:

- manual sharpening machine;

- electric sharpener;

- specialized machine;

- chemical influence.

During welding, tungsten rod does not melt like fusible electrodes. But some burnout occurs. Therefore, from time to time the sharpness of the tip should be checked and, if necessary, sharpened again.

Tungsten electrodes

Non-consumable tungsten electrodes are often used in professional and amateur welding activities. With their help, it is possible to join various metals, the quality of which can be called excellent. This ensures that tungsten has such a property as refractoriness, which allows it to withstand high temperatures during long-term uninterrupted operation.

During manufacturing, pure tungsten can be used, or various impurities can be added to improve their quality. Scope of application: automatic and semi-automatic welding. Tungsten electrodes are called non-consumable because their length practically does not decrease when used.

Manufactured tungsten electrodes are divided by the color of their tips depending on the scope of application, which must be taken into account when choosing them.

The stability of the arc and other factors are influenced by the shape of the electrode tip. However, over time, this surface wears down and becomes deformed, which requires regular updating, called sharpening. A dull electrode can cause lack of penetration.

The shape of the sharpening depends, in particular, on the current used - for direct current, a cone-shaped sharpening is required, and for alternating current, a rounded sharpening is required. The sharpened electrode will still be able to perform its functions.

Non-consumable electrode argon arc welding (TIG)

The technology for producing welded joints in a protective atmosphere of inert gases has a number of advantages. Among them:

- high strength and durability of the seam;

- stability of penetration depth;

- high performance;

- Suitable for welding thin workpieces;

- work with non-ferrous metals, ferrous and stainless steel alloys.

Welding with a non-consumable electrode made of tungsten with certain additives is called TIG (Tungsten Inert Gas) . It is used for welding titanium. When heated, this metal acquires increased chemical activity, reacting with oxygen, nitrogen and water vapor contained in the air. The protective atmosphere prevents the metal of the weld pool and the heat-affected zone from coming into contact with air and protects it from oxidation.

The non-consumable electrode creates an electric arc. To form the weld material, a rod of filler material is used, which welders feed into the work area with their left hand. The rod melts from the heat created by the arc and flows into the weld pool, mixing with the molten edges of the workpieces.

The melting point of tungsten at 3400 ° C allows you to weld any metals and their alloys . Carbon dioxide, argon, and helium, as well as their mixtures, are used as shielding gases.

The most effective protection is provided by helium. It is expensive, so it is used only for the most critical seams and especially active metals.

Argon is significantly cheaper; it is the most widespread shielding gas used for stainless steel and non-ferrous metals and their alloys.

Low-alloy alloys are cooked in a protective atmosphere of carbon dioxide; it is even cheaper and allows one to obtain compounds of good quality.

Modern equipment used in argon arc welding allows for high precision adjustment of welding modes . This helps achieve the goal of optimal arc characteristics. This allows you to obtain high-quality seams on products of various thicknesses and spatial configurations. This is especially important in industries such as:

- aerospace;

- food engineering;

- medicine;

- weapons production;

- nuclear and chemical engineering.

When welding aluminum workpieces, an oxide film is constantly formed on the surface of the weld pool. This refractory joint interferes with normal welding. To destroy the oxides, welding is carried out with alternating current. Constantly changing the polarity prevents a film from forming.

An asymmetrical pulse shape is used: the positive half-wave heats the metal, and the negative half-wave destroys the oxide film. It is especially important to introduce gas into the work area a few seconds before ignition of the arc and stop supply after completion of the weld with some delay to allow the weld to cool in a protective atmosphere.

Argon used for welding must meet stringent requirements for its physical and chemical properties. It must have a normalized proportion of impurities and be completely dehydrated.

It is necessary to properly prepare the workpieces for welding: cut the edges of the seam, clean and degrease the welding area.

Argon arc welding usually takes place on copper backing plates, which protect the seam from contact with air on the reverse side and prevent the melt from flowing down.

Interesting video

Source

The abbreviation TIG stands for Tungsten (tungsten) Inert (inert) Gas (gas). That is, TIG welding means welding with tungsten electrodes in an inert gas environment. In this case, the metal (in the form of a rod) to fill the seam (if necessary) is fed with the second hand. Argon is most often used as an inert gas; it protects the metal, heated by the arc to a high temperature, from air gases - oxygen, nitrogen, water vapor. Inert gas is continuously supplied to the arc combustion zone. It looks like this:

Helium is used less frequently due to its high cost and higher consumption (due to lower density). However, at the same current value, an arc in helium releases 1.5-2 times more energy than in argon. This promotes deeper penetration of the metal and significantly increases the welding speed. Therefore, when welding refractory metals, helium is preferred. A mixture of argon and helium (the optimal composition contains 35-40% argon and 60-65% helium) has the advantages of both gases: argon ensures arc stability, helium provides a high degree of penetration.

Advantages

- TIG welding produces a clean, neat and precise weld.

- TIG welding can weld more metals than any other welding method. Corrosion-resistant steel, aluminum, magnesium, copper, bronze, etc. are welded with high quality.

- TIG welding allows you to better control the weld pool and the entire process, which allows you to make neat and precise seams. There are no sparks or splashes during the welding process (if everything is done correctly), because filler metal is supplied without excess. There is no slag on the seam, and the air does not smoke, as when welding with coated electrodes.

Selection and sharpening of tungsten electrodes

As the name implies, tungsten electrodes are made from tungsten, of which they contain 97-99.5%. In this case, depending on the conditions of use, various additives are used. Tungsten has a very high melting point (3380°C), the highest of the metals. Therefore, electrodes made from it are able to withstand the high arc temperature relatively successfully.

| Tungsten electrode type, composition, marking | Characteristic |

| Tungsten electrodes without special additives Tungsten at least 99.5%, the rest WP impurities (green) | Pure tungsten has a very high energy required for an electron to leave the atom, making it more difficult to strike an arc than with doped electrodes. In addition, due to the high electron output energy, the temperature at the tip is higher, resulting in a short electrode life. These electrodes are only used for AC welding, but it is better not to use them at all. |

| Tungsten electrodes doped with thorium oxide WT-20* (red) | For a long time, thoriated electrodes were the most commonly used and have therefore become the standard used to compare other tungsten electrodes. However, since thorium is radioactive, many users switched to other alternatives (when they became available). Thorium is not harmful to health when it is in the electrode, but the dust generated during sharpening is dangerous, which can get into the lungs or open wounds. Thorium is also released into the air during welding, but in much smaller quantities. Therefore, precautions should be taken when sharpening and welding. Despite these problems, thoriated electrodes are still often used. They have a low electron output energy, and most importantly, they work well under current overload. These electrodes are used for direct current welding and should not be used with alternating current. |

| Tungsten electrodes doped with cerium oxide WC-20* (gray) | These electrodes are especially good for low amperage DC welding because they start the arc very easily and generally cannot operate at the same high currents as thoriated electrodes. Good for short welding cycles. In particular, they are widely used for welding very small parts. Used for direct current welding and should not be used with alternating current. |

| Tungsten electrodes doped with lanthanum oxide WL-20* (blue) | They have low electron output energy and the lowest tip temperature for longer service life. If you do not overload the electrode with current, it can last longer than a thoriated electrode. But it cannot operate at the same high currents as a thoriated electrode. Used for DC welding and will also perform well with AC. |

| Tungsten electrodes doped with zirconium oxide WZ-8 (white) | This material is the most commonly used in AC welding because it has a more stable arc than pure tungsten. They prevent contamination of the bath well during alternating current. Not recommended for DC welding under any circumstances. |

| Tungsten electrodes doped with yttria WY-20* (dark blue) | They withstand high currents without contaminating the weld metal with tungsten. Used for welding particularly critical connections with direct current. |

| Other options | There are other, less common electrodes, for example with a mixture of different oxides. |

* - the number in the marking indicates the concentration of the oxide, and there are electrodes with lower concentrations, for example WL-15 (golden), containing about 1.5% lanthanum oxide. They also have a different color code.

Even if two electrodes are of the same type and have the same dopant concentration, but are manufactured by different companies, they may differ noticeably in performance. The grain size, structure and distribution of the oxide are of great importance. Therefore, choose the manufacturer more carefully.

| Metal | Metal thickness, mm | Electrode diameter, mm | |||||||

| Non-ferrous metals | 1 | 1,6 | |||||||

| 2 | 2 | 4 | 3 | 5-6 | 4 | 7 or more | 5 | ||

| Carbon, structural and stainless steels, heat-resistant alloys | 0,5 | 1 | |||||||

| 1 | 1,6 | 2 | 2 | 3 | 3 | 4 | 4 | 5 or more | 6 |

The sharpening of the electrode is of great importance; over time, the electrodes become deformed and the sharpening needs to be renewed. When welding with direct current, a cone-shaped sharpening is used; when welding with alternating current, a rounded tip is made.

The length of the sharpening affects the depth and width of the seam during welding; its size is about 2-0.5 of the diameter of the electrode. The width of the penetration zone decreases with increasing sharpening length, and with a short sharpening length, the penetration depth noticeably decreases. The stability of the arc is also affected by the risks formed during sharpening. For stable arc burning, the marks must be located strictly along the axis of the electrode, and their size must be minimal. The best option is to polish the electrode after sharpening it. Bluntness at the tip also affects arc burning. The diameter of the blunting is selected depending on the diameter of the electrode and the magnitude of the welding current.

Consumable electrode

In addition to the widely used TIG technology, the method of welding in an argon environment with a consumable electrode is also used. This eliminates the need to manually feed filler material into the welding zone. For this purpose, special welding equipment is used - a semi-automatic machine .

The filler material in the form of wire is continuously fed by a special mechanism into the welding zone. The wire from the reel passes through the feed rollers and then through the sleeve into the torch. Both the shielding gas and the electrical cable pass through the same hose. The welder does not have to monitor the synchronization of the movement of the torch and the filler material rod, but can completely concentrate on the accuracy of the weld pattern.

This technology does not require such high qualifications and experience from the welder as TIG technology . The productivity of a semi-automatic machine is also much higher, since there is no need to take breaks to replace the filler rod. The wire on the spool is enough for the longest seam.

Features EWM TGM 40230 HANDY

The device has a number of design features that make its use as comfortable as possible:

- The sharpening angle is set and adjusted using a graduated scale;

- using a special clamp, short electrodes up to 15 mm long, used for orbital welding of pipes, are sharpened;

- the processing process can be observed through the viewing window;

- using a special caliber, electrode wear, dust emission and wheel wear during sharpening are minimized, and processing time is also reduced;

- built-in suction and replaceable filter allow you to completely protect your respiratory system;

- The weight of the device is reduced to 2.5 kg due to the use of aluminum parts.

EWM TGM 40230 HANDY is a convenient, lightweight and accurate device. It allows you to perform the necessary operations for sharpening tungsten electrodes as quickly and safely as possible. This is a guarantee of obtaining high-quality welds.